the "foundry" while a second man (6) keeps him supplied with metal from another ladle which is skimmed by a boy (7). At 8 is a man cleaning a cast-iron pipe. Pipes made at this period were rarely over three feet in length, and were provided with polygonal flanges at each end for fastening them together with bolts. Pipes two inches in diameter had oval flanges and two bolts; three inch pipes had triangular flanges; eight-inch pipes were square-flanged; while pipes of twelve and eighteen inches in diameter had flanges of six and eight sides respectively, the number of bolts always equaling the number of angles in the flanges.

It is not at all certain when the first castings were made from remelted sow, or other form of crude cast iron; but the crucible has been used for remelting cast iron since a very remote period, and is largely employed in China for that purpose at the present

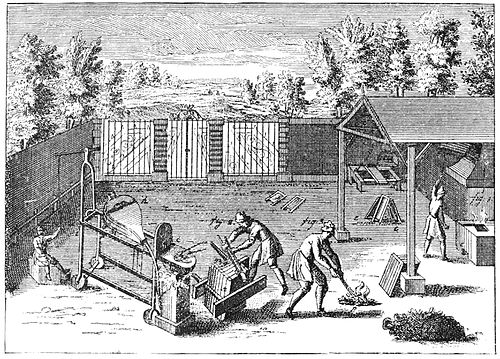

Fig. 7.—The Process of Casting Crucible-melted Iron.

day, and the culinary utensils made in that country are remarkable for their thinness. As illustrating the making of castings from crucible-melted iron, we extract Fig. 7, from Réaumur's[1] work. In this plate "b is a shed, under which is placed a furnace c, such as is ordinarily found in the shops of the makers of small castings. This furnace was blown by bellows, held but one crucible, and was quite similar in construction to many furnaces in use at the present day; d d is a box for holding the molding-

- ↑ L'art de convertir le fer forgé en Acier, et L'art d'adoueir le fer fondu. Par Monsieur de Réaumur, de l'Académie Royale des Sciences. Paris, 1722.