Popular Science Monthly/Volume 8/January 1876/The Sand-Blast

| THE SAND-BLAST. |

By W. S. WARD.

PROF. WILLIAM P. BLAKE, in a communication "On the Grooving and Polishing of Hard Rocks and Minerals by Dry-Sand," which appeared in the American Journal of Science and Arts, September, 1855, describes the phenomena observed by him in 1838, in the Pass of San Bernardino, California, as follows: "On the eastern declivities of the pass, the side turned toward the desert, the granite and associate rocks which form the sharp peak San Gorgonio extend down the valley of the pass in a succession of sharp ridges, which, being devoid of soil and of vegetation, stand out in bold and rugged outlines against the clear, unclouded sky of that desert-region. It was on these projecting spurs of San Gorgonio that the phenomena of grooving were seen; the whole surface of the granite over broad spaces was cut into long and perfectly parallel grooves and little furrows, and every portion of it was beautifully smoothed, and, though very uneven, had a fine polish." While contemplating these curious effects, the solution of the problem was presented. The wind was blowing very hard, and carried with it numerous little grains of sand. A closer examination disclosed the fact that the whole of the polished surface was enveloped in an atmosphere of moving sand, and it was through the grinding and rubbing of these minute but numberless quartz-atoms that the rough surfaces of these rocks had been made smooth, and the natural grooves deepened and polished. "Even quartz," he observed, "was cut away and polished; garnets and tourmaline were also cut and left with polished surfaces. . . . Whenever a garnet or a lump of quartz was imbedded in compact feldspar and favorably presented to the action of the sand, the feldspar was cut away around the hard mineral, which was thus left standing in relief above the general surface."

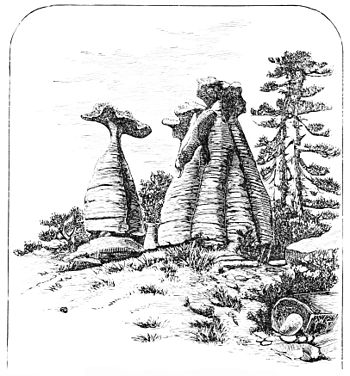

The traveler whose good fortune it is to visit our Western wonderland, will note among the many fingers in his guide-book one pointing in the direction of the now famous Monument Park. Entering a narrow valley bordered by mountain-walls, he will find himself gazing in wonderment at the rounded stone columns, rising about him in groups or singly, to a height ranging from ten to forty feet, and in many instances surmounted with grotesque cap-like coverings, that rest balanced upon the frail pinnacles of the rock-columns. An inquiry as to the causes of their existence, standing as they do in isolation on the surface of the valley lowlands, will elicit the reply that they were made by the wearing away of the surrounding rocks by sand, which, whirling about in water or air eddies, acted like chisels of the turner's lathe. Where the depressions were deepest there the rocky strata were soft and yielding, and were the more readily cut away; but where the opposing surface was hard, as in the case of the black cap-pieces, the action was less rapid, and the reduction of the rock less decided. Glancing off from these, the whole force of the driving sand was projected against the strata immediately below, thus reducing it in size till there seems hardly circumference enough left to sustain the weight above.

Fig. 1.—Sand-cut Columns in Monument Park.

So much for the observations of the geologist and explorer, made nearly half a century ago, and placed on record as forming but one of the many startling features of that wonderful region, but suggesting to the traveler little else than a reasonable theory by which to account for a hitherto mysterious class of physical phenomena. From this, the record of the student of Nature, we turn to a second record, more practical in character, and having a direct bearing upon the subject under review.

Whether the author or inventor of the modern sand-blast deserves any less credit for having had his idea anticipated in the workshops of Nature, we will not say; certain it is, however, that the former work suggested the latter, though the prior claim does not seem to have been considered by the American Commissioner of Patents.

