1911 Encyclopædia Britannica/Malt

MALT (O. Eng., mealt; O. Sax., malt; O. Teut., maltos; Mod. Ger., Malz; Scand., malt; probably derived from the Sanskrit mrdu, soft, thus having reference to the fact that malt is raw grain rendered soft or tender), the name given to grain in which germination has been caused to proceed to a certain stage and has then been arrested by the removal of water and the application of heat. During this limited germination enzymes are developed (see Fermentation), and the constituents of the grain modified so that the finished malt, when ground and submitted to the mashing process (see Brewing), differs from the original raw grain in that the greater portion dissolves. This solubility is, however, a direct one to a slight extent only; it is due for the most part to the action of the malt enzymes, diastase, &c. on the constituents of the grain, the main portion of which are of themselves insoluble. Thus starch, the main constituent of all graminaceous seeds, probably exists in the same condition in raw grain and in malt. When however the malt is mashed, the starch is attacked by the enzyme diastase, and converted by the process of hydrolysis into a mixture of soluble compounds, e.g. the crystalline sugar, maltose, and a number of gummy substances known as maltodextrins. But to a certain extent starch and other carbohydrate substances are rendered directly soluble and diffusible during the malting process, some of the products serving the respiratory needs of the growing germ, others being assimilated by the plantlet and reconverted into reserve carbohydrates in the tissues of the germ and rootlets, whilst the remaining portions are retained as such in the finished malt. Similarly certain of the nitrogenous constituents of the grain, the proteïns, are broken down and rendered soluble by proteolytic enzymes, the products being assimilated to a certain extent by the germ and rootlets, by the cells of which they are again built up into complex proteïns, whilst others remain in their simplified form. It is now known that proteolytic enzymes exist in finished malt, and that, when the mashing process is conducted under certain conditions, these are able to degrade and render soluble some of the higher proteïns present in the malt. When germination is allowed to proceed as it does when the grain is planted in the soil, the whole of the contents are rendered soluble by degrees and in turn assimilated by the growing plantlet. By the limited germination which constitutes the malting process, however, the balance of soluble compounds left in the finished malt is from 15 to 25% of the total weight of the corn.

Although other seeds of the natural order Gramineae are occasionally malted, the greater portion of malt is made from the various species of Hordeum, known by the name of barley (q.v.), bigg, or bere. Indeed ordinary beer derives its characteristic flavour to the greatest extent from barley malt. A small proportion of malted oats or malted wheat is sometimes used in conjunction with barley malt for certain kinds of beer, whilst rye, maize, and even rice are occasionally malted. Barley is, however, the grain best adapted for making malt intended for brewing beer, and accordingly some space will be devoted to a description of those varieties of this grain which are used by the brewer.

Barley belongs to the genus Hordeum, of which there are numerous species and varieties. Linnaeus and the earlier botanists recognized six species of cultivated barleys, but modern botanists usually consider all cultivated barleys as belonging to one species to which the name H. sativum has been given. Körnicke regards H. spontaneum, a very long thin-grained two-rowed barley (see below) which grows in the East, as being the parent form; but E. S. Beaven inclines to the view that wild species of more than one form were originally used as food and subsequently cultivated. The last-named author has drawn up a scheme of classification for the varieties and races of cultivated barleys.

| |||

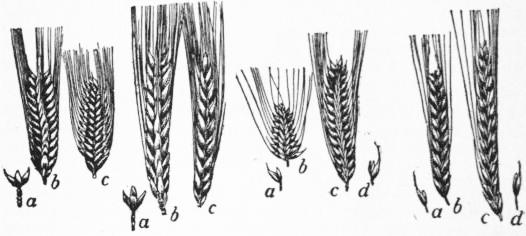

| Fig. 1. | Fig. 2. | Fig. 3. | Fig. 4. |

| Six-rowed barleys. | Fig. 1.—H. hexastichum. | |

| a. Three spikelets in situ on the rachis, showing short internodes. | ||

| b. Spike. Median spikelets uppermost, and with lower awns removed. | ||

| c. Spike. Lateral spikelets uppermost, and with lower awns removed. | ||

| Fig. 2.—H. vulgare. | ||

| a. Three spikelets in situ on the rachis, showing long internodes. | ||

| b. Spike. Median spikelets uppermost. | ||

| c. Spike. Lateral spikelets uppermost. | ||

| Two-rowed barleys. | Fig. 3.—H. zeocriton. | |

| a, d. Spikelets. Rachis edgewise, showing short internodes. | ||

| b. Var. zeocrithum (fan barley). Spike converging. | ||

| c. Var. erectum (Goldthorpe). Spike parallel. | ||

| Fig. 4.—H. distichum. | ||

| a, d. Spikelets. Rachis edgewise, showing long internodes. | ||

| b. Var. nutans (Chevallier). | ||

| c. Ouchak barley. |

In an ear of barley the primary axis or rachis is divided into internodes of which there may be any number up to forty. Each internode bears three single-flowered spikelets arranged alternately on either side of the rachis. In the six-rowed varieties the whole of these spikelets attain maturity, whilst in the two-rowed varieties only one on each side of the rachis, viz. the median, develops. British beer is brewed principally from the malt made from home-grown two-rowed barleys. Of late years, however, it has been found advantageous to employ a proportion of malt made from the thinner and more husky foreign barleys, mostly six-rowed varieties. The corns of two-rowed barleys are as a rule plumper than those of six-rowed barleys.

The most favourite barley for malting purposes grown in the United Kingdom is the narrow-eared two-rowed H. distichum, commonly known as Chevallier, from the name of the original cultivator, the Rev. John Chevallier. Of late years the quantity of barley of the so-called Goldthorpe type (H. zeocriton), used for malting, has increased. The paleae or outer coverings of the corns of this variety are somewhat “greasy” in appearance, and do not adhere so closely to the corn as in the Chevallier. The corns of Goldthorpe barley possess a small dimple or transverse furrow near the basal end. Further the basal bristle or rachilla (the prolongation of the axis or point from which the corn was originally developed) is invariably covered with long hairs, whilst in the case of Chevallier it has generally very short hairs. In the variety of Chevallier known as Archer, however, the rachilla has somewhat long hairs. Further the corns of Chevallier barley lie nearly vertical, that is almost parallel to the rachis, whereas in Goldthorpe they are spread out at a greater angle, hence the name fan or peacock barley given to that variety commonly known as sprat. It is believed by some brewers that Goldthorpe barleys never yield malt of so high a quality as do Chevallier barleys. On the other hand, when well matured, Goldthorpes work evenly and freely on the malting floors; and from an agricultural point of view they have the advantage of standing up better against unfavourable weather conditions on account of their stouter straws. Numerous fresh varieties of barley are continually being introduced as a result of artificial cross-fertilization, but cross-fertilization rarely if ever occurs naturally.

