Encyclopædia Britannica, Ninth Edition/Clocks

CLOCKS

THE origin of clock work is involved in great obscurity. I Notwithstanding the statements by many writers that clocks, horologia, were in use so early as the 9th century, and that they were then invented by an archdeacon of Verona, named Pacificus, there appears to be no clear evidence that they were machines at all resembling those which have been in use for the last five or six centuries. But it may be inferred from various allusions to horologia, and to their striking spontaneously, in the 12th century, that genuine clocks existed then, though there is no surviving description of any one until the 13th century, when it appears that a horologiuni was sent by the sultan of Egypt in 1 232 to the Emperor Frederick II. " It resembled a celestial globe, in which the sun, moon, and planets moved, being impelled by weights and wheels, so that they pointed out the hour, day, and night with cer tainty." A clock was put up in a former clock tower at Westminster with some great bells in 1288, out of a fine imposed on a corrupt chief-justice, and the motto Discite justiliam, moniti, inscribed upon it. The bells were sold or rather, it is said, gambled away, by Henry VIII. In 1292 one is mentioned in Canterbury Cathedral as costing 30. And another at St Albans, by R. Wallingford the abbot in 1326, is said to have been such as there was not in all Europe, showing various astronomical phenomena. A description of one in Dover Castle with the date 1348 on it was published by the late Admiral Smyth, P.R.A.S., in 1851, and the clock itself was exhibited going, in the Scientific Exhibition of 1876. In the early editions of this Encyclopaedia there was a picture of a very similar one, made by De Vick for the French king Charles V. about the same time, much like our common clocks of the last century, exeept that it had a vibrating balance, but no spring, instead of a pendulum, for pendulums were not invented till three centuries after that.

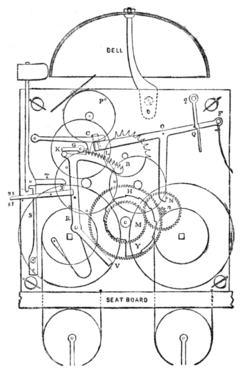

The general construction of the going part of all clocks, except large or turret clocks, which we shall treat separ ately, is substantially the same, and fig. 1 is a section of any ordinary house clock. B is the barrel with the rope coiled round it, generally 16 times for the 8 days ; the barrel is fixed to its arbor K, which is prolonged into the winding square coming up to the face or dial of the clock ; the dial is here shown as fixed either by small screws x, or by a socket and pin z, to the prolonged pillars p, p, which (4 or 5 in number) connect the plates or frame of the clock together, though the dial is commonly, but for no good reason, set on to the front plate by another set of pillars of its own. The great wheel G rides on the arbor, and is connected with the barrel by the ratchet R, the action of which is shown more fully in fig 1 4. The intermediate wheel r in this drawing is for a purpose which will be de scribed hereafter, and for the present it may be considered as omitted, and the click of the ratchet R as fixed to the great wheel. The great wheel drives the pinion c which is called the centre pinion, on the arbor of the centre whee.1 C, which goes through to the dial, and carries the long, or minute-hand; this wheel always turns in an hour, and the great wheel generally in 12 hours, by having 12 times as many teeth as the centre pinion. The centre wheel drives the " second wheel " D by its pinion d, and that again drives the scape-wheel E by its pinion e. If the pinions d and e have each 8 teeth or leaves (as the teeth of pinions are usually called), C will have 64 teeth and D 60, in a clock of which the scape-wheel turns in a minute, so that the seconds hand may be set on its arbor prolonged to the dial. A represents the pallets of the escapement, which will be described presently, and their arbor a goes through a large hole in the back plate near F, and its back pivot turns in a cock OFQ screwed on to the back plate. From the pallet arbor at F descends the crutch F/, ending ic the /or/;/, which embraces the pendulum F, so that as the pendulum vibrates, the crutch and the pullets necessarily vibrate with it. The pendulum is hung by a thin spring S from the cock Q, so that the bending point of the spring may be just opposite the end of the pallet arbor, and the edge of the spring as close to the end of that arbor aa possible a point too frequently neglected.

We may now go to the front (or left hand) of the clock, and describe the dial or " motion-work." The minute hand fits on to a squared end of a brass socket, which is fixed to the wheel M, and fits close, but not tight, on the pro longed arbor of the centre wheel. Behind this wheel is a bent spring which is (or ought to be) set on the same arbor with a square hole (not a round one as it sometimes is) in the middle, so that it must turn with the arbor; the wheel is pressed up against this spring, and kept there, by a cap and a small pin through the end of the arbor. The consequence is, that there is friction enough between the spring .and the wheel to carry the hand round, but not enough to resist a moderate push with the finger for the purpose of altering the time indicated. This wheel M, which is sometimes called the minute-wheel, but is better called the hour-wheel as it turns in an hour, drives another wheel N, of the same number of teeth, which has a pinion attached to it; and that pinion drives the twelve-hour tcheel H, which is also attached to a large socket or pipe carrying the hour hand, and riding on the former socket, or rather (in order to relieve the centre arbor of that extra weight) on an intermediate socket fixed to the bridge L, which is screwed to the front plate over the hour-wheel M. The weight W, which drives the train and gives the impulse to the pendu lum through the escapement, is generally hung by a catgut line passing through a pulley attached to the weight, the other end of the cord being tied to some convenient place in the clock frame or seat-board, to which it is fixed by screws through the lower pillars. It has usually been the practice to make the case of house clocks and astronomical clocks not less than 6 feet high ; but that is a very unnecessary waste of space and materials ; for by either diminishing the size of the barrel, or the number of its turns, by increasing the size of the great wheel by one-half, or hanging the weights by a treble instead of a double line; a case just long enough for the pendulum will also be long enough for the fall of the weights in 7? or 8 days. Of courso the weights have to be increased in the same ratio, and indeed ratharmore, to overcome the increased friction; but that is of no consequence.

Pendulum.

The claim to the invention of the pendulum, like the claim to most inventions, is disputed ; and we have no intention of trying to settle it. It was, like many other discoveries and inventions, probably made by various persons independently, and almost simul taneously, when the state of science had become ripe for it. The discovery of that peculiarly valuable property of the pendulum called isochronism, or the disposition to vibrate different arcs in very nearly the same time (provided the arcs are none of them large), is commonly attributed to Galileo, in the well-known story of his being struck with the isochronism of a chandelier hung by a long chain from the roof of the church, at Florence. And Galileo s son appears as a rival of Avicenna, Huyghens, Dr Hooke, and a London clockmaker named Harris, for the honour of having first applied the pendulum to regulate the motion of a clock train, all in the early part of the 17th century. Be this as it may, there seems little doubt that Huyghens was the first who mathematically investi gated, and therefore really knew, the true nature of those properties of the pendulum which may now be found explained in any mathe matical book on mechanics. He discovered that if a simple pen dulum (i.e., a weight or lob consisting of a single point, and hung by a rod or string of no weight) can be made to describe, not a circle, but a cycloid of which the string would be the radius of cur vature at the lowest point, all its vibrations, however large, will be performed in the same time. For a little distance near the bottom, the circle very nearly coincides with the cycloid ; and hence it is that, for small arcs, a pendulum vibrating as usual in a circle is nearly enough isochronous for the purposes of horology ; more espe cially when contrivances are introduced either to compensate for the variations of the arc, or, better still, to destroy them altogether, by making the force on the pendulum so constant that its arc may never sensibly vary.

