Practical Treatise on Milling and Milling Machines/Chapter 7

CHAPTER VII

General Notes on Milling, together with Typical Milling Operations

Milling, as we have already explained, is a process that cannot be governed by any fixed set of rules, but there are a few general instruc- tions which, if carefully followed, will enable the machine to be more efficiently operated and largely influence the success that is attained. These we have collected in this chapter, ana, in addition, show illustrations of a number of common milling operations to give an idea of how various and widely different jobs can be set up.

GENERAL NOTES ON MILLING

Pickling Castings and Forgings. Due to the rapid cooling or chilling of the outside of castings and forgings, a tough, hard skin, or scale forms, that is very destructive to the cutting edges of the teeth of milling cutters. There is also considerable of the moulding sand left on castings, and this is likewise harmful to the cutting edges. The sand can be removed and scale softened to some degree by the process of pickling, and it is essential that this be done preparatory to milling. Castings are usually pickled in the foundry, but it is well to make sure that this has been done before attempting to mill them. It is also an advantage in some cases to have castings rattled after being pickled. Where they are small, and are to be finished rapidly, they should be annealed.

For pickling castings, a solution of oil of vitriol, or sulphuric acid, reduced with water to a specific gravity of 25° (Beaume hydrometer) is recommended. The castings should be stacked on a bench over a vat containing the solution, and the solution poured over them.

Castings should never be immersed in the pickling bath if they are to be painted, because the iron is more or less porous, and the acid that is absorbed in pickling will work out after the pieces are finished, causing the paint to flake off. Furthermore, the pickle works better when it is poured over the castings and then allowed to dry off before another application of the solution. The time required for the process is usually about a day, and the solution should be poured over the castings from four to five times.

Forgings may be pickled by immersing in a solution of sulphuric acid and water of 30° specific gravity (Beaume hydrometer) for a period of from 3 to 12 hours, according to hardness of scale.

When either castings or forgings are pickled, they should be thoroughly washed off with hot water, as this will wash out sand and remove the acid better than cold water. The water may be conveniently heated for this purpose by injecting steam into the cold water pipe.

Cutter Close to End of Spindle. In all milling operations, especially the heavier ones, care should be taken to have milling cutters as near the nose of the spindle as practicable. This will reduce to a minimum any possible vibration and spring of the arbor. It also brings the table close to the face of the column and ensures additional rigidity. Other valuable points about cutters have been taken up in Chapter VI, and it may be well to review these previous to starting to operate a machine.

Fastening Cutter on Arbor. See that the ends of the collars and washers are clean, for particles of dirt or chips between them will cause the arbor to be sprung when the nut is tightened. Small cutters can be held securely by the mere clamping effect of the collars on each side when the nut is tightened, but medium and large cutters should always be keyed to the arbor to prevent slipping.

Manner of Driving and Supporting Arbors. Milling machine arbors are driven in several different ways, some of which are shown in Fig. 58. In A, the arbor has a tenon at the small end of the taper that fits a slot at the end of the taper hole in spindle, thus giving a positive drive. The method of driving arbors B and C is similar to that of driving face milling cutters, described on page 98. The arbor is provided with a clutch, and has threaded hole in end of shank; the clutch fits into recess in end of spindle, and the arbor is drawn into place and held securely by the drawing-in bolt, (see Fig. 58.) The method of driving collets is the same as that of arbors.

All milling machines are equipped with some support for the outer end of the cutter arbor. The adjustable centre shown at A is one form that is used for lighter classes, or work where an arbor with a flat tenon is employed. The centre serves to support the outer end of the arbor and helps to keep the flat tenon in place in the slot in the spindle. Another form of support is shown at B. This support is a bronze bushing mounted in the arm that extends down from the overhanging arm, and is used where an arbor with clutch drive is employed. An example of the use of arm braces that extend from the knee to the overhanging arm and carry the bronze bushing for the outer end of the arbor is shown at C. These braces firmly tie the knee and overhanging arm together, and give a stiff support for the arbor. They should be used whenever the character of the work is heavy. This illustration also shows the use of an arbor yoke for stiffening the arbor between the cutters. This yoke should be used to bring a bearing either between or as near to the cutters as possible.