Hungarian two-rowed barleys are excellent as regards quality, and command a high price. The so-called Californian Chevallier and Chilean Chevallier contain a certain admixture of the six-rowed H. vulgare.

Of the imported thin barleys may be mentioned Brewing Californian, Brewing Chilean, Danubian and Smyrna (Yerli), all for the most part six-rowed varieties; also Ouchak, consisting principally of a two-rowed variety. For the manufacture of grain spirit a malt of high diastatic activity is required, and this is largely made from a very thin barley shipped from Odessa.

In the common six-rowed English barley or Scottish bere (H. vulgare), the two lateral rows of spikelets springing from one side of the rachis, either partially or entirely intersect and overlap the alternate lateral spikelets which spring from the opposite side of the rachis. This has given rise to the term “four-rowed barley.” Figs. 1–4 show some typical barleys in the ear.

The production of new varieties by cross-fertilization has of late years attained a degree of almost mathematical precision by the application of the law of inheritance first discovered by Gregor Mendel in 1865, and brought to light in 1901 independently by de Vries, Correns and Tschermak.

Constitution of Barley.—A grain of barley is shuttle-shaped; the end containing the germ which was originally attached to the rachis is known as the proximal end, whilst the opposite end of the corn is called the distal end. A deep furrow runs down the more convex side, which is accordingly denoted the ventral side, the opposite side being distinguished as the dorsal side. Within the ventral furrow at the proximal end is the rachilla already referred to. The skin or husk of a barleycorn consists of two paleae, one adhering to the dorsal side (the palea inferior) and the other to the ventral side (the palea superior); the former overlaps the edges of the latter. The awn or beard is merely an elongation of the palea inferior. If the two paleae are removed from a barleycorn after soaking it in water, it will be seen that there are other skins completely enveloping the embryo and endosperm. These are the true skins, and are known as the pericarp and the testa respectively. It may here be mentioned that A. J. Brown has shown recently that the embryo and endosperm of a barleycorn are enclosed in a semi-permeable membrane, i.e. one which allows the passage of water to the interior of the corn, but not of certain salts and acids. This property appears to be associated with one of the layers of the testa. Next to these skins will be seen the triple layer of thick-walled square-shaped aleurone cells.

The histology of the barleycorn is best studied by the examination of sections under the microscope. The grain consists of two main portions, the embryo or germ, and the endosperm, the storehouse of reserve materials for the growing plant.

The accompanying illustrations show portions of longitudinal sections of a barleycorn magnified to different degrees.

On examining fig. 5, which represents a section of the germ end of a grain of barley cut through the ventral furrow, it will be noticed that the rudimentary leaves, stem and roots are distinguishable. The embryo lies embedded in a mass of cells, the part dividing it from the endosperm being known as the scutellum. Special note should be taken of the elongated cells known as the absorptive epithelial layer, which has certain very important functions to fulfil during the process of germination, notably in feeding the embryo when it begins to develop into a young plant. Next to this, actually between the scutellum and the endosperm, will be seen a layer of empty cells. These at one time in the history and the development of the corn contained starch granules, but this starch was absorbed during its later development by the embryo. It will be observed further that the endosperm is filled with a network of thin-walled cells closely packed with starch granules, and smaller granules of proteïn matter (fig. 6). Nearest the skin will be seen the triple layer of aleurone cells already referred to (fig. 7).

Germination.—The barleycorn in its resting stage is in a state which may be described as one of dormant vitality; it respires very slowly and thus loses weight during storage. The best and driest barleys are said to lose 1.3% of their weight in the first year, 0.9% in the second, and 0.5% in the third. The loss is considerably more with coarse and damp samples. When the grain is steeped this dormant vitality gives place to that complicated series of processes comprised under the general term germination. When germination begins, enzymes are secreted, and these act on the reserve materials, starch and proteïns of the endosperm, converting them into simpler compounds, capable of diffusing to various parts of the growing germ. Following this, starch and proteïns are re-formed, the former being deposited in the tissues of the germ and in the cells of the scutellum, which previously were almost free from starch; the proteïn matter deposited in the latter disappears to a considerable extent, and the protoplasmic content of the cells assumes a very granular appearance. The pointed mass of cells constituting the root-sheath is pushed forward by the root which protrudes through the base of the grain. It is at this stage that the barley is said by the maltster to “chit.” After the first rootlet has broken through the ends of the sheath, it is followed by others. The cotyledonary sheath begins to elongate on the third or fourth day of germination and ruptures the true covering of the seed; it then grows upwards between this and the husk and forms the acrospire or “spire” of the maltster.

| |

| Fig. 7.—Section showing the aleurone layer. | |

g, Starch cells; |

k, Layers which collectively constitute the husk. |

[Figs. 5–7 from Sykes & Ling, Principles and Practice of Brewing (1907), Charles Griffin & Co., Ltd.]

According to Brown and Morris, when the first rootlet is breaking through the sheath, starch begins to appear in the tissues of the grain, also in the protoplasm of those cells which are nearest the epithelial layer, and it gradually invades the deeper-seated cells. Further the cellulose walls of the endosperm, situated immediately above the secretory layer, are partially dissolved, the dissolved matter passing into the scutellum, there to be transformed into starch. Brown and Morris state that this process gradually extends to the cellulose walls of the endosperm, and until these are affected there is no evidence of any solvent action on the starch granules themselves. Thus according to these authors the first enzyme to be formed is one which dissolves cell walls, and it was consequently termed by them a “cytohydrolyst.” They assert further that the so-called mealy or modified condition, which the maltster desires to bring about to the fullest degree, depends on the extent to which the cell walls have been affected, and they enter into a minute description of the entire disappearance of these during the malting process. On the other hand, J. Grüss has pointed out that the action which takes place on the cell walls of the endosperm during germination does not consist in their complete solution. Schulze has shown that these cell walls consist of two carbohydrates, an araban and a xylan. Grüss states that the araban is completely dissolved, whilst the xylan is more or less unattacked. The cell walls become, however, transparent so that they can only be seen in sections which have been stained; Brown and Morris examined unstained sections. The writer (A. R. Ling) has proved that the cell wall is present in the most friable and well modified finished malt.

