T.O. 21M-LGM25C-1

The source document of this text is not known. Please see this document's talk page for details for verification. "Source" means a location at which other users can find a copy of this work. Ideally this will be a scanned copy of the original that can be uploaded to Wikimedia Commons and proofread. If not, it is preferably a URL; if one is not available, please explain on the talk page. |

The "Dash One"[edit]

This is a manual for the United States Titan II Intercontinental Ballistic Missile weapon system as displayed at the Titan Missile Museum in Sahuarita, Arizona.

INTRODUCTION[edit]

The LGM-25C Weapon System consists of an inertially guided, liquid fueled, airborne weapon and associated ground equipment necessary to maintain and launch the airborne weapon. The weapon system is capable of destroying enemy targets over 5000 nautical miles distant. The launch complex is designed to maintain an operational readiness condition with no outside support after sustaining an attack that destroys all non-hardened facilities. For maximum safety and effectiveness, individual launch complexes are separated by distance of 7 to 10 nautical miles. All in-commission missiles are maintained in a constant alert condition and may be counted down individually or simultaneously. Safety rules for the LGM-25C (Titan II) MK6 RV/MK53 Weapon System (U) are contained in AFR 122-22. Squadron maintenance areas provide facilities for supply, administration, operations, and maintenance necessary to maintain the launch complexes in a constant state of readiness.

LAUNCH COMPLEX FACILITIES[edit]

LAUNCH COMPLEX.[edit]

The launch complex includes both above ground and hardened underground facilities. Hardened facilities include the missile silo, control center, blast lock, interconnecting cable-ways, emergency escape hatch, and hardened communications equipment. Above ground, non-hardened facilities include vehicle parking areas, security fencing and lighting, propellant and electrical connections, static grounding system, commercial power lines, a transformer, cooling tower pits, access portal, non-hardened antennas, soft water storage, area security surveillance system, and weather instruments.

The launch complex includes both above ground and hardened underground facilities. Hardened facilities include the missile silo, control center, blast lock, interconnecting cable-ways, emergency escape hatch, and hardened communications equipment. Above ground, non-hardened facilities include vehicle parking areas, security fencing and lighting, propellant and electrical connections, static grounding system, commercial power lines, a transformer, cooling tower pits, access portal, non-hardened antennas, soft water storage, area security surveillance system, and weather instruments.

MISSILE SILO.[edit]

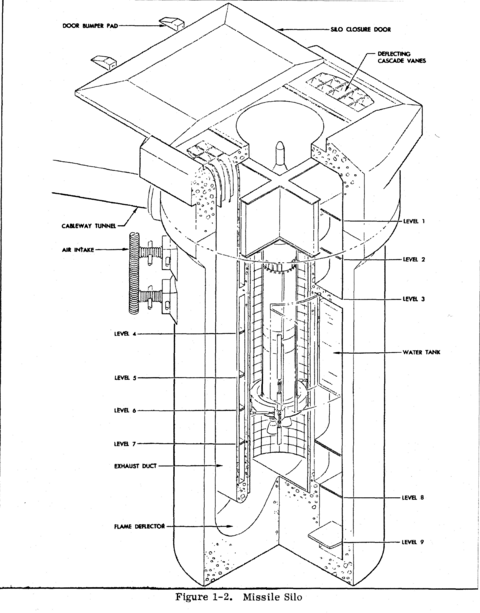

The missile silo (figure 1-2) is a reinforced, concrete structure with inside dimensions of approximately 146 feet in depth and 55 feet in diameter. A launch duct, constructed with a sound-attenuating lining, is located in the center of the silo. Associated installed equipment and structures include a silo closure door, retractable work platforms, hazard sensing devices, and a small equipment and personnel elevator operating between levels 2 and 8. Two exhaust ducts carry missile exhaust and ingested air from the flame deflector, through deflecting cascade vanes, to the surface. Equipment areas are located between the launch duct and the missile silo walls on nine separate levels. Equipment contained on the various levels is as follows:

- Level 1. Hydraulic panel, power pump unit, accumulator rack, nitrogen tanks, elevator power control, silo closure door operating equipment, silo elevator operating machinery, and control station for retractable platforms on level 1.

- Level 2, Water chiller units, main and spare chilled water circulating pumps, chilled water makeup tank, emergency eye wash and shower, cables and cable-way entrance, control station for retractable platforms on level 2, and two retractable platform hydraulic power valve panels, and an environmental protection unit.

- Level 3. Air handler, air supply and exhaust fans, ducting, steam separator, diesel generator and heat exchanger, switch gear, main circuit breakers, motor control center, shower and eyewash, two blast valves (intake and exhaust), control station for retractable platforms on levels 3 and 4, manhole to hard storage tank, and retractable platform hydraulic power valve panel.

- Level 4. Exhaust fan, air washer and water tank, two blast valves (air intake and exhaust), retractable platform hydraulic power valve panel, and silo blast valve control station.

- Level 5. Launch duct air conditioning unit, diesel service tank, slop tank and pumps, chilled water pump, water tank, control station for retractable work platforms on level 5, and retractable platform hydraulic power valve panel.

- Level 6. Air receiver, nitrogen tank, hydro-pneumatic power unit for silo blast valves and retractable work platforms, heating and ventilating control panel, water tank, valve panels, accumulators, pumps, reservoir, and fuel oxidizer vapor sensor racks.

- Level 7. Starting air pressure vessels, air compressor, standby air compressor, utility air pressure vessels, main cooling water pump, spare cooling water pump, fire protection pump, cooling water mix pump, industrial water pump, emergency eyewash and shower, retractable platform hydraulic power valve panel, control station for retractable platforms on level 7, and domestic water pumps. The thrust mount and shock isolation system that supports the missile is located at this level (inside launch duct),

- Levels 8 and 9. Engine deluge system, dehumidifier, oxidizer pump room, emergency eyewash and shower (two), sump pumps, flame deflector and sump, fuel pump room, sump spray, and sound attenuation system.

SILO CLOSURE DOOR.[edit]

The launch silo closure door consists of the closure door, wheel trucks, track rails, buffers and a door actuating system. The door actuating system consists of rail bridge jacks, door locks, a drive unit, cables, a pneudraulic power system, and electrical, hydraulic, and pneumatic controls. 1-9. The door is a 740-ton structure of steel and concrete mounted on four 4-wheeled truck assemblies. The purpose of the door Is to protect the silo from nearby nuclear blasts and resulting radiation. When closed, the door rests upon a seal with truck wheels clear of the rails. Door locks hold the door in the lowered, locked position, preventing movement from shock or vibration. For maintenance, the door may be opened or closed locally from the silo closure maintenance control panel located at silo level 1 after being activated by a key switch. The door is normally opened automatically during launch sequence by the control-monitor group in the control center. Door opening, by local control, is initiated by pressing and holding the silo closure maintenance control panel UNLOCK push-button until an unlocked indication is present. An override open panel mounted directly below and electrically connected to the maintenance control panel, contains electrical circuitry to automatically bypass faulty circuits of the maintenance control panel. An override close control panel is located beside the maintenance control panel and may be operated manually by a push-button mounted on the face of the panel in the event of an automatic close control failure. A door lock cylinder directional control valve solenoid is energized and directs hydraulic fluid at 3315 to 3525 psig from pressurized accumulators to the four lock cylinder unlock ports. The door locks rotate and lower to the fully unlocked and lowered position. Pressing and holding the silo closure maintenance control panel RAISE push-button energizes the rail bridge jacks directional control valve solenoid, directing hydraulic fluid to four rail bridge jack cylinders, raising the door wheel trucks even with the track rails. Pressing and holding the silo closure maintenance control panel OPEN push-button energizes the drive unit directional control valve solenoid, directing fluid to the drive unit motors. The drive unit motors turn two drum units with wrap cables attached to the closure door, opening the silo closure door. The door is arrested by hydraulic buffers, preventing damage to door and door arresters. Limit switches are installed at door activating locks, rail bridge jacks, and door arresting points, to monitor silo closure door opening and closing cycles from the silo closure maintenance control panel, control-monitor group (CMG), and launch control complex facilities console (LCCFC). The door is closed locally by the CLOSE, LOWER, and LOCK push-buttons on the silo closure maintenance control panel. The door is buffered by the door closing buffer. During launch sequence, the door is automatically controlled by the CMG and door limit switches. Upon demand, the door locks rotate and lower, the door raises, and the drive unit is energized. The force of the drive unit opens the closure door within 17 to 21 seconds, including unlocking and raising time. Debris on tracks may extend opening time. If silo closure door opening buffers or bumpers have been destroyed by a blast, an emergency means of stopping the door is required to prevent damage to the drive cables and hydraulic system by over-travel of the door. Emergency door stopping capability is provided by removal of both the 4-foot track rail sections and the adjacent 2-foot removable sections. Rail sections are stored on a concrete slab near the silo closure door tracks for ease of replacement when required. The silo closure door will operate normally with these rail sections removed and opening buffers and bumpers intact. If the silo closure overruns Limit switches, the silo closure (fully) open signal will be locked up in CMG-1 and launch sequence will continue.

