Popular Science Monthly/Volume 12/January 1878/The Growth of the Steam-Engine III

THE

POPULAR SCIENCE

MONTHLY.

JANUARY, 1878

| THE GROWTH OF THE STEAM-ENGINE.[1] |

By Professor R. H. THURSTON,

OF THE STEVENS INSTITUTE OF TECHNOLOGY.

III.

THE NON-CONDENSING ENGINE, AND ITS APPLICATION IN THE LOCOMOTIVE.

45. The engines of Hero and Branca were, it will be remembered, non-condensing; but the first plan of a non-condensing engine that could have been made of any really practical use is given in the "Theatrum Machinarum" of Leupold, published in 1720. His sketch is copied in Fig. 23. It is stated by Leupold that this plan was suggested by Papin. It consists of two single-acting cylinders, r s, receiving steam alternately from the same steam-pipe through a "four-way-cock," and exhausting into the atmosphere. We find no evidence that this engine was ever built.

|

| Fig. 23.—Leupold's Papin Engine, 1720. |

When, during the last century, the steam-engine had so far been perfected that the possibility of its application to other purposes than the elevation of water had become generally recognized, the problem of its adaptation to the propulsion of carriages was attacked by many engineers and inventors.

As early as 1759, Dr. Robison, who was at the time a graduate of the University of Glasgow, and an applicant for an assistant professorship there, and who had made the acquaintance of the instrument-maker, James Watt, when visiting the workshop, called the attention of the latter, who was probably then more ignorant of the principles of the steam-engine than was the young student, to the possibility of constructing a carriage to be driven by a steam-engine, thus, perhaps, setting in operation that train of thoughtful experiment which finally earned for Watt his splendid fame.

46. Watt, at a very early period, proposed to apply his engine to locomotion, and contemplated using either a non-condensing engine, or an air-surface condenser. He actually included the locomotive-engine in his patent of 1784, and his assistant, Murdoch, in the same year, made a working-model locomotive which was capable of running at a rapid rate.

|

| Fig. 24.—Murdoch's Model, 1784. |

This model, now deposited in the Patent Museum, at South Kensington, London, had a flue-boiler, and a "grass-hopper" engine. Its steam-cylinder was three-quarters of an inch in diameter, and had two inches stroke of piston (Fig. 24). The driving-wheels were nine and a half inches in diameter. It is reported to have run six to eight miles an hour, its little driving-wheels making from two hundred to two hundred and seventy-five revolutions per minute.

47. In 1765 that singular genius, Dr. Erasmus Darwin, whose celebrity was acquired by speculations in poetry and philosophy as well as in medicine, urged Matthew Boulton (subsequently Watt's partner, and just then corresponding with our own Franklin in relation to the use of steam-power), to construct a steam-carriage, or "fiery chariot," as he poetically styled it, and of which he sketched a set of plans.

A young man, named Edgeworth, became interested in the scheme, and in 1768 published a paper which had secured for him a gold medal from the Society of Arts. In this paper he proposed railroads on which the carriages were to be drawn by horses, or by ropes from steam-winding engines.

Fig. 25.—Cugnot's Steam-Carriage, 1770.

48. These were merely promising schemes, however. The first actual experiment was made, as is supposed, by a French army officer, Nicolas Joseph Cugnot, who in 1769 built a steam-carriage (Fig. 25), which was set at work in presence of the French Minister of War, the Duke de Choiseul. The funds required by him were furnished by the Comte de Saxe. Encouraged by the partial success of the first locomotive, Cugnot, in 1770, constructed

Fig. 26. Read's Steam-Carriage, 1790. a second which is still preserved in the Conservatoire des Arts et Métiers, Paris. This more powerful carriage (Fig. 25) was fitted with two non-condensing single-acting cylinders, thirteen inches in diameter. Although the experiment seems to have been successful, there appears to have been nothing more done with it.

An American of considerable distinction, Nathan Read, patented a steam-carriage, 1790,[2] of the form seen in Fig. 26, which is copied from his patent. The cylinders F F lie under the body of the carriage: the pistons E F drive racks B G, which turn the wheels A K. The steering-wheel I moves the large wheels A K, which latter, turning, carries the engines about with it. It is an ingenious and curious device.

49. "To Oliver Evans," says Dr. Ernest Alban,[3] the learned German engineer, "was it reserved to show the true value of a long-known principle, and to establish thereon a new and more simple method of applying the power of steam—a method that will remain an eternal memorial to its introducers." Dr. Alban here refers to the earliest successful introduction of the non-condensing high-pressure steam-engine.

Oliver Evans, one of the most ingenious mechanics that America has ever produced, was born at Newport, Delaware, in 1755 or 1756, the son of people in very humble circumstances.