Condition.—Barley is bought in the open market solely on the evidence of certain external signs, and judgment can only be acquired by long experience. The corns should be plump, even in size, and the colour should be uniform from end to end. The sample should have a sweet odour, and it should be dry to the touch. The presence of light or weevilled corns may be detected by the fact that they float in water. Careless threshing or dressing is responsible for much damage done to barley. In this way many of the corns may be broken, have the palcae partly stripped off or portions removed along with the awn. All broken and dead corns are prone to become mouldy on the malting floors, the contagion thus presented becoming general. E. R. Moritz drew attention in 1895 to the ill effects of close dressing, and more recently (1905) the matter has been brought before the Highland and Agricultural Society, chiefly through Montagu Baird, who with C. H. Babington was instrumental in inducing the Board of Agriculture to publish a leaflet recommending more careful methods of threshing barley. Close dressing was at one time practised as a means of raising the bushel weight, and thus giving a fictitious value to the barley. Immature barley feels cold to the hand, has a greenish-yellow colour, and, when dry, a starved wrinkled appearance. Over-ripeness in barley is distinguished by a white dead appearance of the corn. Mature or dry grains slip through the fingers more readily than unripe or damp ones. The contents of the endosperm should present a white friable or mealy appearance when the corns are bitten or cut in two with a penknife. The condition of the grain may be determined by means of a mechanical cutter, which cuts a certain number of corns (fifty or more) at one time. Some cutters are constructed to cut the corns transversely, others to cut them longitudinally. The so-called transparency test may be used for the same purpose. It is carried out in an apparatus known as the diaphanoscope, which consists of a box fitted with a sliding tray, furnished with a certain number of shuttle-shaped holes (usually 500), each of such a size as just to hold a barleycorn longitudinally. Into the portion of the box below this tray an electric lamp is placed, and the corns are looked at from above. Thoroughly mealy corns are opaque, whilst steely corns are transparent. When certain portions of a corn are steely, these present the appearance of lakes. By this means the percentage of mealy, steely, or half steely corns in a sample may readily be estimated.

E. Prior points out that steeliness of barley is of two kinds, one of which disappears after the grain has been steeped and dried, and therefore does not necessarily influence the malting value of the sample, and the other which is permanent, and therefore retards the modification of the corn. He proposed to determine what he called the coefficient of mellowness of a sample of barley by means of the formula:—

in which A is the degree of mellowness, M is the percentage of mealy corns in the original barley, and M1 is the percentage of mealy corns after steeping and drying the barley. Prior points out that, generally speaking, the degree of mellowness varies inversely as the proteïn content.

The physical differences between steely and mealy grains were first investigated by Johansen, who arrived at the conclusion that mealiness is always accompanied by the presence of air spaces in the endosperm. Munro and Beaven confirmed and extended this. Their conclusions are as follow: “Mealy grains have a lower specific gravity than steely grains, and contain a larger amount of interstitial air. The total nitrogen content of mealy grains is less than that of steely grains. Steely grains contain a relatively high proportion of nitrogenous substances soluble (a) in 5% salt solution, and (b) in alcohol of specific gravity 0.9. Mealy barley modifies better than steely during germination. The process of drying damp and under-matured barley intact at 100° F. produced an apparent mellowing or maturation. Other things being equal, maturation, which is physiologically a post-ripening process, is correlated with the mealy appearance of the endosperm.” H. T. Brown and his collaborators point out that thin sections of steely corns when examined under the microscope no longer exhibit a translucent appearance, but show the mealy properties as completely as if they had been cut from a mealy grain, and they suggest that in a steely corn the whole of the endosperm is under a state of tensile stress which cannot be maintained in the thin sections. If, however, a thin section of a steely barley be cemented to a slide with Canada balsam and then pared away with a razor, steeliness and translucency may be preserved even in the thinnest sections. The mealy appearance in the endosperm of barley is assumed to be a direct consequence of the formation of interspaces around the cell-contents and within the cell walls. Under ordinary conditions it is conjectured that these interspaces are filled with air, but it is pointed out that they can also be produced under circumstances which suggest that they are at times vacuous or partly so. According to the last-mentioned authors they appear to originate from a system of stresses and strains induced within the endosperm by its gradual loss of water, a break of continuity taking place which gives rise to these interspaces when the cohesive power of the heterogeneous cell-contents falls below a certain point. It is further suggested by them that the most important factor in producing the stresses and strains is probably the shrinkage of the starch granules as their water content is reduced from, say, 40 to about 15%. It is pointed out, however, that actual discontinuity in the cell-contents can only take place when the tensile strength of the protoplasmic matrix in which the starch granules are embedded has been surpassed, and this being so it might be anticipated that those cells which contain the larger amount of proteïn material would probably best resist the internal stresses and strains, a deduction in close agreement with observed facts, steely grains being as a rule richer in proteïn than mealy grains. Brown and his co-workers determine the coefficient of mealiness of a barley as follows: Five hundred corns are cut transversely in a corn cutter and the percentage of mealy, half mealy and steely corns is noted. The number 100 is taken to represent complete mealiness, 1 complete steeliness, and 50 the intermediate class. If the percentage of each class be multiplied by its special value, and the sum of the products divided by 100, the result is the coefficient of mealiness. By steeping and drying a very steely Scottish barley, the coefficient of mealiness was raised from 29.7 to 87.1, whilst concurrently the specific gravity fell from 1.417 to 1.289.

Barley even of the same kind varies widely in its chemical composition, but on an average the proximate constituents of British malting barleys be within the following limits:—

| Moisture | 18 | —12 | per cent. |

| Nitrogenous matters expressed as proteïns | 8 | —15 | ” |

| Fat | 2 | — 2.5 | ” |

| Starch | 60 | —65 | ” |

| Sugars | 1.5 | — 2.0 | ” |

| Gums | 1.7 | — 2.0 | ” |

| Fibre (cellulose) | 5 | — 7 | ” |

| Ash | 2 | — 2.5 | ” |

Any sample of barley which contains more than 20% of moisture would be considered damp. The late Professor Lintner expressed the view several years ago that a good malting barley should not contain more than 10% of proteïn, but R. Wahl asserts that in America six-rowed barleys containing a far higher percentage of proteïn are used successfully, indeed preferably, for malting purposes. The only precise knowledge we possess of the proteïn compounds of barley is due to the researches of T. B. Osborne. According to this observer, barley contains the under-mentioned compounds of this class in the following proportions:—

| Soluble in water | Leucosin (albumin) Proteose | 0.30 | per cent. | |

| Soluble in salt solution: | Edestin (globulin) | 1.95 | ” | |

| Soluble in 75% alcohol | Hordeïn | 4.00 | ” | |

| Insoluble proteïn | 4.50 | ” | ||

| ——— | ||||

| Total | 10.75 | ” | ||

It should be pointed out here that the above are only average values for the particular samples of barley investigated. Undoubtedly the nitrogenous constituents of different barleys vary widely in nature as well as in amount.

Raw barley contains enzymes, thus diastase of translocation, so called by Horace T. Brown and G. H. Morris, and catalase (H. van Laer). Proteolytic enzymes appear only to arise with the beginning of germination; but it has been asserted that raw barley contains proenzymes (zymogens), which can be rendered active by treatment with dilute lactic acid at an appropriate temperature. The action of the diastase of raw barley on starch has been studied by Julian L. Baker.

