Wireless Commu- nication

���The Home

Electrician

��Practical Electrical Hints

��Spark-Plugs Tested Without Removal from Cylinders

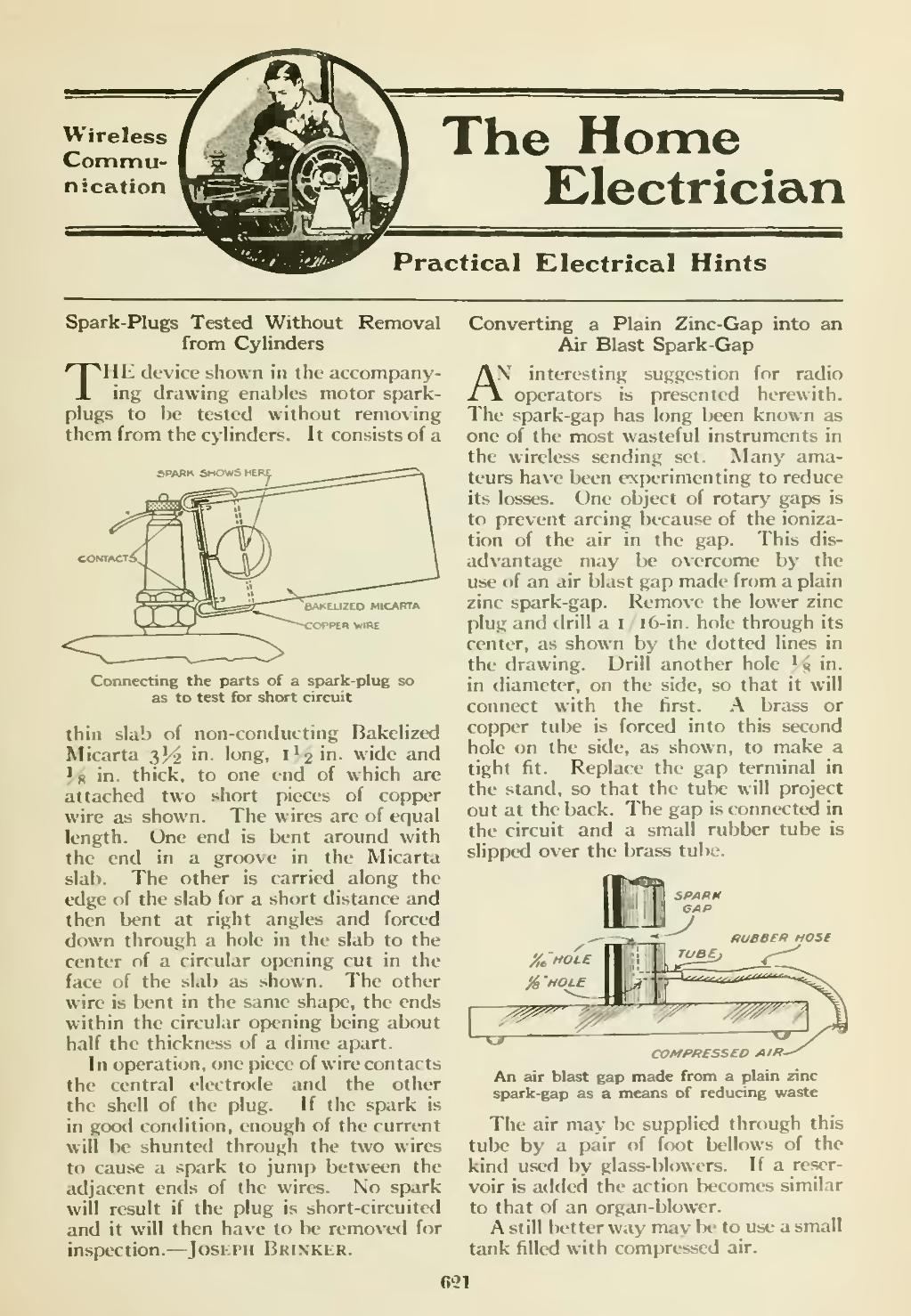

THE device shown in the accompany- ing drawing enables motor spark- plugs to be tested without removing them from the cylinders. It consists of a

��5PARK SHOWS HEI

���BAKELIZCO MICARTA

- OPPEn WIRE

��Connecting the parts of a spark-plug so as to test for short circuit

thill slab of non-conducting Bakelized Micarta 3^^ in. long, ij-o in- wide and ^^ in. thick, to one end of which are attached two short pieces of copper wire as shown. The wires are of equal length. One end is bent around with the end in a groove in the Micarta slab. The other is carried along the edge of the slab for a short distance and then bent at right angles and forced down through a hole in the slab to the center of a circular opening cut in the face of the slab as shown. The other wire is bent in the same shape, the ends within the circular opening being about half the thickness of a dime apart.

In operation, one piece of wire contacts the central electrode and the other the shell of the plug. If the spark is in good condition, enough of the current will be shunted through the two wires to cause a spark to jump between the adjacent ends of the wires. No spark will result if the plug is short-circuited and it will then have to be removed for inspection.— Joseph Brinker.

��Converting a Plain Zinc-Gap into an Air Blast Spark-Gap

AN interesting suggestion for radio L operators is presented herewith. The spark-gap has long l)een known as one of the most wasteful instruments in the wireless sending set. Many ama- teurs have been experimenting to reduce its losses. One object of rotary gaps is to prevent arcing because of the ioniza- tion of the air in the gap. This dis- advantage may be o\'ercome by the use of an air blast gap made from a plain zinc spark-gap. Remove the lower zinc plug and drill a i/i6-in. hole through its center, as shown by the dotted lines in the drawing. Drill another hole 3 8 'n. in diameter, on the side, so that it will coimect with the first. A brass or copper tube is forced into this second hole on the side, as shown, to make a tight fit. Replace the gap terminal in the stand, so that the tube will project out at the back. The gap is connected in the circuit and a small rubber tube is slipped over the brass tul>c.

��RuBBefi Host

��-CT-

���/e 'hole

��COMPRESSED AIR-

��An air blast gap made from a plain zinc spark-gap as a means of reducing waste

The air may be supplied through this tuljc by a pair of foot bellows of the kind used by glass-blowers. If a reser- voir is added the action becomes similar to that of an organ-blower.

A still better way may be to use a small tank filled with compressed air.

��621

�� �