1911 Encyclopædia Britannica/Bridges/Stresses 3

27. Influence Lines.—In dealing with the action of travelling loads much assistance may be obtained by using a line termed an influence line. Such a line has for abscissa the distance of a load from one end of a girder, and for ordinate the bending moment or shear at any given section, or on any member, due to that load. Generally the influence line is drawn for unit load. In fig. 52 let A′B′ be a girder supported at the ends and let it be required to investigate the bending moment at C′ due to unit load in any position on the girder. When the load is at F′, the reaction at B′ is m/l and the moment at C′ is m(l−x)/l, which will be reckoned positive, when it resists a tendency of the right-hand part of the girder to turn counter-clockwise. Projecting A′F′C′B′ on to the horizontal AB, take Ff = m(l−x)/l, the moment at C of unit load at F. If this process is repeated for all positions of the load, we get the influence line AGB for the bending moment at C. The area AGB is termed the influence area. The greatest moment CG at C is x(l−x)/l. To use this line to investigate the maximum moment at C due to a series of travelling loads at fixed distances, let P1, P2, P3, . . . be the loads which at the moment considered are at distances m1, m2, . . . from the left abutment. Set off these distances along AB and let y1, y2, . . . be the corresponding ordinates of the influence curve (y = Ff ) on the verticals under the loads. Then the moment at C due to all the loads is

M = P1y1+P2y2+. . .

The position of the loads which gives the greatest moment at C may be settled by the criterion given above. For a uniform travelling load w per ft. of span, consider a small interval Fk = ∆m on which the load is w∆m. The moment due to this, at C, is wm(l−x)∆m/l. But m(l−x)∆m/l is the area of the strip Ffhk,

Fig. 53.that is y∆m. Hence the moment of the load on ∆m at C is wy∆m, and the moment of a uniform load over any portion of the girder is w × the area of the influence curve under that portion. If the scales are so chosen that a inch represents 1 in. ton of moment, and b inch represents 1 ft. of span, and w is in tons per ft. run, then ab is the unit of area in measuring the influence curve.

If the load is carried by a rail girder (stringer) with cross girders at the intersections of bracing and boom, its effect is distributed to the bracing intersections D′E′ (fig. 53), and the part of the influence line for that bay (panel) is altered. With unit load in the position shown, the load at D′ is (p−n)/p, and that at E′ is n/p. The moment of the load at C is m(l−x)/l−n(p−n)/p. This is the equation to the dotted line RS (fig. 52).

If the unit load is at F′, the reaction at B′ and the shear at C′ is m/l, positive if the shearing stress resists a tendency of the part of the girder on the right to move upwards; set up Ff = m/l (fig. 54) on the vertical under the load. Repeating the process for other positions, we get the influence line AGHB, for the shear at C due to unit load anywhere on the girder. GC = x/l and CH = −(l−x)/l. The lines AG, HB are parallel. If the load is in the bay D′E′ and is carried by a rail girder which distributes it to cross girders at D′E′, the part of the influence line under this bay is altered. Let n (Fig. 55) be the distance of the load from D′, x1 the distance of D′ from the left abutment, and p the length of a bay. The loads at D′, E, due to unit weight on the rail girder are (p−n)/p and n/p. The reaction at B′ is {(p−n)x1+n(x1+p)}/pl. The shear at C′ is the reaction at B′ less the load at E′, that is, {p(x1+n)−nl}/pl, which is the equation to the line DH (fig. 54). Clearly, the distribution of the load by the rail girder considerably alters the distribution of shear due to a load in the bay in which the section considered lies. The total shear due to a series of loads P1, P2, ... at distances m1, m2, ... from the left abutment, y1, y2, ... being the ordinates of the influence curve under the loads, is S = P1y1+P2y2+.... Generally, the greatest shear S at C will occur when the longer of the segments into which C divides the girder is fully loaded and the other is unloaded, the leading load being at C. If the loads are very unequal or unequally spaced, a trial or two will determine which position gives the greatest value of S. The greatest shear at C′ of the opposite sign to that due to the loading of the longer segment occurs with the shorter segment loaded. For a uniformly distributed load w per ft. run the shear at C is w × the area of the influence curve under the segment covered by the load, attention being paid to the sign of the area of the curve. If the load rests directly on the main girder, the greatest + and − shears at C will be w × AGC and −w × CHB. But if the load is distributed to the bracing intersections by rail and cross girders, then the shear at C′ will be greatest when the load extends to N, and will have the values w × ADN and −w × NEB. An interesting paper by F. C. Lea, dealing with the determination of stress due to concentrated loads, by the method of influence lines will be found in Proc. Inst. C.E. clxi. p.261.