Barley should not be cut until it is properly ripe, but over-ripeness is much more to be guarded against by the maltster than premature cutting, as it is accompanied by a loss in germinative power. Moreover, unripe corn may to a certain extent be matured in stack, whilst a great improvement in germinative capacity is frequently produced by sweating. Very wet seasons are prejudicial to the ripening of the grain, and when the latter is stacked in too moist a condition it is apt to become what is known as mow burnt. Especially is this the case with barleys containing large percentages of nitrogen and of high enzymatic activities. Such barleys are denoted “warm” by M. Delbrück from their tendency to heat when stored in a moist condition. The effect of this heating is exhibited in the corns becoming black and discoloured at the tips; they are then said to be magpied. Even in an otherwise dry season a large amount of rain during harvest causes the corns to become “weathered,” whilst some of them begin germinating and rot. At the same time heavy dews at night whilst the barley lies cut in the field, or even a sprinkling of rain, assists in mellowing the grain, which often in consequence works the more freely on the malting floors. Properly harvested barley is all the better for remaining in stack for two or three months, as was the practice in former years; if, however, it has been stacked too wet the sooner it is broken down the better.

It is difficult to give any specific test for ripeness, but a series of observations has been made by H. T. Brown and F. Escombe. Samples of barley were taken from the field on the 20th, 24th and 29th of July, and on the 2nd, 6th and 10th of August, and preserved in spirit so that they remained in the same state as when they were gathered. Sections were then cut of these corns, when it was found that the progress of maturation is attended by deformation and ultimate disintegration of the cell nuclei. The change which is denoted by the term nuclear senescence is said to begin in the starch-containing cells, near the periphery of the corn, immediately underlying the layer next to the aleurone layer. This deformation is followed by complete disintegration of the nucleus, and at the end of seven or eight days nearly the whole of the endosperm has been involved. Brown and Escombe state that when this nuclear test is properly applied it stamps as immature those corns in a sample which are manifestly unripe owing to premature desiccation as well as those in which the ratio of nitrogen to carbohydrate is unduly high, owing to an excess of nitrogenous manure in the soil, or to sparser sowing with its consequent reduction of root competition. This method, interesting though it be, is not fitted for practical use, and the agriculturist must rely as heretofore upon empirical methods for deciding whether or not the grain has attained ripeness or maturity.

The bushel weight is a useful criterion in arriving at an opinion regarding the value of a sample of barley; but in basing judgment upon this factor regard must be paid to the fact already mentioned that if the grains be dressed closely the bushel weight is increased. The reason of this is that with the removal of the awns the corns pack more closely together. The best British malting barleys should weigh 52-56 ℔ per bushel, the standard weight for malting barleys being 56 ℔.

During the storage of barley access of air is necessary, otherwise the grain dies from asphyxiation. Sound barley after being kiln-dried retains its vitality for a number of years; but the statement that the corns found in the Egyptian mummy cases, in which they had remained for several thousands of years, were still capable of germination, is contrary to modern experience. Moisture must also be carefully excluded, as it initiates germination in a few cells only of the endosperm and causes heating. A constant repetition of wetting such as may take place on account of alterations of the atmospheric temperature, which causes moisture to be deposited, in the form of dew, may ultimately destroy the vitality and foster the growth and development of mould fungi which usually grow on broken and damaged corns. In this connexion the advantage of screening and sweating of barley before storing it will be apparent (see below).

An immense amount of damage is caused to the grain, during storage, by various insects, one of the most destructive of these being the common weevil (Calandra granaria). When fully developed this insect measures 16th to 18th of an inch in length, and is of a bright chestnut colour. The larvae are fleshy legless grubs, shorter than the perfect insect, with a series of tubercles along each side of the body; the head is round with strong jaws. The pupa is white, clear and transparent, showing the form of the future weevil. The female bores a hole in the grain with her snout and deposits an egg. The larva when hatched lives on the contents of the grain and undergoes its changes therein. Windisch asserts that only barley which has ripened in the granary is attacked by weevil. Grain which is only slightly attacked should be kilned at a temperature of 122° F., which destroys the weevil in all stages of development. To detect weevil in a sample of barley, the grain should be spread out on a sheet of white paper in bright sunlight. If weevils are present they soon appear, and betake themselves to a position outside the sunlight, to which they are averse. Treatment of the grain with carbon bisulphide has been suggested as a means of destroying weevil; even if efficacious, however, such a process could not be recommended on account of its danger, carbon bisulphide being highly inflammable. The only practical means of ridding a granary or shop of weevil is to clear out all the grain and leave it empty for a year or more.

The vitality of barley may be determined by causing a sample to germinate in any of the well-known forms of apparatus devised for that purpose, and counting the percentage of germinating and idle corns. The germinative capacity of a sample of barley may frequently be raised by sweating (see below), which, as already mentioned, brings about a kind of artificial maturation.

Malting.—There are two systems of malting used in England: floor malting and pneumatic or drum malting. These systems will be described separately.

A floor malting consists of a rectangular building of several storeys, having the cisterns at one end and the kilns at the other. The uppermost floor is devoted to barley.

Figure 8 shows a longitudinal section of Messrs Watney, Combe, Reid & Co.’s 200 quarter malting at Mortlake. The barley is carried to the top of the building by the elevator A, where the screening and dressing machinery is situated. After leaving these machines the grain is conveyed on bands to the barley floors B and C. The floor C contains also the steeping cisterns. The six working floors are D, E, F, G, H, K. The floors are ventilated by louvres, N, N, N. The cisterns are connected to the floors by means of plugs. The “pieces,” as they are termed, of germinating barley are gradually worked along the floors to the kilns M, M, on to which they are loaded by rotary bands. The fire-places O, O, are arranged so that the draught may be easily controlled. The hot air and products of combustion pass up the shafts P, P, to the hot-air chamber R, R, where they strike the baffle plates S, S. These plates disperse the hot air and gases evenly beneath the kiln floors T, T, through the green malt. After drying and curing, the malt is allowed to cool and is then carried by bands to the floor U, where by suitable machinery the coombs or rootlets are removed. The finished malt is stored in the bins V, V, V.

On arrival at the malting the barley has to be put through the following operations seriatim: receiving, hoisting and weighing, rough screening, drying and sweating, storing until required for use, screening, grading and removing broken corns, steeping, couching, flooring, withering, drying and curing, dressing and polishing, storing, weighing, sacking and discharging the finished malt.

In sweating barley the temperature should not be allowed to rise above 120° F.; it is usually conducted at 100° F.; and subsequently the barley should be stored for some weeks before it is steeped.