To close the door, the sequence is reversed. The cable system drives the door to the full closed position and the hydraulic shock absorber in the door closing buffer slows it to a stop. Two sequencing controls lower the rail bridge jacks and set the door on a seal. The control then actuates the locking mechanisms, securing the door in place. Closing time is 17 to 21 seconds.

CONTROL CENTER.[edit]

The control center (figure 1-3) is a buried, reinforced, concrete structure designed to withstand the effects of a nuclear blast. The ground shock accompanying the blast is nullified in the control center by a three-level, steel, shock- isolation cage, which is supported by eight shock mounts hung from the domed roof. Grounding of the control center is accomplished by completely enclosing the structure with a 1/4-inch steel shell. The control center contains living quarters, communications equipment, battery power supplies, equipment for checkout and monitoring of the weapon system, and equipment for initiating launch sequence. These facilities allow the missile combat crew to maintain an alert condition with a minimum of down time. By the use of monitoring equipment contained in the control center, malfunctions which could affect launch capability can be recognized and isolated. Radio, telephone, and loudspeaker systems provide inter- and intra-site communications. VAFB equipment is not shown in figure 1-3.

The control center (figure 1-3) is a buried, reinforced, concrete structure designed to withstand the effects of a nuclear blast. The ground shock accompanying the blast is nullified in the control center by a three-level, steel, shock- isolation cage, which is supported by eight shock mounts hung from the domed roof. Grounding of the control center is accomplished by completely enclosing the structure with a 1/4-inch steel shell. The control center contains living quarters, communications equipment, battery power supplies, equipment for checkout and monitoring of the weapon system, and equipment for initiating launch sequence. These facilities allow the missile combat crew to maintain an alert condition with a minimum of down time. By the use of monitoring equipment contained in the control center, malfunctions which could affect launch capability can be recognized and isolated. Radio, telephone, and loudspeaker systems provide inter- and intra-site communications. VAFB equipment is not shown in figure 1-3.

BLAST LOCK, CABLE-WAYS, AND DECONTAMINATION AREA.[edit]

(See figure 1-4.) The blast lock is a buried, rectangular shaped, reinforced concrete structure with steel blast doors at all personnel openings. The blast lock is adjacent to the access portal and decontamination area. Cable-ways extend from the blast lock to the control center and from the decontamination area to the silo. The cable-ways are 9-1/2 feet in diameter, and are constructed with steel floors. Cable-ways provide for passage of personnel and equipment, control wiring, utility distribution, air ducts, and piping. Blast door No. 8 is installed where the cable-way from the control center connects with blast lock junction No. 201. Blast door No. 9 separates blast lock junction No. 201 and the decontamination area. The personnel decontamination area, located between blast door No. 9 and silo cable-way, contains a dressing room, decontamination shower, and an emergency reporting net telephone. The decontamination area is used for showering prior to removal of rocket fuel handler's clothing outfits. The rocket fuel handler's clothing outfits are not stored at the launch complex. 1-13. The blast lock structure provides blast-protected entry from the access portal to the hardened facility and between the control center and the launch silo. Four blast-resistant doors, interlocked in pairs, are manually opened and closed. The doors are secured in the closed position by hydraulically operated latches. Adjacent to each blast door, on each side of the wall, is a control station with OPEN and CLOSE (LOCK and UNLOCK at VAFB) push-buttons which engage or disengage the hydraulic latches. The blast doors are interlocked in pairs; 6 with 7, and 8 with 9. Pressing either push-button dc-energizes the control circuitry of the mating door, preventing the two doors from being opened at the same time. If normal hydraulic power fails, the latches can be operated by manual hydraulic pumps which override the Interlock feature. After MCL 3226, for blast lock entry from the access portal area, the push-button on the push-button-alarm light panel mounted on the LCCFC must be momentarily pressed at the same time the OPEN push-button for door No. 6 is pressed. A buzzer will sound when blast door 6 is open. The buzzer may be silenced by pressing the .alarm silence push-button.

ACCESS PORTAL.[edit]

The access portal (figure 1-4) is a rectangular, reinforced concrete structure, flush with ground level, which provides personnel entry to the launch complex. The portal contains a stairway leading to the outer door of the blast lock. A freight elevator is provided for movement of equipment down through the access portal and into the blast lock. A television camera, located near the first landing in the access portal, permits personnel identification by the missile combat crew commander (MCCC) from the control center. A telephone, located on the first landing of the access portal, permits verbal identification. After MCL 3226, OUTER ENTRANCE OPEN on the LCCFC will flash when the access portal sidewalk doors at grade are open.

ENVIRONMENTAL PROTECTION.[edit]

(See figures 1-3 and 1-4.) Electrical power, control, and communications circuits entering the launch complex are electromagnetically shielded from over-voltage surges which may be generated by natural phenomenon (electrical storms). Electrical interference filter groups are located on level 2 of the silo equipment area, in blast lock No. 202, on level 3 of the control center, and in the HF hard antenna silo.

AIR CONDITIONING, HEATING, AND VENTILATION SYSTEM.[edit]

CONTROL CENTER AIR CONDITIONING, HEATING AND VENTILATION SYSTEM.[edit]

The control center air conditioning system (figure 1-5) supplies air to the control center at a temperature of approximately 74 degrees F and a relative humidity of 55 percent maximum. Outside air is supplied through the intake shaft to the air conditioning unit. The air conditioning unit fan continuously circulates conditioned air to all areas within the control center. The control center air conditioning, heating, and ventilation system is controlled from the BM-1 control center heating and ventilating control panel (figure 1-6).

ACCESS PORTAL AND BLAST LOCK VENTILATING SYSTEM.[edit]

The access portal and blast lock ventilating system circulates outside air through the access portal, and conditioned air through the blast lock area. Conditioned air is exhausted from the control center, passed through the blast lock, the decontamination area, and out to the launch silo. This provides air flow from the control center toward the launch duct area to prevent the flow of toxic vapors through the cableway toward the control center.

LAUNCH DUCT AIR CONDITIONING SYSTEM.[edit]

The launch duct air conditioning system, in conjunction with the silo heating and evaporative cooling system, supplies conditioned air at a constant temperature and humidity to the launch duct. 1-20. Intake and exhaust fans provide air circulation and purge capability in the launch duct area. Purging is controlled automatically by the hazard sensing and warning system, but may be manually controlled when necessary. 1-21. Outside air entering the launch duct area is filtered by an electrical motor-driven roll-type filter located on level 3 of the launch silo between the intake blast valve and the air conditioning unit. A new filter media is automatically provided as needed; however, periodic changing of the roll is necessary.

CHILLED WATER SYSTEM.[edit]

The chilled water system is composed of the following major items: an expansion tank, supply pumps, a chilling unit, a mix pump, distribution equipment, heating and ventilating control panel BM-3, and various items of associated system equipment. 1-23. The chilled water system chills and circulates water from the water chillers to the portable hydraulic units, the after-cooler of the air compressor, the chilled water coils of the air conditioning units, and a cooling water mix pump. (After MCL 3259) Chilled water will also circulate through diesel engine lube oil-cooler. The system is automatically controlled by associated electrical and pneumatic components to maintain required water chilling and circulation. The system functions consist of circulation and control, refrigeration and control, and electrical control.

COOLING WATER SYSTEM.[edit]

The cooling water system is composed of the following major items: industrial water supply equipment, supply pumps distribution equipment, cooling towers, flow diversion equipment, and various items of associated equipment. (After MCL 3259) Cooling towers are not installed. 1-25. (Prior to MCL 3259) The cooling water system circulates water from cooling towers to the diesel engine lube oil cooler, and the water cooled condensers in the chilled water system. During normal circulation and control when the temperature of the water is above 50 degrees F, the water is cooled by CT101 and CT102. When the temperature of the water is less than +50 degrees F, the system circulates water through the 100, 000-gallon water storage tanks During the post-attack operation, the system is electrically and pneumatically controlled by the heating and ventilating control panels }3M and BM-3 1-25A. (After MCL 3259) he cooling water system will operate only during post-attack mode and circulates water from the 100, 000 gallon water storage tank to water condensers in chilled water system. The system is electrically and pneumatically controlled by heating and ventilating control panels BM and BM-3.