Before tightening or loosening the arbor nut, when putting on or removing cutters, be sure the arbor support is in position, so that a bearing is provided near the nut, otherwise the arbor is liable to spring.

Clamping Work. An operator should pay particular attention to clamping work on a milling machine, for the success of milling is more dependent on this than on would realize at first thought. It is an easy matter to place clamps on some work in such positions that the piece is sprung, consequently when the clamps are loosened and the piece resumes its natural shape, the milled surface is found inaccurate. Again, faulty clamping results in work becoming loosened during operation, and not only impairs the accuracy of the piece, but many times damages the cutters and machine. It is very essential, therefore, that work be clamped solidly, but in such a manner that it is not sprung.An assortment of clamps or straps, together with jacks, a shim, step block and clamping bolt, are shown on the opposite page. These accessories form an important part of the equipment of a milling machine, and are needed where a variety of work is done. Several sets of each style of strap, and different sizes of step blocks and clamping bolts should always be at hand for use on work of varied shapes.

Whenever clamping a piece to the table, the straps should be placed squarely across, so as to have a full bearing at each end and, if possible, at points where the work extends down to the table beneath the strap. If it is necessary to place a strap over an overhanging part, such as on the piece of work shown on the next page, some support should be put between the overhanging part and the table, otherwise this part is liable to be sprung or broken off.

Another point in connection with clamping such work is the position of the clamping bolt. It should always be placed as near the work as the slot in the strap or other conditions will permit, for in this position it will exert the greatest pressure on the work and will not require setting up so tightly.

When milling work held in a jig or fixture, it is advisable to have the thrust of the cutter taken against the solid support, not against the removable member, for in this case there is more tendency toward vibrations that might loosen the clamping nuts.

When duplicate pieces are milled, using a fixture, care should be taken to clean the bearing points each time before putting

a new piece of work in place. A narrow, stiff hair-bristle brush is good for this purpose when milling cast iron, but one with wire bristles is better for cleaning out steel or wrought iron chips. It is well to clamp a piece lightly, then tamp it down at all bearing points with a hammer; after which it can be solidly fastened.

Aside from these few general instructions on placing and clamping work, little can be said, because the shape of a piece of work alone determines how it may be best fastened. But a study of the methods of clamping shown in the examples of work in this and succeeding chapters will be of great value to the reader.

Setting Vise. Light work is usually held in a vise, as it is more convenient than any other method of fastening it to the table. To set a vise with plain base so that its jaws are parallel to the spindle, place an arbor in the spindle and then bring the vise jaws up to the arbor. (See Fig. 59). It can be set at right angles with the spindle by a square placed against the arbor and the jaws. The front of the table of the machine can also be used in setting the vise.

Swivel vises can be set by aid of the graduations on their base.

Direction to Move Work Under Cutter. Whenever possible, it is advantageous to feed the work in the opposite direction from that in which the cutter runs. (See A, Fig. 60). Then the cutter cannot draw the work in as it is liable to do when the table moves in the direction indicated at B. Moreover, when the piece moves as shown at A, the cutter teeth are first brought into contact with the softer metal, and as the scale on the surface is reached, it is pried or broken off.

On the other hand, in milling deep slots, or in cutting off stock with a thin cutter, or saw, it is sometimes better to move the work with the cutter, as the cutter is then less likely to crowd sidewise and make a crooked slot.

When the work is moving with the cutter, the table gib screws must be set up rather hard, for the teeth of the cutter tend to draw the work in, and if there is any lost motion in the table, the teeth may catch and injure the cutter or work. A counter- weight to hold back the table is excellent in such milling.

With vertical spindle milling machines, when a cutter is working on a flat surface, it does not matter which way the table is fed, but if the cutter is milling a side of a casting, as well as a flat surface, the table should be fed in the opposite direction to that in which the cutter revolves, for the reasons already mentioned.