The capacity of a malting is described by the number of quarters which are put through it every four days. A fifty quarter malting does not merely mean that the cisterns have a capacity of fifty quarters, but that this quantity of barley goes through the house every four days. The average time the germinating barley is on the floors is twelve days, and, as a rule, kilning occupies four days. If, as sometimes happens, the malt has to be kept on the floors thirteen, fourteen, fifteen days, or even longer, the malting is not being worked at the capacity under which it is described, and the kilns may remain unused for a day or more. Conversely, when the malt is loaded at less than twelve days, a day or two has to be missed in steeping. In the former case when the kilns are not being used for drying and curing malt, advantage may be taken to utilize them for sweating barley.

Steeping cisterns were formerly rectangular vessels, of slate, brick or cement, from which the barley had to be discharged by shovelling it out. The forms approved most at the present day are conical and constructed of iron; they have arrangements at the apex of the cone, the lower portion, for discharging the grain by gravitation. The steeping period ranges from 48 to 70 hours; it varies according to the kind of barley, and the time of the year. In some of the older maltings there are no arrangements for heating the steep water, and in the winter steeping has occasionally to be performed with water at a temperature near its freezing-point. Steeping should be carried out at a temperature as near as possible to 55° and not higher than 60° F. The usual practice is to fill the cistern up to a certain height with water and throw the barley into it, stirring it until it is about level; the heavy corns will then sink directly to the bottom, whilst the light corns and refuse float on the surface and may be skimmed off. During the time the barley remains in the cistern it is usual to change the steep water two or three times, generally at intervals of twelve hours or tides. The advantage of this is not merely to keep the grain fresh and sweet, but to bring it into contact with the air during the time it is taking up water. Aëration of the steep has long been recognized in Germany as promoting germination, and several arrangements are on the market enabling air to be passed through the grain while it is in the cistern. It has been recommended by Graham, Stopes, Moritz and Morris, and experimental evidence as to its beneficial effects has been published by Windisch, Bleisch, Will, and Baker and Dick. When the corn is steep ripe it contains some 60% of water. Steeping does not consist, however, merely in the imbibition of a certain amount of water; in order to bring about germination this water must remain within the corn a certain length of time. Thus, although it is quite possible to force the necessary amount of water into the grain in less than the 48–70 hours usually taken up by the steeping process, the grain is not steep-ripe until certain changes initiated by the water have taken place, and these require time for their completion. The following average data are useful to remember in connexion with the steeping process:—

- Amount of water in steep-ripe barley (about) 60%.

- Matter removed from barley during steeping (about) 1.5%.

- Increase in volume of barley due to water absorption (about) 18–20%.

There has been much discussion as to the influence of saline matters in water on the steeping process. The late Professor Lintner stated that common salt in water tended to extract the nitrogenous constituents of the grain, but impeded its germination. Mills and Pettigrew found that waters containing calcium salts extracted a minimum of nitrogenous compounds from the barley; they also came to the conclusion that the esteem in which the Lichfield water is held for steeping purposes is due to the presence of nitrates which, they assert, have a stimulating effect on the subsequent germination of the grain. The writer has added lime-water to the extent of one-third of the total volume of water at the first change, believing it to promote regularity of germination. Bearing in mind, however, the observations of Adrian J. Brown, that the barleycorn is enclosed in a membrane permeable to water but impermeable to most salts, it is difficult to see how the saline constituents of water can have any effect except in removing matter from the external portions of the grain and on those corns which are broken. The apparent beneficial effect of lime-water in the steep is probably entirely due to the removal of matters from the husks or paleae.

Malting floors may be constructed of cement, tiles or slate, the two former being preferable to the latter. Ford, in 1849, recommended 200 sq. ft. per quarter of barley steeped as the area of the working floors, and he was quite convinced of the necessity of allowing ample floor room, so that the grain could be worked on the slow, cool system. Subsequently, however, maltsters reduced their floor area, and put the grain rapidly through the malting, thus producing what is termed “forced” malt. This kind of malt was, however, condemned by practical brewers, and a chemical test whereby forcing could be detected having been devised by E. R. Moritz and G. H. Morris, maltsters have been compelled again to increase the area of their working floors. At the present time the approved area may be placed at 175–200 sq. ft. per quarter of barley steeped. The area is, however, largely ruled by the kind of barley to be malted.

After the barley has been thrown out of the cistern it is made up in a rectangular heap 16–20 in. deep, called the “couch”; the object of this is to enable it to gather heat and so start germinating. It usually remains in couch for 12–24 hours, until in fact the interior portion of the heap registers a temperature of about 60° F. During the days of the malt tax the exciseman gauged the quantity of the barley while it was in the couch. After couching the barley is spread thinly and evenly on the floor, forming what is known as the young floor or No. 1 piece. The first visible sign of germination is the sprouting of the rootlet, termed “chitting,” and this occurs either while the grain is on the couch or on the young floor. As already mentioned, it may be quickened by aerating the grain in the cistern. From the time the barley is first cast out of the cistern up to the stage of the young floor, or No. 1 piece, it has a pleasant ethereal odour resembling apples. Drs Thomson, Hope and Coventry stated in the earlier part of the 19th century that they distilled “spirits” from germinating barley at this stage. In the light of our present knowledge it would not be surprising if alcoholic fermentation were proved to occur within the grain at this stage, since intramolecular or anaerobic respiration in certain vegetables has been found to be due to alcoholic fermentation.

The thickness at which the young floor is spread depends upon the outside temperature and the nature of the barley. If the weather be warm, or if there be a tendency for the barley to heat, the piece must be spread all the thinner. At this stage the grain loses its external wet appearance. When spread too thickly the grain will begin to sweat, and the rootlets will be thrown out suddenly and unevenly. As a rule, under these circumstances, the rootlets will be long and thin, when they are said to be “wild.” A piece which has been allowed to get into this condition must at once be spread thinner. If the sweating has not continued long, the harm done may be confined to increased loss by respiration. The young floor is usually turned with a plough twice during twelve hours, and it may be forked between whiles, but no hard and fast rule can be laid down as to when this is necessary; it must be left to the maltster’s judgment, as it depends entirely on what is going on within the grain. The object of turning is in the first place to aerate the grain and freshen it, secondly to check excessive rise of temperature, and thirdly to promote evenness of growth. Too frequent turning is not to be advised. After remaining four days on the young floor three or four rootlets should have appeared, and the acrospire should have begun to grow up the back of the corn. The apple-like odour of the piece then gives place to one resembling that of the common rush, and this should continue the whole time that the malt remains on the floor. On the fifth day the piece is next moved to No. 2 position, a stage nearer the kiln. It is here that sprinkling is resorted to when necessary. The amount of sprinkling and the time it is given cannot be exactly prescribed. The amount may vary from two to five gallons per quarter, and it should only be given when the rootlets, which ought to be short and curly, and five or more in number, show signs of losing their freshness. If an excessive amount of sprinkling be given forced growth ensues. It is preferable not to add the whole of the water at one time, but to divide it over two lots; and immediately after the piece has been sprinkled it should be thoroughly and carefully mixed, otherwise some of the grain will receive an undue proportion of water. When all the sprinkling water has been given to the piece, which as a rule should not be done later than at the sixth or seventh day of flooring, the temperature should be kept down to about 55° F. by turning. Too frequent turning may, however, detach the rootlet, and it may cause the grain to lose its vitality prematurely, so that growth of the acrospire stops.