ELECTRICAL POWER.[edit]

COMMERCIAL POWER.[edit]

Power for the launch complex is normally supplied by a commercial source. Maximum power available to operate the launch complex is 500 kva (750 kva at VAFB). Failure of commercial power will not affect launch capability. A standby power supply, designed to operate in the event commercial power fails, is located on level 3 of the launch silo. 1-28. To insure adequate power to the launch complex, a transformer, consisting of three sections located In a recessed transformer vault above ground, is connected by primary terminals through an underground conduit to the commercial power source. Provisions are incorporated in the high-voltage portion of the transformer to ensure that commercial power can be disconnected for maintenance.

STANDBY POWER.[edit]

If commercial power fails, standby power supply equipment provides power to the launch complex. This equipment consists of a diesel engine, a generator, a transformer, switches, cables and heating, cooling, and venting facilities for power generating equipment. The diesel generator consists of a six-cylinder diesel engine and one synchronous ac generator rated at 350 kw, with a dc exciter mounted on the stator housing. Both the generator and exciter are driven by the diesel engine. The generator rotor shaft is directly coupled to the engine fly wheel. The exciter is belt driven from the generator rotor shaft. 1-30. The diesel engine is supercharged and rated at 510 brake horse power at 900 rpm. To ensure starting reliability, the engine is equipped with a 480-volt immersion heater designed to maintain the engine water jacket temperature at +126(+8) degrees F during standby. Engine cooling is accomplished by an embullient type cooling system. An embullient cooling system is one in which the coolant is circulated through the system by a temperature differential. Engine oil cooling is accomplished by a water cooled lubricating oil cooler which maintains the oil temperature below +190 degrees F during engine operation. Heat from the lubricating oil is absorbed by cooling water metered into the cooler by the lubricating oil cooler temperature control valve. The fuel supply for the engine is contained in underground storage tanks connected to a 55-gallon engine fuel tank. 1-31. Switching from commercial power to standby power is accomplished by 480-volt switch gear (figure 1-7) which monitors both commercial and standby power sources. The switch gear controls the standby power source and automatically switches from commercial to standby. Manual switching control is provided for commercial to standby and standby to commercial. When a failure of commercial power is sensed, automatic controls send a signal to start the diesel engine. The diesel engine starts, attains operating speed, generator voltage comes up to normal, and a circuit breaker closes. Closing of the circuit breaker supplies power to the motor control centers (MCC). Normal time elapsed from sensing of commercial power failure to closing of the circuit breaker is 60 seconds or less. The standby power source may also be controlled by switches on the diesel engine control and instrument panel (figure 1-8) mounted on the engine, from the 480-volt switch gear, or from the FACILITY POWER CONTROL BOARD (FPCB), FACILITY POWER panel, located on level 2 of the control center.

PERMISSIVE CONTROL.[edit]

Permissive control is used to prevent damage to the diesel generator when power is switched from commercial to standby power. This is accomplished by three permissive control relays located in the control center, blast lock area, and missile silo. When the GENERATOR CIRCUIT BREAKER on the 480-volt switch gear is closed, contacts close, routing 120 vac from the standby power metering transformer to the permissive relays. The permissive relays have contacts in the control circuits of the equipment to be disabled, and remove control power when energized. Some of the disabled circuits can be energized by closing permissive switches located on the FPCB, MCC-1, and lighting panels throughout the launch complex. 1-33. The diesel engine immersion heater is de-energized when facility is on standby power. There are no provisions for manual operation. 1-34. When equipment is manually energized, the WATTMETER on the FACILITY POWER panel of the FPCB must be monitored to prevent the generator from becoming overloaded. The following equipment is dc-energized when facility is on generator power, but may be energized manually. Equipment energized at the PERMISSIVE CONTROL panel of the FPCB is not listed. a. Receptacle pit (except RP-1 lighting panel). b. Control center lighting panel, CC-2A (keyswitch override). c. Cableway and access portal lighting panels, CW-1 and AP-1 (on distribution panel No. 1). d. Launch silo lighting panel, LS-6 on silo level 6 (kevswitch override).

FACILITY POWER CONTROL BOARD.[edit]

The FPCB panels (figure 1-9) consist of pushbuttons, indicators, controls, and meters which control and monitor commercial and standby power, propellant transfer operations and facility water supply. Panels located on the FPCB are as follows: FACILITY POWER panel, which controls and monitors both commercial and standby power; PERMISSIVE CONTROL panel, which allows operation of designated items of facility equipment; P. T. S. UNLOADING CONTROL panel, which controls and monitors propellant transfer operations and deflector fill and drain operations and FACILITY WATER SYSTEM panel, which monitors the facility water system. A LAMP TEST pushbutton on the FPCB allows the indicators on all panels to be tested. A communications jack permits wire-type communications between the FPCB and other areas of the launch complex.

MOTOR CONTROL CENTERS.[edit]

See figures 1-10 and 1-11.) MCC-1 and MCC-2, located on silo level 3 and control center level 3 respectively, serve as power distribution centers and contain equipment for electrical motor control. Each MCC is divided into panels containing circuit breakers, combination circuit breaker and motor starters, magnetic contactors, and control transformers. MCC-1 also contains a lighting transformer and lighting panel (LS-3) not found on MCC-2. 1-37. Circuit breakers are plug-in units with stab connectors which clip to vertical buses within the MCCs. The breakers provide overcurrent and short circuit protection for the power circuits. Each breaker is provided with a switch handle and escutcheon plate located on the front of the individual panel. 1-38. The combination circuit breaker and motor starter is a plug-in unit with stab connectors that clip to vertical buses within the MCCs. The breakers are similar to those described in paragraph 1-37; except that the motor starters are magnetically operated, have an overload protection device, and a manual RESET pushbutton located on the front of the individual panel. The motor starters are operated by a control transformer within the MCCs or by external 120-vac control circuits. When excessive current flows in the power circuit to the motor, the overload contacts open, de-energizing the motor starter which removes power from the motor. The protection device is reset by pressing the RESET pushbutton. 1-39. Magnetic contactors are magnetically operated switches used to close or interrupt electrical circuits. Contactors are provided for electrical motors where overload protection is not needed or is provided separately, and to connect lighting loads to the power source. The main line contacts open when the control circuit to the magnetic coil is interrupted. Control transformers supply 120-vac control power to the motor starter control circuits.

WATER SUPPLY SYSTEMS.[edit]

(See figure 1-12.) 1-41. Water at operational complexes is supplied by deep wells or a commercial source. The water is chemically treated, softened if necessary, and stored in a 100,000-gallon: tank located within the silo area between levels 3 and 6. 1-42. Control of the water system is maintained by both automatic and manual controls. These control the storage tank water level, water flow, isolation of water system, and detect over-pressurization of the supply line. 1-43. Indicators that monitor water supply, water storage external to silo, and water treatment are located on the FACILITY WATER SYSTEM panel of the FPCB. The SILO WATER SUPPLY LOW indicator, on the LCCFC lights amber when the water level in the 100, 000-gallon tank falls below the 242 foot level. The indicator will remain lighted until the water level is restored above the 242 foot level. Level indicator LI-1, located on the 100, 000-gallon storage tank silo level 6, provides a visual indication of water level in the tank. The gauge indicates green from the low water level through the high water level and red for a low level alarm or overflow condition. After MCL 3239 SILO WATER SUPPLY LOW indicator on LCCFC will flash when the water level is 3 inches below the outlet, indicating a probable overflow condition.

FIRE WATER SYSTEM.[edit]

The fire water system is controlled during commercial power utilization by the P-1 FIRE WATER PUMP selector switch on MCC-1. During standby power utilization, the system is controlled by FIRE PUMP P-i ON and OFF pushbuttons on the PERMISSIVE CONTROL panel of the FPCB. The fire water system supplies water to the launch duct spray units and to other water and foam spray units throughout the launch complex for control of fires. If Fire Water Pressure Controller PC-lS should malfunction while on commercial power the fire water pump can be turned on by pressing FIRE WATER PUMP P-1 ON pushbutton indicator on the FPCB. When the fire water pump is turned on from the FPCB, the FIRE WATER PUMP P-1 ,OFF pushbutton must be pressed to stop pump operation.