The difference between the time of any small arc of the circle an any arc of the cycloid varies nearly as the square of the circular arc ; and again, the difference between the times of any two smal and nearly equal circular arcs of the same pendulum, varies nearly as the arc itself. If a, the arc, is increased by a small amount da, the pendulum, will lose IQSOOada seconds a day, which is rather more than 1 second, if a is 2 (from zero) and da is 10 , since the numerical value of 2 is 035. If the increase of arc is considerable, t will not do to reckon thus by differentials, but we must take the difference of time for the day as 5400 (a, 2 a 2 ), which will be j ist seconds if a ? 2 and a t 6. For many years it wag thought of great importance to obtain cycloidal vibrations of clock pendulums, ind it was done by making the suspension string or spring vibrate Between cycloidal checks, as they were called. But it was in time discovered that all this is a delusion, first, because there is and can be no such thing in reality as a simple pendulum, and cycloidal cheeks will only make a simple pendulum vibrate isochronously ; secondly, because a very slight error in the form of the cheeks (as Huyghens himself discovered) would do more harm than the circular error uncorrected, even for an arc of 1 0, which is much larger than the common pendulum arc ; thirdly, because there was always some friction or adhesion between the cheeks and the string ; and fourthly (a reason which applies equally to all the isochronous contrivances since invented), because a common clock escapement itself generally tends to produce an error exactly opposite to the circular error, or to make the pendulum vibrate quicker the farther it swings ; and therefore the circular error is actually useful for the purpose of helping to counteract the error due to the escapement, and the clock goes better than it would with, a simple pendulum, describing the most perfect cycloid. At the same time, the thin spring by which pendulums are always suspended, except in some French clocks where a silk string is used (a very inferior plan), causes the pendulum to deviate a little from circular and to approxi mate to cycloidal motion, because the bend does not take place at one point, but is spread over some length of the spring.

The accurate performance of a clock depends so essentially on the pendulum, that we shall go somewhat into detail respecting it. First then, the time of vibration depends entirely on the length of the pendulum, the effect of the spring being too small for considera tion until we come to differences of a higher order. But the time does not vary as the length, but only as the square root of the length ; i.e., a pendulum to vibrate two seconds must be four- times as long as a seconds pendulum. The relation between the time of vibration and the length of a pendulum is expressed thus : t TT/-, where t is the time in seconds, it the well-known symbol for 3 141 59, the ratio of the circumference of a circle to ita diameter, I the length of the pendulum, and g the force of gravity at the latitude where it is intended to vibrate. This letter g, in the latitude of London, is the symbol for 32 2 feet, that being the velocity (or number of feet per second) at which a body is found by experiment to be moving at the end of the first second of its fall, being necessarily equal to twice the actual number of feet it has fallen in that second. Consequently, the length of a pendulum to beat seconds in London is 39 14 inches. But the same pendulum carried to the equator, where the force of gravity is less, would lose 2J minutes a day.

The seconds we are here speaking of are the seconds of. a common clock indicating mean solar time. But as clocks are also required for sidereal time, it may be as well to mention the proportions between a mean and a sidereal pendulum. A sidereal day is the interval between two successive transits over the meridian of a place by that imagin ary point in the heavens called T, the first point of Aries, at the intersection of the equator and the ecliptic ; and there is one more sidereal day than there are solar days in a year, since the earth has to turn more than once round iii space before the sun can coma a second time to the meridian, on account of the earth s own motion in its orbit during the day. A sidereal day or hour is shorter than a mean solar one in the ratio of 99727, and consequently a sidereal pendulum must be shorter than a mean time pendulum in the squaro of that ratio, or in the latitude of London the sidereal seconds pen dulum is 38 87 inches. As we have mentioned what is or 24 o clock by sidereal time, we may as well add, that the mean day is also reckoned in astronomy by 24 hours, and not from midnight as in civil reckoning, but from the following noon ; thus, what wo call 11 A.M. May 1 in common life is 23 h. April 30 with astronomers.

It must be remembered that the pendulums whose lengths _we have been speaking of are simple pendulums ; and as that is a thing which can only exist in theory, the reader may ask how the length of a real pendulum to vibrate in any required time is ascertained. In every pendulum, that is to say, in every body hung so as to be capable of vibrating freely, there is a certain point, always some where below the centre of gravity, which possesses these remarkable properties that if the pendulum were turned upside down, and set vibrating about this point, it would vibrate in the same time as before, and moreover, that the distance of this point from the point of suspension is exactly the length of that imaginary simple pendulum which would vibrate in the same time. This point is therefore , called the centre of oscillation. The rules for finding it by calcula-

tbn are too complicated for ordinary use, except in bodies of certain simple and regular forms ; but they are fortunately not requisite in practice, because in all clock pendulums the centre of oscillation is only a short distance below the centre of gravity of the whole pendulum, and generally so near to the centre of gravity of the bob in fact a little above it that there is no difficulty in making a pendulum for any given time of vibration near enough to the proper length at once, and then adjusting it by screwing the bob up or down until it is found to vibrate in the proper time.

Revolving or Conical Pendulum.

Thus far we have been speaking of vibrating pendulums but now useu universally, in all but some interior foreign clocks, which have strings instead, is a thin and short spring, with one end let into the top of the pendulum, and the other screwed between two luiu me lujj vi uic peuuiuum, iinu uie inner screwed ueiwecn two chops ot metal with a pin through them, which rests firmly in n nick in the cock which carries the pendulum as shown in fig. 2 a little farther on ; and the steadiness of this cock, and its firm Qxing to a wall, are essential to the accurate performance of the rlnc V. Tlio thinner flip Qnrinrr flip 1^o<fnT. -rn^t-i.!*./! ff isMii*cr> if lilUS I UT We nave uccll suettmiig ui iuianii^ ^/CUILIUIUUO , L>uii the notice of pendulums would be incomplete without some allusion to revolving or conical pendulums, as they are called, because they describe a cone in revolving. Such pendulums are used where a continuous instead of an intermittent motion of the clock train is required, as in the clocks for keeping an equatorial telescope directed to a star, by driving it the opposite way to the motion of the earth, to whose axis the axis on which the telescope turns is made parallel. Clocks with such pendulums may also be used in bedrooms by persons who cannot bear the ticking of a common clock. The pendulum, instead of being hung by a flat spring, is hung by a thin piece of piano-forte wire ; and it should be under stood that it has no tendency to twist on its own axis, and so to twist off the wire, as may be apprehended ; in fact, it would require some extra force to make it twist, if it were wanted to do so. The time of revolution of such a pendulum may be easily ascertained as follows : Let Z be its length ; a the angle which it makes with the vertical axis of the cone which it describes ; w the angular velocity ; then the centrifugal force ? u> 2 ? sin. a ; and as this is the force which keeps the pendulum away from the vertical, it must balance the force which draws it to the vertical, which is g tan. a : and therefore / 2 ? the angular velocity, or the angle de- v/ i cos. 6 scribed in a second of time ; and the time of complete revolution through the angle 360 or 2w is^?2ir^/L2L ; that is to say, the time of revolution of a pendulum of any given length is less than the time of a double oscillation of the same pendulum, in the proportion of the cosine of the angle which it makes with the axis of revolution to unity.

A rotary pendulum is kept in motion by the train of the clock ending in a horizontal wheel with a vertical axis, from which pro jects an arm pressing against a spike at the bottom of the pendu lum ; and it has this disadvantage that any inequality in the force of the train, arising from variations of friction or any other cause, is immediately transmitted to the pendulum ; whereas it will be seen that in several kinds of escapements which can be applied to a vibrating pendulum, the variations of force can be rendered nearly or quiteinsensible. And it is a mistake to imagine that there is any self-correcting power in a conical pendulum analogous to that of the governor of a steam-engine ; for that apparatus, though it is a couple of conical pendulums, has also a communication by a system of levers with the valve which supplies the steam. _ The governor apparatus has itself been applied to telescope-driving clocks, with a lever ending in a spring which acts by friction on some revolving plate in the clock, increasing the friction, and so diminishing the force as the balls of the governor fly out farther under any increase in the force . And with the addition of some connection with the hand of the observer, by which the action can be farther moderated, the motion can be made sufficiently uniform for that purpose.