He was, in his youth, apprenticed to a wheelwright, and soon exhibited great mechanical talent and a strong desire to acquire knowledge.

His attention was at an early period drawn to this possible application of the power of steam to useful purposes by a boyish prank. Placing a small quantity of water in a gun-barrel, and ramming down a tight wad, he put the barrel in the fire of a blacksmith's forge. The loud report which accompanied the expulsion of the wad was an evidence to young Evans of the great, and, as he supposed, previously undiscovered power of steam.

Subsequently, meeting with a description of a Newcomen engine, he at once noticed that the elastic force of confined steam was not there utilized.

Fig. 27.—Oliver Evans's Engine, 1800.

He then designed the non-condensing engine, in which the power was derived exclusively from the tension of high-pressure steam, and proposed its application to the propulsion of carriages.

50. About the year 1780 Evans joined his brothers, who were millers by occupation, and at once employed his inventive talent in improving the details of mill-work, and with such success as to reduce the cost of attendance one-half, and also to increase the fineness of the flour made.

In 1785 he applied for, but was refused, a patent for a steam carriage.

In 1800 or 1801, Evans, after consulting with Prof. Robert Patterson, of the University of Pennsylvania, and getting his approval of the plans, commenced the construction of a steam-carriage, to be driven by a non-condensing engine.

He soon concluded, however, that it would be a better scheme, pecuniarily, to adapt his engine, which was novel in form and of small first cost, to driving mills; and he accordingly changed his plans, and built an engine of six inches diameter of cylinder and eighteen inches stroke of piston, which he applied with perfect success to driving a plaster mill.

51. This engine (Fig. 27), which he called the "Columbian engine," was of a peculiar form.

The beam is supported at one end by a rocking column; at the other it is attached directly to the piston-rod, while the crank lies beneath the beam, the connecting-rod being attached to the latter at about the middle point.

The head of the piston-rod is compelled to rise and fall in a vertical line by the "Evans parallelogram," a kind of parallel motion very similar to one of those designed by Watt.

52. Subsequently, Evans continued to extend the application of his engine and to perfect its details, and, others following in his track, the non-condensing engine is to-day fulfilling the predictions which he made seventy years ago, when he said:

"The time will come when people will travel in stages moved by steam engines, from one city to another, almost as fast as birds can fly—fifteen or twenty miles an hour. A carriage will start from Washington in the morning, the passengers will breakfast at Baltimore, dine at Philadelphia, and sup at New York the same day. . . .

"Engines will drive boats ten or twelve miles an hour, and there will be hundreds of steamers running on the Mississippi, as predicted years ago."53. In 1804 Oliver Evans completed a flat-bottomed boat (Fig. 28), to be used at the Philadelphia docks, and, mounting it upon wheels, drew it by its own steam-engine to the river-bank. Launching the craft, he propelled it down the river, using its steam-engine to drive its paddle-wheels. Evans's "oructor amphibolis" as he named the machine, was the first road-locomotive that we find described after Cugnot's time. Evans asserted that carriages propelled by steam would soon be in common use; and offered a wager of three hundred dollars that he could build a "steam-wagon" that should excel in speed the swiftest horse that could be matched against it.

Evans's connection with steam-navigation will be referred to when considering that subject.

Fig. 28.—"Oructor Amphibolis," 1804.

To this brief sketch of Evans's inventions it can only be added that he devised the flue-boiler, now generally called the Cornish, and used it to furnish steam to his engines.

Richard Trevithick.

54. The earliest non-condensing engine brought into use in Great Britain seems to have been constructed by Richard Trevithick and Andrew Vivian in 1802. It is stated, by friends of Oliver Evans, that be had, at an earlier date, sent Mr. John Sampson to England, and, by him, had forwarded drawings and specifications, which Trevithick and Vivian inspected, and to which, it is not improbable, they may have been indebted for their plans.

They used a non-condensing, return connecting-rod engine, and carried as high as sixty to eighty pounds of steam.

They built a locomotive-engine in 1804 (Fig. 29), for the railway

Fig. 29.—Trevithick's Locomotive, 1804.

at Merthyr-Tydvil, in South Wales, which was quite successful, although sometimes giving trouble by slipping its wheels.

This engine had one steam-cylinder 4¾ inches diameter, and carried forty pounds steam.

In consequence of a fear of the wheel slipping, Blenkinsop employed, in 1811, a pinion on the locomotive shaft, gearing into a rack on the road-bed.

In 1813 Brunton, of Butterly, tried to introduce a locomotive-engine propelled by levers, like an animal's legs, pushing behind; and just at this time mechanics, all over the world, seem to have become very much interested in this problem.

55. It is at about this period that we find evidence of the intelligent labors of another of our countrymen—one who, in consequence of the unobtrusive manner in which his work was done, has never received the full credit to which he is entitled.

