partial vacuum, In the smoke-box roughly proportional to the weight of steam discharged per unit of time. The difference of pressure between the outside air and the smoke-box gases may be measured by the difference of the water levels in the limbs of a U tube, one limb being in communication with the smokebox, the other with the atmosphere. The difference of levels varies from 1 to as much as 10 in. in extreme cases. The draught corresponding to the smallest rate of combustion shown in Table XX. in Professor Goss’s experiments, was 1·72 in. of water, and for the highest rate, namely 181, 7·48 in. of water. To get the best effect the area of the blast-nozzle must be properly proportioned to the size of the cylinders and be properly set with regard to the base of the chimney. The best proportions are found by trial in all cases.

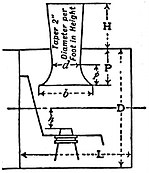

Figs. 18 and 19 show two smoke-boxes typical of English practice. Fig. 18 is the smoke-box of the 6 ft. 6 in. six-coupled express passenger engines designed by G. Whale for the London & North-Western Railway Company in 1904, and fig. 19 shows the box of the four-coupled express passenger engine designed by J. Holden for the Great Eastern Railway Company. In the case of the London & North-Western engine (fig. 18), the blast-pipe orifice B is placed at about the centre of the boiler barrel, and the exhaust steam is discharged straight into the trumpet—shaped end of the chimney, which is continued down inside the smoke-box. In fig. 19 the blast orifice B is set much lower, and the steam is discharged through a frustum of a cone set in the upper part of the smoke-box into the short chimney. Fig. 20 shows the standard proportions, recommended by the committee of the Railway Master Mechanics’ Association on Exhaust Pipes and Steam Passages (Proc. Amer. Railway Master Mechanics’ Assoc., 1906). According to the Report, for the best results both H and h should be made as great as practicable, and then d= 0·21D + 0·16h, b = 2d of 0·5D, P = 0·32D, p = 0·22D, L = 0·6D or 0·9D, but not of intermediate values. This last relation is, however, not well established. For much detailed information regarding American smoke-box practice, reference may be made to Locomotive Sparks, by Professor W. F. M. Goss (London, 1902).

Fig. 19.—Smoke-box and Spark Arrester, G.E.R. four-coupled express engine.

The arrangements for arresting sparks in American practice and on the continent of Europe are somewhat elaborate. In English practice where a spark-arrester is put in it usually takes the form of a wire-netting dividing the smoke-box horizontally into two parts at a level just above the top row of tubes, or arranged to form a continuous connexion between the blast-pipe and the chimney.

|

| Fig. 20.—Smoke-box, American Master Mechanics’ Association. |

Fig. 19 illustrates an arrangement designed by, J. Holden. The heavy sparks are projected from the tubes in straight lines and are caught by the louvres L, L, L, and by them deflected downwards to the bottom of the smoke-box, where they collect in a heap in the space D round a tube which is essentially an ejector. At every blast a small quantity of steam is caught by the orifice O and led to the ejectors, one on each side, with the result that the ashes are blown out into the receptacles on each side of the engine, one of which is shown at E. The louvres l, l, l are placed to shield the central region occupied by the blast-pipe.

As the indicated horse-power of the engine increases, the weight of steam discharged increases, and the smoke-box vacuum is increased, thereby causing more air to flow through the furnace and increasing the rate of combustion. Thus the demand for more steam is automatically responded to by the boiler. It is this close automatic interdependence of engine and boiler which makes the locomotive so extraordinarily well suited for the purpose of locomotive traction.

§ 13. The Steam Engine.—The steam engine of a locomotive has the general characteristics of a double-acting non-condensing engine (see Steam Engine). Distribution of steam is effected by a slide valve, sometimes fitted with a balancing device, and sometimes formed into a piston valve. All types of valves are with few exceptions operated by a link motion, generally of the Stephenson type, occasionally of the Allan type or the Gooch type, or with some form of radial gear as the Joy gear or the Walschaert gear, though the latter gear has characteristics which ally it with the link motions. The Stephenson link motion is used almost universally in England and America, but it has gradually been displaced by the Walschaert gear on the continent of Europe, and to some extent in England by the Joy gear. The general characteristics of the distribution effected by these gears are similar. Each of them, besides being a reversing gear, is an expansion gear both in forward and backward running. The lead is variable in the Stephenson link motion, whilst in the Walschaert and the Joy gears it is constant. Illustrations of these gears are given in the article Steam Engine, and the complete distribution of steam for both forward and backward running is worked out for a typical example of each of them in Valves and Valve Gear Mechanisms by W. E. Dalby (London, 1906).

§ 14. Cylinder Dimensions.—Adhesion.—Tractive Force.—A locomotive must be designed to fulfil two conditions. First, it must be able to exert a tractive force sufficient to start the train under the worst conditions possible on the railway over which it is to operate—for instance, when the train is stopped by signal on a rising gradient where the track is curved and fitted with a guard-rail. Secondly, it must be able to maintain the train at a given speed against the total resistances of the level or up a gradient of given inclination. These conditions are to a certain extent mutually antagonistic, since an engine designed to satisfy either condition independently of the other would be a different engine from that designed to make the best compromise between them.

Equation (3), § 1 expresses the fundamental condition which must be satisfied when a locomotive is starting a train. The torque exerted on the driving-axle by the steam engine just at starting may be that due to the full boiler pressure acting in the cylinders, but usually the weight on the coupled wheels is hardly sufficient to enable advantage to be taken of the full boiler pressure, and it has to be throttled down by the regulator to prevent slipping. Sand, driven between the wheel and the rail by a steam jet, used just at starting, increases the adhesion beyond the normal value and enables a larger pressure to be exerted on the piston than would otherwise be possible. When the train is started and is moving slowly, the torque acting on the driving-axle may be estimated as that due to about 85% of the full boiler pressure acting in the cylinders. The torque