Various other contrivances have been invented for producing a continuous clock-motion. The great equatorial telescope at Green wich is kept in motion by a kind of water clock called in books on hydrostatics Barker s Mill, in which two horizontal pipes branching out from a vertical tubular axis have each a hole near their ends on opposite sides, from which water flows, being poured constantly into the tubular axis, which revolves on a pivot, resistance of the air to the water issuing from the holes drives the mill round, and there are means of regulating it. Another plan is to connect a clock train having a vibrating pendulum with another clock havin" a conical pendulum by one of the lower wheels in the train, with a spring connection ; the telescope is driven by the revolving clock train, and the other pendulum keeps it sufficiently in order, though allowing it to expatiate enough for each beat ot the pendulum The more complicated plan of Wagner of I ans described in Sir E. Beckett s Rudimentary Treatise on Clocks and JFatches and Bdls does not appear to have ever come i and therefore it is now omitted.

Pendulum Suspension.

The suspension of the pendulum on what are called like those of a scale-beam, has often been advocated. But it may do well enough for short experiments, in which th iiii.iv in me LUIIV nuivii lituTieH uiu pciKimuiii as snown in rig. z a little farther on ; and the steadiness of this cock, and its firm Gxing to a wall, are essential to the accurate performance of the clock. The thinner the spring the better ; provided, of course, it is strong enough to carry the pendulum without being bent beyond its elasticity, or bent short ; not that there is much risk of that in practice. Pendulum springs are much oftener too thick than too thin ; and it is worth notice that, independently of their greater effect on the natural time of vibration of the pendulum, thick and narrow springs are more liable to break than thin nnd broad ones of the same strength. It is of great importance that the spring should be of uniform thickness throughout its breadth ; and the bottom of the chops which carry it should be exactly horizontal ; otherwise the pendulum will swing with a twist, as they may he often seen to do in ill-made clocks. If the bottom of the chops is left sharp, where they clip the spring, it is very likely to break there ; and therefore the sharp edges should be taken off.

The bob of the pendulum used to be generally made in the shape of a lens, with a view to its passing through the air with the least resistance. But after the importance of making the bob heavy was discovered, it became almost necessary to adopt a form of more solid content in proportion to its surface. A sphere has beOn occa sionally used, but it is not a good shape, because a slight error in the place of the hole for the rod may make a serious difference in the amount of weight on each side, and give the pendulum a ten dency to twist in motion. The mercurial jar pendulum suggested the cylindrical form, which is now generally adopted for astronomical clocks, and in the best turret clocks, with a round top to prevent any bits of mortar or dirt falling and resting upon it, which would alter the time ; it also looks better than a flat-topped cylinder. There is no rule to be given for the weight of pendulums. It will be shown hereafter that, whatever escapement may be used, the errors due to any variation of force are expressed in fractions which inva riably have the weight and the length of the pendulum in the denominator, though some kind of escapements require a heavy pendulum to correct their errors much less than others. And as a heavy pendulum requires very little more force to keep it in motion than a light one, being less affected by the resistance of the air, we may almost say that the heavier and longer a pendulum can be made the better ; at any rate, the only limit is one of convenience ; for instance, it would obviously be inconvenient to put a large pen dulum of 100 lb weight in the case of an astronomical or common house clock. It may perhaps be laid down as a rule, that no astronomical clock or regulator (as they are also called) will go as well as is now expected of such clocks with a pendulum of less than 28 lb weight, and no turret clock with less than 1 cwt. Long pendulums are generally made with heavier bobs than short ones ; and such a clock as that of the Houses of Par liament, with a two-seconds pendulum of 6 cwt., ought to go 44 times as well as a small turret clock with a one-second pendulum of 60 lb. Pendulums longer than 14 feet (2 seconds) are incon venient, liable to be disturbed by wind, and expensive to compen sate, and they are now quite disused, and most or all of the old ones removed, with their clocks, for better ones.

Pendulum Regulation.

The regulation of pendulums, or their exact adjustment to the proper length, is primarily effected by a nut on the end of the rod by which the bob can be screwed up or down. In the best clocks the rim of this nut is divided, with an index over it ; so the exact quantity of rise or fall, or the exact acceleration or retardation, may be known, the amount due to one turn ot tlic nut being previously ascertained. By the calculation used below for compensation of pendulums, it may be seen that if the J gtfl of the pendulum rod is I, and the breadth of one thread of the screw is called dl, then one turn of the nut will alte rate of the clock by 43200 y seconds a day ; which would be iust 80 seconds, if the pendulum rod is 45 inches long and the screw has 32 threads in the inch. To accelerate the clock the nut has always to be turned to the right, as it is called, and t But in astronomical and in large turret clocks, it i to avoid stopping, or in any way disturbing the pendulum ; and f the finer adjustments other methods of regu ation are adopted The best is that of fixing a collar, as shown in fig 2, capable o having very small weights laid upon it, half-way down th dulunf, this being the place where the addition of any smal 1 eig ht produces the greatest effect, and where, it may be added aiij moving of that weight up or down on the rod produces

effect If M is the weight of the pendulum and I its length (down to the centre of oscillation), and m a small weight added at the distance d below the centre of suspension or above the c.o. (since they are reciprocal), I the time of vibration, and - dt the acceleration due to adding m; then

| A table should appear at this position in the text. See Help:Table for formatting instructions. |

-dt m_ id d*. ~T~ ~ 2M V " I 1 )

from which it is evident that if d? i, then - d T the daily acceleratioij:? 1080 m; or if m is the 10800th of the weight of M the pendulum it will accelerate the clock a second a day, or 10 grains will do that on a pendulum of 15 Ib. weight (7000 gr. being? 1 Ib.), or an ounce on a pendulum of 6 cwt. In like manner if d? - from either top or bottom, m must?, - to accelerate 3 7200 the clock a second a day. The higher up the collar is the less risk there is of disturbing the pendulum in putting on or taking oft the regulating weights. The weights should be made in a series, and marked 4, 1, 2, according to the number of seconds a day by which they will accelerate; and the pendulum adjusted at first to lose a little, perhaps a second a day, when there are no weights on the collar, so that it may always have some weight on, which can be diminished or increased from time to time with certainty, as the rate may vary.

Compensation of Pendulums.

Soon after pendulums began to be generally used in clocks, it was discovered that they contained within themselves a source of error independent of the action of the clock upon them, and that they lost time in the hot weather and gained in cold, in consequence of all the substances of which they could be made expanding as the temperature increases. If I is the length of a pendulum, and dl the small increase of it from increased heat, t time of the pendulum I, and t + d that of the pendulum l + dl; then't + dt VI dl + 2 J since ( ) may be neglected as very small; or dt?! and the daily loss of the clock will be 43200^ seconds The following is a table of the values of ^ for 1000 Fahr. of heat in different sub stances, and also the weight of a cubic inch of each:

| A table should appear at this position in the text. See Help:Table for formatting instructions. |

ft White deal ..................................... 0024 036 Flint glass ........................................... 0048 116 Steel rod ......................................... 0064 28 Iron rod ............................................. 007 26 Brass ............................................... 010 30 Lead ................................................ -016 41 Zinc ............................................ -017 25 Mercury (iu bulk, not in length) ............. 100 49

Thus a common pendulum with an iron wire rod would lose 43200 x -00007? 3 seconds a day for 10 of heat; and if adjusted for the winter temperature it would lose about a minute a week in summer, unless something in the clock happened to produce a counteracting effect, as we shall see may be the case when we come to escapements. We want therefore some contrivance which will always keep that point of the pendulum on which, its time depends, viz., the centre of oscillation,, at the same distance from the point of suspension. A vast number of such contrivances have been made, but there are only three which can be said to be at all in common use; and the old gridiron pendulum, made of 9 alter nate bars of brass and steel is not one of them, having been super seded by one of zinc and iron, exactly on the same principle, but requiring much fewer bars on account of the greater expansion of zinc than brass. The centre of oscillation so nearly coincides in most clock pendulums with the centre of the bob that we may prac tically say that the object of compensation is to keep the bob always at the same height. For this purpose we must hang the bob from the top of a column of some rnetal which has so much more expan sion than the rod that its expansion upwards will neutralize that of the rod, and of the wires or tube by which the bob is hung, down wards. The complete calculation, taking into account the weight of all the rods and tubes is too long and complicated to be worth going through, especially as it must always be finally adjusted by trial either of that very pendulum or of one exactly similar. For prac tical purposes it is found sufficient to treat the expansion of zinc as being "016 to steel "0064, instead of "017 as it is really; and for large pendulums with very heavy tubes even the 016 is a little too much. Moreover the c.o. is higher above the e.g. of the bob in such large pendulums than in small ones with light rods and tubes.