"On the 18th of October, 1870," we read, "letters-patent of the United States were granted to General B. C. Tilghman, of Philadelphia, for the cutting, grinding, etching, engraving, and drilling stone, metal, wood, or any hard substance, by means of a jet or blast of sand." We are also informed, from the same official source, that the inventor of the sand-blast process obtained his first hints from Nature, and, by means of a mechanism which is a marvel of simplicity, has been able to utilize this same force so as to make it render most efficient service in several departments of the applied arts.

It is the object of the present paper to describe and illustrate the invention known as the Tilghman Sand-Blast, an invention which, in simplicity of construction, and yet extent of application, has hardly an equal in the annals of the American Patent-Office. We are aware that this is a broad claim, when it is remembered that under the protection of the same authority the sewing-machine, reaper, and mower, positive-action loom, and a score or more of great mechanical devices, first saw the light. It is possible that there is that in the idea of the sand-blast which adds to its charm, and secured for it the admiring indorsement of Torrey, Tyndall, and other men of science; and yet a careful study of ils principle, and an observance of its practical operation, seem to justify all and more than is claimed for it by the inventor or his distinguished indorsers.

If the reader will refer to the simple "claim" as given above, he will notice that it is proposed to accomplish the several results there named "by means of a jet or blast of sand." The italics are our own, and are now introduced since it is in this idea of a jet of sand that the first principle of the device rests; and, moreover, it was an attempt made by others to adopt this falling jet of sand that compelled the inventor to institute his first proceeding against infringement. With the legal history of the sand-blast, however, we have nothing to do, save as it concerns the general history of the invention and its progress. In order that the methods by which a simple falling column or stream of sand is made to do service as an engraver of glass and metal plates may be understood, attention is directed to Fig. 2, which may be described as follows:

A is a box, elevated as high above the engraver's table as the height of the ceiling will permit. When designed for several workmen, this box may be divided into compartments, as indicated, each compartment being filled with common quartz or sea-sand, of varying degrees of fineness. From the bottom of each division a metal tube, c, depends, reaching to within a few inches of the table below. A slide, B, serves to regulate or check the flow of the sand. Thus much for the simplest form of sand-blast. A word as to the manner of its operation; and here, again, reference must be made to the original "claim," where it will be found that the operation of the blast is limited to the cutting, grinding, etc., of any hard substance. It may be well to note the significance of this word hard since in it lies the secret of the whole process. The substance upon which the sand acts must be a hard or brittle

Fig. 2.—Device for etching with Sand.

one, falling or being blown upon which, the angular sand-grains chip away minute portions, till at length the whole surface is reduced or scratched to any desired depth. Thus, if the plate which, as shown in the figure, be a glass one, and the workman wishes to engrave on it a flat design, he has only to protect the portions which are not to be acted upon, by a stencil made from rubber, soft iron, leather, or even paper, since, these substances not being hard or brittle, will not be affected by the descending blows of the sand-grains. This the workman has done, and by this means he has been able to depolish or grind the surface of the plate as indicated. Of the methods of constructing and applying these stencils, their variety and several uses, descriptions will be given as we advance.

From the use of a simple jet of falling sand, we pass on a step, and in Fig. 3 present the Tilghman Sand-blast Machine, in its original and complete form, all subsequent improvements having been made only with a view to some special form of service. The feature of this device, it will be observed, is the use of a blast of air or steam which shall be made to accelerate the falling of the sand through the tube, and thus cause each grain to act with additional force upon the opposing surface. If the reader will, by the aid of the illustration, observe closely the construction of this simple device, he will be able to comprehend, once for all, not only the novelty of the invention, but also its extreme simplicity.