Limits in Milling to Size. The limit for error in size to which work should be milled depends entirely upon the character of the job. With some work, a limit of one-hundredth of an inch is plenty good enough, while many other pieces must be finished to within one-thousandth of an inch of being exactly parallel or straight, as the case may be.

In milling to a given thickness or size, the most accurate results are ordinarily obtained by straddle mills or side milling cutters; for when only one side is milled at a time, and the piece has to be changed from one side to the other, it is hardly practicable to work to a smaller limit than two -thousandths of an inch. Side milling frequently requires more attention to keep the work smooth than ordinary surface milling.

Very accurate milling may be done and excellent surfaces obtained by small end mills running at high speeds.

In all cases where roughing and finishing cuts are to be taken on work, and precision is required, it is best to first remove most of the stock with a coarse feed, leaving enough for a light finishing cut. At a second operation, finish at a higher speed with a feed that will give the required surface.

Some light work will spring when the scale and a thickness of the metal are removed by the roughing cut. It is, therefore, advisable to loosen the holding clamps and permit the piece to assume a natural form before taking the finishing cut; otherwise, whatever inaccuracy that might result from the foregoing cause would be present in the finished work.

Remove Backlash or Lost Motion from Feed Screws. Backlash or lost motion is apt to be present in the feed screws and nuts of any machine, especially in those that have been in use some time. To obviate errors in making fine adjustments, the operator should be very careful to eliminate all backlash before setting to the graduations on the feed screw dials. This may be done by turning the hand-wheel a quarter or half turn in the opposite direction to that in which the adjustment is to be made, and then bringing the wheel back to the point from which adjustment is to be made.

Use of Oil or Other Lubricant. Lubricant is used in milling to obtain smoother work, to keep the cutters cool so that the teeth will retain their cutting edges longer, and, where the nature of the work requires, to wash the chips from the work or from the teeth of the cutters. Oil is generally used in milling steel, wrought iron, malleable iron or tough bronze, where a smooth finish is desired. A soda water mixture can also be used to good advantage on these materials.

For very light cuts, oil should be applied to the cutter with a brush; for heavier cuts, it should be allowed to drip freely upon the cutter from a can, and on the heaviest cuts, a large supply of lubricant should be supplied by means of a pump, which can be affixed to the machine.

A good quality of lard oil is generally used, but any animal or fish oils may be employed. An excellent soda water lubricant that is less expensive and cleaner to use than oil, can be made by mixing together and boiling for one-half hour, 14 lb. sal soda, 12 pint lard oil, 12 pint soft soap and water enough to make ten quarts.

Cutting Cast Iron. In cutting cast iron, lubricant is seldom used, as cutters do not usually heat very much, and the chips are so fine that the use of a lubricant results in a sticky mass that clogs the teeth of the cutter, and is difficult to clean from the work and machine.

Compressed air can be used to some advantage on cast iron, and will serve to keep the cutters cool and free from chips. In using compressed air care should be exercised not to have too much pressure, as it will scatter the dust and chips, which will fill bearings and cause trouble.

Collars and Washers for Arbors. Collars sent with milling arbors are not always the right thickness to bring cutters into the desired position. In these cases, washers should be employed. The following thicknesses are convenient: .001", .002", .004", .008", .016", and .032", as these give all steps from .001" to .032".

The collars should be of uniform thickness, otherwise they are likely to spring an arbor when they are clamped up.

Lead or Brass Hammer, and Brass Bar. Lead or brass hammers are useful to drive arbors or collets into the spindle, and seat work in a jig or vise. A steel hammer should not be used for these purposes, as it will mar pieces. Short lengths of gas piping with a cap on the protruding end make good handles for lead hammers.

A bar of brass or copper, 34 inch in diameter and five or six inches long, will also be found useful to place against end mills, or the end of small collets after the mills are in place. In this way the driving is often more conveniently done, and any hammer may be used.

TYPICAL MILLING OPERATIONS

In the illustration above, the work is of cast iron, in which a groove 14 inch wide is to be milled parallel with the hole. The piece is held on an arbor mounted in a V block and clamped to the surface of the table. Its overhanging end rests on a set screw tapped into the base of a knee bolted to the table, and a bolt and strap clamp the end firmly to the side of the knee.