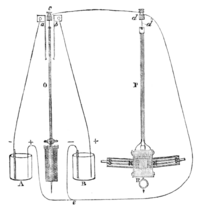

But neglecting these minutiae for the first approximation, and supposing the bob either to be of iron, in which case it may be con sidered fixed anywhere to the iron tube which hangs from the top of the zinc tube, or a lead bob attached at its own centre, which obviates the slowness of the transmission of a change of temperature through it, the following calculation will hold. Letr be the length of thesteel rod and spring, z that of the zinc tube, b half the height of the bob; the length of the iron tube down the centre of the bob is % - b. If the iron tube is of steel for simplicity of calculation, we must evidently have -064(r + z-i)? I6z: z - g(r-J). It is practically found that for a seconds pendulum with a lead cylindrical bob 9 in. x 3 hung by its middle r has to be about 44 inches, and 2 nearly 27. At any rate it is safest to make it 27 at first, especially if the second tube is iron, which expands a little more than steel; and the tube can be shortened after trial but not lengthened. The rod of the standard sidereal pendulum at Green wich (down to the bottom of the bob, which is such as has been described and weighs 26 ft), is 43? and z is 26 inches, the descending wires being steel. A solar time pendulum is about % inch longer, as stated above. If the bob were fixed at its bottom to the steel tube the zinc would have to be 4 88 longer. Fig. 2 is a section of the great West minster pendulum. The iron rod which runs from top to bottom, ends in a screw, with a nut N, for adjusting the length of the pendulum after it was made by calculation as near the right length as possible. On this nut rests a collar M, which can slide up the rod a little, but is prevented from turning by a pin through the rod. On a groove or annular channel in the top of this collar stands a zinc tube 10 feet 6 inches long, and nearly half an inch thick, made of three tubes all drawn together, so as to become like one (for it should be observed that cast zinc cannot be depended on; it must be drawn). On the top of this tube or hollow column fits another collar with an annulai groove much like the bottom one M. The object of these grooves is to keep the unc column in its place, not touching the rod within it, as contact might produce friction, which would interfere with their relative motion under expansion and con traction. Round the collar C is screwed a large iron tube, also not touching the zinc, and ita lower end fits loosely on the collar M; and round its outside it has another collar D of its own fixed to it, on which the bob rests. The iron tube has a number of large holes in it down each side, to let the air get to the zinc tube; before that was done, it was found that the compensation lagged a day or two behind the changes of temperature, in consequence of the iron rod and tube being exposed, while the zinc tube was enclosed without touching the iron. The bottom of the bob is 14 feet 11 inches from the top of the spring A, and the bob itself is 18 inches high, with a domeshaped top, and twelve inches in diameter. As it is a 2-seconds pendulum, its centre of oscilla- _, . . tion is 13 feet from the top A, which is higher t m. t n than usual above the centre of gravity of the bob, t p i i on account of the great weight of the compensation tubes. The whole weighs very nearly 700 ft, and is probably the heaviest pendulum in the world.

Fig. 2.—Section of Great Westminster Pendulum.

The second kind of compensation pendulum in use is still more simple, but not so effective or certain in its action; and that is merely a wooden rod with a long lead bob resting on a nut at the bottom. According to the above table, it would appear that this bob ought to be 14 inches high in a 1-second pendulum; but the expansion of wood is so uncertain that this proportion is not found capable of being depended on, and a somewhat shorter bob is said to be generally more correct in point of compensation . All persons who have tried wooden pendulums severely have come to the same conclusion, that they are capricious in their action, and consequently unfit for the highest class of clocks.

The best of all the compensations was long thought to be the mercurial, which was invented by Graham, a London clockmaker, above a century ago, who also invented the well-known dead escapement for clocks, which will be hereafter explained, and the horizontal or cylinder escapement for watches. And the best form of the mercurial pendulum is that which was introduced by the late E. J. Dent, in which the mercury is enclosed in a cast iron jar or cylinder, into the top of which the steel rod is screwed, with its end plunged into the mercury itself. For by

this means the mercury, the rod, and the jar all acquire the new temperature at any change more simultaneously than when the mercury is in a glass jar hung by a stirrup (as it is called) at the bottom of the rod ; and moreover the pendulum is safe to carry about, and the jar can be made perfectly cylindrical by turning, and also air-tight, so as protect the mercury from oxidation ; and, if necessary, it can be heated in the jar so as to drive off any moisture, without the risk of breaking. The height of mercury required in a cast-iron jar, 2 inches in diameter, is about 6 8 inches; for it must be remembered, in calculating the rise of the mercury, that the jar itself expands laterally, and that expansion has to be deducted from that of the mercury in bulk.

The success of the Westminster clock pendulum, however, and of smaller zinc and steel pendulums at Greenwich and elsewhere, has established the conclusion that it is unnecessary to incur the expense of a heavy mercurial pendulum, which has become more serious from the great rise in the price of mercury and the admitted necessity for much heavier bobs than were once thought sufficient for astronomical clocks. The complete calculation for a compen sated pendulum in which the rods and tubes form any considerable proportion of the whole weight, as they must in a zinc pendulum, is too complicated to be worth undertaking generally, especially as it is always necessary to adjust them finally by trial, and for that purpose the tubes should be made at first a little longer than they ought to be by calculation, except where one is exactly copying pendulums previously tried.

Barometrical Error.

It has long been known that pendulums are affected by varia tions of density of the air as well as of temperature, though in a much less degree, in fact, so little as to be immaterial, except in the best clocks, where all the other errors are reduced to a minimum. An increase of density of the air is equivalent to a diminution of the specific gravity of the pendulum, and that is equivalent to diminution of the force of gravity while the inertia remains the same. And as the velocity of the pendulum varies directly as the force of gravity and inversely as the inertia, an increase of density must diminish the velocity or increase the time. The late Francis Baily, P. R.A.S., also found from some elaborate experiments (See Phil. Trans, of 1832) that swinging pendulums carry so much air with them as to affect their specific gravity much beyond that due to the mere difference of stationary weight, and that this also varies with their shape, a rod with a flat elliptical section dragging more air with it than a thicker round one (which is not what one would expect), though a lens-shaped bob was less affected than a spherical one of the same diameter, which of course is much heavier. The frictional effect of the air is necessarily greater with its increased density, and that diminishes the arc. In the ll.A.S. Memoirs of 1853 Mr Bloxam remarked also that the current produced in the descent of the pendulum goes along with it in ascending, and there fore does not retard the ascent as much as it did the descent, and therefore the two effects do not counteract each other as Baily assumed that they did. He also found the circular error always less than its theoretical value, and considered that this was due to the resistance of the air. The conclusions which were arrived at by several eminent clockmakers as to the effect of the pendulum spring on the circular error about 40 years ago were evidently erroneous, and the effect due to other causes.