|

| Fig. 55. |

Influence lines were described by Fränkel, Der Civilingenieur, 1876. See also Handbuch der Ingenieur-wissenschaften, vol. ii. ch. x. (1882), and Levy, La Statique graphique (1886). There is a useful paper by Prof. G. F. Swain (Trans. Am. Soc. C.E. xvii., 1887), and another by L. M. Hoskins (Proc. Am. Soc. C.E. xxv., 1899).

|

| Fig. 56. |

28. Eddy’s Method.—Another method of investigating the maximum shear at a section due to any distribution of a travelling load has been given by Prof. H. T. Eddy (Trans. Am. Soc. C.E. xxii., 1890). Let hk (fig. 56) represent in magnitude and position a load W, at x from the left abutment, on a girder AB of span l. Lay off kf, hg, horizontal and equal to l. Join f and g to h and k. Draw verticals at A, B, and join no. Obviously no is horizontal and equal to l. Also mn/mf = hk/kf or mn−W(l−x)/l, which is the reaction at A due to the load at C, and is the shear at any point of AC. Similarly, po is the reaction at B and shear at any point of CB. The shaded rectangles represent the distribution of shear due to the load at C, while no may be termed the datum line of shear. Let the load move to D, so that its distance from the left abutment is x+a. Draw a vertical at D, intersecting fh, kg, in s and q. Then qr/ro = hk/hg or ro = W(l−x−a)/l, which is the reaction at A and shear at any point of AD, for the new position of the load. Similarly, rs = W(x+a)/l is the shear on DB. The distribution of shear is given by the partially shaded rectangles. For the application of this method to a series of loads Prof. Eddy’s paper must be referred to.

29. Economic Span.—In the case of a bridge of many spans, there is a length of span which makes the cost of the bridge least. The cost of abutments and bridge flooring is practically independent of the length of span adopted. Let P be the cost of one pier; C the cost of the main girders for one span, erected; n the number of spans; l the length of one span, and L the length of the bridge between abutments. Then, n = L/l nearly. Cost of piers (n−1)P. Cost of main girders nG. The cost of a pier will not vary materially with the span adopted. It depends mainly on the character of the foundations and height at which the bridge is carried. The cost of the main girders for one span will vary nearly as the square of the span for any given type of girder and intensity of live load. That is, G = al2, where a is a constant. Hence the total cost of that part of the bridge which varies with the span adopted is—

C =(n−i)P+nal2

= LP/l−P+Lal.

Differentiating and equating to zero, the cost is least when

dCdl = −LPl2+La = 0,

P = al2 = G;

that is, when the cost of one pier is equal to the cost erected of the main girders of one span. Sir Guilford Molesworth puts this in a convenient but less exact form. Let G be the cost of superstructure of a 100-ft. span erected, and P the cost of one pier with its protection. Then the economic span is l = 100√P/√G.

30. Limiting Span.—If the weight of the main girders of a bridge, per ft. run in tons, is—

w3 = (w1+w2)lr/(K−lr)

according to a formula already given, then w3 becomes infinite if k−lr = 0, or if

l = K/r,

| Limiting Span in Ft. | |

| r = 12 | l = 600 to 750 |

| r = 10 | l = 720 to 900 |

| r = 8 | l = 900 to 1120 |

The practical limit of span would be less than this. Professor Claxton Fidier (Treatise on Bridge Construction, 1887) has made a very careful theoretical analysis of the weights of bridges of different types, and has obtained the following values for the limiting spans. For parallel girders when r = 10, the limiting span is 1070 ft. For parabolic or bowstring girders, when r = 8, the limiting span is 1280 ft. For flexible suspension bridges with wrought iron link chains, and dip = 110th of the span, the limiting span is 2800 ft. For stiffened suspension bridges with wire cables, if the dip is 1/10th of the span the limiting span is 2700 to 3600 ft., and if the dip is 1/8th of the span, 3250 to 4250 ft., according to the factor of safety allowed.