A plain milling cutter, 14 inch face, 2 inches diameter, is used, and the table is fed longitudinally. This is a simple and common milling operation. The cast iron bracket is supported on an arbor that rests on V blocks at each end. Bolts and straps hold the arbor and V blocks in place, and teh projecting portions of the bracket are supported by small jack screws. As the full width of the surface is milled at one cut, the arm braces are used to support the arbor. Also, the cutter is placed as near the nose of the spindle as the work allows.

Because of width of cut, a plain milling cutter with spiral teeth and 6 inch face and 234 inch diameter, is used. The operation shown on this page is that of milling a slot on the bottom of the base casting of a milling machine vise, such as that shown in Fig. 18. The casting is clamped directly to the table and the farther end is supported on parallels.

An interlocking side milling cutter, 34'' wide, is used, and the table is fed longitudinally. The value of the interlocking cutter is apparent here, for it is essential that the width of slot milled be maintained after the cutters have been ground. This is accomplished by packing thin washers between the two parts of the cutter. Milling a T slot consists, as we have already explained in Chapter VI, of two separate operations. A straight slot is first milled to the full depth with a plain milling cutter, which is 12'' wide in this case. The work is then turned on edge and clamped to knees so that it is square with the spindle. It is leveled by means of a surface gauge or height gauge, measuring from the straight slot to the top of the table.

A standard 12'' T slot cutter is used, and the table is fed longitudinally in the path of the straight slot.

This job can be done to good advantage on a vertical spindle machine, or with a vertical spindle attachment, using a two-lipped end mill and T slot cutter. This operation is, apparently, simple enough, but care must be exercised if accuracy is required. The piece is supported on parallels and clamped in a vise. In fastening it one must be careful to be sure that there are no particles of dirt or chips between the parallels and bottom of piece, and that it is tamped down so that it seats properly when the vise is firmly clamped.

A plain milling cutter with spiral teeth is used, as this is best where a finished surface is desired. A cutter with nicked teeth would be better if considerable stock were to be taken off.

The table is fed longitudinally, and it should be noted that lubricant is used upon the cutter. The flat surface and V on a bracket can be milled in the manner shown in this cut. The bracket illustrated is of cast iron, and is clamped to the table by a bolt passing through a hole at the outer end of the casting, and a strap and bolt near the middle of the piece.

A 60° angular cutter is used and the table is fed longitudinally. A smaller cutter of the same angle can be used, but it will require several cuts to finish the piece.

This job, and others of a similar character, can also be done to good advantage on a vertical spindle milling machine or a horizontal machine fitted with a vertical spindle attachment. This operation illustrates the use of a face milling cutter with inserted teeth for surfacing a piece of work.

The piece, which is of cast iron, is clamped to a knee to keep it square with the spindle. A strap in front prevents it being pushed away from the cutter, toward which there is a strong tendency.

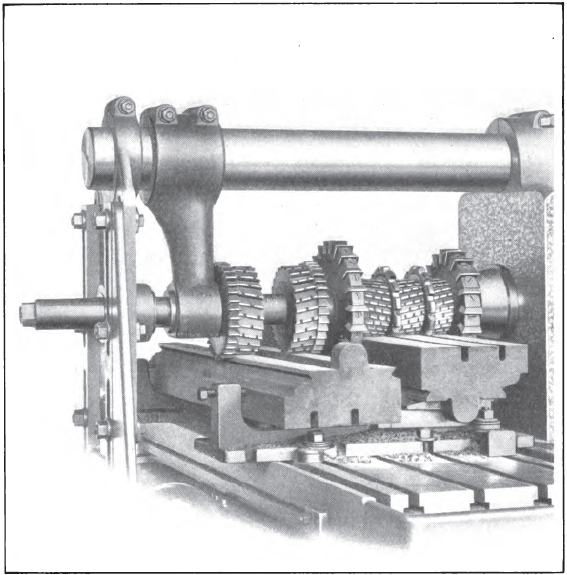

The cutter is mounted directly on the nose of the spindle, and, in feeding, the work is moved longitudinally from right to left, or so as to force the work down against the table, rather than raise it. Only one cut is taken over the surface. An example of light gang milling is shown in the accompanying cut. The two top surfaces and one end of the casting are being milled simultaneously by the use of two plain milling cutters, and a larger side milling cutter.