FIRE PROTECTION AND PREVENTION SYSTEM.[edit]

The fire protection and prevention system is composed of the engine spray and sound attenuation systems, which are gravity fed from the 100,000-gallons silo storage tank. When fire is sensed in the Stage I missile engine area, the system supplies water to the engine spray nozzles, which direct the water into the Stage I missile engine compartment. During Stage I missile engine firing, the system supplies 9,000 gallons of water per minute (12,000 gallons per minute at VAFB) to the sound attenuating deluge header. This water is sprayed into the launch duct by the sound attenuating deluge nozzles for attenuation of sound. At VAFB, a thrust chamber spray is activated by the missile combat crew in the event abort occurs.

DOMESTIC WATER SYSTEM.[edit]

The domestic water system distributes water to all emergency showers and eyewash fountains; to the fuel and oxidizer hardstand hose connection valves; to the depressed fuel and oxidizer hardstand hose connection valves (VAFB); to the industrial water system; and to the control center facility plumbing. (AFTER MCL3284) it is also distributed to fuel propellant storage facility.

INDUSTRIAL WATER SYSTEM.[edit]

The Industrial water system provides make-up water, under pressure, to repinish losses In the chilled water system and cooling water system, humidifying water to the launch silo heating and evaporative cooling system; diesel engine cooling water to the power generation system; and pressurizing water to the fire water system. During commercial power utilization, the industrial water system is pressurized by the domestic water system. When the launch complex is in the hardened condition, the system is pressurized by the industrial water pump.

FIRE WATER RECIRCULATION SYSTEM (After MCL 3315).[edit]

The fire water recirculation system allows reuse of the fire water (during a fuel spill only) by returning it to the hardwater storage tank through use of the sump pumps. Normal sump operation shall require the recirculation valve to be closed prior to pumping topside and reopened after the sump is empty.

FIRE WATER CONTROL SWITCH (After MCL 3316).[edit]

The Fire Water Control Switch-1 (FWCS-1) on RC-22 allows permissive control of the fire in engine, fire launch duct and explosive fuel launch duct sprays when in the MANUAL position. Then the EWCS-1 is in the AUTO position, the fire in engine, fire launch duct, and explosive fuel sprays will come on automatically as they are required.

PROPELLANT TRANSFER SYSTEM.[edit]

The propellant transfer system (PTS) consists of both fixed (launch complex) and mobile maintenance ground equipment (NGE). Functions of the PTS are to load and unload the missile tanks, purge the missile tanks and transfer lines, and to initially pressurize the missile tanks to flight pressure. Normal PTS operations are controlled from the mobile propellant control trailer. Emergency propellant unloading operations can be controlled from the P.T.S. UNLOADING CONTROL panel on the FPCB. Fuel and oxidizer are delivered to the launch complex in tank trucks and transferred from the tank trucks through portable hoses to the fuel andoxidizer holding trailers. The propellants are then conditioned and transferred to the missile tanks where they are stored. Gaseous nitrogen is delivered to the launch complex in a tube trailer and transferred through hoses to the holding trailers or facilities systems to perform purging, and pressurizing operations. The missile propellant tanks are prepared for loading by pressure testing and purging the PTS; manually connecting the vent and fill-drain disconnects to the missile; leak checking the missile tanks; purging the missile fuel tanks; and loading, adjusting, and conditioning propellants in the holding trailers.

Propellant loading is accomplished by gravity flow of the propellants from the holding trailers to the missile tanks. The fill-drain disconnects are then manually disconnected from the missile and connected to the pressure-drain disconnects, the missile tanks are pressurized with gaseous nitrogen, the vent disconnects are removed from the missile and stored on the silo wall, the propellants remaining in the facility lines are pressure drained to the holding trailer, the propellants in the holding trailers are drained to the transport trailers, and the mobile MGE is disconnected and removed from the launch complex.

Propellants are unloaded from the missile if certain airborne components are to be replaced or repaired, or if it is necessary to remove the missile from the silo. The PTS is prepared for unloading operations by connecting, inspecting, pressure testing, and purging various items of mobile and fixed equipment. Propellants are then unloaded from the missile to the holding trailers. Gaseous nitrogen from the nitrogen tube trailer is used to pressurize the missile tanks during the unloading to ensure a positive head pressure to prevent a negative tank pressure as propellant level decreases. Unloading stops when liquid sensors in the facility are uncovered after the missile tanks are empty.

Emergency unloading facilities are provided in the event fuel or oxidizer must be unloaded. This Is performed by manually connecting the vent and fill-drain disconnects to missile and operating switches on FPCB. Prior to MCL 3263, the capability exists to transfer propellants from missile to fixed dump tanks by unloading pumps. After MCL 3263, the fixed dump tanks are no longer used, and propellant must be pumped from missile to mobile tank equipment. Gaseous nitrogen from the tube trailer is used to pressurize the missile tanks during unloading to ensure a positive head pressure to unloading pumps and prevent a negative tank pressure as missile tank propellant level decreases. When mobile MGE becomes available, it is connected and propellants remaining in facility lines are pressure drained to holding trailers.

Propellant pump rooms, located on silo level 8, contain fixed equipment used for transfer of propellants. Fuel or oxidizer unloading pumps and safety relief valves are installed in pump rooms to transfer propellants from missile tanks to holding trailers during normal transfer operations. Pump room indicators give direct indications of nitrogen pressure in missile tanks during transfer of propellants. Valves contained in pump rooms are used for isolation, draining, bypassing, bleeding, and venting various parts of the system. Figures 1-13 and 1-14 illustrate equipment contained in propellant pump rooms. (After MCL 3284) Propellant transport trailer storage facilities are designed to store oxidizer fuel transport trailers when not in use. Each facility has an external equipment building which contains vapor sampling system equipment. Both fuel and oxidizer facilities are equipped with toxic analyzers and automatically controlled vent fans. Additionally, the fuel facility contains an explosive analyzer which initiates automatic corrective action (water spray) when a high explosive level (20,000 PPM) is detected. Each TITAN unit has one fuel and one oxidizer storage facility.

HYDRAULIC SYSTEMS.[edit]

HYDRAULIC POWER UNIT HS-1.[edit]

Hydraulic power unit HS-1 (figure 1-15), located on silo level 1, consists of an electric motor driven pump, related components, piping, and a hydraulic fluid reservoir. Twelve accumulators (figure 1-16) are provided to store the hydraulic power. 1-58. Hydraulic power is produced by pumping hydraulic fluid to the accumulators, which are pressurized with nitrogen gas. The accumulators retain the hydraulic power until needed for operation of the silo closure door locks, jacks, and drive unit. Controls and indicators for HS-1 are located on silo levels 1 and 3, and in the control center.

HYDRAULIC POWER UNIT HS-2.[edit]

The hydraulic power unit HS-2 (figure 1-17), located on silo level 6, consists of an electric motor driven pump, a reservoir, strainer, filter, valves, switches, and indicators. An accumulator is provided to store the hydraulic power. 1-60. Hydraulic power is produced by pumping fluid from the reservoir, with the electric motor driven pump, to the accumulator until pressure reaches 3500 50 psig. The accumulator is pressurized with nitrogen gas supplied by the nitrogen receiver, and retains hydraulic power until needed for operation of the retractable platforms and silo blast valve systems. 1-61. The retractable platform locks are operated by compressed air supplied by the air receiver. The air receiver is located adjacent to HS-2 accumulator, and receives air from the facilities air supply.

HYDRAULIC POWER UNIT HS-3.[edit]

Hydraulic power unit HS-3 (figure 1-18), located beneath the blast door control panel in the blast lock area, consists of a motor driven pump, hand pump, reservoir, filters, and valves. An accumulator is provided to store the hydraulic power. 1-63. During operation, the motor driven pump starts automatically when hydraulic pressur Idrops below 835 (±15) psig, and charges the accumulator to 1475 (±15) psig. The hand pump is used to charge the accumulator if the motor driven pump fails. Hydraulic power is stored in the accumulator until needed to operate the blast doors and the blast damper assemblies.

HYDRAULIC POWER UNIT HS-4.[edit]

Hydraulic power unit HS-4 (figure 1-19), located on level 2 of the control center, consists of a hydraulic hand pump, reservoir, accumulator, and electrical and hydraulic components housed in a metal cabinet. 1-65. The accumulator is nitrogen precharged to 500 psig and is pressurized to 1000 psig when the hand pump is operated. The hydraulic power is stored by the accumulator until needed for manual or remote operation of the control center blast valve BV-5.