By about the eighth day of flooring the acrospire should be about three-quarters up the corn. After this the germinating corn is moved forward to No. 3 piece, which is at first spread as thinly on the floors as in the previous pieces. Here it gradually dries and incipient withering of the rootlets sets in. The only treatment which is now given to the grain is to heap it up thicker and thicker by degrees until it is ready for loading on the kiln. This increase in thickness of the piece (now called the old piece) should not be too sudden, especially if the grain be fresh in appearance and contain a large quantity of water. When the piece is thickened up to say 10 in. in depth, while it is in a very moist condition, heating and sweating take place, with additional growth of acrospire and rootlet. Under such forcing conditions a large production of sugar and degradation of the proteïns will take place. When, however, the moisture has been gradually reduced before thickening up, the rootlet dies off; and although increase of temperature may occur, this is accompanied by little or no further growth of the acrospire, action being confined to the mellowing of the grain by the enzymes. When the malt is ready for loading on the kiln it should be possible to break down the contents of each corn between the thumb and finger. Opinions differ as to what the final temperature on the withering floor should be. If the moisture content of the malt be about 50%, the piece must be kept thin to avoid sweating. But under these conditions mellowing does not occur, hence the necessity of reducing the moisture content gradually after the last sprinkling water has been given. When the process has been conducted properly the temperature of the old piece may be allowed to rise as high as 70° F. during the six hours previous to loading. The moisture content of the green malt when loaded should not be much above 40%.

The endosperm of green malt which is ready for the kiln should be soft and mealy, and should not exude moisture when pressed between the thumb-nails, but should crumble and disintegrate to a chalky mass having little or no adhesiveness.

The foregoing observations are not to be regarded as hard and fast rules, but they are simply intended to give some indications of the malting process when it proceeds on normal lines; it may be that on account of the presence of damaged corns the piece begins to develop mould by about the tenth day, and it then has to be kept thin and sometimes even loaded on kiln prematurely.

The malt made for grain distillers, in which a high diastatic activity is required, is manufactured on quite different lines from those above indicated. It is often sprinkled late, and loaded on kiln often in a sodden condition. In some cases sprinkling on kiln is resorted to, but it is doubtful if this leads to the desired object. Other things being equal, the smaller the corns—i.e. the greater number of embryos in a given weight—the higher the diastatic activity of the malt. In selecting a barley for the production of highly diastatic malt, the diastatic power of the original raw grain is a factor of great importance.

Kilning.—When loaded on kiln, malt intended for brewing ale and stout is, if properly withered, in a moribund condition; nevertheless, during the first stages of the kilning process a certain amount of vital activity is manifested, and the malt undergoes mellowing by the action of enzymes on the contents of the endosperm. If the malt be loaded while the rootlets appear fresh on account of the presence of too much moisture, rapid growth of the acrospire ensues, giving rise to overshot corns, known in Germany as “hussars.” To check this the moisture must be rapidly removed by the passage of large volumes of air through the malt. But under such circumstances mellowing does not occur. The ideal conditions of kilning are when the malt has been properly withered on the floors before loading, and, assuming that drying and curing occupy four days, that 25–30% of the moisture be removed very gradually, this occupying the first three days, at the end of which the malt is said to be hand-dry. The thickness at which the malt is spread on the kiln should not exceed 7–8 in., and until hand-dry (that is to say, reduced to a moisture content of 12–15%) it should not be turned; if moved at all (and that only is necessary when reek occurs), it should only be lightly forked. The rate at which the temperature is raised depends largely on the kind of malt to be made and the construction of the kiln. If high flavour and colour are required, these are produced by keeping the malt for several hours near a temperature of 160° F. while it still contains 12–15% of moisture. If more than this amount of moisture be present when the temperature reaches the limit just mentioned, the conditions known as stewing would obtain, with the result that “forced” malt would be produced. A certain amount of colour is produced at the final temperature to which the malt is raised; but when such means are relied upon for the production of the greater part of the colour, reduction of extract and deficiency of flavour follow, the colour being then almost exclusively the result of caramelization of the carbohydrates.

The so-called curing stage constitutes the last part of the kilning process, and the malt must then be turned frequently to ensure uniformity of action. Mechanical turners are exceedingly useful for this purpose. Curing in a drum, as in the so-called pneumatic malting process (see below), also effects satisfactory curing.

The following table will give an idea of the kilning temperatures usually employed for the three kinds of malt mentioned, but it must be remembered that these temperatures are largely regulated by the construction of the kiln and the amount of draught available. In this connexion it may be mentioned that the final curing temperature is not necessarily a criterion of the tint of the malt. A malt may have been finished off at a very high temperature and still be a pale malt, provided the moisture percentage has been sufficiently reduced in the initial stages of kilning.

| Running | ||||||

| Pale Malt. | Ale Malt. | Amber Malt. | ||||

| 1st day temp. | 90–100° | F. | 90–100° | F. | 90–100° | F. |

| 2nd ” ” | 100–120 | 100–120 | 100–130 | |||

| 3rd ” ” | 120–130 | (10 hrs.) | 120–130 | ( 6 hrs.) | 130–150 | ( 6 hrs.) |

| 3rd ” ” | 130–180 | ( 8 ” ) | 130–150 | (12 ” ) | 150–160 | (12 ” ) |

| 3rd ” ” | 180–190 | ( 6 ” ) | 150–180 | ( 6 ” ) | 160–180 | ( 6 ” ) |

| 4th ” ” | drop to 170 | (12 ” ) | 180–190 | (12 ” ) | 180–200 | (12 ” ) |

| 4th ” ” | 190–200 | ( 6 ” ) | 200–220 | ( 6 ” ) | ||

| 4th ” ” | drop to 180 | ( 6 ” ) | drop to 190 | ( 6 ” ) | ||

The average laboratory values obtained from malts of the descriptions after about two months’ storage should be as follows:—

| Running | |||

| Pale Malt. | Ale Malt. | Amber Malt. | |

| Extract per standard quarter of 336 ℔ | 95–98 ℔ | 94–96 ℔ | 94–96 ℔ |

| Moisture | about 2.0% in each case | ||

| Diastatic activity (Lintner) | 30–35 | 20–30 | 8–10 |

| Tint (Lovibond 52 series neutral) | 3–5 | 6–8 | 20–25 |

Metabolic Changes.—All through the malting process metabolic changes are proceeding, in which both carbohydrates and proteïns are concerned. In its resting stage the embryo of a barleycorn is generally free from starch; as soon as germination sets in, however, starch appears in the scutellum, while the amount of sucrose there present increases, these being apparently formed from maltose originating from the action of diastase on the starch of the endosperm. Sucrose also augments in the aleurone layer, but starch is never formed in the aleurone cells. These changes occur when the malt is first loaded on kiln; indeed, at no part of the malting process is there greater physiological activity.

