The Forth Bridge/On Cantilever Bridges Generally

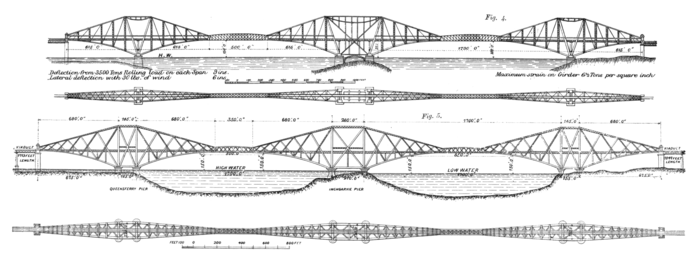

THE FORTH BRIDGE, CANTILEVER TYPE; ORIGINAL AND FINAL DESIGNS

MESSRS. HARRISON, BARLOW, FOWLER, AND BAKER, ENGINEERS.

On Cantilever Bridges Generally

Some little confusion of thought would appear to exist in many minds as regards this type of construction. Most people are willing to concede the antiquity of the arch and of the suspension system, but are doubtful whether the "continuous girder," if it be rechristened "cantilever and central girder," be not a modern and patentable invention. As a matter of fact, it is a pre-historic arrangement. In the earliest Egyptian and Indian temples will be found the stone corbel and lintel combination shown in Fig. 6 (see next page), and in the oldest, as in the most modern, wooden bridges will be seen practically the same thing in timber (Fig. 7).

Skeleton bridges on a similar principle have for ages past been thrown by savages across rivers. A sketch of one such on the route of the Canadian Pacific Railway is given in Fig. 8. Perhaps one of the most interesting structures of this kind ever built is a bridge in Thibet, constructed about 220 years ago, and illustrated by Fig. 9.

This sketch is reproduced from a drawing made in 1783 by Lieutenant Davis, R.N., who formed part of the embassy to the Court of the Teshoo Lama in Thibet, an account of which with illustrations was published in London in the year 1800. The book was a popular one at the time, and was translated and republished in Germany, so that both English and German engineers had the opportunity eighty years ago of reading the following, probably the first, description of a "cantilever and central girder" bridge ever published. "The bridge of Wandipore is of singular lightness and beauty in its appearance. The span measures 112 ft.; it consists of three parts, two sides, and a centre nearly equal to each other, the sides having a considerable slope raise the elevation of the centre platform, which is horizontal, some feet above the floor of the galleries. A quadruple row of timbers, their ends being set in the masonry of the bank, and the pier supports the sides; the centre part is laid from side to side." Making allowance for difference of material the preceding work may fairly be looked upon as the prototype of the proposed Forth Bridge.

Descending to more recent times, it will be found that the term "cantilever and central girder" has ever been familiar as a household word to all educated engineers, because in treating on the strains in continuous girders it has almost invariably been the rule of authors to regard the structure as a central girder suspended from two cantilevers at the points of contrary flexure. Thus writing in 1850 on the Britannia Bridge, Mr. Edwin Clark premises severing the beam at the point of contrary flexure, and suspending the central portion from the "semi-beams or cantilevers," and appends the diagram (Fig. 10) in illustration of the resultant strains.

He also gives a sketch (Fig. 11) of "a shorter tube resting on brackets from the pier at either extremity, as below," which had been discussed by Mr. Stephenson in 1846.

In the former year also Sir John Fowler not only talked about severing the beam at the point of contrary flexure and suspending it, but had the experiment tried with a large wooden model, and the result was recorded in the discussion on the Torksey Bridge (Min. Proc. Inst. C.E., vol. ix., page 256).

In 1855 Mr. Barton, in a paper on the Boyne Viaduct (Min. Proc. Inst. C.E., vol. xiv., page 457), pointed out that the points of contrary flexure might be made to coincide with any previously determined points by severing the beam, and he added this most suggestive comment: "In very large spans where it may be a matter of great importance to reduce the weight in the middle of the beam as much as possible, the quantity in material in the top and bottom tables, as well as of the sides, may be reduced to a minimum by throwing the points of contrary flexure towards the middle of the beam, the great weight of material being placed over the piers." This is exactly what has been done in the Forth Bridge girders.