HAZARD SENSING AND WARNING SYSTEM.[edit]

1-67. Hazard sensing and warning equipment is located throughout the launch complex for sensing, warning of personnel, propellant vapor level, and fires. The sensing and warning system consists of fuel vapor, oxidizer vapor, and Lire sensors; vapor detector annunciator panel; fuel and oxidizer vapor sensing racks; and associated circuitry.

FIRE SENSING EQUIPMENT.[edit]

When a fire sensor detects a temperature of approximately +140 degrees F, associated circuitry activates the applicable indicator on the LCCFC, turns on water or foam spray when automatic corrective action is provided, shuts down fans, and sounds warning horns throughout the launch complex. Fire sensing circuits are located in the control center, Stage I missile engine area, diesel engine and diesel fuel service tank areas, launch duct, and oxidizer and fuel pump rooms.

FIXED VAPOR SENSING EQUIPMENT.[edit]

(Prior to MCL 3252) Fixed vapor sensing equipment consists of an oxidizer vapor detector, a fuel vapor detector, a vapor detector annunciator panel, and associated sensing devices located throughout the silo area. The equipment detects, monitors, and records the concentration of fuel vapor and oxidizer vapor in designated areas of the silo. Vapor sensing devices initiate sounding of warning horns and automatic corrective action such as purging and turning on water spray. When a fuel vapor concentration or an oxidizer vapor concentration of 5 PPM is sensed, associated circuitry lights the applicable indicator on the LCCFC. As higher concentrations of vapor are sensed, the purge and water spray systems are activated, and applicable indicators on the LCCFC are lighted. (After MCL 3252) Fixed vapor sensing equipment consists of an oxidizer, fuel vapor detector, vapor detector annunciator panel, and associated sensing devices located throughout the silo area. The equipment is normally set to sample EF-102 exhaust (silo level 5), but other silo areas may be manually selected. The equipment detects and monitors concentration of fuel vapor and oxidizer vapor in designated areas of silo. Vapor sensing devices initiate sounding of warning horns and automatic corrective action such as purging and turning on water spray. When a fuel vapor concentration or an oxidizer vapor concentration of 5 PPM is sensed, associated circuitry lights the applicable Indicator on LCCFC. As higher concentrations of vapor are sensed, purge and water spray systems are activated, and applicable indicators on LCCFC are lighted. When SELECTOR switch is set to sample the fuel pump room or the silo equipment area, LCCFC alarm indications and automatic corrective action for explosive fuel launch duct are disabled. 1-70. when launch duct spray, engine spray, sound attenuating deluge, or fuel pump room spray Is activated, a signal is sent to the vapor sensing equipment, de-energizing the toxic sampling solenoid valves to prevent water from being drawn through the sensing lines. This Is referred to as water lockout. During water lockout the vapor detection equipment is sampling for toxic and explosive vapors on silo equipment area level 6 only, Any meter indications or light indications which occur on the VDAP or LCCFC are a result of vapors on silo equipment area level 6. The system remains in water lockout I for approximately two minutes after the sprays have been turned off, then returns to the normal sampling mode. 1-70A. (After MCL 3284) On those complexes containing propellant storage facilities, a vapor sensing sampling system provides continuous monitoring and automatic corrective action. A vapor sensing alarm panel (VSAP) is located on the side of the FPCB in the control center. A TOXIC ALARM indicator lights and a buzzer sounds when vapor concentrations in excess of TLV are detected. Automatic circuitry controls the storage facility fan and in fuel facilities only activates water spray when explosive levels (20,000 PPM) of fuel are detected.

MAINTENANCE GROUND EQUIPMENT (MGE).[edit]

1-72. MGE Is located at the squadron maintenance areas (SMA) and at launch complexes, and is used to place and maintain launch complexes in an operational condition on a scheduled or as required basis. Major items of MGE are described in the following paragraphs.

PORTABLE MAINTENANCE GROUND EQUIPMENT.[edit]

1-74. Various items of maintenance ground equipment are portable and are used above and below ground at the launch complexes. 1-75. PROTECTIVE CLOTHING. Protective clothing is utilized when personnel are required to investigate or perform operations in certain hazardous or potentially hazardous areas. Protective clothing is described in paragraph 1-262. 1-76. SAFETY NETS. Safety nets are installed over launch duct openings for personnel safety when the missile is removed and work platforms are lowered. 1-77. ENGINE ALIGNMENT KIT. The engine alignment kit is used to set the exact distance required between the booster actuators, roll nozzle actuators and sustainer actuators; and to assure required pitch, yaw, and roll control of the missile. 1-78. MISSILE POSITIONING SET. The missile positioning set is used to transport a missile to the launch complex and install both stages In the launch silo. The set consists of missile trailers, slings, lifting adapters, lines and special tools. The missile positioning set is used in conjuction with prime movers and the missile handling crane. 1-79. MAINTENANCE PLATFORMS. Maintenance platforms are installed in various missile compartments and the launch duct when needed for special maintenance functions. Maintenance platforms Include Stage I engine compartment work platforms, Stage TI engine compartment work platforms, a RV inspection ladder, and work stands. 1-80. MOBILE HYDRAULIC PUMPING UNIT. The mobile hydraulic pumping unit Is used to flush, proof pressure test, bleed, and fill missile hydraulic systems in the silo after maintenance has been performed. The pumping unit Is positioned at level 7 of the launch silo for Stage I and at level 3 of the launch silo for Stage II, and is connected to missile hydraulic disconnects by flexible hoses. 1-81. MOBILE PROPELLANT TRANSFER SYSTEM EQUIPMENT. Mobile PTS equipment Is used at the launch complex for missile propellant loading and unloading. The equipment includes transport trailers, holding trailers, a conditioning trailer, a control trailer, a tube trailer, portable oxidizer vapor burner set, portable shower and eyewash fountains, fuel and oxidizer unloading pump kit, safety relief valve kit,portable fuel and oxidizer filters, fuel and oxidizer missile tank pressurization kit, the propellant vapor scrubber system (PVSS) and the portable foam vapor suppression system (PFVSS). 1-82. A PTS structural pressure control unit provides the signal conditioning to connect the low level output of the tank pressure transducers into a 28 vdc signal that will activate the relays in RC22 to control th loading/unloading pumps. 1-83. A pressure transducer monitor system calibration box provides an accurate adjustable voltage from 0-5 vdc that simulates the tank pressure transducer output for use in calibration of the monitor unit and PTS structural pressure control unit as well as in system troubleshooting and maintenance. 1-84. MONITOR-SIMULATORS. Missile and facilities monitor-simulators are used at the launch complex to verify proper operation of the launch control set (LCS). The simulators simulate all missile and facility responses necessary to exercise the LCS in all operating modes. Simulators perform related functions and cannot be used individually. 1-85. The missile monitor-simulator simulates all necessary missile and RV static and dynamic responses required by the LCS to perform various functions. Switches are provided on the simulator for simulating all probable missile and RV system malfunctions. The simulator is positioned on level 3 work platform and connected to the electrical umbilicals by adapter cables. 1-86. The facilities monitor-simulator simulates target functions, inertial guidance system (IGS) functions, and facility functions required by the LCS to perform its various functions. Switches are provided to simulate malfunctions in the target system, the IGS, and the facility. Switcies are also provided for simulating facility hazards. The simulator is positioned on level 2 of the control center adjacent to the LCCFC, and connected to operating ground equipment (OGE) cabling by adapters. 1-87. With both simulators installed, the LCS is capable of readiness operation, launch sequence, missile verification, launch verification, and missile/launch verification.

NON-PORTABLE MAINTENANCE GROUND EQUIPMENT.[edit]

1-89. Non-portable MGE includes test equipment, cleaning equipment, maintenance tools and stands, liquid storage, and other electrical and tnechan-ical items utilized within the SMA. 1-90. OPERATING GROUND EQUIPMENT. 1-91. The 0GE, located at the launch complexes, maintains the missile in a constant state of launch readiness. Primary items comprising the 0GB are the LCS, missile systems fault locator (NFL), and the coded switch system (CSS). Other 0GE supporting the operation of the missile includes the missile guidance alignment-checkout group (MGACG), battery power supplies, 28 vdc power supplies, and communications systems. During readiness monitoring, personnel at the launch complex utilize the LCCFC to continuously perform readiness monitoring of the missile and systems directly supporting launch. The missile combat crew performs malfunction isolation utilizing the LCCFC, CMG, MFL, MGACG and power distribution control (PDC). During a tactical operation, personnel at the launch complex utilize the CSS and the LCCFC to receive alert or strike commands, confirm missile status to the wing command post (WCP), achieve a launch enabling signal, receive target information, initiate launch sequence of the missile, and monitor the missile launch. 1-92. Major items of OGE are described in the following paragraphs. Other items will be included in the paragraphs describing the missile systems.