It appears from further investigation of the subject in several papers in the R.A.S. Notices of 1872 and 1873, that the barometrical error also varies with the nature of the escapement, and (as Baily had before concluded from calculation) with the arc of the pendulum, so that it can hardly be determined for any particular clock a priori, except by inference from a similar one. The barometrical error of an ordinary astronomical clock with a dead escapement was said to be a loss of nearly a second a day for an inch rise of barometer, but with a gravity escapement and a very heavy pendulum not more than 3 second. Dr Robinson of Armagh (see R.A.S. Mem., vol. v.) suggested the addition of a pair of barometer tubes to the sides of the pendulum, with a bulb at the bottom, and such a diameter of tube as would allow a sufficient quantity of mercuiy to be transposed to the top by the expansion under heat, to balance the direct effect of the heat upon the pendulum. But it is not necessary to have two tubes. In a paper in the R.A.S. Notices of January 1873 Mr. Denison (now Sir E. Beckett) gave the calculations requisite for the barometrical compensation of pendulums of various lengths and weights, the principle of which is just the same as that above given for regulating a pendulum by adding small weights near the middle of its length. The formula is also given at p. 69 of the sixth edition of his Rudimentary Treatise on Clocks. A barometrical correction of a different kind has been applied to the standard clock at Green wich. An independent barometer is made to raise or lower a magnet so as to bring it into more or less action on the pendulum and so to accelerate or retard it. But we do not see why that should be better than the barometer tube attached to the pendulum. The necessity for this correction seems to be obviated altogether by giving the pendulum a sufficient arc of vibration. Baily calculated that if the arc (reckoned from 0) is about 2 45 the barometrical error will W self-corrected. And it is remarkable that the Westminster clock pendulum, to which that large arc was given for other reasons, appears to be free from any barometric error, after trying the results of the daily rate as automatically recorded at Greenwich for the whole of the year 1872. We shall see presently that all the escape ment errors of clocks are represented by fractions which have the square or the cube of the arc in the denominator, and therefore if the arc can be increased and kept constant without any objectionably increase of force and friction, this is an additional reason for pre ferring a large arc to a small one, though that is contrary to the usual practice in astronomical clocks.

Escapements.

The escapement is that part of the clock in which the rotary motion of the wheels is converted into the vibratory motion of the balance or pendulum, which by some contrivance or other is made to let one tooth of the quickest wheel in the train escape at each vibration; and hence that wheel is called the " scape 77heel. " Fig. 3 shows the form of the earliest clock escapement, if it is held sideways, so that the arms on which the two balls are set may vibrate on a horizontal plane. In that case the arms and weights form a balance, and the farther out the weights are set, the slower would be the vibrations. If we now turn it as it stands here, and consider the upper weight left out, it becomes the earliest form of the pendulum clock, with the crown- ivheel or vertical escapement. CA and CB are two flat pieces of steel, called pallets, projecting from the axis about at right angles to eacli other, one of them over the front of the wheel as it stands, and the other over the back. The tooth D is just escaping from the front pallet CA, and at the same time the tooth at the back of the wheel falls on the other pallet CB, a little above its edge. But the pendulum which is now moving to the right does not stop immediately, but swings a little further (otherwise the least failure in the force of the train would stop the clock, as the escape would not take place), and in so doing it is evident that the pallet B will drive the wheel back a little, and produce what is called the recoil; which is visible enough in any common clock with a seconds-hand, either with this escapement or the one which will be- next described.

It will be seen, on looking at figure 3, that the pallet B must turn through a considerable angle before the tooth can escape; in other words, the crown-wheel escapement requires a long vibration of the pendulum. This is objectionable on several accounts, first, because it requires a great force in the clock train, and a great pressure, and therefore friction, on the pallets ; and besides that, any variation in a large arc, as was explained be fore, produces a much greater variation of time due to the circular error than an equal variation of a small arc. The crown wheel escapement may in deed be made so as to allow a more moderate arc of the pendulum, though not so small as the 2 usually adopted in the best clocks, by putting the pallet arbor a good deal higher above the scape-wheel, and giving a small number of teeth to the wheel; and that also diminishes the length of the run of the teeth, and consequently the friction, on the pallets, though it makes the recoil very great and sudden; but, oddly enough, it never appears to have been resorted to until long after the escapement had be come superseded by the "anchor" escapement, which we shall now

describe, and which appears to have been invented by the celebrated Dr Hooke as early as the year 1656, very soon after the invention of pendulums.

In fig. 4 a tooth of the scape-wheel is just escaping from the left pallet, arid another tooth at the same time falls upon the right hand pallet at some distance from its point. As the pendulum moves on in the same direction, the tooth slides farther up the pallet, thus pro ducing a recoil, as in the crown-wheel escapement. The acting faces of the pallets should be convex, and not Hat, as they are generally made, much less concave, as they have sometimes been made, with a view of checking the motion, of the pendulum, which is more likely to injure the rate of the clock than to improve it. But when they are flat, and of course still more when they are concave, the points of the teeth always wear a hole in the pallets at the extremity of their usual swing, and the motion is obviously easier and therefore better when the pallets are made convex ; in fact they then approach more nearly to the "dead" escapement, which will be described presently. We have already alluded to the effect of some escapements in not only counteracting the circular error, or the natural increase of the time of a pendulum as the arc increases, but overbalancing it by an error of the contrary kind. The recoil escapement does so ; for it is almost invariably found that whatever may be the shape of these pallets, the clock loses as the arc of the pendulum falls off, and vice versa. It is unfortunately impossible so to arrange the pallets that the circular error may be thus exactly neutralized, because the escapement error depends, in a manner reducible to no law, upon variations in friction of the pallets themselves and of the clock train, which produce different effects ; and the result is that it is impossible to obtain very accurate time keeping from any clock of this construction.

But before we pass on to the dead escapement, it may be proper to notice an escapement of the recoiling class, which was invented for the purpose of doing without oil, by the famous Harrison, who was at first a carpenter in Lincolnshire, but afterwards obtained the first Government reward for the improvement of chronometers. We shall not however stop to describe it, since it never came into general use, and it is said that nobody but Harrison himself could make it go at all. It was also objectionable on account of its being directly affected by all variations in the force of the clock. It had the peculiarity of being very nearly silent, though the recoil was very great. Those who are curious about such things will find it described in the seventh edition of this Encyclopaedia. The recorded performance of one of these clocks, which is given in some accounts of it, is evidently fabulous.

Dead Escapements.

The escapement which has now for a century and a half been con sidered the best practical clock escapement (though there have been constant attempts to invent one free from the defects which it must be admitted to pos sess) is the dead escapement, or, as the French call it with equal expressiveness, I echappement d repos, bu- cause instead of the recoil of the tooth upon the pallet, which took place in the pre vious escapements, it falls dead upon the pallet, and reposes there until the pen dulum returns and lets it off again. It is represented in fig. 5. It will be observed that the teeth of the scape- wheel have their points set the opposite way to those of the recoil escapement in fig. 4, the wheels themselves both turning the same way ; or (as our engraver has re presented it), vice versa. The tooth B is here also represented in the act of dropping on to the right hand pallet as the tooth A scapes from the left pallet. But instead of the pallet having a con tinuous face as in the recoil escapement, it is divided iiito~two, of which BE on the right pallet, and FA on the left, are called the im pulse faces, and BD, FG, the dead faces. The dead faces are portions of circles (not necessarily of the same circle), having the axis of the pallets C for their centre; and the consequence evidently is, that as the pendulum goes on, carrying the pallet still nearer to the wheel than the position in which a tooth falls on to the corner A or B of the impulse and the dead faces, the tooth still rests on the dead faces without any recoil, until the pendulum returns and lets the tooth slide down the impulse face, giving the impulse to the pendulum as it goes.

