English bond, to preserve the transverse and yet not destroy the longitudinal bond, it is frequently necessary to use half bricks. It may be taken as a general rule that a brick should never be cut if it can be worked in whole, for a new joint is thereby created in a construction, the difficulty of which consists in obviating the debility arising from the constant recurrence of joints. Great insistence must be laid on this point, especially at the junctions of walls, where the admission of closers already constitutes a weakness which would only be increased by the use of other bats or fragments of bricks.

Fig. 6.—Flemish Bond.Another method of bonding brickwork, instead of placing the bricks in alternate courses of headers and stretchers, places them alternately as headers and stretchers in the same course, the appearance of the course being the same on each face. This is called “Flemish bond.” Closers are necessary to this variety of bond. From fig. 6 it will be seen that, owing to the comparative weakness of the transverse tie, and the numbers of half bricks required to be used and the thereby increased number of joints, this bond is not so perfect nor so strong as English. The arrangements of the face joints, however, presenting in Flemish bond a neater appearance than in English bond, it is generally selected for the external walls of domestic and other buildings where good effect is desirable. In buildings erected for manufacturing and similar purposes, and in engineering works where the greatest degree of strength and compactness is considered of the highest importance, English bond should have the preference.

A compromise is sometimes made between the two above-mentioned bonds. For the sake of appearance the bricks are laid to form Flemish bond on the face, while the backing is of English bond, the object being to combine the best features of the two bonds. Undoubtedly the result is an improvement on Flemish bond, obviating as it does the use of bats in the interior of the wall. This method of bonding is termed “single Flemish bond,” and is shown in fig. 7.

In stretching bond, which should only be used for walls half a brick in thickness, all the bricks are laid as stretchers, a half brick being used in alternate courses to start the bond. In work curved too sharply on plan to admit of the use of stretchers, and for footings, projecting mouldings and corbels, the bricks are all laid as headers, i.e. with their ends to the front, and their length across the thickness of the wall. This is termed “heading bond.”

In thick walls, three bricks thick and upwards, a saving of labour is effected without loss of strength, by the adoption of “herring bone” or “diagonal bond” in the interior of the wall, the outer faces of the wall being built in English and Flemish bond. This mode should not be had recourse to for walls of a less thickness than 27 in., even that being almost too thin to admit of any great advantage from it.

Hoop-iron, about 112 in. wide and 116 in. thick, either galvanized or well tarred and sanded to retard rusting, is used in order to obtain additional longitudinal tie. The customary practice is to use one strip of iron for each half-brick in thickness of the wall. Joints at the angles, and where necessary in the length, are formed by bending the ends of the strips so as to hook together. A patent stabbed iron now on the market is perforated to provide a key for the mortar.

A difficulty often arises in bonding when facing work with bricks of a slightly different size from those used in “backing,” as it is technically termed. As it is, of course, necessary to keep all brickwork in properly levelled courses, a difference has to be made in the thickness of the mortar joints. Apart from the extra labour involved, this obviously is detrimental to the stability of the wall, and is apt to produce unequal settlement and cracking. Too much care cannot be taken to obtain both facing and backing bricks of equal size.

Fig. 8.Dishonest bricklayers do not hesitate, when using for the face of a wall bricks of a quality superior to those used for the interior, to use “snapped headers,” that is cutting the heading bricks in halves, one brick thus serving the purposes of two as regards outward appearance. This is a most pernicious practice, unworthy of adoption by any craftsman of repute, for a skin of brickwork 412 in. thick is thus carried up with a straight mortar joint behind it, the proper bonding with the back of the wall by means of headers being destroyed.

American building acts describe the kind of bond to be used for ordinary walls, and the kind for faced walls. Tie courses also require an extra thickness where walls are perforated with over 30% of flues.

The importance for sanitary and other reasons of keeping walls dry is admitted by all who have observed the deleterious action of damp upon a building.

Walls are liable to become damp, (1) by wet rising up the wall from the earth; (2) by water soaking down from the top of the wall; (3) by rain being driven on to the face by wind. Dampness from the first cause may be prevented by the introduction of damp-proof courses or the constructionPrevention

of damp. of dry areas; from the second by means of a coping of stone, cement or other non-porous material; and from the third by covering the exterior with impervious materials or by the adoption of hollow walls.

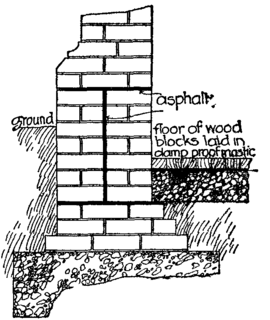

Fig. 9.After the footings have been laid and the wall has been brought up to not less than 6 in. above the finished surface of the ground, and previous to fixing the plate carrying the ground floor, there should always be introduced a course of some damp-proof material to prevent the rise of moisture from the soil. There are several forms of damp-proof course. A very usual one is a double layer of roofing slates laid in neat Portland cement (fig. 8), the joints being well lapped. A course or two of Staffordshire blue bricks in cement is excellent where heavy weights have to be considered. Glazed stoneware perforated slabs about 2 in. thick are specially made for use as damp-proof courses. Asphalt (fig. 9) recently has come into great favour with architects; a layer 12 or 34 in. thick is a good protection against damp, and not likely to crack should a settlement occur, but in hot weather it is liable to squeeze out at the joints under heavy weights. Felt covered with bitumen is an excellent substitute for asphalt, and is not liable to crack or squeeze out. Sheet lead is efficient, but very costly and also somewhat liable to squeezing. A damp-proof course has been introduced consisting of a thin sheet of lead sandwiched between layers of asphalt. Basement storeys to be kept dry require, besides the damp-proof course horizontally in the wall, a horizontal course, usually of asphalt, in the thickness of the floor, and also a vertical damp-proof course from a level below that of the floor to about 6 in. above the level of the ground, either built in the thickness of the wall or rendered on the outside between the wall and the surrounding earth (fig. 10).

By means of dry areas or air drains (figs. 11 and 12), a hollow