large cylinder. This cylinder, which has a high surface speed,

carries part of the fibre towards the workers and strippers; the

surface speed of the workers being much slower than that of the

cylinder. The pins in the two rollers oppose each other, those of

the workers being “back-set,” and this arrangement, combined

with the relative angle of the pins, and the difference in the surface

speeds of the two rollers, results in part of the fibre being broken and

carried round by the worker towards the stripper. This, as its

name implies, strips the fibre off the worker, and carries it round to

the cylinder. The pins of the stripper and cylinder point in the

same direction, but since the surface speed of the cylinder is much

greater than the surface speed of the stripper, it follows that the

fibre is combed between the two, and that part is carried forward

by the cylinder to be reworked. The strippers and workers are in

pairs, of which there may be two or more. After passing the last

pair of workers and strippers the fibre is carried forward towards the

doffing roller, the pins of which are back-set, and the fibre is removed

from the cylinder by the doffer, from which it passes between the

drawing and pressing rollers into the conductor, and finally between

the delivery and pressing rollers into the sliver can. It may be

mentioned that more or less breaking takes place between each pair

of rollers, the pins of which are opposed, and that combing and

drawing out obtains between those rollers with pins pointing in

the same direction. The ratio of the surface speeds of the drawing

roller and the feed roller is termed the draft:—

| surface speed of drawing roller | = draft. |

| surface speed of feed roller |

In this machine the draft is usually about thirteen.

|

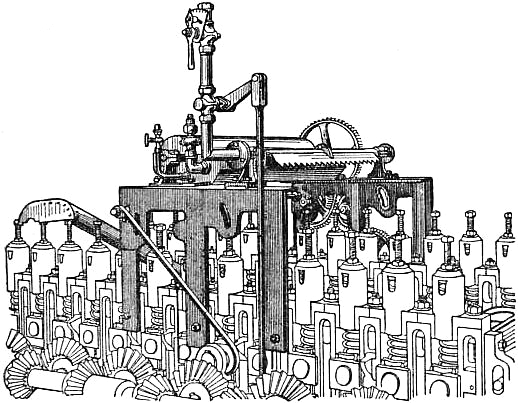

| Fig. 5.—Improved Batching Gear. |

The sliver from the can of the breaker card may be wound into balls, or it may be taken direct to the finisher card. In the latter method from eight to fifteen cans are placed behind the feed rollers, and all the slivers from these cans are united before they emerge from the machine. The main difference between a breaker card and a finisher card is that the latter is fitted with finer pins, that it contains two doffing rollers, and that it usually possesses a greater number of pairs of workers and strippers—a full circular finisher card having four sets.

After the fibre has been thoroughly carded by the above machines, the cans containing the sliver from the finisher card are taken to the first drawing frame. A very common method is to let four slivers run into one sliver at the first drawing, then two slivers from the first drawing are run into one sliver at the second drawing frame. There are several types of drawing frames, e.g. push-bar or slide, rotary, spiral, ring, open-link or chain, the spiral being generally used for the second drawing. All, however, perform the same function, viz., combing out the fibres and thus laying them parallel, and in addition drawing out the sliver. The designation of the machine indicates the particular method in which the gill pins are moved. These pins are much finer than those of the breaker and finisher cards, consequently the fibres are more thoroughly separated. The draft in the first drawing varies from three to five, while that in the second drawing is usually five to seven. It is easy to see that a certain amount of draft, or drawing out of the sliver, is necessary, otherwise the various doublings would cause the sliver to emerge thicker and thicker from each machine. The doublings play a very important part in the appearance of the ultimate rove and yarn, for the chief reason for doubling threads or slivers is to minimize irregularities of thickness and of colour in the material. In an ordinary case, the total doublings in jute from the breaker card to the end of the second drawing is ninety-six: 12 × 4 × 2 = 96; and if the slivers were made thinner and more of them used the ultimate result would naturally be improved.