Colonel John Stevens, of Hoboken, as he is generally called, was born in the city of New York, in 1749, but, throughout his business life, he was a resident of New Jersey.

He was undoubtedly the greatest engineer and naval architect living at the beginning of the present century.

John Stevens.

Without having made any one superlatively great improvement in the mechanism of the steam-engine, like that which gave Watt his fame; without having the honor of being the first to propose navigation by steam, or steam transportation on land, he exhibited a far better knowledge of the science and of the art of engineering than any man of his time, and he entertained and urged more advanced opinions and more statesmanlike views, in relation to the economical importance of tire improvement of the steam-engine, both on land and water, than seem to have been attributable to any other leading engineer of that time.

His attention is said to have been first called to the application of steam-power by seeing the experiments of John Fitch with his steamer. He entered upon the work of the introduction of steam in navigation with characteristic energy, and with a success that will be indicated when we come to the consideration of that branch of the subject.

But this far-sighted engineer and statesman saw plainly the importance of applying the steam-engine to land transportation as well as navigation; and not only that, but he saw with equal distinctness the importance of a well-devised and carefully-prosecuted scheme of internal communication by a complete system of railroads.

56. In 1812 he published a pamphlet embodying "Documents tending to prove the Superior Advantages of Railways and Steam Carriages over Canal Navigation."[4]

At this time, the only working locomotive in the world was that of Trevithick and Vivian, at Merthyr-Tydvil, and the railroad itself had not grown beyond the old wooden tram-roads of the collieries.

Yet, Colonel Stevens says in this paper, "I can see nothing to hinder a steam-carriage moving on its ways with a velocity of one hundred miles an hour," adding in a foot-note: "This astonishing velocity is considered here merely possible. It is probable that it may not, in practice, be convenient to exceed twenty or thirty miles per hour. Actual experiments can only determine this matter, and I should not be surprised at seeing steam-carriages propelled at the rate of forty or fifty miles an hour."

At a yet earlier date he had addressed a memoir to the proper authorities, urging his plans for railroads.

He proposed rails of timber, protected when necessary by iron plates, or to be made wholly of iron. The car-wheels were to be of cast-iron, with inside flanges to keep them on the track. The steam engine was to be driven by steam of fifty pounds pressure, and to be non-condensing.

Answering the objections of Robert R. Livingston and of the commissioners of New York, he goes further into details.

57. He gives 500 to 1,000 pounds as the maximum weight to be placed on each wheel, shows that the trains or "suites of carriages," as he calls them, will make their journeys "with as much certainty and celerity in the darkest night as in the light of day," shows that the grades of proposed roads would offer but little resistance, and places the whole subject before the public with such accuracy of statement, and such evident appreciation of its true value, that every one who reads this remarkable document will agree fully with the late President Charles King, of Columbia College, who said that "whosoever shall attentively read this pamphlet will perceive that the political, financial, commercial, and military aspects of this great question were all present to Colonel Stevens's mind, and that he felt that he was fulfilling a patriotic duty when he placed at the disposal of his native country these fruits of his genius.

"The offer was not then accepted. The Thinker was ahead of his age, but it is grateful to know that he lived to see his projects carried out—though not by the Government—and that before he finally, in 1838, closed his eyes in death, at the great age of eighty-nine, he could justly feel assured that the name of Stevens, in his own person and that of his sons, was imperishably enrolled among those which a grateful country will cherish."

A patent issued to Colonel Stevens by the British Government in 1805, and a section of a "safety-tubular" boiler subsequently built oil the same plan, and used on a locomotive, are preserved in the Stevens Institute of Technology, at Hoboken, New Jersey.

George Stephenson.

58. In 1814 George Stephenson, to whom is generally accorded the honor of having first made the locomotive-engine a success, built his first engine at Killingworth, England.

It had been found during the previous year, by Blackett & Headly, whose engine is still preserved at the South Kensington Patent Museum, that the slipping of the wheels could be avoided without recourse to extraordinary contrivances, and Stephenson made his engine a success, using smooth wheels.

At this time, Stephenson was by no means alone in the field, for the idea of applying the steam-engine to driving carriages on common roads and on railroads was beginning to attract considerable attention.

Stephenson, however, combined in a very fortunate degree the advantages of great natural inventive talent and an excellent mechanical training, his characteristics as an engineer reminding one strongly of those of James Watt. Indeed, Stephenson's portrait bears some resemblance to that of the great inventor.

59. George Stephenson was born in Wylam, in the north of England, near Newcastle-upon-Tyne, and was the son of a "north-country miner." When still a child, he exhibited great mechanical talent and unusual love of study.

When set at work about the mines, his attention to duty and his intelligence obtained for him rapid promotion, until, when about seventeen years of age, he was made engineer, and took charge of the pumping-engine at which his father was fireman.

