1911 Encyclopædia Britannica/Dredge and Dredging

DREDGE and DREDGING. The word “dredge” is used in two senses. (1) From Mid. Eng. dragie, through Fr. dragée, from Gr. τραγήματα, sweetmeats, it means a confection of sugar formed with seeds, bits of spice or medicinal agents. The word in this sense is obsolete, but survives in “dredger,” a box with a perforated top used for sprinkling such a sugar-mixture, flour or other powdered substance. “Dredge” is also a local term for a mixed crop of oats and barley sown together (“maslin” or “meslin,” cf. Fr. dragée), and in mining is applied to ore of a mixed value. (2) Connected with “drag,” or at least derived from the same root, dredge or dredger is a mechanical appliance for collecting together and drawing to the surface (“dredging”) objects and material from the beds of rivers or the bottom of the sea. In the following account the operations of dredging in this sense are discussed (1) as involved in hydraulic engineering, (2) in connexion with the work of the naturalist in marine biology.

1. Hydraulic Engineering

Dredging is the name given by engineers to the process of excavating materials under water, raising them to the surface and depositing them in barges, or delivering them through a shoot, a longitudinal conveyor, or pipes, to the place where it is desired to deposit them. It has long been useful in works of marine and hydraulic engineering, and has been brought in modern times to a state of high perfection.

The employment of dredging plant and the selection of special appliances to be used in different localities and in varying circumstances require the exercise of sound judgment on the part of the engineer. In rivers and estuaries where the bottom is composed of light soils, and where the scour of the tide can be governed by training walls and other works constructed at reasonable expense, so as to keep the channel clear without dredging, it is manifest that dredging machinery with its large cost for working expenses and for annual upkeep should be as far as possible avoided. On the other hand, where the bottom consists of clay, rock or other hard substances, dredging must, in the first instance at any rate, be employed to deepen and widen the channel which it is sought to improve. In some instances, such as the river Mississippi, a deep channel has for many years been maintained by jetties, with occasional resort to dredging to preserve the required channel section and to hasten its enlargement. The bar of the river Mersey is 11 m. from land, and the cost of training works would be so great as to forbid their construction; but, by a capital expenditure of £120,000 and an annual expense of £20,000 for three years, the depth of water over the bar at low tide has been increased by dredging from 11 ft. to 27 ft., the channel being 1500 ft. wide.

“Bag and Spoon” Dredger.—The first employment of machinery for dredging is, like the discovery of the canal lock, claimed by Holland and Italy, in both of which countries it is believed to have been in use before it was introduced into Britain. The Dutch, at an early period, used what is termed the “bag and spoon” dredger for cleansing their canals. The “spoon” consisted of a ring of iron about 2 ft. in diameter flattened and steeled for about a third of its circumference and having a bag of strong leather attached to it by leathern thongs. The ring and bag were fixed to a pole which was lowered to the bottom from the side of a barge moored in the canal or river. The “spoon” was then dragged along the bottom by a rope made fast to the iron ring actuated by a windlass placed at the other end of the barge, the pole being prevented from rising by a hitched rope which caused the “spoon” to penetrate the bottom and fill the bag. When the “spoon” reached the end of the barge where the windlass was placed, the winding was still continued, and the suspended rope being nearly perpendicular the “bag” was raised to the gunwale of the barge and the excavated material emptied into the barge. The “bag” was then hauled back to the opposite end to be lowered for another supply. This system is still in use, but is only adaptable to a limited depth of water and a soft bottom; it has been largely used in canals and frequently in the Thames. At the Fosdyke Canal in Lincolnshire 135,000 tons were raised in the manner described. According to J. J. Webster (Proc. Inst. C. E. vol. 89), the first application of steam power for dredging operations was to a “spoon & bag” dredger for cleansing Sunderland harbour, the engine being made by Messrs Boulton & Watt of Soho, Birmingham.