The two plain milling cutters are 212" diameter, 114" and 78" wide respectively; and the side milling cutter is 8" in diameter. To equalize the cutting speeds due to the wide difference between the diameters of the cutters, the large one is made of high speed steel, and the small ones of carbon steel.

If only one or two pieces are wanted, this work can be done more speedily with an end mill, as it takes more time to set up and adjust the three cutters shown above than would be required for making special settings with an end mill. These plates are used on the spiral head to support the intermediate, or reverse gear. Before milling, a hole is drilled at each end of the plate, and then several plates are strung on rods. The ends of the rods are allowed to protrude, and slots are cut in the vise jaws to receive them. When one side of the plates is milled, the vise is undamped and the plates are turned over, dropping the ends of the rods again into the slots in the vise jaws. The other side of the plates is then milled, producing the entire outline of several plates at two cuts and insuring duplication.

The outline is cut from the solid, and the material is steel, hence the cut is a heavy one. Lard oil or soda water is used as a cutting lubricant. Several of these work drivers are placed in the special fixture shown and clamped by means of the set screws at the side and end.

The cutter at one traverse mills the curved end and the deep slot in the plates. Then the set screws are slackened, each plate is reversed in the fixture, and the other ends are milled to duplicate the first.

The middle cutter is 712" in diameter, and as the cut is taken from solid steel, a heavy machine with rigid support for the cutter arbor is required. Lard oil or soda water is used as a cutting lubricant in this operation. It is the usual practice to put the caps on bearings, and bore them out, but this operation shows how bearings can be milled to good advantage. The caps can be milled at another operation so accurately that it is only necessary to pass a reamer through the bearings after the caps are put on to line them up exactly.

The cutter is made in two parts that are interlocking, and thin washers may be packed between to maintain the correct diameter.

It should also be noted that the cutter has to be located at the end of the arbor because of the high projection on the casting. This operation is of interest largely because the height of the sides milled is such that a gang of cutters of unusually large diameter is required. Three castings are lined up, strapped to the table, and milled at one cut. The outsides of the uprights are surfaced, and the space between is cut to the required width.

The cutters employed are inserted tooth side milling cutters 12 inches in diameter. Teeth are set parallel with the axis in the outside cutters, as their width is not great. In the middle cutter, which is wider, the teeth are set at an angle to give a shearing cut, and are nicked to break up the chips. The possibility of milling the deep sides of a casting, and at the same time surfacing the bottom, is illustrated in this cut.

A special fixture is employed to hold the piece, which is supported on three pins and located in position against stops. Set screws at both ends of the fixture clamp the piece.

The two side milling cutters shown are 16 inches in diameter, and the nicked tooth spiral cutter in the middle is 4 inches in diameter.

Only one casting can be milled at a time, owing to the distance it takes for the large cutters to clear the work at the beginning and end of the cut. This is the second operation on the casting shown in the preceding illustration. The cut is a simple, but heavy one, being 17 inches wide and 332 of an inch deep.

Interlocking inserted tooth milling cutters, 8 inches in diameter, are used, the large diameter being necessary because of the height of the casting at the ends.

Where the end thrust on the arbor cannot be equalized, the greatest thrust should be toward the spindle nose. Thus in the above operation, two right-hand angle cutters are used against one left-hand, and the greatest thrust is toward the spindle nose. An excellent example of heavy, plain gang milling is shown in this illustration. The surface being milled is 1512" wide, and the casting is held in a special fixture.

The table is fed longitudinally against the direction in which the cutters revolve. As the cut is comparatively heavy, nicked tooth cutters are employed, and it will be noticed that the thrust is mostly toward the spindle nose.

For such work as this, where considerable power is required to drive the cutters, the Constant Speed drive machine is superior to the Cone drive type. Three parallel slots are cut in the top of this table by spacing three cutters on the arbor by means of collars.