A little later he was made engine-wright at Killingworth, where he soon inspired those who employed him with such confidence in his skill and reliability as to obtain an opportunity to design his first locomotive-engine, Lord Ravensworth, one of the principal proprietors, furnishing the necessary funds.

60. In 1815 he applied the blast-pipe in the chimney, by which the puff of the exhaust steam is made useful in intensifying the draught, and applied it successfully to his second locomotive, here seen in section

Fig. 30.—Stephenson's Locomotive, 1815.

(Fig. 30). This is the essential characteristic of the locomotive-engine.

In 1815, therefore, we may say that the modern locomotive steam-engine came into existence, for it is this invention of the blast-pipe that gives it its life, and it is the mechanical adaptation of this and of the other organs of the steam-engine to locomotion that gives George Stephenson his greatest claim to distinction.

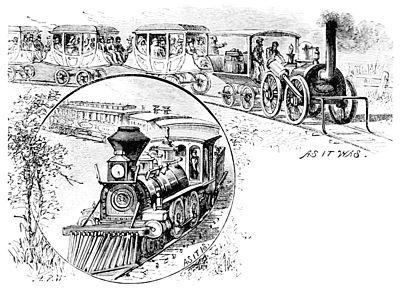

61. In 1825 the Stockton & Darlington Railroad was opened, and one of Stephenson's locomotives, in which he employed his "steam-blast," was successfully used, drawing passenger as well as coal trains. Stephenson had at this time become engineer of the road.

The time required to travel the distance of twelve miles was two hours. This "No. 1 Engine" is still preserved at Darlington Station, mounted on a granite pedestal, as shown in the picture (Fig. 32).

62. One of the most important and interesting occasions in the history of the application of the non-condensing steam-engine to railroads, as well as in the life of Stephenson, was the opening of the Liverpool & Manchester Railroad in the year 1829.

Fig. 31.—Opening of the Stockton & Darlington Railroad, 1825.

When this road was built, it was determined, after long and earnest discussion, to try whether locomotive-engines might not be used to the exclusion of horses, and a prize of £500 was offered for the best that should be presented at a date which was finally settled at the 6th of October, 1829.

Four engines competed, and the "Rocket," built by Stephenson, received the prize.

63. This engine (Fig. 33) weighed four and one-fourth tons, with its supply of water. Its boiler was of the fire-tubular form, a form

that had grown into shape in the hands of several inventors,[5] and was three feet in diameter, six feet long, with twenty-five three inch tubes, extending from end to end of the boiler. The steam-blast was carefully adjusted by experiment, to give the best effect. Steam-pressure was carried at fifty pounds per square inch.

The average speed of the Rocket on its trial was fifteen miles per hour, and its maximum was nearly double that, twenty-nine miles an hour; and afterward, running alone, it reached a speed of thirty-five miles.

The shares of the company immediately rose ten per cent, in value. Thus the combination of the non-condensing engine with a steam-blast and the multitubular boiler, designed by the clear head and constructed under the watchful eye of an accomplished engineer and mechanic, made steam-locomotion so evident and decided a success that thenceforward its progress has been uninterrupted and wonderfully rapid.

64. In America the locomotive was set at regular work on railroads, for the first time, on the 8th of August, 1829.[6]

This first locomotive was built by Foster, Rastrick & Co., at Stourbridge, England, and was purchased by Mr. Horatio Allen for the Delaware & Hudson Canal Company's road from Carbondale to Honesdale, Pennsylvania.

Mr. Peter Cooper, of New York, placed an experimental locomotive on the Baltimore & Ohio Railroad in 1829. It ran about fifteen miles an hour at maximum speed.

The first American locomotive to do real service continuously was the "Best Friend" (Fig. 34), built at the West Point Iron Foundery,

Fig. 34.—The "Best Friend," 1830.

in the year 1830, for the South Carolina Railroad, on which road it ran from January, 1831, to June 17th of the same year, when it was destroyed by the explosion of its boiler.

A second locomotive (Fig. 35) was built at West Point for the same road in 1831, which resembled somewhat those built at about the same time, and a little later, by Stephenson.

It was at this time (1831), also, that Mr. Horatio Allen introduced the first eight-wheeled locomotives ever built, and gave them a form (Fig. 36) which will be at once recognized by the engineer as the prototype of a recently-built locomotive which has been brought out in Great Britain. In this year, also, an engine, the De Witt Clinton, was built for John B. Jervis of the Mohawk & Hudson Railroad.

65. At about the time of the opening of the early railroads, the introduction of steam-carriages on the common highway had become a favorite idea with engineers.[7]

Fig. 35.—The West Point, 1831.

In December, 1833, about twenty steam-carriages and traction road-engines were running or were in course of construction in and near London.