The great merit of this escapement is that a moderate variation in the force of the clock train produces a very slight effect in the time of the pendulum. This may be shown in a general w~ay, without resorting to mathematics, thus : Since the tooth B drops on to the corner of the pallet (or ought to do so) immediately after the tooth A has escaped, and since the impulse will begin at B when the pendulum returns to the same point at which the impulse ceased on A, it follows that the impulse received by the pendulum before and after its vertical position, is very nearly the same. low that part of the impulse which takes place before zero, or while the pendulum is descending, tends to augment the natural force of gravity on the pendulum, or to make it move faster ; but in the de scending arc the impulse on the pallets acts against the gravity of the pendulum, and prevents it from being stopped so soon ; and so the two parts of the impulse tend to neutralize each other s disturbing effects on the times of the pendulum, though they both concur in. increasing the arc, or (what is the same thing) maintaining it against the loss from friction and resistance of the air. However, on the whole, the effect of the impulse is to retard the pendulum a little, because the tooth must fall, not exactly on the corner of the pallet, but (for safety) a little above it ; and the next impulse does not bt-gin until that same corner of the pallet has come as far as the point of the tooth ; in other words, the retarding part of the impulse, or that which takes place after zero, acts rather longer than the accel erating part before zero. Again, the friction on the dead part of the pallets tends to produce the same effect on the time ; the arc of course it tends to diminish. For in the descent of the pendulum the friction acts against gravity, but in the ascent with gravity, and so shortens the time ; and there is rather less action on the dead part of the pallets in the ascent than in the descent. For these reasons the time of vibration of a pendulum driven by a dead escapement is a little greater than of the same pendulum vibrating the same arc freely ; and when you come to the next difference, the variation of time of the same pendulum with the dead escapement, under a moderate variation in the force, is very small indeed, which is not the case in the recoil escapement, for there the impulse begins at each end of the arc, and there is much more of it duiing the descent of the pendulum than during the ascent from zero to the arc at which the escape takes place and the recoil begins on the opposite tooth ; and then the recoil itself acts on the pendulum in its ascent in the same direction as gravity, and so shortens the time. And hence it is that an increase of the arc of the pendulum with a recoil escapement is always accompanied with a decrease of the time. Something more than this general reasoning is re quisite in order to compare the real value of the dead escapement with others of equal or higher pretensions, or of the several contrivances that have been suggested for remedying its defects. But we must refer to the Rudimentary Treatise on Clocks for details of the mathematical calculations by which the numerical results are obtained, and the relative value of the different kinds of escape ments determined.

It camiot be determined a priori whether cleaning and oiling a dead escapement clock will accelerate or retard it, for reasons explained in those calculations ; but it may be said conclusively that the larger the arc is for any given weight x the fall per day, the better the clock will be ; and in order to diminish the friction and the necessity for using oil as far as possible, the best clocks are made with jewels (sapphires are the best for the purpose) let into the pallets.

The pallets are generally made to embrace about one-third of the circumference of the wheel, and it is not at all desirable that they should embrace more ; for the longer they are, the longer is the run of the teeth upon them, and the greater the friction. There is a good deal of difference in the practice of clockmakcrs as to the length of the impulse, or the amount of the angle 7 + if the im pulse begins at /8 before zero and at y after zero. Sometimes you see clocks in which the seconds hand moves very slowly and rests a very short time, showing that 7 + /3 is large in proportion to 2a ; and in others the contrary. The late Mr Dent was decidedly of opinion that a short impulse was the best, probably because there is less of the force of the impulse wasted in friction then. It is not to be forgotten that the scape-wheel tooth docs not overtake the face of the pallet immediately, on account of the menu-lit of inertia of the wheel. The wheels of astronomical clocks, and indeed of all English house-clocks, are generally made too heavy, especially the scape-wheel, which, by increasing the moment of inertia, requires a larger force, and consequently has more friction. We shall see presently, from another escapement, how much of the force is really wasted in friction in the dead escapement.

But before proceeding to other escapements, it is proper to notice a very useful form of the dead escapement, which is adopted in many of the best turret clocks, called the pin-wheel escapement. Fig. 6 will sufficiently explain its action and construction. Its advantages are that it does not require so much accuracy as the other; if a pin gets broken it is easily replaced, whereas in the oth^r the wheel is ruined if the point of a tooth is injured ; a wheel of given size will work with more pins than teeth, and therefore a

train of less velocity will do, and that sometimes amounts to a savin<? of one wheel in the train, and a good deal of friction; and the blow on both pallets being downwards, instead of one up and the other down, the action is more steady; all which things are of more consequence in the heavy and rough work of a turret clock than in an astronomical one. The details of the construction are given in the Rudimentary Treatise. It has been found expedient to make the dead faces not quite dead, but with a very slight recoil, which rather tends to check the variations of arc, and also the general disposition to lose time if the arc is increased; when so made the escapement is generally called "half-dead."

Passing by the various other modifications of the dead escapement which have been suggested and tried with little or no success, we proceed to describe one of an entirely different form, which was patented in 1851 by Mr C. Macdowall, though it appeared afterwards that one very similar had been tried before, but failed from the proportions being badly arranged. It is represented in fig. 7. The scape-wheel is only a small disc with a single pin in it, made of ruby, parallel and very near to the arbor. The disc turns half round at every beat of the pendulum, and the pin gives the impulse on the vertical faces of the pallets, and the dead friction takes place on the horizontal faces. Its advantages are that the greatest part of the impulse is given directly across the line of centres, and consequently with very little friction; and therefore also, the friction on the dead faces is less than usual, and scarcely any oil is required; moreover, it is very easy to make. But there must be two more wheels in the train, consuming a good deal of the force of the clock-weight by their friction, which rather more than makes up for the friction saved in the escapement. It was applied successfully to watches, but the expense of the additional wheels prevented their adoption. In order to make the angle of escape not more than 1º, the distance of the pin from the centre of the disc must not be more than 160th of the distance of centres of the disc and pallets.

With the view of getting rid of one of these extra wheels in the train, and that part of the impulse which is least effective and most oblique, Mr Denison shortly afterwards invented the three-legged dead escapement; which, though afterwards superseded by his three-legged gravity escapement, is still worth notice on account of the exceedingly small force which it requires, thereby giving a practical proof of the large proportion of the force which is wasted in friction in all the other impulse escapements.

Fig. 7. Macdowall's Escapement.

}}

In fig. 8, the three long teeth of the scape-wheel are only used for locking on the dead pallets D and E, which are set on the front of the pallet plate; A and B are impulse pallets, being hard bits of steel or jewels set in the pallet plate, and they are acted upon by the three sharp-edged pins which are set in the scape-wheel and point backwards. As soon as the pendulum moves a little further to the left than is here shown, the long tooth will slip past the dead pallet or stop D, and the pin at B will run after and catch the corner of that impulse pallet and drive it until the wheel has turned through 60º, and then it will escape; and by that time the uppermost tooth will arrive at the stop E, and will slide along it as in the common dead escapement, but with a pressure as much less than that which gives the impulse as the points of the teeth are farther from the centre of the wheel than the impulse pins are. But the impulse is here given with so little friction, that even where the points of the teeth were made identical with the pins, the clock-weight required to keep the same pendulum with the same train (a common turret-clock movement), swinging to 2º, was only one-fifth of what had been required with the pin-wheel escapement; and the scape- wheel which kept the 6 cwt. pendulum of the Westminster clock going for half-a-year, until superseded by the gravity escapement, weighed only a sixth of an ounce. It appears also that it would be possible so to adjust the recoil of the half-dead pallets that the time would not be affected by any small variation of the force and the arc; since it was found that, when a certain amount of recoil was given the clock gamed instead of losing, under an increase of arc due to an increase of clock-weight. And if the force were kept constant by a train remontoire, such as will be described hereafter, there would in fact be nothing capable of altering the arc or the time. But on account of the small depth of intersection of the circles of the pins and the pallets, on which its action depends, this escapement requires very careful adjustment of the pallets, except where they are on a large scale; and considering the superior qualities of the corresponding gravity escapement, it is not likely to be used, except perhaps in clocks required to go a long time, in which economy of force is a matter of consequence. The pallets should be connected with the pendulum by a spring fork (which indeed is advisable in the common dead escapement with a heavy pendulum, especially the pin-wheel escapement), to prevent the risk of their driving backwards against the scape-wheel when it is not in motion, as it will not clear itself. The distance of the centres should be not less than 25 times the radius of the circle of the edges of the impulse pins.