Considerable power is required for the operation, as the slots are cut from solid stock to the depth of 78 of an inch, and 916 of an inch wide.

Specially shaped straps are necessary to fasten the work to the table, in order to make use of cutters of small diameter.

The cutters employed are regular stocking cutters 6 inches in diameter, and are rigidly supported on the arbor. Jobs similar to this are done on the planer in many shops, but by setting the work up as shown, it is often possible to get a greater production from the milling machine.

The bed is lined up against a parallel inserted in one of the table T slots, so that there is no trouble lining up each successive casting. The saddle does not have to be readjusted for depth of cut each time. Straps at each end hold the piece on the table, and stops set in the table T slots prevent the tendency of the casting to slip, due to the action of the cutter. The value of gang milling, and the advantages of the milling machine over the planer, are very apparent in this operation, for it is essential that the ways on every bed be exact duplicates in width and distance apart. Once the gang of cutters is accurately set, each succeeding casting must necessarily be a duplicate of the first.

The bed has a boss cast on each end by means of which it is clamped directly to the table. After milling, the two bosses are taken off.

The gang of cutters is composed of four side milling cutters, and two plain spiral milling cutters with nicked teeth. The arbor is firmly supported in the arm braces, and the arbor yoke is employed to bring a bearing nearer the cutters. This illustration shows the possibilities of the milling machine for doing work that might be termed in many shops as suitable for the planer only.

The extreme weight, large size and powerful leverage due to the large overhang of the piece, are all factors that serve to make this an unusual milling job that requires a rigid machine.

The work and fixture together weigh over 1000 pounds, and the piece as it is fastened to the table is 25" high, and extends 35" out from the cutter.

Another unusual point is the size of the inserted tooth face milling cutter, which is 26" in diameter. Where the size of machine and character of work permit, it is very advantageous to mill more than one piece at a time. This operation illustrates how two plain grinding machine tables are milled simultaneously.

The two tables are held in a fixture, the essential features of which are plainly apparent in the cut. There are two sets of cutters made up of plain milling cutters and interlocking mills.

Another feature of this operation is the placing of the arbor yoke between the two sets of cutters. Milling machines are employed wherever possible in manufacturing parts of milling machines in our works. The operation above shows one example of this.

The width of cut on this saddle is 17 inches, and 316 of an inch of stock is removed, making a heavy cut.

The work is held in a special fixture, as it can be more firmly clamped, and more quickly put in place and removed from the table.

All of the cutters have nicked teeth, and the larger ones have inserted teeth. It should also be noted that end thrust on the arbor is equalized by using cutters of both right and left-hand angle teeth. The job shown above is that of milling the cast iron tables of small milling machines, and it is an interesting example, illustrative of the economy of gang milling. The top of one table and the bottom of another are milled simultaneously. The castings are held in a special fixture, and when one cut is taken, the piece at the left is removed, the one on the right turned over so that the ways on the bottom can be cut, and a new casting is put on the right-hand side of the fixture.

The table is fed longitudinally from left to right, and the cutters comprise four side milling cutters, one 912", one 1112", and two 778"

in diameter; five plain milling cutters, two 718", and three 434" in diameter; and two slotting cutters, 62932" in diameter. This illustration shows an unusually heavy milling operation, consisting of cutting two grooves, each 1.17" wide and 516" deep, in six steel forgings at one traverse of the table.

Three sets of index centres of a special design are employed, and two steel cores are mounted on the arbor on each pair of centres.

The cutters are of a special form to cut two grooves and the top of the intervening space between the grooves.

For such a cut as this, a large arbor is required, and it must be very rigidly supported; intermediate arbor yokes are, therefore, placed between the cutters.

Lard oil is used as a cutting lubricant. A vertical spindle milling machine is peculiarly adapted to work having a long projecting hub, or where it is necessary to surface off some part inside, such as in gear cases. The operation above is typical of such work, and shows a casting that must be milled all around the outside edge.