Connected with a wooden box, supported on a shelf, as here indicated, is a flexible rubber tube, which in turn is attached at its lower end to an iron tube, that rises through the floor of a miniature wagon. This wagon rests on the roof of a box through which a slit is cut in the direction shown. Through this slit the iron tube passes, projecting into the box below. It is to the structure of this metal tube, or gun, as it is called, that attention is specially directed. As shown in the

Fig. 3.—The Tilghman Sand-blast Machine.

section at the right, it consists of two tubes, the one leading down from the box and conveying the sand being smaller, thus allowing of an annular space between it and the lower section. Into this lower section, and at a right angle to it, the blast of air is admitted from a suitable reservoir. The sand falling down, as shown by the upper arrow, enters the lower tube at a point below that at which the air is admitted. Having passed below the limits of its conducting-tube, it receives an extra impulse from the air-current that also is passing downward, and by it is projected with greater force upon the hard substance below. In addition to the advantage gained by this new impulse, it will also be seen that the blast serves another purpose in blowing away the sand, so soon as its work is done, and thus leaving the surface below clean and in a condition to be the more readily acted upon by the succeeding blasts. The purpose of the wagon is merely to admit of the tube being moved forward and backward along the line of the plate to be engraved, the lateral movement of the plate being effected by a suitable device not here shown. This plate is inclosed in a box, for the reason that the falling grains of sand, while they chip away the surface of the plate, are also broken up and powdered. And it is that this dust may not interfere with the health and comfort of the workmen that the whole is confined in a closed box.

Before describing the several methods by which, through the aid of specially-prepared stencils, the surfaces to be treated are exposed to the action of the blast, we will direct attention to certain of the more recent forms of the machines, all embodying the same general principles, but so modified as to adapt them to the special service for which they are intended.

Foremost among these devices is the large machine, by the aid of which flat plates are ground or engraved.

Fig. 4.—Machine for engraving Flat Plates.

The distinctive feature of this machine is the substitution of a long, narrow slit for the tube; through this the sand falls or is blown in a thin sheet. Referring to Fig. 4, we find the machine composed of a large supply-box, into which the sand is elevated by a series of hoppers attached to a moving belt. From this box the sand falls of its own weight into a second receptacle, which serves also as a receiving-chamber for the air-blast that enters at the right through the large blast-pipe. From this receiver the sand is driven downward through a second slit, and emerges from it with great force.

At right angles with this slit a series of leather straps or moving belts serves to convey the polished plate beneath the sheet of falling sand, and it is during the passage of the plate under this sand-sheet that its surface is depolished or ground. As these plates move at the rate of from six to thirty inches a minute, an estimate can be made as to the rapidity with which the work of grinding is effected. When it is desired to merely roughen the whole surface, it is evident that no preliminary processes are needed, the plates of glass being fed in at the opening indicated on the right, and passing through to be received and delivered at once as ground glass.

Fig. 5.—Plates engraved by Sand-Blast.

When it is desired, however, to engrave figures or designs upon the plates, a special process precedes the grinding. This consists in the designing and attaching of the stencils, and may be described as follows: The glass plate, which it is proposed to ornament with any suitable device, is laid upon the designer's table and covered over its whole surface with a thin sheet of tin-foil. Upon this bright metallic surface the designer sketches his pattern, and then by the aid of a sharp knife-point cuts through the foil along the lines of the pattern. The foil, which indicates the design, is then carefully lifted and removed, leaving the glass exposed, showing the exact form of the pattern. The plate is then removed and placed upon a second table, where it receives over its entire surface a thin layer of melted wax. When this wax has become sufficiently hardened, a knife is introduced beneath the portions of foil that .remain, and these are gently lifted and removed with the wax immediately over them. What remains now is the original pattern traced in wax and resting on the glass. The plate thus prepared is then placed on the moving belts, or feeders, of the large machine and by them is conveyed under the falling sand-blast. Of course, this sheet of sand strikes with equal force on the whole surface; but where the wax layers intervene they act as shields, receiving the sand but checking its progress, while the exposed portions being glass, and therefore brittle, are roughened so as to present the appearance of a ground surface. After each plate passes through, it is again slightly heated, the wax removed, and the final appearance is such as indicated in Fig. 5. These illustrations, it may be stated, are from photographic imprints, taken from actual plates, and, as such, indicate with perfect exactness the character of the work. In these the light portions represent the ground or depolished surfaces, while the dark lines are those which, having been protected by the stencil shield of wax, were untouched.