Fig. 36.—The South Carolina, 1831.

In our own country, the roughness of roads discouraged inventors, and, in Great Britain even, the successful introduction of road-locomotives, which seemed at one time almost an accomplished fact, finally met with so many obstacles that even Hancock and Gurney, the most ingenious, persistent, and successful constructors, gave up in despair. Hostile legislation procured by opposing interests, and possibly also the rapid progress of steam-locomotion on railroads, caused this result.

In consequence of this interruption of experiment, almost nothing was done during the succeeding quarter of a century, and it is only within a few years that anything like a business success has

been founded upon the construction of road-locomotives, although the scheme seems to have been at no time entirely given up.

Messrs. Aveling & Porter, J. Scott Russell, Boydell, and a few others in England, and Messrs. Roper, Dudgeon, Fawkes, Latta, and J. K. Fisher, in the United States, have all, at various times, labored in this direction.

The last-named engineer designed his first steam-carriage in 1840, and was still at work at the time of his death, in 1873.

Abroad, a few firms have succeeded, within a few years past, in making a business of considerable extent in constructing road-locomotives for hauling heavy loads, and in building steam road-rollers.

While steam-carriages of high speed, and adapted to the transportation of passengers, have not yet been successfully introduced, a most promising start has been made in the application of steam to the heavier kinds of work on the common road.

The great impediments seem to be the roughness and bad construction of the ordinary highway, the damages arising from the taking fright of horses, the engineering difficulties of construction, and the limited power of the machine as it has usually been built. Hostile legislation might perhaps be placed in the category, but we are probably sufficiently far advanced in civilization today to be able to secure liberal legislation when the people shall be satisfied that the introduction of the road-locomotive will be of great public advantage.

66. The capabilities of the road-locomotive are readily determined by experiment, and the following is an abstract of the results of several series of trials.[8] A trial of a road-engine was made by the well-known French engineer, H. Tresca, in presence of Prof. Fleeming Jenkin, and the report was submitted on January 15, 1868. The results were as follows: 1. The coefficient of traction was about 0.25 on a good road with easy grades. 2. The consumption of coal was 4.4 pounds per horse-power per hour. 3. The consumption of water was 132.2 gallons an hour with the ten-horse engine. 4. The coefficient of adherence, or of friction between the wheels and the soil, was 0.3. 5. A speed of seven miles an hour caused no special difficulty in managing either the locomotive or its load. At about this time M. Servel conducted

Fig. 38.—Gurnet's Steam-Carriage, 1833.

a series of experiments with a similar machine upon paved and upon macadamized roads, during what he described as the most trying of winter weather. He reports the following distribution of weight per cent.:

| Weight of | locomotive | 41.4 |

| "" | wagons | 18.2 |

| "" | paying load | 40.4 |

| ——— | ||

| Total | 100 | |

The average total weight of three loaded wagons, which was the usual load, was 22,575 kilogrammes, or about twenty-two tons. The experiment was made in 1867-'68 of applying these engines to the towage of boats on the French canals, with very encouraging results.

In 1871 several traction-engines were exhibited before the Royal Agricultural Society of England at Wolverhampton, and the judges made a series of careful tests, reported in its "Journal" for that year. The coal used on special trial amounted to 3.2 pounds per indicated horse-power per hour, and the evaporation of water was 7.62 pounds per pound of coal consumed, the average temperature of feed being 175° Fahr. The load drawn up the maximum grade of 264 feet to the mile on Tottenham Hill, which is 1,900 feet from top to bottom, was twenty-six tons, and including weight of engine thirty-eight tons, giving a coefficient of traction of 0.35. On a country-road sixteen miles long it drew fifteen tons at an average rate of 3½ miles an hour, using 2.85 pounds of coal and 1.94 gallon of water per ton of useful load per mile.

67. In October, 1871, the writer conducted a public trial of road-engines and steam road-rollers, on a well-macadamized road at South Orange, New Jersey. Two road-steamers (Fig. 39) or traction-engines and a steam road-roller were tried. The following were the principal dimensions: Weight of engine complete, five tons four hundred-weight (11,648 pounds); diameter of steam-cylinder, 7¾ inches; stroke of piston, ten inches; revolutions of crank to one of driving-wheel, seventeen; diameter of driving-wheels, sixty inches; length of boiler over all, eight feet; diameter of boiler-shell, thirty inches; load on driving-wheels, four tons ten hundred-weight (10,080 pounds). The boiler was of the ordinary locomotive type, and the engine was mounted upon it, as is usual with portable engines. The engine valve-gear consisted of a three-ported valve and Stephenson-link, with reversing lever, as generally used on locomotives. The connection between the

Fig. 39.—Modern Road-Locomotive.