|

Fig. 57. |

31. Braced Girders.—A frame is a rigid structure composed of straight struts and ties. The struts and ties are called bracing bars. The frame as a whole may be subject to a bending moment, but each member is simply extended or compressed so that the total stress on a given member is the same at all its cross sections, while the intensity of stress is uniform for all the parts of any one cross section. This result must follow in any frame, the members of which are so connected that the joints offer little or no resistance to change in the relative angular position of the members. Thus if the members are pinned together, the joint consisting of a single circular pin, the centre of which lies in the axis of the piece, it is clear that the direction of the only stress which can be transmitted from pin to pin will coincide with this axis. The axis becomes, therefore, a line of resistance, and in reasoning of the stresses on frames we may treat the frame as consisting of simple straight lines from joint to joint. It is found in practice that the stresses on the several members do not differ sensibly whether these members are pinned together with a single pin or more rigidly jointed by several bolts or rivets. Frames are much used as girders, and they also give useful designs for suspension and arched bridges. A frame used to support a weight is often called a truss; the stresses on the various members of a truss can be computed for any given load with greater accuracy than the intensity of stress on the various parts of a continuous structure such as a tubular girder, or the rib of an arch. Many assumptions are made in treating of the flexure of a continuous structure which are not strictly true; no assumption is made in determining the stresses on a frame except that the joints are flexible, and that the frame shall be so stiff as not sensibly to alter in form under the load. Frames used as bridge trusses should never be designed so that the elongation or compression of one member can elongate or compress any other member. An example will serve to make the meaning of this limitation clearer. Let a frame consist of the five members AB, BD, DC, CA, CB (fig. 57), jointed at the points A, B, C and D, and all capable of resisting tension and compression. This frame will be rigid, i.e. it cannot be distorted without causing an alteration in the length of one or more of the members; but if from a change of temperature or any other cause one or all of the members change their length, this will not produce a stress on any member, but will merely cause a change in the form of the frame. Such a frame as this cannot be self-strained. A workman, for instance, cannot produce a stress on one member by making some other member of a wrong length. Any error of this kind will merely affect the form of the frame; if, however, another member be introduced between A and D, then if BC be shortened AD will be strained so as to extend it, and the four other members will be compressed; if CB is lengthened AD will thereby be compressed, and the four other members extended; if the workman does not make CB and AD of exactly the right length they and all the members will be permanently strained. These stresses will be unknown quantities, which the designer cannot take into account, and such a combination should if possible be avoided. A frame of this second type is said to have one redundant member.

32. Types of Braced Girder Bridges.—Figs. 58, 59 and 60 show an independent girder, a cantilever, and a cantilever and suspended girder bridge.

In a three-span bridge continuous girders are lighter than discontinuous ones by about 45% for the dead load and 15% for the live load, if no allowance is made for ambiguity due to uncertainty as to the level of the supports. The cantilever and suspended girder types are as economical and free from uncertainty as to the stresses. In long-span bridges the cantilever system permits erection by building out, which is economical and sometimes necessary. It is, however, unstable unless rigidly fixed at the piers. In the Forth bridge stability is obtained partly by the great excess of dead over live load, partly by the great width of the river piers. The majority of bridges not of great span have girders with parallel booms. This involves the fewest difficulties of workmanship and perhaps permits the closest approximation of actual to theoretical dimensions of the parts. In spans over 200 ft. it is economical to have one horizontal boom and one polygonal (approximately parabolic) boom. The hog-backed girder is a compromise between the two types, avoiding some difficulties of construction near the ends of the girder.

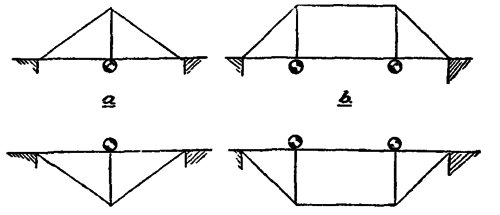

Most braced girders may be considered as built up of two simple forms of truss, the king-post truss (fig. 61, a), or the queen-post truss (fig. 61, b). These may be used in either the upright or the inverted position. A multiple truss consists of a number of simple trusses, e.g. Bollman truss. Some timber bridges consist of queen-post trusses in the upright position, as shown diagrammatically in fig. 62, where the circles indicate points at which the flooring girders transmit load to the main girders. Compound trusses consist of simple trusses used as primary, secondary and tertiary trusses, the secondary supported on the primary, and the tertiary on the secondary. Thus, the Fink truss consists of king-post trusses; the Pratt truss (fig. 63) and the Whipple truss (fig. 64) of queen-post trusses alternately upright and inverted.