Fig. 8.—Denison's Three-Legged Escapement.

Detached Escapements.

In all the escapements hitherto described the pallets are never out of moving contact with the scape-wheel, and there have been several contrivances for keeping them detached except during the impulse and at the moment of passing a click which is to release the wheel to give the impulse. This is an imitation of the chronometer escapement in watches which is sometimes called the "detached." There are only two of such contrivances which appear worth special notice. One was proposed by Sir G. Airy in vol. ii. of the Cambridge Transactions, but not executed (so far as we know) till a few years ago in the standard sidereal clock at Greenwich, which is reported to go extremely well. Suppose a dead escapement consisting of a single pallet only, say the right hand one of the pin-wheel escapement (fig. 6), for the Greenwich clock has a pin escapement, and that the wheel is locked generally by a spring detent hooking into any one of its teeth, and capable of being lifted or pushed aside by the pendulum, i.e., by a pin somewhere on the single pallet as it passes to the right, but also capable of being passed without being lifted as the pendulum goes to the left. We shall see afterwards how this is done, in the article Watches. Then as the pendulum goes .to the right, it first lifts the detent at about 1º before zero, and then a tooth or a pin drops on to the pallet and gives the impulse, exactly as in the dead pin-wheel escapement, and with exactly the same amount of friction, substituting only for the dead friction the resistance and friction of passing the detent one way and lifting it the other.

A different escapement on the same principle but involving less friction was adopted by Sir E. Beckett in a clock described in the later editions of his book as having gone for above ten years very satisfactorily, except that, like all direct impulse escapements, including Sir G. Airy's, it must vary with the force of the clock train, due to different states of the oil. The scape-wheel (fig. 9) is five-legged, and has five sharp-edged pins which give the impulse to the hard steel pallet P whenever it passes to the right, provided the wheel is then free to move. It is stopped by the detent DEF, which turns on a pivot F, not in the pendulum crutch, as it looks in the drawing, but on the clock-frame. When the pendulum going to the right arrives at the position here drawn, the click CE on the crutch pushes the detent aside and so unlocks the wheel, which then gives the impulse, moving through 72º until another tooth arrives at the detent and is stopped, the click having then got far beyond it. When the pendulum returns the click lightly trips over the top of the detent. Here there is practically no friction in giving the impulse, as it is directly across the line of centres, as in the three-legged dead escapement, and the friction of passing

and unlocking is as little as possible, for the pressure on the locking teeth is less than half of that of the impulse pins.

In practice the pallet P is a separate bit of steel, screwed on, and therefore adjustable. The locking teeth are about 6 inches long from the centre, and the impulse pin-edges ¼ in. from the centre, which is 7 in. below the top of the pendulum and crutch, so that the impulse begins 1 before zero and ends 1 after, corresponding each to 36 turn of the scape-wheel. If r is the distance of the pins from the centre and p the length of the crutch down to the centre, rsin. 36must= p sin. 1, if you want an impulse of 1 on each side of; which makes p = 33 7r. BB are eccentric beat pins for adjusting the beat to whatever 1 position of the pendulum you please, i.e., you can make it less than 1 before or after zero as you please. In some respects it would be better to have no crutch, but it would be very difficult to make the adjustments. This escapement should evidently be at the bottom of the clock-frame instead of the top, as in the gravity escapements which will be described presently. The back part of the scapewheel is carried by a long cock or bridge within which the crutch also moves.

Remontoire or Gravity Escapements.

A remontoire escapement is one in which the pendulum does not receive its impulse from the scape-wheel, but from some small weight or spring which is lifted or wound up by the scape-wheel at every beat, and the pendulum has nothing to do with the scapewheel except unlocking it. When this impulse is received from a weight the escapement is also called a gravity escapement; and in asmuch as all the remontoire clock escapements that are worth notice have been gravity escapements, we may use that term for them at once. The importance of getting the impulse given to the pendulum in this way was recognized long before all the properties of the dead escapement, as above investigated, were known. For it was soon discovered that, however superior to the old recoil escapement, it was far from perfect, and that its success depended on reducing the friction of the train and the pallets as far as possible, which involves the necessity of high-numbered pinions and wheels, small pivots, jewelled pallets, and a generally expensive style of workmanship. Accordingly the invention of an escapement which will give a constant impulse to the pendulum, and be nearly free from friction, has been for a century the great problem of clockmaking. We can do no more than shortly notice a very few of the attempts which have been made to solve it. The most simple form of gravity escapement, and the one which will serve the best for investigating their mathematical properties (though it fails in some essential mechanical conditions), is that invented by Mudge. The tooth A of the scape-wheel in fig. 10 is resting against the stop or detant a at the end of the pallet OA, from the axis or arbor of which descends the half fork CP to touch the pendulum. From the other pallet CB descends the other half fork CO. The two arbors are set as near the point of suspension, or top of the pendulum spring, as possible. The pendulum,,,, A as here represented, must be moving to the right, and just leaving contact with the left pallet in. going to take up the right one; as soon as it has raised that 3t a little it will evidently unlock the wheel and let it turn, and then the tooth B will raise the left pallet until it is caught by the .top b on that pallet and then it will stay until the pendulum reurns and releases it by raising that pallet still higher! Each pallet!vW? tT" J h? IT lulum to a lo Point than that where it is taken up, and the difference between them is supplied by B lifting of each pallet by the clock, which does not act on the pendulum at all; so that the pendulum is independent of all varia tions of force and friction in the train.

Fig. 10.—Mudge's Gravity Escapement.

Again referring to the Rudimentary Treatise on Clocks for the mathematical investigation of the errors of this class of escapements, or to a paper by the late J. M Bloxam, in the R. A. S. M^unrs of Io3, we may say it is proved that though the time of a crravitv escapement pendulum differs from that of a free r.endulum more than from that of a dead escapement, yet the variations of that hflerence (which are the real variations of the dock) may be made much less than m any kind of dead escapement.

The difficulty which long prevented the success of gravity escapements was their liability to what is called (ripping. .Referring again to fig. 10, it will be seen at once that if the scape-wheel should happen to move too fast when it is released, the left pallet will not be raised gradually by the tooth B, but be thrown up with a jerk, perhaps so high that the tooth slips past the hook; and then not only will that tooth slip, but several more, and at last when the wheel is stopped it will be running fast, and the points of some of the teeth will probably be bent or broken by catching against the pallets. And even if the pallet is not raised high enough for the tooth to get past or completely trip, it may still be raised so high that the point of the tooth does not rest on the hook exactly where the slope of the pallet ends, but lower v and the friction between them is quite enough to keep the pallet there; and consequently the pendulum does not begin to lift it at the proper angle 7, but at some larger angle; and as the pallet always descends with the pendulum to the same point, the duration of the impulse is increased, and the pendulum made to swing farther. Sir E. Beckett called this approximate tripping, and though not so injurious to the clock as actual tripping, it is obviously fatal to its accurate performance, though it appears never to have been noticed before he pointed it out in 1851. Various contrivances have been resorted to for preventing tripping. But on account of the delicacy required in all of them, and other objections, none of them ever came into use until the invention of the three-legged and four-legged escapements to be mentioned presently. The only one which approached near enough to satisfying all the requisite conditions to be worth description is Mr Bloxam's, and we accordingly give a sketch of it in fig. 11, which is copied (with a little alteration for distinctness) from his own description of it, communicated in 1853 to the Astronomical. Society, some years after he had had it in action in a clock of his own. This drawing will enable any one conversant with these matters to understand its action. He made the pallet arbors cranked, to embrace the pendulum-spring, so that thencentres of motion might coincide with that of the pendulum as nearly as possible, perhaps an unnecessary refinement; at least the three-legged and four-legged gravity escapements answer very well with the pallet arbors set A on each side of the top of the spring. The size of the wheel determines the length of the pallets, as they must be at such an angle to each other that the radii of the wheel when in contact with each stop may be at right angles to the pallet arm; and therefore, for a wheel of this size, the depth of locking can only be very small. The pinion in Mr Bloxam's clock only raises the pallet through 40 at each beat; i.e., the angle which we called 7 is only 20; and probably, if it were increased to anything like -r-, the escapement would trip immediately. The two broad pins marked E, F. are the fork-pins. The clock which Mr Bloxam had went very well; but it had an extremely fine train, with pinions of 18; and nobody else appears to have been able to make one to answer. In short Bloxam's was not a practical solution of the gravity escapement problem, any more than those of Captain Kater, or Hardy, or various other inventors. A few clocks of Hardy's alone still exist.