gearing and the driving-wheels was effected by the device called by builders of cotton-machinery a Jack-in-the-box gear, or differential gear. By this combination, the effort exerted by the engine is made equal at both wheels at all times, even when the engine is turning a corner. The following is a summary of the conclusions deduced from the trial, and published in the Journal of the Franklin Institute: A traction-engine may be so constructed as to be easily and rapidly maneuvered on the common road; and an engine weighing over five tons may be turned continuously without difficulty on a circle of eighteen feet radius, or even on a road but little wider than the length of the engine. A locomotive of five tons four hundred-weight has been constructed, capable of drawing on a good road 23,000 pounds up a grade of 533 feet to the mile, at the rate of four miles an hour; and one might be constructed to draw more than 63,000 pounds up a grade of 225 feet to the mile, at the rate of two miles an hour. It was further shown that the coefficient of traction with heavily-laden wagons on a good macadamized road is not far from 4100; the traction-power of this engine is equal to that of twenty horses; the weight, exclusive of the weight of the engine, that could be drawn on a level road, was 163,452 pounds; and the amount of fuel required is estimated at 500 pounds a day. The advantages claimed for the traction-engine over horse-power are: No necessity for a limitation of working-hours; a difference in first cost in favor of steam; and in heavy work on a common road the expense by steam is less than twenty-five per cent, of the average cost of horse-power, a traction-engine capable of doing the work of twenty-five horses being worked at as little expense as six or eight horses.

68. Now, thirty years after the defeat of the intelligent, courageous and persistent Hancock and his co-workers in the scheme of applying the steam-engine usefully on the common road, we find strong indications that, in a new form, the problem has been again attacked and at least partially solved. It was formerly supposed that success in the transportation of passengers by steam on post-routes would lead to the application of that motor to the movement of heavy loads and to agricultural purposes generally. When, after so long a trial, the experiment finally seemed to have failed of success, it was believed that steam could not be applied to heavier work on common roads. As we have now seen, however, it appears probable that the inventors of that day attacked the problem at the wrong point, and that, on the common road, the transportation of heavy loads by steam being accomplished with economical success, under ordinarily favorable circumstances, it may prove introductory to the use of steam in carrying passengers and light freight at higher velocities.

One of the most important of the prerequisites to ultimate success in the substitution of steam for animal power on the highway is that our roads shall be well made.

As the greatest care and judgment are exercised, and an immense outlay of capital is considered justifiable, in securing easy grades and a smooth track on our railroad routes, we may readily believe that similar precaution and outlay will be found advisable in adopting the common road to the road-locomotive.

It is undeniably the fact that, even when relying upon horse-power, far less attention has been paid to the improvement of our roads than true economy would dictate. With steam-power, the gain by careful grading and excellence of construction of the road-bed becomes still more important. The animal mechanism is less affected in its power of drawing heavy loads than is the machine. With the horse, a bad road impedes transportation principally by resisting the movement of the load rather than of the animal, while with the traction-engine the motor is as seriously retarded as the train which follows it, and frequently much more, on soft ground.

Steam, therefore, cannot be expected to attain its full measure of success on rough and ill-made roads; but where highways are intelligently engineered and thoroughly well built, or where Nature has relieved the engineer and the road-builder of the expensive work of grading, as throughout a very large extent of the Western and Southern portion of our country, we may expect to see the road-locomotive rapidly introduced.

The earliest and most perfect success of the traction-engine, and its probable successor, the steam-carriage, may be expected to occur in such districts. Its great economical advantage over animal power, its freedom from liability to become disabled by epizoötic diseases, its reliability under all circumstances, and the many other advantages which are possessed by the machine, are already securing its introduction, despite the difficulties arising from popular prejudice and unfamiliarity, from hostile municipal laws and other existing obstacles.

We are learning that this motor, when it can be used at all, is comparatively inexpensive; that our roads are improved by it; and that the ancient idea of its conflicting with the interests of owners and workers of horses is only a superstition.

Fig. 40.—Hancock's Steam-Carriage, 1833.

Such a commencement having been made, it is difficult to conceive how great may not be the future of this branch of industry when the valley of the Mississippi and our Western plains, the natural habitat of this motor, shall have become finally a principal seat of its manufacture as well as of its employment.[9]