Dredging by Bucket between Two Lighters.—Another plan of dredging, practised at an early period in rivers of considerable breadth, was to moor two barges, one on each side of the river. Between them was slung an iron dredging bucket, which was attached to both barges by chains wound on the barrels of a crab winch worked by six men in one barge and round a simple windlass worked by two men in the other barge. The bucket, being lowered at the side of the barge carrying the windlass, was drawn across the bottom of the river by the crab winch on the other barge; and having been raised and emptied, it was hauled across by the opposite windlass for repetition of the process. This process was in use in the River Tay until 1833.

Bucket Ladder Dredgers.—The earliest record of a bucket ladder dredger is contained in the first paper of the first volume (1836) of the Transactions of the Institution of Civil Engineers. This machine was brought into use at the Hull Docks about 1782. The bucket chain was driven by two horses working a horse-gear on the deck of the vessel. The buckets were constructed of 58 in. bars of iron spaced 18 in. apart, and were 4 ft. long, 13 in. deep, 12 in. wide at the mouth and about 6 in. wide at the bottom. This dredger raised about 30 tons per hour at the cost of 212d. per ton, which covered the wages of three men working the dredger, eight men working the lighters and the keep of three horses. A dredger of this kind and power would only work in ballast, mud or other soft material, but the machine was gradually improved and increased in capacity and power by different manufacturers until it became a very efficient machine in skilful hands, excavating and raising material from depths of 5 ft. to 60 ft. of water at a cost not very different from, and in many cases less than, that at which the same work could be performed on land. With the powerful dredgers now constructed, almost all materials, except solid rock or very large boulders, can be dredged with ease. Loose gravel is perhaps the most favourable material to work in, but a powerful dredger will readily break up and raise indurated beds of gravel, clay and boulders, and has even found its way through the surface of soft rock, though it will not penetrate very far into it. In some cases steel diggers alternating with the buckets on the bucket frame have been successfully employed. The construction of large steam dredgers is now carried on by many engineering firms. The main feature of the machine is the bucket ladder which is hung at the top end by eye straps to the frame of the vessel, and at the lower end by a chain reived in purchase blocks and connected to the hoisting gear, so that the ladder may be raised and lowered to suit the varying depths of water in which the dredger works. The upper tumbler for working the bucket chain is generally square or pentagonal in form and made of steel with loose steel wearing pieces securely bolted to it. The tumbler is securely keyed to the steel shaft which is connected by gearing and shafting to the steam engine, a friction block being inserted at a convenient point to prevent breakage should any hidden obstacle causing unusual strain be met with in the path of the buckets. The lower tumbler is similar in construction to the upper tumbler, but is usually pentagonal or hexagonal in shape. The buckets are generally made with steel backs to which the plating of the buckets is riveted; the cutting edge of the buckets consists of a strong steel bar suitably shaped and riveted to the body. The intermediate links are made of hammered iron or steel with removable steel bushes to take the wear of the connecting pins, which are also of steel. The hoisting gear may be driven either from the main engine by frictional gearing or by an independent set of engines. Six anchors and chains worked by powerful steam crabs are provided for regulating the position of the dredger in regard to its work.

Barge-loading Dredgers used formerly to be provided with two ladders, one on each side of the vessel, or contained in wells formed in the vessel near each side. Two ladders were adopted, partly to permit the dredger to excavate the material close to a quay or wall, and partly to enable one ladder to work while the other was being repaired. Bucket ladder dredgers are now, however, generally constructed with one central ladder working in a well; frequently the bucket ladder projects at either the head or stern of the vessel, to enable it to cut its own way through a shoal or bank, a construction which has been found very useful. In one modification of this method the bucket ladder is supported upon a traversing frame which slides along the fixed framing of the dredger and moves the bucket ladder forward as soon as it has been sufficiently lowered to clear the end of the well. In places where a large quantity of dredging has to be done, a stationary dredger with three or four large hopper barges proves generally to be the most economical kind of plant. It has, however, the disadvantage of requiring large capital expenditure, while the dredger and its attendant barges take up an amount of space which is sometimes inconvenient where traffic is large and the navigable width narrow. The principal improvements made in barge-loading dredgers have been the increase in the size of the buckets and the strength of the dredging gear, the application of more economical engines for working the machinery, and the use of frictional gearing for driving the ladder-hoisting gear. It is very important that the main drive be fitted with the friction blocks or clutches before alluded to.

