Encyclopedia of Needlework/Mending

The mending of wearing-apparel and house-linen, though often an ungrateful task, is yet a very necessary one, to which every female hand ought to be carefully trained. How best to disguise and repair the wear and tear of use or accident is quite as valuable an art, as that of making new things.

Under the head of mending, we include the strengthening and replacing of the worn and broken threads of a fabric, and fitting in of new stuff in the place of that which is torn or damaged. The former is called darning, the latter, patching.

DARNING.--When only a few of the warp or woof threads are torn or missing, a darn will repair the mischief, provided the surrounding parts be sound. When the damage is more extensive, the piece must be cut out.

In some cases the warp of the stuff itself can be used for darning, otherwise thread as much like the stuff as possible should be chosen.

MATERIALS SUITABLE FOR MENDING.--Coton à repriser D.M.C is used for most kinds of darning. It can be had in 18 different sizes, from Nos. 8 to 100, white and unbleached, and in all the colours of the D.M.C colour-card in Nos. 12, 25 and 50.

It is but very slightly twisted and can be split or used double, if necessary, according to the material. For all the coarser articles of house-linen, unbleached cotton is the best, and for the finer white fabrics, Coton surfin D.M.C Nos. 110, 120 and 150[A]. This cotton, which is not the least twisted, and is to be had both white and unbleached, can be used, by subdividing it, for darning the finest cambric.

VARIETIES OF DARNING.--These are four, (1) Linen darning, (2) Damask darning, (3) Satin or Twill darning, and (4) Invisible darning, called also, Fine-drawing.

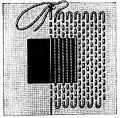

(1) LINEN DARNING (figs. 40 and 41).--All darns should be made on the wrong side of the stuff, excepting fig. 54, which it is sometimes better to make on the right side. The longitudinal running, to form the warp, must be made first. The thread must not be drawn tightly in running your stitches backwards and forwards, and be careful to leave loops at each turning, to allow for the shrinking of the thread in the washing, without its pulling the darn together.

-

Fig. 40. Linen darning.jpg

-

Fig. 41. Linen darning. Drawing in the woof threads.

Run your needle in, about one c/m. above the damaged part, take up one or two threads of the stuff and miss the same number, working straight to a thread; on reaching the hole, carry your cotton straight across it, take up alternate threads beyond, and proceed as before. Continue the rows backwards and forwards, taking up in each row, the threads left in the preceding one. Turn the work round and do the same for the woof; alternately taking up and leaving the warp threads, where the cotton crosses the hole. The threads must lie so alone both ways, that the darn, when completed, replaces the original web. The threads are only drawn so far apart in the illustrations, for the sake of clearness.

When the material to be darned does not admit of a fleecy thread, such as Coton à repriser D.M.C, one that as nearly as possible matches the material, should be chosen from the D.M.C cottons.[A]

DIAGONAL LINEN DARNING (fig. 42).--Darns are sometimes begun from the corner, so as to form a diagonal web, but they are then much more visible than when they are worked straight to a thread, and therefore not advisable.

(2) Satin or twill darning (fig. 43).—By twill darning, the damaged web of any twilled or diagonal material can be restored. It would be impossible to enumerate all the varieties of twilled stuffs, but the illustrations and accompanying directions will enable the worker to imitate them all.

Begin, as in ordinary darning by running in the warp threads, then take up one thread, and miss three. In every succeeding row, advance one thread in the same direction. Or, miss one thread of the stuff and take up two, and as before, advance, one thread in the same direction, every succeeding row. The order in which threads should be missed and taken up, must depend on the web which the darn is intended to imitate.

When the original is a coloured stuff, it is advisable to make a specimen darn first, on a larger scale, so that you may be more sure of obtaining a correct copy of the original web.

(3) DAMASK DARNING (figs. 44, 45, 46, 47, 48, 49).--A damask darn is begun in the same way as all other darns are; the pattern is formed by the cross-runnings and will vary with the number of warp threads taken up and missed, in each successive running. The woven design which you are to copy with your needle must therefore be carefully examined first.

Figs. 44 and 45 show the wrong and right sides of a damask darn, in process of being made.

-

Damask darning. Wrong side.

-

Damask darning. Right side.

Fig. 46 represents a completed one. In the case of coloured webs, a light shade of cotton is generally used for the warp, one that matches the stuff, for the shot or woof.