Kilning has been specially studied by J. Grüss, who divides the process into four stages, the first being that at which the temperature limit is 113° F. It is characterized by a continuation of the living processes, especially growth of the acrospire, which, as already stated, proceeds too far if the malt be loaded too wet. In any case the rootlet dies away. The metabolism of the carbohydrates already mentioned is accompanied by that of the nitrogenous constituents, the reserve proteïn of the sub-aleurone layer being attacked by proteolytic enzymes and broken down into simpler compounds. This is a most important matter from the point of view of the brewing value of barley, for the degradation products of the proteïns are necessary constituents of wort as yeast food. Moreover, unless proper modification of these proteïn bodies occurs it is impossible to produce tender malt. A barley which contains a high percentage of reserve proteïn is as a rule unfitted for malting purposes, and indeed, the higher the proteïn content the greater the difficulty the maltster experiences in dealing with it. Proteïn hydrolysis requires the presence of a certain amount of moisture, and if this be removed too rapidly by a forced draught at the early stages of kilning the proteolytic enzymes cannot perform their function. If, on the other hand, the grain be loaded in too moist a condition, and the temperature be raised too quickly, the proteolytic enzymes lose their activity and the proteïns remain for the most part unattacked. When germination is allowed to proceed on the kiln too great degradation of the proteïn occurs, and the malt is liable to produce fretty beers, on account of the presence of an excessive amount of nitrogenous nutritive matter, which leads to the development of disease organisms.

The second stage of the kilning process, according to Grüss, is that at which the temperatures range from 113° to 167° F. The life of the corn is now suspended, but enzymatic processes continue. The starch is further saccharified, and the dividing line of the aleurone layer at the furrow is attacked, as are also the cell walls of the endosperm, which are still intact, these being partially converted into gummy substances. This change, however, also requires the presence of a certain amount of moisture. If too much air be passed through the malt at this stage the above-named dividing partition of the cell walls is not attacked. The air may expand the grain to some extent and produce malt of a low bushel weight, which, however, is not properly modified and cannot give satisfactory results in practice.

During the third stage of kilning, an enzyme, which Grüss claims to have recognized, and which he denotes spermoxidase, is said to exert its activity.

Schönfeld has confirmed the discoveries of Grüss by practical experiments.

Fuel.—The fuel used for drying and curing malt is either anthracite or coke, and the greatest care is necessary in selecting it on account of its liability to contain arsenic, which is to a greater or less extent an invariable constituent of all coal. The fuel used for malting purposes should not contain more arsenic than 120th grain per ℔. Gas coke should on no account be used, unless it has been proved to be sufficiently free from arsenic; but the best oven coke frequently contains so little arsenic that it may be employed with perfect safety, especially if it be mixed with a proportion (e.g. 5%) of milk of lime, which retains the arsenic as calcium arsenate. In Germany malt is, as a rule, dried and cured with hot air, whilst in Great Britain the products of combustion are passed through the malt, as it is believed that they exert a beneficial influence on the flavour. The proportion of fuel used for drying and curing malt varies according to the quality of the fuel and the construction of the kiln, but on an average it may be placed at 50-80 ℔ per quarter.

|

| [From Sykes & Ling, Principles and Practice of Brewing (1907), Charles Griffin & Co., Ltd.] |

| Fig. 9.—Diagrammatic view of pneumatic malting, showing pneumatic washing and steeping cisterns. |

Storing.—After the malt has passed through the curing stage it is generally heaped up for a few hours. This is believed to increase its flavour. The malt is then stripped from the kiln, and the rootlets, technically known as the coombs, are removed. Formerly this was effected by workmen treading the malt, who wore heavy boots for the purpose. At the present time, however, the rootlets are usually removed by machinery, special forms of which have been devised for this as well as for dressing and polishing the malt. It is the custom of some maltsters to store malt with the rootlets still attached; but this is an objectionable practice, since malt coombs attract moisture, and the presence of more than 3% of moisture in malt produces the condition known as “slackness.” When the malt is packed in bin it is often covered with a layer of coombs, which then prevent access of atmospheric moisture. Malt, to preserve its good qualities intact, should be stored in bins made as nearly as possible air-tight, and it should never be placed in bin until it is quite cool. It is probably wrong to store malt in bins adjacent to the kilns, where it is kept at a higher temperature than that of the surrounding atmosphere. During storage of the malt a kind of mellowing occurs, the mechanism of which is not understood. It is, however, known by practical brewers that the best results cannot be obtained when new malt is used.

Premature Malting.—Several years ago Galland suggested germinating barley in a drum, his idea being to do away with handling of the grain, and also to be independent of changes of atmospheric temperature. The latest development of this system, the so-called Galland-Henning process of pneumatic malting, has been improved by Mr R. Blair Robertson, and a diagrammatic view of the interior of one of these maltings, showing the drums and conical steeping cisterns, is shown in fig. 9.

The drums are provided with a perforated channel for the passage of air through the malt, which is packed in the annular space between this channel and outside wall of the drum. Each drum is capable of revolving on its axis, and there are arrangements for passing either moist, saturated or dry air through the malt. The system as now improved is capable of producing some of the best malt, especially if, after germination has been completed in the drums, the green malt is loaded on an ordinary kiln and the initial stages of kilning (see above) conducted in the usual way; the curing, however, may be carried out successfully in a special form of drum.

Yield and Weight.—The malting process is attended with a certain amount of loss of dry substance of the barley, as follows:—

| In the steep | 1.5 | to | 2.0% |

| By respiration on floors and on kilns | 3.0 | ” | 5.0% |

| Coombs | 3.0 | ” | 4.0% |

| —– | ——— | ||

| Total | 7.5 | ” | 11.0% |

In addition to this, barley, as already mentioned, contains from 15 to 20% of moisture, whereas finished malt contains 1 to 2%. The total loss in weight which barley undergoes in the malting process may be put down at from 17 to 28%. Since, however, malt is lighter than barley (and the quantity of both was in former years measured exclusively by volume), it frequently happens that a given number of quarters of barley yields a larger number of quarters of finished malt. When this happens it is usual to speak of an increase having been obtained. At the present time weight replaces measure for both barley and malt, and although it is usual to speak of the quantity of grain in terms of quarters, what is meant is not the measured quarter, but so many weighed standard quarters. The standard quarter for English malting barley is 448 ℔ and for malt 336 ℔. From this it will be seen that when a given number of weighed quarters of barley yields the same number of quarters of finished malt, the actual yield is 75%, and there is then said to be neither increase nor decrease. As a rule, in practical working the yield of malt varies from a 4% decrease to a 10% increase, corresponding to an actual yield on the original barley of 72 to 82.5%.