Up to the year 1877 dredgers were seldom made with buckets of a capacity exceeding 9 cub. ft., but since that time they have been gradually increased in capacity. In the dredger “Melbourne,” constructed by Messrs William Simons & Co. to the design and specification of Messrs Coode, Son & Matthews, about the year 1886, the buckets had a capacity of 22 cub. ft., the dredger being capable of making 37 ft. of water. The driving power consists of two pairs of surface-condensing engines, each of 250 i.h.p., having cylinders 20 in. and 40 in. in diameter respectively, with a 30 in. stroke, the boiler pressure being 90 ℔ per sq. in. The vessel is 200 ft. long by 36 ft. wide and 11 ft. 6 in. deep, and is driven by twin screw propellers. The gearing is arranged so that either pair of engines can be employed for dredging. The speed under steam is 7 knots, and in free-getting material 800 tons per hour can be dredged with ease. On one occasion the dredger loaded 400 tons in 20 minutes. The speed of the bucket chain is 83 lineal ft. per minute. The draught of the dredger in working trim is 7 ft. forward and 9 ft. aft. The efficiency of the machine, or the net work in raising materials compared with the power exerted in the cylinders, is about 25%. The dredged material is delivered into barges moored alongside. Contrasting favourably with former experience, the “Melbourne” worked for the first six months without a single breakage. She is fitted with very powerful mooring winches, a detail which is of great importance to ensure efficiency in working.

The “St Austell” (Plate I. fig. 3), a powerful barge-loading dredger 195 ft. long by 35 ft. 6 in. beam by 13 ft. deep, fitted with twin-screw compound surface-condensing propelling engines of 1000 i.h.p., either set of engines being available for dredging, was constructed for H.M. Dockyard, Devonport, by Messrs Wm. Simons & Co. in 1896. This dredger loaded thirty-five 500-ton hopper barges in the week ending April 2, 1898, dredging 17,500 tons of material in the working time of 29 hours 5 minutes.

An instance of a still larger and more powerful dredger is the “Develant,” constructed by Messrs Wm. Simons & Co., for Nicolaiev, South Russia. She is a bow-well, barge-loading, bucket ladder dredger, with a length of 186 ft., a breadth, moulded, of 36 ft., and a depth, moulded, of 13 ft. The bucket ladder is of sufficient length to dredge 36 ft. below the water level. The buckets are exceptionally large, each having a capacity of 36 cub. ft., or fully two tons weight of material, giving a lifting capacity of 1890 tons per hour. At the dredging trials 2000 tons of spoil were lifted in one hour with an expenditure of 250 i.h.p. The propelling power is supplied by one pair of compound surface-condensing marine engines of 850 i.h.p., having two cylindrical boilers constructed for a working pressure of 120 ℔ per sq. in. Each boiler is capable of supplying steam to either the propelling or dredging machinery, thus allowing the vessel to always have a boiler in reserve. On the trials a speed of 812 knots was obtained. The bucket ladder, which weighs over 100 tons, exclusive of dredgings, is raised and lowered by a set of independent engines. For manœuvring, powerful winches driven by independent engines are placed at the bow and stern. The vessel is fitted throughout with electric light, arc lamps being provided above the deck to enable dredging to be carried on at night. Steam steering gear, a repairing shop, a three-ton crane, and all the latest appliances are installed on board.