A combination bridge is built partly of timber, partly of steel, the compression members being generally of timber and the tension members of steel. On the Pacific coast, where excellent timber is obtainable and steel works are distant, combination bridges are still largely used (Ottewell, Trans. Am. Soc. C.E. xxvii. p. 467). The combination bridge at Roseburgh, Oregon, is a cantilever bridge. The shore arms are 147 ft. span, the river arms 105 ft., and the suspended girder 80 ft., the total distance between anchor piers being 584 ft. The floor beams, floor and railing are of timber. The compression members are of timber, except the struts and bottom chord panels next the river piers, which are of steel. The tension members are of iron and the pins of steel. The chord blocks and post shoes are of cast-iron.

33. Graphic Method of finding the Stresses in Braced Structures.—Fig. 65 shows a common form of bridge truss known as a Warren girder, with lines indicating external forces applied to the joints; half the load carried between the two lower joints next the piers on either side is directly carried by the abutments. The sum of the two upward vertical reactions must clearly be equal to the sum of the loads. The lines in the diagram represent the directions of a series of forces which must all be in equilibrium; these lines may, for an object to be explained in the next paragraph, be conveniently named by the letters in the spaces which they separate instead of by the method usually employed in geometry. Thus we shall call the first inclined line on the left hand the line AG, the line representing the first force on the top left-hand joint AB, the first horizontal member at the top left hand the line BH, &c; similarly each point requires at least three letters to denote it; the top first left-hand joint may be called ABHG, being the point where these four spaces meet. In this method of lettering, every enclosed space must be designated by a letter; all external forces must be represented by lines outside the frame, and each space between any two forces must receive a distinctive letter; this method of lettering was first proposed by O. Henrici and R. H. Bow (Economics of Construction), and is convenient in applying the theory of reciprocal figures to the computation of stresses on frames.

34. Reciprocal Figures.—J. Clerk Maxwell gave (Phil. Mag. 1864) the following definition of reciprocal figures:—"Two plane figures are reciprocal when they consist of an equal number of lines so that corresponding lines in the two figures are parallel, and corresponding lines which converge to a point in one figure form a closed polygon in the other."

Let a frame (without redundant members), and the external forces which keep it in equilibrium, be represented by a diagram constituting one of these two plane figures, then the lines in the other plane figure or the reciprocal will represent in direction and magnitude the forces between the joints of the frame, and, consequently, the stress on each member, as will now be explained.

Reciprocal figures are easily drawn by following definite rules, and afford therefore a simple method of computing the stresses on members of a frame.

The external forces on a frame or bridge in equilibrium under those forces may, by a well-known proposition in statics, be represented by a closed polygon, each side of which is parallel to one force, and represents the force in magnitude as well as in direction. The sides of the polygon may be arranged in any order, provided care is taken so to draw them that in passing round the polygon in one direction this direction may for each side correspond to the direction of the force which it represents.

This polygon of forces may, by a slight extension of the above definition, be called the reciprocal figure of the external forces, if the sides are arranged in the same order as that of the joints on which they act, so that if the joints and forces be numbered 1, 2, 3, 4, &c., passing round the outside of the frame in one direction, and returning at last to joint 1, then in the polygon the side representing the force 2 will be next the side representing the force 1, and will be followed by the side representing the force 3, and so forth. This polygon falls under the definition of a reciprocal figure given by Clerk Maxwell, if we consider the frame as a point in equilibrium under the external forces.

Fig. 66 shows a frame supported at the two end joints, and loaded at each top joint. The loads and the supporting forces are indicated by arrows. Fig. 67a shows the reciprocal figure or polygon for the external forces on the assumption that the reactions are slightly inclined. The lines in fig. 67 a, lettered in the usual manner, correspond to the forces indicated by arrows in fig. 66, and lettered according to Bow’s method. When all the forces are vertical, as will be the case in girders, the polygon of external forces will be reduced to two straight lines, fig. 67 b, superimposed and divided so that the length AX represents the load AX, the length AB the load AB, the length YX the reaction YX, and so forth. The line XZ consists of a series of lengths, as XA, AB . . . DZ, representing the loads taken in their order. In subsequent diagrams the two reaction lines will, for the sake of clearness, be drawn as if slightly inclined to the vertical.