J. Baverstock, an old writer, says that finished malt should weigh one-fifth less than the barley from which it is produced. This corresponds to a malting increase of about 7%, which is a high yield. As a rule, foreign barley will give a greater malting increase than English barley, because, on the one hand, the former usually contains less moisture than the latter, and, further, because there is less loss on the floors by respiration and rootlet growth.

The yield of malt from barley may be determined in the laboratory in an extremely simple manner. Since every grain of barley must yield a grain of malt, if we know the respective weights of a definite number of barley and malt grains, provided that this number is large enough to represent the average, then obviously this gives the data requisite for calculating the yield of malt from barley. The number of corns the weight of which is determined for this purpose is usually 1000, and if the weight of this number be determined on several different 1000 corns, the average will closely approximate to the truth. Instead of counting the corns by hand, an instrument may be used for this purpose.

If 1000 corns of a barley were found to weigh 42 grammes, and 1000 corns of a finished malt from the same barley 32 grammes, then the yield of malt is 32 × 10042 = 76.1, this corresponding to a 1% increase. Assuming that the moisture content of the barley was 15% and that of the finished malt 2%, 100 grammes of malt will contain 2 grammes of moisture, and 76.1 grammes will contain 76.1 × 2100 = 1.5 grammes moisture; therefore 76.1 grammes of malt contain 76.1 − 1.5 = 74.6 grammes of dry matter. This was obtained from 100 − 15 = 85 grammes of barley dry substance. Hence 100 parts of barley dry substance will yield 74.6 × 10085 = 87.7 corresponding with a loss of dry substance equal to 12.5% of the dry substance of the barley, or with a loss of 10.7% on the barley containing 15% of moisture.

The results obtained by this method of laboratory control when it is accurately carried out agree very closely with those deduced from the practical results of weighing the barley, malt and coombs in the malting.

Special Malts.—In addition to the kinds of malt considered in what precedes, there are others mostly used for imparting specific flavours and colour to beers and stout. These are crystal malt, imperial malt, brown or blown malt, and black or roasted malt. Crystal malt is grown for a shortened period on the floors, and then placed in a wire cylinder, which is rotated over a fire so that it is dried at a very high temperature. The weight per quarter is from 250 to 280 ℔. Imperial malt is dried off on an ordinary kiln at a final temperature of 240–270° F., but it is not allowed the usual length of time on the withering floor. It is placed on the drying kiln in a layer not exceeding one inch and a half in thickness. A moderate heat from burnt wood is first applied until the bulk of the moisture has been driven off, when the temperature is suddenly raised so that the grains swell some 25% and the malt takes up a strong empyreumatic flavour from the products of combustion. This kind of malt weighs 270–300 ℔ per quarter. Black or roasted malt is prepared by roasting malt in a cylinder. Ford states that perfectly malted corn gives a colour of less intensity and permanence than does partially malted corn, and this has been confirmed by other observers. A certain quantity of the so-called black malt is actually made from raw barley, but this gives a product of inferior flavour. The weight per quarter of black malt varies as much as from 215 to 290 ℔.

Valuation.—For the valuation of malt the following determinations are usually carried out: Extract per standard quarter, moisture, diastatic activity by the Lintner process, tint, and matters soluble in cold water. The physical examination of malt is also a matter of importance, inasmuch as direct evidence is obtained thereby of the modification of the malt. Among the methods adopted for this purpose may be mentioned counting the percentage of corns in which the acrospire has grown up to one-half, two-thirds and three-fourths the entire length of the corn. In properly made malt the modification of the endosperm should proceed pari passu with the growth of the acrospire. The sinker test is also useful when carried out in an intelligent manner. Those corns which sink in water and lie flat are improperly modified. Normal malt has a specific gravity less than water and the corns have equal density throughout; consequently they float horizontally in water. In forced samples the proximal ends are frequently lighter than the distal ends, and the corns float horizontally in water, with the germ directed upwards. The latter, however, may in some cases fill with water, and the corns lie flat or sink. This is a characteristic of over-modified malt. It will be seen from these remarks that it is essential to carry out the sinker test under standard conditions. The modification of the malt may also be determined by means of the diaphanoscope already referred to under Barley.

Bibliography.—M. M. W. Baird, Journ. Inst. Brewing (1905), 11, 431; J. L. Baker, Journ. Chem. Soc. Trans. (1902), 81, 1177; The Brewing Industry; J. L. Baker and W. D. Dick, Journ. Inst. Brewing (1905), 11, 380; J. Baverstock, Treatise on Brewing and Malting (1824); E. S. Beaven, Journ. Fed. Inst. Brewing (1902), 8, 542; R. H. Biffen, Journ. Inst. Brewing (1906), 12, 366; Board of Agriculture and Fisheries (Leaflet 149); A. J. Brown, Annals of Botany (1907), 21, 79; H. T. Brown and G. H. Morris, Journ. Chem. Soc. Trans. (1890), 57, 458; H. T. Brown and others, Trans. Guinness Research Lab. (1903), vol.—pt. I. (1906), pt. II.; M. Delbrück, Journ. Inst. Brewing (1906), 12, 642; Ford, A Treatise on Malting (1849); C. Graham, Cantor Lectures, Society of Arts (1874); J. Grüss, Wochenschrift für Brauerei (1895), 12, 1257; (1896), 13, 729; (1897), 14, 321, 409; (1898), 15, 81, 269; (1899), 16, 519, 621; (1902), 19, 243; W. Johannsen, Résumé. Comptes rendus trav. lab. Carlsberg (1884), 2, 60; A. R. Ling, Brewers’ Journal (1904), 40, 741; E. J. Mills and J. B. Pettigrew, Journ. Chem. Soc. Trans. (1882), 41, 38; E. R. Moritz, Journ. Fed. Inst. Brewing (1895), 1, 228; E. R. Moritz and G. H. Morris, A Textbook of the Science of Brewing (1891); J. M. H. Munro and E. S. Beaven, Journ. Roy. Agric. Soc. (1900), 11, pt. II., 5; T. B. Osborne, Report of Connecticut Agricultural Experiment Station (1894); H. Stopes, Malt and Malting (1895); W. J. Sykes and A. R. Ling, Principles and Practice of Brewing (1907); H. Van Laer Bull. de la soc. chim. de Belgique (1905), 337; R. Wahl, Amer. Brewers’ Rev. (1904), 18, 89. (A. R. L.*)