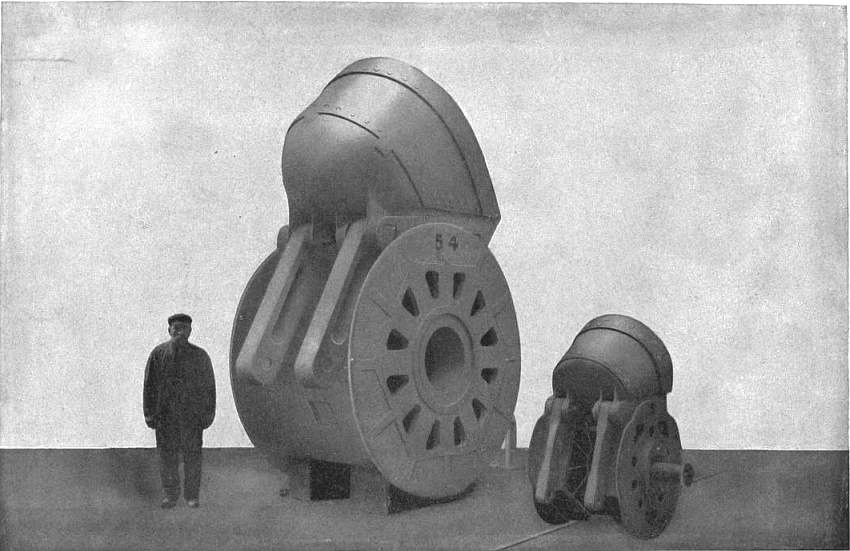

The “Dérocheuse” (Plate II. fig. 12), constructed by Messrs Lobnitz & Co., is a good example of the dredger fitted with their patent rock cutters, as used on the Suez Canal. These rock cutters consist of stamps passing down through the bottom of the dredger, slightly in advance of the bucket chain, and are employed for breaking up rock in front of the bucket ladder so that it may be raised by buckets afterwards. This system of subaqueous rock cutting plant, on Messrs Lobnitz’s patent system, was effectively employed in deepening the Manchester Ship Canal, and removed a considerable length of rock, increasing the depth of water from 26 ft. to 28 ft. at a cost of about 9d. per cub. yd. A full and illustrated description of this plant, and of a similar plant supplied to the Argentine Government, was published in Engineering of August 17, 1906. An illustration of a bucket of 54 cub. ft. capacity constructed by Messrs Lobnitz & Co. is given (Plate II fig. 11), from which some idea of the size of dredging machinery as developed in recent practice may be obtained. In regard to the depth of water that can be obtained by dredging, it is interesting to note that the dredger “Diver,” constructed by Messrs. Hunter & English for Mr Samuel Williams of London, is capable of working in 60 ft. of water. In this vessel an ingenious arrangement was devised by Mr Williams, by which part of the weight of the dredger was balanced while the ladder itself could be drawn up through the bucket well and placed upon the deck, enabling a long ladder to be used for a comparatively short vessel. The “Tilbury” dredger, also constructed by Messrs Hunter & English, was able to dredge to a depth of 45 ft. below the surface of the water.

Hopper Barges.—To receive the materials excavated by barge-loading dredgers, steam hopper barges are now generally employed, capable of carrying 500 tons or more of excavation and of steaming loaded at a speed of about 9 m. per hour. These hopper barges are made with hinged flaps in their bottoms, which can be opened when the place of deposit is reached and the dredgings easily and quickly discharged.

Good examples of these vessels are the two steam hopper barges built for the Conservators of the river Thames in 1898. The dimensions are: length 190 ft., breadth 30 ft., depth 13 ft. 3 in., hopper capacity 900 tons. They are propelled by a set of triple expansion engines of 1200 i.h.p., with two return-tube boilers having a working pressure of 160 ℔. Special appliances are provided to work the hopper doors by steam power from independent engines placed at the forward end of the hopper. A steam windlass is fixed forward and a steam capstan aft. The vessels are fitted with cabins for the officers and crew. On their trial trip, the hoppers having their full load, a speed of 11 knots was obtained, the coal consumption being 1·44 ℔ per i.h.p.

