Popular Science Monthly

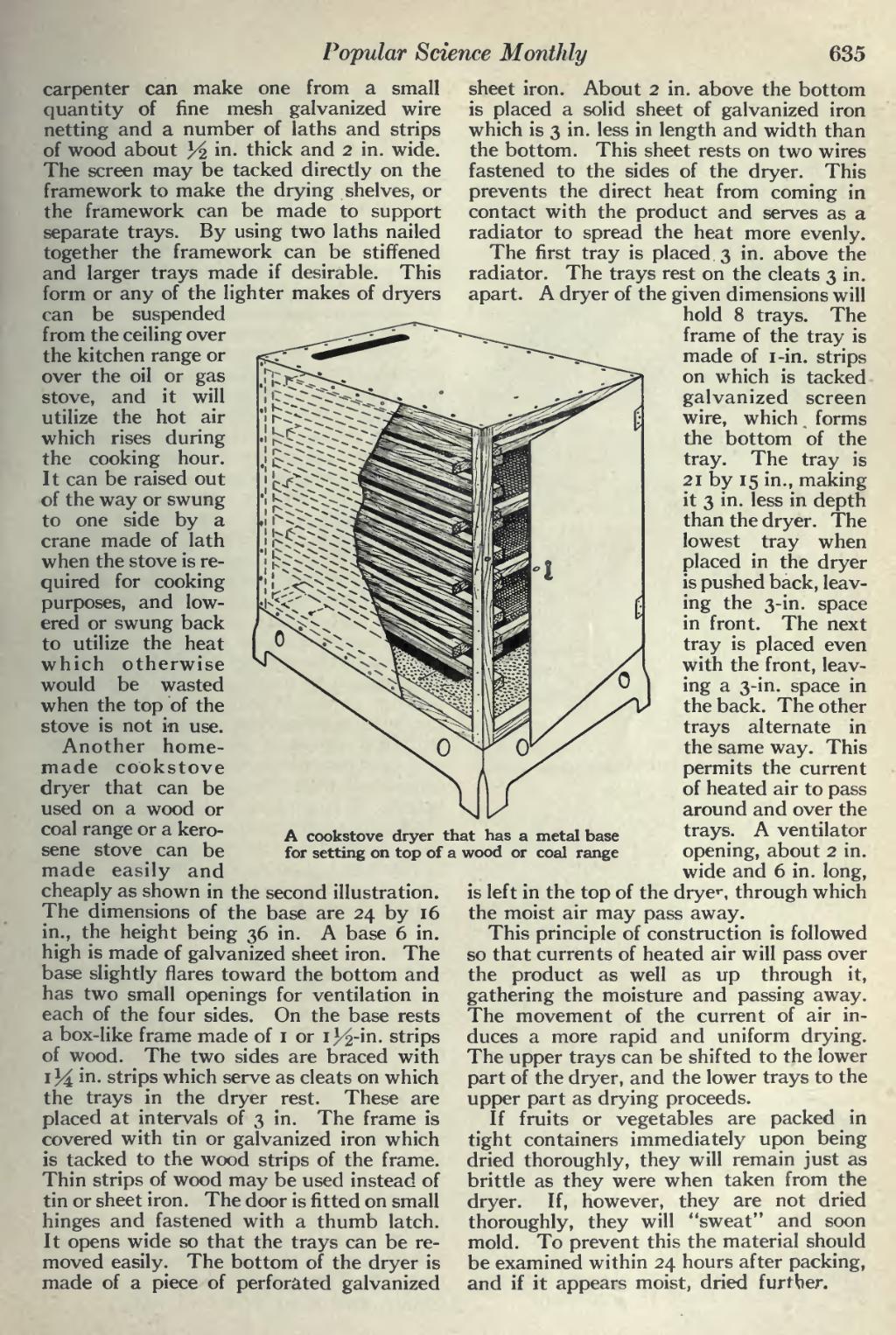

��carpenter can make one from a small quantity of fine mesh galvanized wire netting and a number of laths and strips of wood about }/$, in. thick and 2 in. wide. The screen may be tacked directly on the framework to make the drying shelves, or the framework can be made to support separate trays. By using two laths nailed together the framework can be stiffened and larger trays made if desirable. This form or any of the lighter makes of dryers can be suspended from the ceiling over the kitchen range or over the oil or gas stove, and it will utilize the hot air which rises during the cooking hour. It can be raised out of the way or swung to one side by a crane made of lath when the stove is re- quired for cooking purposes, and low- ered or swung back to utilize the heat which otherwise would be wasted when the top of the stove is not in use. Another home- made cookstove dryer that can be used on a wood or coal range or a kero- sene stove can be made easily and cheaply as shown in the second illustration. The dimensions of the base are 24 by 16 in., the height being 36 in. A base 6 in. high is made of galvanized sheet iron. The base slightly flares toward the bottom and has two small openings for ventilation in each of the four sides. On the base rests a box-like frame made of 1 or 13^-in. strips of wood. The two sides are braced with iJ4 in. strips which serve as cleats on which the trays in the dryer rest. These are placed at intervals of 3 in. The frame is covered with tin or galvanized iron which is tacked to the wood strips of the frame. Thin strips of wood may be used instead of tin or sheet iron. The door is fitted on small hinges and fastened with a thumb latch. It opens wide so that the trays can be re- moved easily. The bottom of the dryer is made of a piece of perforated galvanized

���A cookstove dryer that has a metal base for setting on top of a wood or coal range

��635

sheet iron. About 2 in. above the bottom is placed a solid sheet of galvanized iron which is 3 in. less in length and width than the bottom. This sheet rests on two wires fastened to the sides of the dryer. This prevents the direct heat from coming in contact with the product and serves as a radiator to spread the heat more evenly. The first tray is placed. 3 in. above the radiator. The trays rest on the cleats 3 in. apart. A dryer of the given dimensions will hold 8 trays. The frame of the tray is made of i-in. strips on which is tacked galvanized screen wire, which, forms the bottom of the tray. The tray is 21 by 15 in., making it 3 in. less in depth than the dryer. The lowest tray when placed in the dryer is pushed back, leav- ing the 3-in. space in front. The next tray is placed even with the front, leav- ing a 3-in. space in the back. The other trays alternate in the same way. This permits the current of heated air to pass around and over the trays. A ventilator opening, about 2 in. wide and 6 in. long, is left in the top of the drye r , through which the moist air may pass away.

This principle of construction is followed so that currents of heated air will pass over the product as well as up through it, gathering the moisture and passing away. The movement of the current of air in- duces a more rapid and uniform drying. The upper trays can be shifted to the lower part of the dryer, and the lower trays to the upper part as drying proceeds.

If fruits or vegetables are packed in tight containers immediately upon being dried thoroughly, they will remain just as brittle as they were when taken from the dryer. If, however, they are not dried thoroughly, they will "sweat" and soon mold. To prevent this the material should be examined within 24 hours after packing, and if it appears moist, dried further.

�� �