69. The steam-blast of Hackworth, the tubular boiler of Séguin, and the link-motion of Stephenson, constitute the essential features of the modern locomotive. Locomotives have gradually and steadily increased in size and power from the date of their introduction. The Rocket, which first proved conclusively, in 1829, the value of steam-locomotion, weighed 4¼ tons. In 1835 Robert Stephenson, who had constructed it with his father, writing to Robert L. Stevens, said that he was making his engines heavier and heavier, and that the engine of which he inclosed a sketch weighed nine tons, and could draw "100 tons at the rate of sixteen miles an hour, on a level." Locomotives are now built weighing seventy tons, and powerful enough to draw more than 2,000 tons at a speed of twenty miles an hour. The modern locomotive consists of a boiler, mounted upon a strong light frame of forged iron, by which it is connected with the wheels. The largest engine yet constructed in the United States is said to be one in use on the Philadelphia & Reading Railroad, having a weight of about 100,000 pounds, which is carried on twelve driving-wheels. A locomotive has two steam cylinders, either side by side within the frame, and immediately beneath the forward end of the boiler, or on each side and exterior to the frame. The engines are non-condensing and of the simplest possible construction. The whole machine is carried upon strong but flexible steel springs. The  Fig. 41. British Express-Engine. steam-pressure is usually more than 100 pounds. The pulling-power is generally about one-fifth the weight under most favorable conditions, and becomes as low as one-tenth on wet rails. The fuel employed is wood in new countries, coke in bituminous coal districts, and anthracite coal in the eastern part of the United States. The general arrangement and the proportions of locomotives differ somewhat in different localities. In Fig. 41, a British express-engine, O is the boiler, N the fire-box, X the grate, G the smoke-box, and P the chimney. S is a spring, and H a lever safety-valve, T is the whistle, L the throttle or regulator valve, E the steam-cylinder, and W the driving-wheel. The force-pump, B C, is driven from the cross-head, D. The frame is the base of the whole system, and all other parts are firmly secured to it. The boiler is made fast at one end, and provision is made for its expansion when heated. Adhesion is secured by throwing a proper proportion of the weight upon the driving-wheel W. This is from about 6,000 pounds on standard freight-engines, having several pairs of drivers, to 10,000 pounds on passenger-engines, per axle. The peculiarities of the American type (Figs. 42, 43) are the truck or bogie supporting the forward part of the engine, the system of equalizers, or beams which distribute the weight of the machine equally over the several axles, and minor differences of detail. The cab or house protecting the engine-driver and fireman is an American device, which is gradually coming into use abroad also. The American locomotive (Fig. 43) is distinguished by its flexibility and ease of action even upon roughly-laid roads. The cost of passenger-locomotives of ordinary size is about $12,000; heavier engines sometimes cost $20,000. The locomotive is usually furnished with a tender, which carries its fuel and water. The standard passenger-engine on the Pennsylvania Railroad is quite similar in form to the Baldwin engine (Fig. 42), and has four driving-wheels (G, H), 5½ feet diameter; steam-cylinders (C, D), seventeen inches diameter and two feet stroke; grate-surface (N) 15½ square feet, and heating-surface 1,058 square feet. It weighs 63,100 pounds, of which 39,000 pounds are on the drivers and 24,100 on the truck, L K. The shell of the boiler is 49¼ inches diameter and 20 feet 2½ inches long. The fire-box, N N, is of steel, six feet two inches long outside, 312 feet wide, and five feet four inches high. The tubes, O O, are of iron, 142 in number, 214 inches diameter, and eleven feet seven inches long. The steam-dome, R, is thirty inches outside diameter, the smoke-stack

Fig. 41. British Express-Engine. steam-pressure is usually more than 100 pounds. The pulling-power is generally about one-fifth the weight under most favorable conditions, and becomes as low as one-tenth on wet rails. The fuel employed is wood in new countries, coke in bituminous coal districts, and anthracite coal in the eastern part of the United States. The general arrangement and the proportions of locomotives differ somewhat in different localities. In Fig. 41, a British express-engine, O is the boiler, N the fire-box, X the grate, G the smoke-box, and P the chimney. S is a spring, and H a lever safety-valve, T is the whistle, L the throttle or regulator valve, E the steam-cylinder, and W the driving-wheel. The force-pump, B C, is driven from the cross-head, D. The frame is the base of the whole system, and all other parts are firmly secured to it. The boiler is made fast at one end, and provision is made for its expansion when heated. Adhesion is secured by throwing a proper proportion of the weight upon the driving-wheel W. This is from about 6,000 pounds on standard freight-engines, having several pairs of drivers, to 10,000 pounds on passenger-engines, per axle. The peculiarities of the American type (Figs. 42, 43) are the truck or bogie supporting the forward part of the engine, the system of equalizers, or beams which distribute the weight of the machine equally over the several axles, and minor differences of detail. The cab or house protecting the engine-driver and fireman is an American device, which is gradually coming into use abroad also. The American locomotive (Fig. 43) is distinguished by its flexibility and ease of action even upon roughly-laid roads. The cost of passenger-locomotives of ordinary size is about $12,000; heavier engines sometimes cost $20,000. The locomotive is usually furnished with a tender, which carries its fuel and water. The standard passenger-engine on the Pennsylvania Railroad is quite similar in form to the Baldwin engine (Fig. 42), and has four driving-wheels (G, H), 5½ feet diameter; steam-cylinders (C, D), seventeen inches diameter and two feet stroke; grate-surface (N) 15½ square feet, and heating-surface 1,058 square feet. It weighs 63,100 pounds, of which 39,000 pounds are on the drivers and 24,100 on the truck, L K. The shell of the boiler is 49¼ inches diameter and 20 feet 2½ inches long. The fire-box, N N, is of steel, six feet two inches long outside, 312 feet wide, and five feet four inches high. The tubes, O O, are of iron, 142 in number, 214 inches diameter, and eleven feet seven inches long. The steam-dome, R, is thirty inches outside diameter, the smoke-stack