LAUNCH CONTROL SET.[edit]

(See figure 1-20.) The function of the LCS is to monitor, display, and control signals pertaining to readiness, launch, verification, targeting, and hazard status, and to control and monitor power for the weapon system. The LCS consists of three independent sub-systems; the LCCFC, the CMG, and the PDC.

LAUNCH CONTROL COMPLEX FACILITIES CONSOLE.[edit]

The LCCFC (figure 1-21) controls and monitors readiness, facilities and launch sequence. It includes all the parts and subassemblies, other than logic, required to monitor and identify hazardous conditions which may exist. Controls are provided for the activation of damage control equipment. The LCCFC consists of a base and a two-panel mounting section. The console has two center drawers and an access door on each leg section. A communications panel, containing necessary controls and indicators for maintaining communication, is also provided. Cables enter the console through the legs to a connector panel directly behind the console panel. The desk top has a writing area with a phone dial mounted on the right-hand side, and operator's headset jacks mounted on both sides of the knee well. (After incorporation of TCTO 21M-LGM25C-728.) A propellant tank pressure monitor unit which consists of digital meter reading PSIG and a pushbutton switch for selecting various propellant tanks is mounted on top of the console panel section. After MCL 3226, a pushbutton alarm light panel is mounted on the LCCFC left arm which has indicators for an open blast door 6 or 9 and a pushbutton to enable opening of blast door 6 from the access portal area. A buzzer will sound when blast door 6 is open. The buzzer may be silenced by pressing the alarm silence pushbutton,

1-96. The console panel is divided into three sections: LAUNCH CONTROL AND MONITOR, READINESS CONTROL AND MONITOR, and FACILITIES CONTROL AND MONITOR. The LAUNCH CONTROL AND MONITOR section contains switches to lock out the system, select a target, initiate a launch, shutdown and reset. It also contains indicators to monitor the prelaunch, missile and launch verification, and launch sequence functions. The READINESS CONTROL AND MONITOR section contains operational guidance system indicators, power distribution indicators, missile status indicators, and RV indicators. The FACILITIES CONTROL AND MONITOR section contains pushbutton-indicators and indicators which monitor and control hazards and abnormal conditions which may exist throughout the launch complex. Flashing red indicators denote fire and toxic vapor hazards; the associated spray, foam, and purge indicators denote corrective action taken. Amber and red indicators indicate other hazardous or abnormal conditions which require immediate attention. The function of, and corrective action for each indicator on the LCCFC is contained in figure 5-1. LCCFC switches are of three types. Momentary switches remain on only as long as they are pressed. Push-push switches are turned on or off by pressing, then pressing again to release. The key-lock switch is covered by a switch guard and sealed for security. This seal must be broken before the switch guard is lifted for insertion of the launch key. The key is inserted in the key-lock switch, turned clockwise, held momentarily and released. Spring action returns it to off. 1-97. Indicator lights on the LCCPC are coded as follows:

- Green - go or ready.

- Red - no-go or not ready.

- White - in process or operating.

- Amber/flashing amber - caution, potential hazard, or marginal.

- Flashing red - hazard.

CONTROL-MONITOR GROUP.[edit]

The CMG (figure 1-22) monitors and controls prelaunch, launch, readiness, and verification mode signals, and monitors target and facilities signals. The single rack of the CMG-1 (LAUNCH SEQUENCE), CMG-2 (FACILITY AND TARGET SELECTION), CMG-3 (RE-ENTRY VEHICLE MONITOR), and CMG-4 (SIMULATION CONTROL AND OVERRIDE MONITOR). Cable entry is through the bottom of the rack.

1-99. The CMG-1 chassis contains the logic required to control launch. The logic structure contains circuit assemblies to perform the necessary And, Or, Inversion, Lock-Up, and Time Delay operations. Logic is performed by solid state devices or relays operating from a 28 vdc power supply.

1-100. The CMG-2 chassis contains the logic required to control target, facilities, and damage control. The logic structure contains circuit assemblies to perform the necessary And, Or, Inversion, Lock-Up, and Time Delay functions. The logic is performed by solid state devices operating from a 28 vdc power supply.

1-101. The CMG-3 chassis monitors RV status, target and burst selection, and verifies that either ground or air burst has been selected. Additionally, the CMG-3 chassis provides control for periodic pressure and continuity monitoring of the warhead and provides target burst control.

1-102. The CMG-4 chassis contains circuits required to provide manual permissive control and indication for the electrical simulation of opening the silo closure door, locking the thrust mount, and turning on the water deluge system during a launch verification. This chassis also contains th circuitry required for the override of the silo closure door. In an actua launch sequence, the CMG-4 manual permissive control is disabled by the presence of the 28 vdc ordnance-bus signal from CMG-1. CMG-4 also contain; circuitry, controls and indicators required to perform a missile ordnance circuit impedance test. The ordnance circuit impedance test will be performed prior to any IGS up-mode from off to higher modes, missile verification, launch verification, or any missile hydraulic pump run.

POWER DISTRIBUTION CONTROL.[edit]

The PDC (figures 1-23 and 1-24) contains power and logic switching circuits, interface termination provisions, power protection and distribution circuits, monitoring provisions, and checkout provisions. There are two racks in the PDC, one containing functional circuits (figure 1-23) and the other containing contactors and circuit breakers (figure 1-24). Both racks have cable entry through the bottom. Functional circuitry is divided into three panels consisting or PDC-1 (VOLTAGE MONITOR) PDC-2 (POWER SEQUENCE) and PDC-3 (CONTROL). The PDC-1 chassis contains seven solid state component boards which together perform four independent functions. The PDCpanel contains relay logic to control the power during readiness, checkout, or launch mode The logic is mounted on a single chassis composed of modules. The PDC-3 chassis contain logic driven relays, switches, and meters to monitor and control the power supplies used ir the OGE. A single module, extending across the width of the chassis, is used as a mountin for the relays. An ac-dc voltmeter and eight pushbutton-indicators are mounted on the pane so that voltages of power supply No. 1, power supply No. 2, battery power supply No. 1, battery power supply No. 2, readiness bus, transient bus, and faciltities phase A can be monitored. The STATUS AND CONTROL section provides control and monitor of power sources.

MISSILE SYSTEMS FAULT LOCATOR.[edit]

The missile systems fault locator MFL (figure 1-25) checks missile equipment in conjunction with the CMG, LCCFC, and PDC. The MFL is capable of isolating malfunctions to replaceable units in the missile, of logic level decisions, of simulating missile functions and evaluating missile outputs, and of self testing.

1-105. The MFL rack is composed of four individual, yet dependent, chassis. The MFL-1 (STIMULATOR MONITOR) chassis provides autopilot stimulus, travel position switch excitation voltage,checks valve drive amplifier output, and complete launch checkout. The MFL-1 front panel contains 34 indicators and a LAMP TEST pushbutton. The MFL-2 (CONTROL) chassis provides program control and selection for the MFL, indicates status of no-go indicators, and accomplishes critical checkout prerequisites and requisites. The front panel of the MFL-2 chassis contains a MFL status indicator; 3 mode selection pushbutton-indicators; 3 pushbutton-indicators for controlling power, program advance, and program reset; 2 component replace indicators; 25 no-go indicators; 4 spare indicators; and a LAMP TEST pushbutton. The MFL-3 (LOGIC ANALYZER) chassis verifies missile statu5 and isolates missile malfunctions to a replaceable component. The front panel of the MFLis composed of 34 system status indicators, and a LAMP TEST pushbutton. Te fourth chassis (not illustrated) contains an air cooler system to provide cool air for the other three chassis.

1-106. The MFL is functionally isolated from the LCS except when performing a checkout. When the MFL is disconnected, a launch connected signal is sent to the CMG.

1-107. The MFL is capable of operation in both the missile verification and launch verification modes. The missile verification mode checks operation of the flight control system, including the airborne hydraulic system. The launch verification mode checks the ability of the LCS to follow a normal launch sequence by checking recognition by the CMG of proper launch conditions. 1-108. Functional signals, grouped according to inputs and outputs, are displayed on the front panel of each chassis when an operation is performed on the signal. A test-timeexpired signal will be indicated if a sequence is not completed in the allotted time and a missile malfunction has not been indicated. In the event of MFL power failure, the system will return to the ready condition.