Figs. 47 and 48, illustrate two specimens of darning, formerly done in the convents, from which it will be seen, that the warp and the woof were first drawn in with rather fine thread and the pattern then worked into this foundation with coarser, or else, coloured thread. When this kind of darn is in two colours, take, for the darker shade, Coton à broder D.M.C, or Coton à repriser D.M.C, which are both of them to be had in all the bright and faded shades, to match alike both old and new linen.

-

Fig. 47. Damask darning on needle-made ground.

-

Fig. 48. Damask darning on needle-made ground.

Fig. 49, which is executed in two colours, and is likewise copied from an old work on darning, shows you the manner in which a dice-pattern is to be reproduced.

(4) DARNING, LOST IN THE GROUND (fig. 50).--A kind of darn used for repairing rents, the edges of which fit exactly into one another. Neither the torn threads of the material nor the rough edges must be cut off; the torn part is to be tacked upon a piece of oil-cloth, wrong side uppermost, and the edges, drawn together by a thread, run in backwards, and forwards, across them. The stitches must be set as closely together as possible, and regularly inverted, as in every other darn. A much finer thread relatively than that of which the material is composed should, in all cases be used for darning. In this instance also, for the sake of greater distinctness, the size of the thread has been magnified in the illustration. Coton surfin D.M.C, will be found the best for darning both calico and linen.

FINE DRAWING (fig. 51).--The art of making invisible darns in cloth, though such a useful one, is all but unknown. It is a tedious process and one which, though easy enough to understand, requires great care in the execution.

Use as fine a needle as possible and thread it with hair, instead of silk, or any other kind of fibre. Red and white hair is the strongest, and stronger than the ravellings of the stuff. Of course the hair has first to be carefully cleansed from grease. Pare the edges of the rent, on the right sides, quite clean and even, with a razor, so that both rent and stitches may be lost in the hairy surface of the cloth. Scissors do not cut so closely, and are liable moreover, to disturb the nap, and render the darn more visible. When this is done, fit the edges exactly together, and overcast them. Then thread a needle with a hair by the root, and slip it in, 2 or 3 m/m. from the one edge and back again pointed towards you, through the other, so that, neither needle nor hair, are visible on either side. The stitches should be set slightly slanting and must be quite lost in the thickness of the cloth. The needle must always be put in, exactly at the place where it came out, and the hair not be too tightly drawn.

When the darn is finished, lay the article on a bare table, or ironing-board, cover it with a damp cloth, and iron it. The sharpest eye will fail to detect a rent, when carefully darned in this manner.

PATCHING.--As we have already said, when the defective part is past darning, it must be cut out, and a new piece of stuff inserted in its place. If the garment be no longer new, it should be patched with a slighter material than that of which it was originally made. The patch should be of the same shape, and cut the same way of the stuff, as the piece it is to replace, it should also be, just so much larger, as to allow for the turnings in, and can either be top-sewn, or else, run and felled in.

BACK-STITCHING AND FELLING IN A PATCH (fig. 52).--Tack in the new piece, so that its edges over-lap the edges of the hole. The back-stitching must be done on the article itself, as this renders it easier to do the corners neatly. The hem is turned down on to the patch. Make a little snip at the corners with your scissors to prevent puckering. The back-stitching should form a right angle at each corner.

TOP-SEWING IN A PATCH (fig. 53).--To do this, the edges of the hole and of the patch, must first be turned in, and either overcast or hemmed, to prevent their fraying, after which, sew the two edges together. The raw edges may also be turned in with herring-boning as in fig. 39, putting the needle, only through one layer of stuff.

DRAWING IN A PATCH (fig. 54).--Take a square piece of the original stuff, 5 or 6 c/m. larger each way, than the hole it is to fill, draw out threads on all the four sides, till the piece exactly matches the hole, and tack it into its place. Thread a very fine needle with the two ends of a thread of silk or Fil d'Alsace D.M.C No. 700, run it in at the corner of the stuff, and draw it out, leaving a loop behind. Into this loop, slip the first of the threads, which as it were, form a fringe to the patch, and tighten the loop round it, and so on with each thread, alternately taking up and leaving threads in the stuff, as in ordinary darning.

To put a patch into a thin material, in this manner, you must darn in the threads, a good long way, into the material, in order that the double layer of threads may be less visible.