Fig. 6.—Machine operated by Exhaust instead of Blast.

When the surfaces to be acted upon are curved, as in the case of globes, tumblers, etc., a special device is needed. The feature of this is an exhaust-chamber, by the aid of which the sand is drawn up through a tube and projected upward, as shown in Fig. 6. Immediately above the orifice through which the sand rises, the stencil-covered globes are caused to revolve on spindles, and, when finished, have the appearance indicated in Fig. 7.

If the reader has been able to follow this necessarily brief description, he will readily perceive how, by the use of duplicate stencils, constructed of .any tough substance, the work of engraving, once an art in itself, becomes merely a mechanical process. As the result of experiments, now nearly completed, a form of rubber ink has been devised which, when laid on paper, converts it into a stencil, sufficiently tough to resist the action of the blast. Then, again, it may be seen how designs, direct from Nature, may be transferred to glass or metal by merely attaching a leaf or, vine to the surface, and exposing it to the action of the blast. Nor is glass the only substance that can be ground and engraved. All metals, when hardened, are as

Fig. 7.

readily cut. The zinc plates which are now being substituted for lithographic stone have their surfaces depolished by the sand-blast. As illustrative of the remarkable rapidity with which the sand-blast accomplishes its work, the following facts, regarding the cutting of inscriptions on the head-stones designed to mark the graves of soldiers buried in the national cemeteries, may be cited. The contractor having this work in charge at Rutland, Vermont, has three sand-blast machines, of the form indicated in Fig. 8.

In addition to the one man employed to tend these machines, he has a small force of boys, whose duty it is to attach and remove the cast-iron letters which act as stencils. Thus equipped, the contractor is able to turn out three hundred head-stones a day, upon each of which is a handsomely-cut inscription averaging eighteen raised letters. It is estimated that, to accomplish a like result by the old process, a force of three hundred men would be needed. Another instance of the rapidity with which these little sand-engines do their work is shown in the engraving of glass globes, tumblers, etc., which can be done at the astounding rate of one a minute.

Fig. 8.—Tilghman's Sand-blast Stone-machine.

Extended space might be devoted to a mere recital of the actual present accomplishments of the sand-blast, and, were we to enter the field of speculation as to its possibilities, the range of its adaptation would tax the reader's credulity. We will therefore be content to refer to the following extract from the report of the judges at the fortieth exhibition of the American Institute, which, in awarding the inventor the great medal of honor, describes and commends his invention as follows:

"The process is designed to execute ornaments, inscriptions in intaglio or relief, or complete perforations, in any kind of stone, glass, or other hard and brittle substance; or to cut deep grooves in natural rocks, in order to facilitate the process of quarrying; or to make circular incisions around the central mass of rock in the process of tunneling; or to remove slag, scale, and sand, from the surfaces of metal castings; or to clear the interior surfaces of boilers or boiler tubes of incrustations; or to cut ornaments or types from wood as well as from stone; or to depolish the surface of glass, producing by the aid of stencils or other partial protections, as the bichromatized gelatine of photographic negatives, every variety of beautiful figures, including copies of the finest lines, and the most delicate line engravings; or to prepare copper-plates in relief for printing, by making gelatine photographic pictures upon smooth surfaces of resin and pitch, cutting them out by the blast, and afterward moulding from them, and electro-typing the moulds.

"This process is without precedent. The use of sand in sawing marble, or in grinding glass by common methods, hardly furnishes an analogy."

Here follows a description of the device, concluding with the statement that "it is regarded by the judges as being one of the most remarkable and valuable inventions which the age has produced."

When it is announced that the judges who thus emphatically indorsed the claims of the sand-blast were Profs. Barnard, Mayer, and Morton, our readers will demand of the writer no apology for or qualification of his expressed opinion that the "Tilghman sand-blast is an invention which, in simplicity of construction and extent of application, has hardly an equal in the annals of American patents."