SIGNAL FLOW.[edit]

LCS signal flow during readiness monitoring is displayed by figure 1-26 and signal flow during launch sequence is displayed by figure 1-27. For detaile information regarding signal flow refer to T. 0. 21M-LGM25C-2-11.

CODED SWITCH SYSTEM (CSS).[edit]

The primary function of the CSS is to prevent an unauthorized or inadvertent missile launch. This is accomplished by locking the Stage I engine, subassembly 2 oxidizer buttérfly valve in the closed position. To unlock the butterfly valve and initiate a launch sequence, a valid operate code must he entered into the CSS, removing the launch-disable signal and providing a launch-enable signal. The status of each butterfly valve lock in the missile wing is monitored at the wing command post. The CSS (figure 1-28) consists of the following major components: a. Butterfly Valve Lock (BVL). b. Butterfly Valve Lock Control (BVLC). c. Butterfly Valve Lock Status Encoder. d. Butterfly Valve Lock Status Decoder and Display. e. Electronic Command Signals Programmer (PROGRAMMER). NOTE : VAFB does not have the BVL Status Encoder or BVL Status Decoder and Display portion of the CSS. All reference to this equipment, herein, does not apply at VAFB; however, all other portions of the CSS do apply. Refer to T. 0. 21M- LGM25C-1-1 for CSS information and equipment peculiar to VAFB only.

BUTTERFLY VALVE LOCK.[edit]

The BVL is mounted on the Stage I engine, subassembly 2 oxidizer butterfly valve. The BVL consists of an electrically driven lock on the valve diaphragm shaft, which locks the valve in the closed position until a valid operate code is entered at the BVLC. In the locked position a launch sequence cannot be initiated. The BVL also consists of code memory/code processing electronics, status monitoring electronics, a security enclosure, a secondary locking mechanism, a 36-hour timer maintenance safe capability and an internal battery power source that retains memory and operates the penetration detection and secondary locking circuits in the event readiness power is removed. 1-113. Security enclosure and secondary locking mechanism. To prevent unauthorized enabling of the system by manual means, the BVL contains two explosive charges which activate the secondary lock. Any attempt to remove the BVL cover and gain access to the primary locking mechanism will result in an explosive activated secondary lock system which locks the driving shaft of the Stage I engine, subassembly 2 oxidizer butterfly valve in the closed position. 1-114. perate attempts limitations. To eliminate an unauthorized trial-and-error method of entering operate codes to open the locking mechanism and enable s launch sequence, the BVL contains electronic circuitry that limits the number of times an operate code may be entered to seven. After the seventh attempt, the BVL circuitry will not accept any more tries. The only indication that the operate monitor counter in the BVL has been exceeded is at the WCP. 1-115. 36-hour timer. Should normal safing procedures fail, or power be removed for maintenance purposes such as ground isolation check, the 36-hour timer will render the BVL maintenance safe 36 +3 hours after power has been removed. The BV will require recoding after maintenance safe is achieved by the 36-hour method; therefore, maintenance functions requiring power removal must be kept to less than 30 hours if at all possible. Applying power to the BVL for three minutes reestablishes the full 36-hour wait time, if possible this should he done during long maintenance power downs at approximately 30 hours. Should the BVL become maintenance safe in this manner the WCP will be aware of the maintenance safe status immediately upon return of power and will notify the complex. A BVL recoth will be required.

BUTTERFLY VALVE LOCK CONTROL.[edit]

The BVLC is located in the top position of the CNG rack (figure 1-28). The BVLC contains the controls and indicators necessary to operate, test, and monitor the BVL. The BVLC also interfaces BVL status information (which is displayed in the WCP) with the Butterfly Valve Lock Status Encoder. Functions of the BVLC controls and indicators are listed in figure 1-29.

BUTTERFLY VALVE LOCK STATUS ENCODER.[edit]

The BVL status encoder is located in the ALOC and contains the necessary electronics to transmit the BVL status information to the WCP. The status word is transmitted over telephone lines. Although acknowledge-call functions are not associated with the CSS, the BVL status erzcbder circuitry provides for transmission of this information within the status word containing the CSS status information. BVL status encoder controls and indicators are shown in figure 1-28 and their functions are listed in figure 1-29.

BUTTERFLY VALVE LOCK STATUS DECODER AND DISPLAY.[edit]

The BVL status decoder and display is located in the command post control officers console at the WCP and contains the electronics necessary to decode and display the status of the CSS for each complex.

ELECTRONIC COMMAND SIGNALS PROGRAMMER.[edit]

The programmer is a portable piece of CSS equipment that does not remain connected in the system as the other components do. When an initial code or recode procedure is required the BVL must be disconnected from the system and the programmer connected directly to the BVL. The programmer transfers code words from a magnetic tape to the BVL memory. Depending upon the coding mode used the BUL is prepared for normal system operation or set up for maintenance functions. The three coding modes are:

- Initial Code Mode - Used at initial installation of the BVL or to return BVL to operational status after it has been reprogrammed for a CST or maintenance function.

- CST/Maintenance Recode Mode - Used to recode the BVL so a combined system test or maintenance procedure can be performed.

- Recode Mode - Used to enter a new set of operate and test words (new tape from SAC). In addition to entering new SAC operate codes, the recode mode must be performed if the operate monitor counter has been exceeded (more than seven operate attempts). The recode mode is also limited to seven attempts to defeat the possibility of electronic scanning to access the lock. The BVL electronics will accept seven recode tries and then it will not recognize any further attempts. Therefore, seven attempts to recode should never be used because the lock cannot be safed by a CST/Maintenance recode to access the lock and reset the recode monitor counter. The only alternative, if seven attempts are made, is to power down the system (removing missile from EWO status) and wait for the BVL 36-hour timer to time out rendering the BVL maintenance safe.

Detailed operating procedures to program the BVL are contained in T.O. 21ML425C-2-26-1 and the programmer checkout and maintenance procedures are contained in T.O. 33D9-131-13-1. 1-120. CSS circuit breaker activation order. PDC circuit breakers 21 and 22 and COffl' PER circuit breaker on the BVLC must be set to ON prior to setting LOCK POWER circuit breaker on the BVLC to ON. Should power be applied to the BVLC with the BVLC OPERATE INITIATE switch /indicator energized and LOCK POWER circuit breaker on, the operate monitor counter would count using one operate try. Therefore, it is to be verified that TEST INITIATE and OPERATE INITIATE are not lighted before setting LOCK POWER circuit breaker to ON. If neither indicator is lighted, LOCK 140WER circuit breaker can be set to ON. Circuit breakers 23 and 206 control only the STATUS ENCODER and may be turned on or off in any order without regard to the condition of CB21, CB22, CONT POWER, or LOCK POWER.

28 VDC POWER SUPPLIES.[edit]

Two 28-vdc power supplies (PS-1 and P8-2), located on level 3 of the control center, convert 480-vac, 60-cps, 3-phase facility power to 28 vdc. The 28 vdc is the main source of operating power during readiness monitoring, missile verification, launch verification, and launch sequence. The 28-vdc output is remotely controlled and monitored by the PDC, and monitored by the LCCFC.

BATTERY POWER SUPPLIES.[edit]

In the event commercial power fails, the interval between power failure and the time that the auxiliary power generator takes the load is normally less than 60 seconds. During this period, two battery power supplies (BPS-1 and BPS-2) contained on level 3 of the control center supply power (PS-1/PS-2) to 0GE readiness and transient busses. If either 28 vdc power supply fails, the applicable battery power supply will supply power to the bus normally supplied by the power supply unit that failed. The battery power supply consists of battery cells, an automatii battery charger, switching equipment, and controls. For classified Information regarding battery power supply operation, refer to T.O. 21WLGM25C-1-2. The batteries used for emergency dc power consist of nickel- cadmium cells arranged and connected in series. The cells are contained in battery trays which allow visual inspection of the cell plates fluid reservoir, and fluid level. Battery chargers, designed to operate on 480-vac, 60 cycle power, are provided to charge the batteries. The charging cycle is such that a high charging rate is used at first, then, automatically, the rate of charge lowers until the batteries are fully charged. Chargers then switch to trickle charge, automatically maintaining the batteries in a fully charged condition. Any time the charge is disconnected by a load-demand signal, removal of the signal causes the chargers to resume the charging cycle. A manual disconnect switch is provided in the dc output load of the battery power supply to isolate the battery from its respective bus for maintenance.