In 1858, Mr. Latham, in his well-known work on wrought-iron bridges (page 222), also speaks of "a girder suspended from the cantilever girders," and in 1859 Mr. W. H. Barlow took out a patent with reference to that and other matters. He preferred making the depth at the pier 11⁄2 times the depth at the centre. In the Forth Bridge the ratio will be 7 to 1 instead of 11⁄2 to 1.

In 1862 Professor Ritter, of Hanover, in his justly popular work "Dach-und-Brucken Constructionen" (Chapter X.) again drew attention to the fact that "hinges can be employed with advantage in girder bridges;" that a "great saving of material is effected by using a continuous girder and breaking the continuity by means of hinges." To enforce his conclusions he works out in full detail the stresses upon all of the members of a continuous girder bridge of 160 metres, or, say, 525 ft. span of the type shown by Fig. 12.

In 1864 Mr. Fowler and Mr. Baker designed a steel bridge of 1000 ft. span on the said system for the proposed South Wales and Great Western Direct Railway Severn Crossing, but the span was subsequently reduced to 600 ft. An Act was obtained for the construction of the bridge, and the contract was let; but, owing to financial difficulties, the work was not proceeded with.

In 1867 Mr. Baker enforced the economical advantages of the continuous girder of varying depths in a series of articles on "Long Span Bridges" (Engineering, vol. iii.) which went through three editions in this country, were republished at Philadelphia, and translated into German and Dutch, and published in the Transactions of the Austrian and Dutch engineers respectively.

In 1871 Mr. Fowler and Mr. Baker made designs and estimates for a bridge across the Severn, comprising two girder spans of 800 ft. each, and in 1873 Mr. Baker, at the request of the Corporation of Middlesbrough, designed the superstructure for a proposed ferry bridge across the Tees, which included a 650 ft. span on the same system (Engineering, vol. xvi., page 60).

In 1876 nine competitive designs were submitted for the proposed New York and Long Island Bridge, comprising one span of 734 ft. and one of 618 ft., and of these three designs, two were on the aforesaid system (Figs. 13 and 14). The first was that of the Delaware Bridge Company, and the second of Colonel Flad, the very able engineer who, under Captain Eads, carried out the great St. Louis steel arch bridge.

In the same year was built the first, and, so far as we know, the only railway bridge of the type under discussion (Fig. 15.) This is a bridge of 148 ft. span across the Warthe, near Posen. It might appear strange at first that the application to railway purposes of so well-known a system should have been deferred until 1876, but the explanation is that there are thousands of bridges in existence on the continuous girder, or in other words cantilever and central girder principle, but engineers as a rule have elected not to sever the bridge at the point of contrary flexure, or to make the girders of varying depth.

A glance at the annexed illustrations and description will satisfy our readers that there is nothing novel or untried in the principle of the structure designed for the Forth crossing. The reasons dictating the design in the case of the Forth Bridge are those which probably influenced the Red Indians in making the structure illustrated by Fig. 8—economy of material and facility of erection. It must be conceded, however, that except as regards principle the design is essentially novel, but the novelties are dictated by the unexampled size of the structure, and are due simply to the perfect adaptation of the principle of the continuous girder and the general laws regarding the strength of materials to the special conditions of the case. Thus it will be observed that the structure is a continuous girder of varying depth on plan as well as elevation, the central girder portion being of the ordinary width required for a double line of rails, and the cantilevers spreading out to an extreme width of 120 ft. at the piers. By this means the stresses on the horizontal bracing from wind pressure are much reduced, and lightness and compactness are attained. To further the same ends the whole of the vertical members are made of two struts inclined towards each other from base to summit and braced together. To reduce the extreme height of the structure, and bring the centre of gravity as low down as possible, the bottom members of the continuous girder are curved, springing from solid masonry piers at a height of 18 ft. only above high water, whereas in the design for the suspension bridge the main chains, carrying of course all the weight, were supported at a height of 550 ft. above the same point! The main compression members are steel tubes ranging up to 12 ft. in diameter, the tubular form being adopted for two reasons, firstly, because experiments have shown that inch for inch the tubular form is stronger than any other, and, secondly, because the amount of stiffening and secondary bracing is thereby reduced to the lowest percentage. It might be thought that columns 350 ft. in length were an untried novelty, but this is not so, as we have the precedent of the Saltash Bridge oval tubes 16 ft. 9 in. by 12 ft. 3 in. in diameter and 460 ft. in length, the strain upon which under the test load was higher per square inch than will be that on the steel columns of the Forth Bridge. The central girder portion is simply an ordinary double-line railway bridge of 350 ft. span with girders of a type intermediate between the girder of parallel depth and the bowstring. This is an economical type, and many Continental bridges have been so constructed.

