in the dense moist forests of the basin of the Rio San Juan, where

the rain falls for nine months in the year. It prefers rich fertile

soil on the banks of watercourses,

but does not flourish in swamps. It

is found also in Costa Rica, Guatemala,

Honduras, Mexico, Cuba and

Hayti, and in Panama with another

species of Castilloa, and on the W.

coast of S. America down to the slopes

of Chimborazo; the Cordilleras of

the Andes separating the Castilloas

from the Heveas of Brazil.

In Nicaragua the latex is collected in April, when the old leaves begin to fall and the new ones are appearing, during which time the latex is richest. The tree is tapped either in the same manner as the Hevea, or by encircling the tree with a simple spiral cut at an inclination of 45°, or by two parallel spirals if the tree be large. At the bottom of the spiral an iron spout about 4 in. long is driven into the tree, and the milk is received in iron pails. A tree 20 to 30 ft. high to its first branches, and about 4 ft. in diameter, is expected to yield annually 20 gallons of milk, each gallon giving about 2 ℔ of rubber. In the evening the milk is strained through a wire sieve and transferred to barrels. The milk, which is acid, is coagulated by the addition of the alkaline juice of the “achete” plant, or of another plant called “coasso.” The strained Juice of either of these plants, obtained by bruising the moistened herb and subsequent expression, is added to the milk in the proportion of about 1 pint to the gallon. In British Honduras an alkaline decoction prepared from the Moon plant (Calonictyon speciosum) is used for the same purpose. If these plants are not procurable, two parts of water are added to one of the milk, and the mixture allowed to stand for twelve hours. The coagulum is next flattened out by a wooden or iron roller to get rid of the cavities containing watery liquid, and the sheets are then hung up for fourteen days to dry, when they weigh about 2 ℔, the sheets being usually 12 to 18 in. thick and 20 in. in diameter. When coagulated in water, the mass is placed in vats in the ground and allowed to dry, this taking place in about a fortnight. It is then rolled into balls. That which dries on the incisions in the tree is called “bola” or “burucha,” and is said to be highly prized in New York. The loss of Nicaragua rubber in drying is estimated at 15%. It is exported chiefly from San Juan del Norte, or Grey Town, and the larger proportion goes to the United States. The Castilloa tree appears to be suitable for cultivation only in districts where the Para rubber would grow equally well. The tree is ready for tapping at about the same age as Hevea and the average yield of rubber is about the same. Since the latex “creams” readily the rubber can be separated from the latex by centrifugalizing, and its quality and market value thus enhanced. Much of the native Castilloa rubber is of inferior quality. The tree has been introduced into S. India, Ceylon and the W. Indies, where it has succeeded well, especially in Trinidad and Tobago. It is also under trial in E. and W. Africa and Nyasaland. Several other species of Castilloa than C. elastica are known to furnish rubber, but little has been recorded as to their advantages.

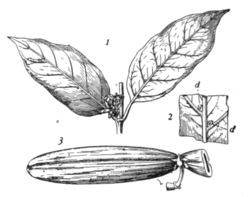

4. Funtumia elastica (formerly known as Kickxia or Kixia elastica) is the W. African (Ire or Irai or Lagos) rubber tree, which belongs to the Apocynaceae, a natural order which includes the Landolphia vines as well as other rubber producers. It is a large forest tree of upright habit extending to 60 or 70 ft. in height and 3 to 4 ft. in diameter. The bright green, glabrous leaves are broad and oblong, about 6 in. in length (see fig. 5). The flowers are yellow, and the seeds enclosed in a pod are long and thin with numerous long silky fibres attached to them, which enable the seeds to be readily carried by the wind. The trees are common throughout the central regions of E. and W. Africa (from Uganda to Sierra Leone). The botanical name is taken from a W. African native name for a rubber tree—“Funtum.”

Many of the trees in the accessible forests of W. Africa have been destroyed by over-tapping and felling. Plantations of Funlumia have been established in several districts, including the Gold Coast and S. Nigeria. The trees are tapped on the “herring-bone” plan and the milk collected in vessels at the base. This is then poured into the hollowed-out trunk of a tree, where it is allowed to stand covered with palm leaves for about a fortnight. The watery portion of the latex soaks into the trunk, and the soft spongy rubber which remains is kneaded and pressed into lumps or balls.

Fig. 4.—Castilloa elastica. 1, leaf; 2, twig with male flowers; 3, twig with female flowers; 4, seed; 4, nat. size.

In some districts the collected milk is heated alone or diluted with water, to coagulate the rubber, but if heated alone an inferior rubber is apt to result owing to overheating.

Fig. 5.—Funtumia elastica (Lagos rubber). 1, twig with flowers; 2, part of under side of leaf showing somatia at d d (about nat. size); 3, fruit (about 13 nat. size).

The Funtumia latex can also be coagulated by the astringent infusion of Bauhinia leaves or by exposing it in shallow dishes, when the liquid “creams.” The yield of rubber is stated as a rule to be less than that of Para. The rubber, if properly prepared, is of excellent quality, and the tree deserves further attention, especially in those regions of W. Africa which are unsuited to Hevea.

Funtumia africana furnishes a very inferior rubber, which is highly resinous.

5. Ficus elastica is the tree which produces Rambong or Assam rubber. It is well known in Europe as a small ornamental tree, but in the tropics it attains very large dimensions, and develops a system of branching roots which act as buttresses to the large trunk (see fig. 6). It is a native of India, Burma and the Malay Archipelago and is most abundant, in those regions in which the climate is distinctly humid, and subject to this condition the tree flourishes at high altitudes. In Assam and in upper Burma there are extensive forests of Ficus elastica, but to a large extent the trees have been damaged by careless tapping. Large plantations have been formed by the Government of India both in Assam and Bengal, but most of the rubber exported is still obtained from the forest trees.

Fig. 6.—Ficus elastica. 1, twig; 2, section of inflorescence.

It has been found that although the tree grows well in many different countries and different localities, it only furnishes a satisfactory yield of rubber in mountainous districts, such as those of Assam and certain parts of Ceylon and Java. The trees. are tapped when about ten years old, and as a rule annually furnish from 5–10 ℔ of rubber per tree. The latex flows fairly well, but is usually allowed to dry on the tree.

The rubber, if of good quality, sells at prices only slightly inferior to that of Para. When the plantations of Ficus in India are in full bearing it is possible that this tree may attract more attention, since the plantation rubber is likely to be of superior quality owing to the greater care taken in its preparation. It seems at present doubtful, however, whether the establishment of plantations of Ficus will be profitable under ordinary conditions in India.

In addition to the trees described above there are numerous plants of some importance as rubber producers. Among these may be mentioned the Landolphia vines, which are still the chief source of African rubber. The vines grow upon forest trees, and the stems are periodically tapped. There are numerous species of these climbing plants, of which the most important as furnishing good rubber are Landolphia owariensis (see fig. 7), which occurs throughout