THRUST MOUNT AND SHOCK ISOLATION SYSTEM.[edit]

(See figure 1-30.)

THRUST MOUNT.[edit]

The thrust mount is a welded box beam ring, manufactured in two sections and bolted together, which provides attachment points for securing the missile. Four missile support arms on the lower, inside periphery of the ring provide attachment points for the four missile longerons. Four cantilevered suspension arms on the outside periphery of the ring provide for attaching the thrust mount to the dampers and ball screw jacks.

SHOCK ISOLATION SYSTEM.[edit]

The shock isolation system supports the missile on the thrust mount and provides protection against shock of nuclear blast. Subassemblies that make up the shock isolation system are vertical dampers, horizontal dampers, ball screw jacks, and suspension spring assemblies. 1-130. Four vertical dampers reduce vertical motion of the missile and thrust mount. The vertical dampers are friction type, 14 inches in diameter, 114 inches long (fully extended), and have a stroke of 30 inches. The vertical dampers are locked up by spring loaded shuttles pressed into a slot in the damper shaft. The lockup system is actuated by pneumatically retracting the lockout pins. The system is unlocked with a Stokes tool. Vertical damper length may be adjusted *2 inches to achieve proper lockup position of the damper shaft. 1-131. Four horizontal dampers reduce horizontal motion of the missile and thrust mount. Operation and configuration of the horizontal dampers is similar to that of the vertical dampers. The dampers are 8 inches in diameter, 81 inches long (fully extended), and have a stroke of 18 inches. Length of the damper shaft may be adjusted ±2 inches to assure proper lockup position of the damper shaft. 1-132. Four ball screw jacks provide for raising, lowering, and leveling of the thrust mount. The jacks are attached to the suspension spring assemblies and to the suspension arms of the thrust mount. The jacks are extended or retracted manually by turning the ball screw jack handles. The jack handles must be turned approximately 80 turns for each inch the jack is extended or retracted. A counter above the jack input shaft records and indicates the number of turns of the jack handle, 1-133. The four suspension spring assemblies attach to the wall mounted support brackets and to the top of the ball screw jacks to support the missile and thrust mount. 1-134. The THRUST MOUNT SOFT indicator on the LCCFC indicates status of the thrust mount. When the indicator is lighted, the thrust mount is locked and in the soft condition. When the indicator is not lighted, the thrust mount is not locked and is capable of withstanding the effects of nuclear blast. During the launch sequence, the thrust mount is locked automatically by the lock-thrust-mount signal from CMG-l. When the thrust mount is locked, a thrust-mount-locked signal is received by CMG-1 and the THRUST MOUNT LOCKED indicator is lighted. Automatic capability for unlocking the thrust mount is not provided. THRUST MOUNT SOFT and THRUST MOUNT LOCKED indicators also light when locking is simulated by CMG-4.

INERTIAL GUIDANCE SYSTEM.[edit]

IGS OGE consists of the MGACG. This component, and the two components of the missile guidance set, the IMU and NGC, comprise the IGS. Figure 1-31 contains a functional diagram of IGS OGE.

MISSILE GUIDANCE ALIGNMENT-CHECKOUT GROUP.[edit]

The MGACG (figure 1-32) located on level 2 of the control center, is a three-and-one-half bay structure containing seven equipment drawers and a cable distribution cabinet. Equipment bays 2 and 3 have electrical equipment air coolers.

The MGACG controls tape loading and mode sequencing operations required to prepare the missile guidance set for flight. IMU coefficients and targeting information for three possible targets are read from punched tapes by the MCACG, recorded in the memory of the MGC and verified by the MGACG. The NGACC controls the sequencing of the IGS from the off mode, through the align and the ready mode. Remote commands can also be issued to the MGACG through the CMG by the LCCFC.Vertical and azimuth alignment of the platform is accomplished during the align and ready modes without an external azimuth reference. The ready mode is the normal operating condition of the IGS.

During all modes of operation, the system checks itself for any malfunction. These test modes check for alignment loop malfunction, calibrate the missile guidance set by calculating and recording changed IMU coefficients, and check the flight program and steering signal functions of the MGC. If a malfunction occurs, indicators on the MGACG show the system status and the area of malfunction. The MGACG provides remote indications of system status to the LCS. The system then issues remote commands to the IGS through the MGACG to select one of the three possible targets and to advance the IGS to the ready mode or through the launch sequence modes. The IGS must be in the ready or memory mode before the LCS can initiate a launch sequence. During the launch sequence, remote commands cause the IGS to reverify target selection and to advance from the ready mode through the memory mode, the countdown steering test mode, and the inertial mode. In the inertial mode, the INU platform is no longer earth-referenced and the flight program of the MGC is initiated.

ELECTRONIC EQUIPMENT AIR COOLERS[edit]

(figure 1-33) provide a flow to cooling air over the electronic equipment in the alignment-checkout group only when the control center air conditioning system experiences a failur. The normal mode of operation of the air coolers is to set the FRONT and REAR circuit breakers to the OFF position. I The SIGNAL DATA RECORDER (figure 1-34) punches coded information from the MGC onto tape to record operating conditions within the IGS. The GUIDANCE CONTROL INDICATOR (figure 1-36) controls target and IMU tapes loading and verification, provides manual and remote sequencing of IGS modes and test, and contains provisions for self-checking of its circuitry and indicators. The GCI also performs malfunction isolation and receives malfunction isolation information from the IGS.

The PUNCHED TAPE READER (figure 1-37) reads the target and IMU tapes at 40 characters per second and supplies digital information to the MGC through the GCI. A TAPE READER malfunction will be indicated by the GCI if the tape breaks or if the tape is not threaded properly when the punched tape reader is operated in the SPOOL mode.

COMMUNICATION SYSTEMS.[edit]

The communications systems provide a means for communicating between the Strategic Air Command (SAC), numbered Air Force (NAF), the WCP, ACPs and launch complexes and for communicating within launch complexes. The five major areas of the communications system are as follows:

- Intra-complex communications (direct lines, wire-type maintenance network (WTNN), radio-type maintenance network (RTMN), television monitor, and voice signaling system (VSS)).

- Inter-complex communications (direct lines, dial lines, and inter. complex radio communications system).

- External communications (primary alerting system (PAS), 465L equipment, 487L SLFC system, hf radio, and uhf radio).

- Antenna systems (RTMN, inter-complex radio communication system, hf discage, hf hard, and uhf).

- Power distribution.

The following paragraphs provide information on the five major communications systems with emphasis on crew understanding of operating characteristics and interpretation of malfunction or alert light indications, to enable the crew to determine the effects of trouble on the communications and launch capability.

INTRA-COMPLEX COMMUNICATIONS SYSTEM.[edit]

The intra-complex communications system provides communication within the launch complex. Intra-complex circuits include direct lines, a WTMN, an RTMN, and a TV monitor. Section III and T.O. 21M-LGM25C-2-18 (T.O. 21M-LGM25C-2-17 atVAFB) contain operating and checkout procedures and a detailed description of components.

DIRECT LINES.[edit]

Direct lines consist of a surface gate phone, portal phones, and an emergency reporting network. These phones provide direct signaling to the LCCFC and alternate launch officer's console (ALOC). Access to the phone Is from the LCCFC and ALOC by pressing the appropriate pushbutton-indicator on the communications panel. The emergency phones are located in the cableway areas, the decontamination area, and the blast locks. The emergency network enables personnel trapped in tunnels or between blast locks to call the LCCFC or ALOC to report hazardous conditions or damage. It also provides one-way signaling between the station telephones and the consoles. A call is made on all direct line phones by lifting the phone handset. This automatically causes a 60 impulse-per-minute flashing Indication at the LCCFC and ALOC, and activates a ringer at each console. For emergency network calls, the light flashes red at 120 impulses-per-minute. All wire lines and RTMN calls are automatically placed on hold when the emergency network is accessed at the LCCFC or ALOC. If a second emergency reporting network call is received, the EMERG NET pushbutton-indicator flashes red on a steady white background. The console operator cannot place an emergency network call on hold. If more than one call is received, the MCCC may speak to each by sequencing through the calls with the EMERG NET pushbutton-indicator. The direct line telephone instruments are standard commercial units, and are either wall or pedestal mounted in a waterproof cabinet. The gate and portal phones contain ringers, but are without dials. The emergency network phones have no dials or ringers.

WIRE-TYPE MAINTENANCE NETWORK.[edit]