| Fig. 66. |

|

|

| Fig. 67. |

If there are no redundant members in the frame there will be only two members abutting at the point of support, for these two members will be sufficient to balance the reaction, whatever its direction may be; we can therefore draw two triangles, each having as one side the reaction YX, and having the two other sides parallel to these two members; each of these triangles will represent a polygon of forces in equilibrium at the point of support. Of these two triangles, shown in fig. 67 c, select that in which the letters X and Y are so placed that (naming the apex of the triangle E) the lines XE and YE are the lines parallel to the two members of the same name in the frame (fig. 66). Then the triangle YXE is the reciprocal figure of the three lines YX, XE, EY in the frame, and represents the three forces in equilibrium at the point YXE of the frame. The direction of YX, being a thrust upwards, shows the direction in which we must go round the triangle YXE to find the direction of the two other forces; doing this we find that the force XE must act down towards the point YXE, and the force EY away from the same point. Putting arrows on the frame diagram to indicate the direction of the forces, we see that the member EY must pull and therefore act as a tie, and that the member XE must push and act as a strut. Passing to the point XEFA we find two known forces, the load XA acting downwards, and a push from the strut XE, which, being in compression, must push at both ends, as indicated by the arrow, fig. 66. The directions and magnitudes of these two forces are already drawn (fig. 67 a) in a fitting position to represent part of the polygon of forces at XEFA; beginning with the upward thrust EX, continuing down XA, and drawing AF parallel to AF in the frame we complete the polygon by drawing EF parallel to EF in the frame. The point F is determined by the intersection of the two lines, one beginning at A, and the other at E. We then have the polygon of forces EXAF, the reciprocal figure of the lines meeting at that point in the frame, and representing the forces at the point EXAF; the direction of the forces on EH and XA being known determines the direction of the forces due to the elastic reaction of the members AF and EF, showing AF to push as a strut, while EF is a tie. We have been guided in the selection of the particular quadrilateral adopted by the rule of arranging the order of the sides so that the same letters indicate corresponding sides in the diagram of the frame and its reciprocal. Continuing the construction of the diagram in the same way, we arrive at fig. 67 d as the complete reciprocal figure of the frame and forces upon it, and we see that each line in the reciprocal figure measures the stress on the corresponding member in the frame, and that the polygon of forces acting at any point, as IJKY, in the frame is represented by a polygon of the same name in the reciprocal figure. The direction of the force in each member is easily ascertained by proceeding in the manner above described. A single known force in a polygon determines the direction of all the others, as these must all correspond with arrows pointing the same way round the polygon. Let the arrows be placed on the frame round each joint, and so as to indicate the direction of each force on that joint; then when two arrows point to one another on the same piece, that piece is a tie; when they point from one another the piece is a strut. It is hardly necessary to say that the forces exerted by the two ends of any one member must be equal and opposite. This method is universally applicable where there are no redundant members. The reciprocal figure for any loaded frame is a complete formula for the stress on every member of a frame of that particular class with loads on given joints.

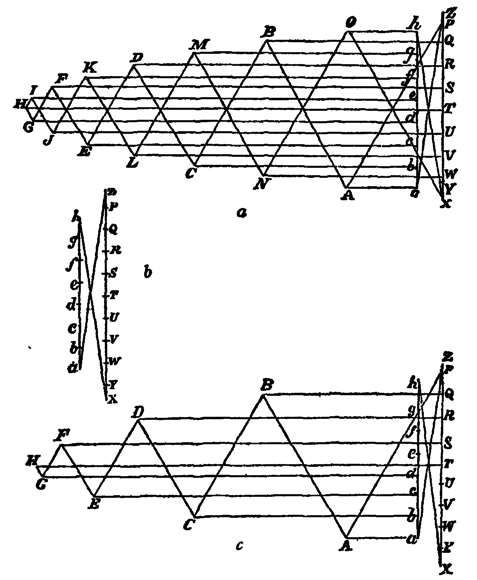

Consider a Warren girder (fig. 68), loaded at the top and bottom joints. Fig. 69 b is the polygon of external forces, and 69 c is half the reciprocal figure. The complete reciprocal figure is shown in fig. 69 a.

The method of sections already described is often more convenient than the method of reciprocal figures, and the method of influence lines is also often the readiest way of dealing with braced girders.

35. Chain Loaded uniformly along a Horizontal Line.—If the lengths of the links be assumed indefinitely short, the chain under given simple distributions of load will take the form of comparatively simple mathematical curves known as catenaries. The true catenary is that assumed by a chain of uniform weight per unit of length, but the form generally adopted for suspension bridges is that assumed by a chain under a weight uniformly distributed relatively to a horizontal line. This curve is a parabola.