The casting is clamped in a special fixture, and a shell end mill is employed. The outline of the edge is followed by using the horizontal and transverse table feeds alternately for the different sides. The casting is held on a special fixture which has a slide corresponding to the slide on the top of the knee of the milling machine. The piece can be removed by simply loosening the gib.

The top plate of the fixture also swivels, so that one side of the ways can be milled on an angle for a taper gib. Both operations are, therefore, completed at one setting of the fixture, thus insuring the surfaces being milled in relation to each other. A 50° angular cutter is used for this operation. This illustration shows the use of a power-driven circular milling attachment, in connection with a vertical spindle milling machine for milling the surface and edge of a cutter carriage of an automatic gear cutting machine.

The special fixture employed is more for the purpose of milling the outside curved edge of the casting than for the operation shown. It has a way cut to correspond to that on the back of the casting, and an arbor inserted through two holes in the piece and into the centre of the circular milling attachment insures the outer edge being milled concentric with the holes.

All necessary movement is obtained from the circular attachment.

Gutting a Circular T Slot in Universal Milling Machine Saddle on a No. 3 Vertical Spindle Milling Machine

The operation shown above illustrates another excellent example of the use of the circular milling attachment in connection with a vertical spindle milling machine, for cutting the circular T slot in the saddle of a universal milling machine.

The piece of work is centred by placing it over a stud and bushing inserted in the hole in the centre of the circular attachment table. It is prevented from swinging by four bolts with washers, two of which are shown, and a strap from a stepped block across to the casting on each side fastens it to the table.

The first, or plain, slot is cut out on a boring mill or can be milled at the same setting shown above, using a two-lipped end mill, which is then replaced by the T slot cutter. Surfacing such a casting as this would ordinarily be done by following the outline of the piece of work, using the longitudinal and transverse automatic table feeds. But this necessitates shifting the feeds at each corner of the casting. A better way was found when the casting and fixture were clamped to the table of a circular milling attachment and fed in a circular path beneath the cutter.

The shorter distance the mill has to travel, the time saved in shifting feeds, and the fact that the operator does not have to give his undivided attention to the job, are all important advantages.

The metal is 12" thick. By the usual method, it is difficult to secure the flat, oil-tight surface that is easily obtained in the way described above. Here a vertical spindle machine equipped with a circular milling attachment is shown milling belt grooves in the rim of a three step pulley.

The pulley is easily fastened in place and a continuous cut is taken around the rim, using the automatic feed of the attachment. The knee is then lowered to bring the cutter at the right height for the next smaller step and the table is moved longitudinally to get the correct depth of cut. This operation is repeated for the smallest step and the piece is finished.

This operation can also be done on a horizontal milling machine when equipped with both vertical spindle and circular milling attachments. It is advisable in milling castings such as that shown, to do the work on a vertical spindle machine, as it is much more convenient. If a horizontal spindle machine is employed, and the work is clamped to the table, plain cutters of unusually large diameter are required, and when a face milling cutter is used, the work must be clamped to a knee. This, too, is unhandy when the casting is somewhat unwieldy.

The piece of work illustrated is of cast iron, and it is fastened directly to the surface of the table by means of straps extending from step blocks to the casting and secured in place by bolts set in the table T slots.

The face mill employed has inserted teeth. The table may be fed longitudinally in either direction. It will be seen from the above cut that in shops where the volume of work does not warrant installing a vertical spindle milling machine, the operation that would generally be done on that machine can be done on a horizontal spindle machine equipped with a vertical spindle attachment. The illustration shows a very heavy style of attachment.

The operation is that of face milling a surface on a cast iron piece which is held in a special jig upon the table.

The cutter is of the inserted tooth style, 912" in diameter. The table is fed from left to right on account of projections at end of casting. This operation is essentially the same as the one just described, with the exception that the casting in the first instance was fastened in a special fixture, while in this case it is clamped directly to the table and the cutter is held on an arbor.

The method of clamping needs little explanation, as it is very clearly shown in the illustration.

If it were not for the height of the hub at the right of the cutter, this job could easily be done without the attachment with plain milling cutters.

The cutter is 712" in diameter and has inserted teeth.