Fig. 42.—The Baldwin Locomotive, 1878.

p, 1412 inches. The feed-water is supplied by one pump, h, of 2½ inches diameter and two feet stroke, and by a No. 8 Giffard injector. The valves, T, are 1612 inches wide by 812 inches long, and have five inches travel. The steam-ports are 151516 inches wide and 114 inch long, and the exhaust-port 151516 by 212 inches. The lap of the valve is, outside 34 inch, inside 164 inch. The eccentrics have a throw of 418 inches. The standard freight-engine has six driving-wheels, 5458 inches in diameter. The steam-cylinders are eighteen inches in diameter, stroke twenty-two inches, grate-surface 14.8 square feet, heating-surface 1,096 feet. It weighs 68,500 pounds, of which 48,000 are on the drivers and 20,500 on the truck. The boiler is nearly of the same dimensions as that of the passenger-engine, but the tubes are 214 inches in diameter, twelve feet 9916 inches long, and 119 in number. The stack is eighteen inches in diameter. The pump is 2¼ inches in diameter, and has a stroke of twenty-two inches. The valve has 34 inch inside lap, 116 inch outside. The former takes a train of five cars up an average grade of ninety feet to the mile. The latter is attached to a train of eleven cars. On a grade of fifty feet to the mile, the former takes seven and the latter seventeen cars. Tank-engines for very heavy work, such as on grades of 320 feet to the mile, which are found on some of the railroads where gradients are very steep, have five pairs of coupled driving-wheels, and are not fitted with trucks. Such engines have, usually, steam-cylinders about twenty inches in diameter and two feet stroke of piston. Their grates have an area of fifteen or sixteen square feet, and the heating-surface has an area of 1,400 to 1,500 square feet. Engines of this class, weighing fifty tons, have hauled 110 tons up the heaviest grades of the Pennsylvania Railroad at the rate of five miles an hour. Steam-pressure is carried at from 125 to 150 pounds on the square inch.

70. A train weighing 150 tons is drawn by an express-engine (Fig. 43)

Fig. 43.—Standard Passenger and Express Engine, 1878.

at the speed of sixty miles an hour, the engine developing about 800 horse-power.[10] An engine drawing a light train has been known to make about one hundred miles in one hundred minutes, which speed may be taken as representing the maximum for the best modern engines on the best existing roads.

The life of the locomotive, when well cared for, cannot be exactly stated, but may be taken as not far from thirty years. Repairs cost, annually, ten or fifteen per cent, of the first cost. While running each engine requires about four pints of oil and two tons of coal for each one hundred miles.

71. After their introduction, the growth of railroads and the use of locomotives extended in the United States and in Europe with great rapidity.

The first railroad in the United States was built near Quincy, Massachusetts, in 1826.

In 1850 there were about 700 miles in operation; in 1860 there were over 30,000; and there are to-day about 76,000 miles of completed road in the United States, and the rate of increase had risen in 1873 to above 7,000 miles per year, as a maximum, and the consumption of rails for renewal alone amounts to nearly a half-million tons per year.

- ↑ An abstract of "A History of the Growth of the Steam-Engine," to be published by D. Appleton & Co.

- ↑ "Nathan Read and his Steam-Engine." New York: Hurd & Houghton, 1870.

- ↑ "The High-Pressure Engine investigated," Dr. Ernest Alban, London, 1847.

- ↑ Printed by T. & J. Swords, 1160 Pearl Street, New York, 1812.

- ↑ Barlow and Fulton, 1795; Nathan Read, Salem, United States, 1796; Booth, of England, and Séguin, of France, about 1827 or 1828.

- ↑ "History of the First Locomotive in America," W. H. Brown. D. Appleton & Co., New York, 1872.

- ↑ "Road-Locomotives and Traction-Engines," Journal of the Franklin Institute, 1871.

- ↑ Appletons' American Cyclopædia, article "Steam-Carriage."

- ↑ Vide paper by the author, Journal of the Franklin Institute, 1871.

- ↑ Nearly equivalent to the actual power of 1,200 horses.