Remembering that in this case the centre bending moment Σwl will be equal to wL2/8, we see that the horizontal tension H at the vertex for a span L (the points of support being at equal heights) is given by the expression

or, calling x the distance from the vertex to the point of support,

H = wx2/2y,

The value of H is equal to the maximum tension on the bottom flange, or compression on the top flange, of a girder of equal span, equally and similarly loaded, and having a depth equal to the dip of the suspension bridge.

Consider any other point F of the curve, fig. 70, at a distance x from the vertex, the horizontal component of the resultant (tangent to the curve) will be unaltered; the vertical component V will be simply the sum of the loads between O and F, or wx. In the triangle FDC, let FD be tangent to the curve, FC vertical, and DC horizontal; these three sides will necessarily be proportional respectively to the resultant tension along the chain at F, the vertical force V passing through the point D, and the horizontal tension at O; hence

H : V = DC : FC = wx2/2y : wx = x/2 : y,

hence DC is the half of OC, proving the curve to be a parabola.

The value of R, the tension at any point at a distance x from the vertex, is obtained from the equation

R2 = H2+V2 = w2x4/4y2+w2x2,

or,

Let i be the angle between the tangent at any point having the co-ordinates x and y measured from the vertex, then

Let the length of half the parabolic chain be called s, then

The following is the approximate expression for the relation between a change ∆s in the length of the half chain and the corresponding change ∆y in the dip:—

s+∆s = x+(2/3x) {y2+2y∆y+(∆y)2} = x+2y2/3x+4y∆y/3x+2∆y2/3x,

or, neglecting the last term,

and

From these equations the deflection produced by any given stress on the chains or by a change of temperature can be calculated.

|

| Fig. 71. |

36. Deflection of Girders.— Let fig. 71 represent a beam bent by external loads. Let the origin O be taken at the lowest point of the bent beam. Then the deviation y = DE of the neutral axis of the bent beam at any point D from the axis OX is given by the relation

d2ydx2 = MEI,

where M is the bending moment and I the amount of inertia of the beam at D, and E is the coefficient of elasticity. It is usually accurate enough in deflection calculations to take for I the moment of inertia at the centre of the beam and to consider it constant for the length of the beam. Then

dy/dx = 1EI Mdx

y = 1EIMdx2.

The integration can be performed when M is expressed in terms of x. Thus for a beam supported at the ends and loaded with w per inch length M = w(a2−x2), where a is the half span. Then the deflection at the centre is the value of y for x = a, and is

δ = 524 wa4EI

The radius of curvature of the beam at D is given by the relation

R = EI/M.

37. Graphic Method of finding Deflection.—Divide the span L into any convenient number n of equal parts of length l, so that nl = L; compute the radii of curvature R1, R2, R3 for the several sections. Let measurements along the beam be represented according to any convenient scale, so that calling L1 and l1 the lengths to be drawn on paper, we have L = aL1; now let r1, r2, r3 be a series of radii such that r1 = R1/ab, r2 = R2/ab, &c., where b is any convenient constant chosen of such magnitude as will allow arcs with the radii, r1, r2, &c., to be drawn with the means at the draughtsman’s disposal. Draw a curve as shown in fig. 72 with arcs of the length l1, l2, l3, &c., and with the radii r1, r2, &c. (note, for a length 12l1 at each end the radius will be infinite, and the curve must end with a straight line tangent to the last arc), then let v be the measured deflection of this curve from the straight line, and V the actual deflection of the bridge; we have V = av/b, approximately. This method distorts the curve, so that vertical ordinates of the curve are drawn to a scale b times greater than that of the horizontal ordinates. Thus if the horizontal scale be one-tenth of an inch to the foot, a = 120, and a beam 100 ft. in length would be drawn equal to 10 in.; then if the true radius at the centre were 10,000 ft., this radius, if the curve were undistorted, would be on paper 1000 in., but making b = 50 we can draw the curve with a radius of 20 in. The vertical distortion of the curve must not be so great that there is a very sensible difference between the length of the arc and its chord. This can be regulated by altering the value of b. In fig. 72 distortion is carried too far; this figure is merely used as an illustration.

38. Camber.—In order that a girder may become straight under its working load it should be constructed with a camber or upward convexity equal to the calculated deflection. Owing to the yielding of joints when a beam is first loaded a smaller modulus of elasticity should be taken than for a solid bar. For riveted girders E is about 17,500,000 ℔ per sq. in. for first loading. W. J. M. Rankine gives the approximate rule

Working deflection = δ = l 2 /10,000h,

where l is the span and h the depth of the beam, the stresses being those usual in bridgework, due to the total dead and live load. (W. C. U.)