When lecturing some years ago, Mr. Baker, with a view of presenting in a form easily understood and popularly remembered, a simple diagram of the manner in which the principal stresses of a cantilever bridge are distributed, devised the following arrangement of a human cantilever, or a living model of the Forth Bridge. (See Fig. 15a.)

Two men sitting on chairs extend their arms, and support the same by grasping sticks which are butted against the chairs. There are thus two complete piers, as represented in the outline drawing above their heads. The central girder is represented by a stick suspended or slung from the two inner hands of the men, while the anchorage provided by the counterpoise in the cantilever end piers is represented here by a pile of bricks at each end. When a load is put on the central girder by a person sitting on it, the men's arms and the anchorage ropes come into tension, and the men's bodies from the shoulders downwards and the sticks come into compression. The chairs are representative of the circular granite piers. Imagine the chairs one-third of a mile apart and the men's heads as high as the cross of St. Paul's, their arms represented by huge lattice steel girders and sticks by tubes 12 ft. in diameter at the base, and a very good notion of the structure is obtained.

The chief desiderata in the Forth Bridge, which is the largest railway bridge ever yet built, were clearly as follow:

1. The maximum attainable amount of rigidity, both vertically under the rolling load and laterally under wind pressure, so that the work when completed may by its freedom from vibration gain the confidence of the public, and enjoy the reputation of being not only the biggest and strongest, but also the stiffest bridge in the world.

2. Facility and security of erection, so that at any stage of erection the incomplete structure may be as secure against a hurricane as the finished bridge.

3. That no untried material be used in its construction, or in other words that no steel be employed which would not comply with the requirement of the Admiralty, Lloyd's, and the Underwriters' Registry, as determined by the experience gained in the use of many thousands of tons of steel plates, bars, and angles for shipbuilding purposes.

4. That the maximum economy be attained consistent with the fulfilment of the preceding conditions. We think it will be apparent to most engineers and bridge builders that the original suspension-bridge design complied with none of these conditions, whilst the girder design complies with all.

Of the present design it may be truly said that all the anticipations have been most brilliantly realised, and its merits can now, in the light of practical experience, and of actual facts, be more easily pointed out. In the first instance the distribution of weight not only offers the advantage of having the greatest proportion, nearly one-fourth of it, immediately over the main supports, where it is most easily erected, but it offers in those places where the wind pressure would act with the greatest amount of leverage, the least amount of surface to act upon. Thus, while in the central tower of the Inchgarvie pier, the most exposed to storms, the weight per foot run is 23 tons, and in the first bay of cantilevers 21 tons, in the central girders of 350 ft. length it is only a little over 2 tons per foot. In a similar manner the structure decreases rapidly in height and breadth of girders, as it extends from the massive central towers towards the extremities of the cantilevers. Again, for purposes of erection every portion of the structure, as put in position, offered itself as a staging for carrying operations further ahead, or afforded every means of suspending temporary staging from it. The greater portion of the work as erected could be securely fixed at once and rivetted up, and this close up to places where new parts were in course of erection. Great rigidity was thereby insured, and less temporary work required than in any other mode of construction, while it gave confidence to the workmen engaged, and offered every facility in providing for their safety, and for that of the structure itself.

Great stability is obtained by straddling the sides of the structure, as viewed in cross-section that is, making it considerably wider at the base than at the top. In the central towers, the width at the base is somewhat more than one-third of the height, and a uniform batter is maintained throughout the structure. This feature conveys a sense of great security against the action of violent gales tending to overturn the bridge. Finally, the arrangement of cantilevers and central girders admits of the simplest and most effective form of expansion-joint, and this problem is solved here in the happiest manner, as will appear from the detailed description given later on.

On December 21, 1882, the contract for the construction of the Forth Bridge was let to the firm of Tancred, Arrol and Co. Both the contract sum and the time specified, have been exceeded, for reasons which will be fully apparent to the reader who follows attentively the development of this work, and who gives intelligent consideration to the conditions under which it had to be carried out.