The final preparing process is that of roving. In this operation there is no doubling of the slivers, but each sliver passes separately through the machine, from the can to the spindle, is drawn out to about eight times its length, and receives a small amount of twist to strengthen it, in order that it may be successfully wound upon the roving bobbin by the flyer. The chief piece of mechanism in the roving frame is the gearing known as the “differential motion.” It works in conjunction with the disk and scroll, the cones, or the expanding pulley, to impart an intermittingly variable speed to the bobbin (each layer of the bobbin has its own particular speed which is constant for the full traverse, but each change of direction of the builder is accompanied by a quick change of speed to the bobbin). It is essential that the bobbin should have such a motion, because the delivery of the sliver and the speed of the flyer are constant for a given size of rove, whereas the layers of rove on the bobbin increase in length as the bobbin fills. In the jute roving frame the bobbin is termed the “follower,” because its revolutions per minute are fewer than those of the flyer. Each layer of rove increases the diameter of the material on the bobbin shank; hence, at the beginning of each layer, the speed of the bobbin must be increased, and kept at this increased speed for the whole traverse from top to bottom or vice versa.

Let R = the revolutions per second of the flyer; |

In the above expression R, π and L are constant, therefore as d increases the term (R − r) must decrease; this can happen only when r is increased, that is, when the bobbin revolves quicker. It is easy to see from the above expression that if the bobbin were the “leader” its speed would have to decrease as it filled.

The builder, which receives its motion from the disk and scroll, from the cones, or from the expanding pulley, has also an intermittingly variable speed. It begins at a maximum speed when the bobbin is empty, is constant for each layer, but decreases as the bobbin fills.

The rove yarn is now ready for the spinning frame, where a further draft of about eight is given. The principles of jute spinning are similar to those of dry spinning for flax. For very heavy jute yarns the spinning frame is not used—the desired amount of twist being given at the roving frame.

The count of jute yarn is based upon the weight in pounds of 14,400 yds., such length receiving the name of “spyndle.” The finest yarns weigh 234 ℔ to 3 ℔ per spyndle, but the commonest kinds are 7 ℔, 8 ℔, 9 ℔ and 10 ℔ per spyndle. The sizes rise in pounds up to about 20 ℔, then by 2 ℔ up to about 50 ℔ per spyndle, with much larger jumps above this weight. It is not uncommon to find 200 ℔ to 300 ℔ rove yarn, while the weight occasionally reaches 450 ℔ per spyndle. The different sizes of yarn are extensively used in a large variety of fabrics, sometimes alone, sometimes in conjunction with other fibres, e.g. with worsted in the various kinds of carpets, with cotton in tapestries and household cloths, with line and tow yarns for the same fabrics and for paddings, &c., and with wool for horse clothing. The yarns are capable of being dyed brilliant colours, but, unfortunately, the colours are not very fast to light. The fibre can also be prepared to imitate human hair with remarkable closeness, and advantage of this is largely taken in making stage wigs.

For detailed information regarding jute, the cloths made from it and the machinery used, see the following works: Watts’s Dictionary of the Economic Products of India; Royle’s Fibrous Plants of India; Sharp’s Flax, Tow and Jute Spinning; Leggatt’s Jute Spinning; Woodhouse and Milne’s Jute and Linen Weaving; and Woodhouse and Milne’s Textile Design: Pure and Applied. (T. Wo.)

JÜTERBOG, or Güterbog, a town of Germany in the Prussian

province of Brandenburg, on the Nuthe, 39 m. S.W. of Berlin,

at the junction of the main lines of railway from Berlin to Dresden

and Leipzig. Pop. (1900), 7407. The town is surrounded by

a medieval wall, with three gateways, and contains two Protestant

churches, of which that of St Nicholas (14th century) is

remarkable for its three fine aisles. There are also a Roman

Catholic church, an old town-hall and a modern school. Jüterbog

carries on weaving and spinning both of flax and wool, and

trades in the produce of those manufactures and in cattle.

Vines are cultivated in the neighbourhood. Jüterbog belonged

in the later middle ages to the archbishopric of Magdeburg,

passing to electoral Saxony in 1648, and to Prussia in 1815. It

was here that a treaty over the succession to the duchy of Jülich

was made in March 1611 between Saxony and Brandenburg,

and here in November 1644 the Swedes defeated the Imperialists.

Two miles S.W. of the town is the battlefield of Dennewitz

where the Prussians defeated the French on the 6th of September

1813.