Fig. 11.—Bloxam's Gravity Escapement.

The only gravity escapement or escapements that really have come into common use are the "four-legged" and the "double threelegged" escapements of Sir E. Beckett. They passed through various phases before settling into the present form, ot which it is unnecessary to say more now than that the first was the single three-legs described in the last edition of this Encyclopaedia, which was suggested by his three-legged dead escapement. A five-legged one was also tried; but though it had some slight advantages they are quite overbalanced by disadvantages, and it requires much more delicacy of construction than either the double three-legs or the four-legs which we shall now describe, remarking that the latter is the best for "regulators," and the formei in large clocks. Fig. 12 is a back view of the escapement part of an astronomical clock with the four-legged wheel; seen from the front the wheel would turn the other way. The long locking teeth are made about 2 inches loi.g from the centre, and the lifting pins, of which there are four pointing forwards and the other four intermediate pointing back wards, are at not more than one-30th of the distance between the

centres EC, of the wheel and pallets; or rather C is the top of the pendulum spring to which the pallets CS, CS converge, though their actual action are a little below C. It is not worth while to crank them as Mr Bloxam did, in order to make them coincide exactly with the top of the pendulum, as the friction of the beat pins on the pendulum at P is in significant, and even then would not be quite destroyed. The pallets are not in the same plane, but one is behind and the other in front of the wheel, with one stop pointing backwards and the other forwards to receive the teeth alternately, it does not matter which; in this figure the stop S is behind and the stop S forward. The pendulum is now going to the right, and just beginning to lift the right pallet and free the stop S; then the wheel will begin to turn and lift the other pallet by one of the pins which is now lowest, and which moves through 45 across the line of centres, and therefore lifts with very little friction. It goes on till the tooth now below S reaches S and is stopped there. Meanwhile the pallet CS goes on with the pendulum as far as it may go, to the end of the arc which we have through out called a, starting from 7; but it falls with the pendulum again, not only to 7 but to-7 on the other side of 0, so that the impulse is due to the weight of each pallet alternately falling through 2y; and the magnitude of the impulse also depends on the obliqueness of the pallet on the whole, i.e., on the distance of its centre of gravity from the vertical through C. The defect of the original three-legged escapement was that the pallets were too nearly vertical.

Fig. 12. Four-Legged Gravity Escapement.

Another most material element of these escapements with very few teeth is that they admit of a fly KK on the scape- wheel arbor to moderate its velocity, which both obviates all risk of tripping, wholly or partially, and also prevents the bang which goes all through the clock where there is no ny. The fly is set on with a friction spring like the common striking-part fly, and should be as long as there is room for, length being much more effective than width. For this purpose the second wheel arbor is shortened and set in a cock fixed on the front plate of the clock, which leaves room for a fly with vanes 2 inches long. The back pivot of the scape-wheel is carried by a long cock behind the back plate, so that the escapement is entirely behind it, close to the pendulum. The pallet arbors are short, as they come just behind the centre wheel, which is here also necessarily above the escapement, and the great wheel arbor on a level with it, and at the left hand (from the front) or the string would be in the way of the fly. No beat screws are required, as the pallets end in mere wires which are easily bent. It is found better to make the tails of the pallets long, rather than short as Mr Bloxam did. It is essential, too, that the angle CSE formed by the tooth and the pallet which is struck upwards should not the least fall short of a right angle, nor the other angle CS E be the least obtuse, or the escapement may very likely trip. Practically, therefore, it is safer to let CSE be just greater than 90 and CS E a little less, so that there may not be the least tendency in the blow on the stops to drive the pallets outwards. For the purpose of calculation, however, we must make them both 90 and then it follows that, calling the length of the teeth r, and the distance of centres d, and the length of the pallets from C down to the stops p, r must d sin. 22^ J and _p - d cos. 22 J D . Therefore if r is made 2 inches CE or d will bo 5 22, say 5j inches, and p ? 4 "82. The distance of the lifting pins from the centre will be

Gravity escapements require more weight than a direct impulse escapement with an equally fine train; and they try the accuracy of the wheelcutting more severely. If there is a weak place in the train of a common clock the scape-wheel only follows the pendulum more weakly; but in a gravity escapement it always has to raise the pallets, and ought to raise them quickly, and especially in clocks for astronomical purposes where you take its exact time from the sound of the beats, and so the lifting must not lag and sound uneven. Therefore although a fine train of high numbers is not requisite it must be perfectly well cut. And as the force of the weight does not reach the pendulum its increase is of no consequence, within reasonable limits. It is worth while to put large friction wheels under the arbor of the great wheel in all astronomical clocks, and it makes a material difference in the friction on account of the necessary thickness of the winding arbor. A variation of arc in dead escapement clocks is sometimes visible between the beginning and the end of the week according as the string is nearest to the thick or the thin end of the great arbor, when there are no friction wheels.

Fig. 13.—Double Three-legged Escapement.

The other form of the gravity escapement, which is now adopted for large clocks by all the best makers, having been first used in the great Westminster clock, is the double three-legged which is shown in fig. 13. The principle of it is the same as of the four-legs; but instead of the pallets being one behind and the other in front of the wheel, with two sets of lifting pins, there are two wheels ABC, abc, with the three lifting pins and the two pallets between them like a lantern pinion. One stop B points forward and the other A backward. The two wheels have their teeth set inter mediately or 60 apart, though that is not essential, and the angle of 120 3 may be divided between them in any other proportions, as 70 and 50, and in that way the pallets may be still more oblique than 30 from the vertical, which however is found enough to prevent tripping even if the fly gets loose, which is more likely to happen from carelessness in large clocks than in astronomical ones. The Westminster one was once found to have been left with the spring loose for several days, and it had not gained a second, and therefore had never tripped. The two wheels legged must be both squared on the arbor, or on a collar common to them both, and must not depend upon the three pins or they will shake loose. If the wheels are set with the teeth equidistant, their centre is evidently twice the length of the teeth below C, the theoretical centre of the pallets. The pins should not be farther from the centre than one-24th of the radius of the wheel; and they should be so placed that the one which is going to lift next may be vertically over the one which has just lifted, and is then holding up the other pallet. The third will then be level with the centre; i.e., they will stand on the radii which form the acting faces of the teeth of one of the wheels, and half way between those of the other. Of course the fly for those escapements in large clocks, with weights heavy enough to drive the hands in all weather, must be much larger than in small ones. For average church clocks with 1 sec. pendulum the legs of the scape-wheels are generally made 4 inches long and the fly from 6 to 7 inches long in each vane by lj orl^ wide. For 1^ sec. pendulums the scape-wheels are generally made 4^ radius. At Westminster they are 6 inches.