STATUTORY COLOURS

23.17 The colours white and yellow are prescribed for road marking materials. Black material may also be used to mask existing markings, where these need to be temporarily obscured during road works (see para 23.13).

23.18 The standard colour for yellow markings is BS 381C No.355 (lemon); No.309 (canary) is also acceptable. In environmentally sensitive areas, yellow markings to No.310 (primrose) or No.353 (deep cream) may be preferred. Special authorisation is not necessary for any of these shades. Different shades should not be used on adjacent lines, as in certain conditions the lighter colour may appear white when seen in direct comparison with the standard yellow.

APPLICATION OF MARKINGS

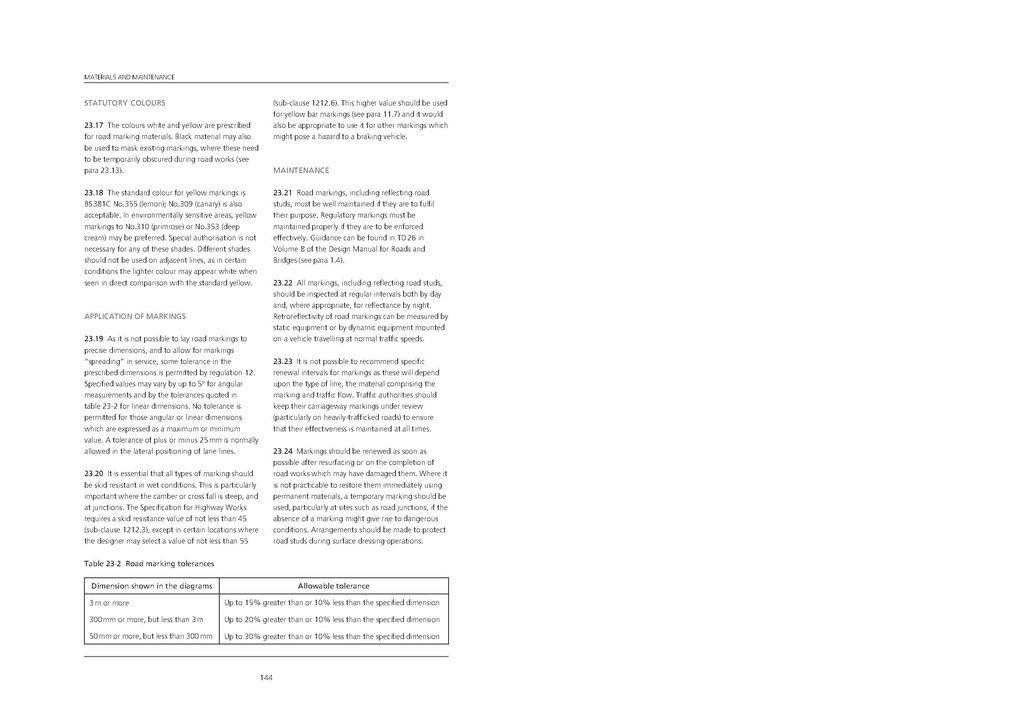

23.19 As it is not possible to lay road markings to precise dimensions, and to allow for markings "spreading" in service, some tolerance in the prescribed dimensions is permitted by regulation 12. Specified values may vary by up to 5º for angular measurements and by the tolerances quoted in table 23-2 for linear dimensions. No tolerance is permitted for those angular or linear dimensions which are expressed as a maximum or minimum value. A tolerance of plus or minus 25 mm is normally allowed in the lateral positioning of lane lines.

23.20 It is essential that all types of marking should be skid resistant in wet conditions. This is particularly important where the camber or cross fall is steep, and at junctions. The Specification for Highway Works requires a skid resistance value of not less than 45 (sub-clause 1212.3), except in certain locations where the designer may select a value of not less than 55 (sub-clause 1212.6). This higher value should be used for yellow bar markings (see para 11.7) and it would also be appropriate to use it for other markings which might pose a hazard to a braking vehicle.

MAINTENANCE

23.21 Road markings, including reflecting road studs, must be well maintained if they are to fulfil their purpose. Regulatory markings must be maintained properly if they are to be enforced effectively. Guidance can be found in TD 26 in Volume 8 of the Design Manual for Roads and Bridges (see para 1.4).

23.22 All markings, including reflecting road studs, should be inspected at regular intervals both by day and, where appropriate, for reflectance by night. Retroreflectivity of road markings can be measured by static equipment or by dynamic equipment mounted on a vehicle travelling at normal traffic speeds.

23.23 It is not possible to recommend specific renewal intervals for markings as these will depend upon the type of line, the material comprising the marking and traffic flow. Traffic authorities should keep their carriageway markings under review (particularly on heavily-trafficked roads) to ensure that their effectiveness is maintained at all times.

23.24 Markings should be renewed as soon as possible after resurfacing or on the completion of road works which may have damaged them. Where it is not practicable to restore them immediately using permanent materials, a temporary marking should be used, particularly at sites such as road junctions, if the absence of a marking might give rise to dangerous conditions. Arrangements should be made to protect road studs during surface dressing operations.

| Dimension shown in the diagrams | Allowable tolerance |

|---|---|

| 3 m or more | Up to 30% greater than or 10% less than the specified dimension |

| 300 mm or more, but less than 3 m | Up to 20% greater than or 10% less than the specified dimension |

| 50 mm or more, but less than 300 mm | Up to 15% greater than or 10% less than the specified dimension |

144