Methods of Dredging.—In river dredging two systems are pursued. One plan consists in excavating a series of longitudinal furrows parallel to the axis of the stream; the other in dredging cross furrows from side to side of the river. It is found that inequalities are left between the longitudinal furrows when that system is practised, which do not occur, to the same extent, in side or cross dredging; and cross dredging leaves a more uniform bottom. In either case the dredger is moored from the head and stern by chains about 250 fathoms in length. These chains in improved dredgers are wound round windlasses worked by the engine, so that the vessel can be moved ahead or astern by simply throwing them into or out of gear. In longitudinal dredging the vessel is worked forward by the head chain, while the buckets are at the same time performing the excavation, so that a longitudinal trench is made in the bottom of the river. After proceeding a certain length, the dredger is stopped and permitted to drop down and commence a new longitudinal furrow, parallel to the first one. In cross dredging, on the other hand, the vessel is supplied with four additional moorings, two on each side, and these chains are, like the head and stern chains, wound round barrels worked by steam power. In cross dredging we may suppose the vessel to be moored at one side of the channel to be excavated. The bucket frame is set in motion, but instead of the dredger being drawn forward by the head chain, she is drawn across the river by the starboard chains, and, having reached the extent of her work in that direction, she is then drawn a few feet forward by the head chain, and the bucket frame being still in motion the vessel is hauled across by the port chains to the side whence she started. By means of this transverse motion of the dredger a series of cross cuts is made; the dredger takes out the whole excavation from side to side to a uniform depth and leaves no protuberances such as are found to exist between the furrows in longitudinal dredging, even when it is executed with great care. The two systems will be understood by reference to fig. 1, where A and B are the head and stern moorings, and C, D, E and F the side moorings. The arc e f represents the course of the vessel in cross dredging; while in longitudinal dredging, as already explained, she is drawn forward towards A, and again dropped down to commence a new longitudinal furrow.

|

| Fig. 1.—Diagram showing Moorings for Transverse Dredging. |

Hopper Dredgers.—In places where barge-loading dredgers are inconvenient, owing to confined space and interference with navigation, and where it is necessary to curtail capital expenditure, hopper dredgers are convenient and economical. These dredgers were first constructed by Messrs. Wm. Simons & Co. of Renfrew, who patented and constructed what they call the “Hopper Dredger,” combining in itself the advantages of a dredger for raising material and a scow hopper vessel for conveying it to the place of discharge, both of which services are performed by the same engines and the same crew.

The vessel for this type of dredger is made of sufficient length and floating capacity to contain its own dredgings, which it carries out to the depositing ground as soon as its hopper is full. Considerable time is of course occupied in slipping and recovering moorings, and conveying material to the depositing ground, but these disadvantages are in many instances counterbalanced by the fact that less capital is required for plant and that less room is taken up by the dredger. If the depositing ground is far away, the time available for dredging is much curtailed, but the four-screw hopper dredger constructed by Messrs Wm. Simons & Co. for Bristol has done good work at the cost of 5d. per ton, including wages, repairs, coals, grease, sundries and interest on the first cost of the plant, notwithstanding that the material has to be taken 10 m. from the Bristol Dock. She can lift 400 tons of stiff clay per hour from a depth of 36 ft. below the water line, and the power required varies from 120 i.h.p. to 150 i.h.p., according to the nature of the material. The speed is 9 knots, and 4 propellers are provided, two at the head and two at the stern, to enable the vessel to steam equally well either way, as the river Avon is too narrow to permit her to be turned round.

The hopper dredger “La Puissante” (Plate I. fig. 4), constructed by Messrs Wm. Simons & Co. for the Suez Canal Co. for the improvement of Port Said Roads, is a fine example of this class of dredger. She is 275 ft. long by 47 ft. beam by 19 ft. deep. The hopper capacity is 2000 tons, and the draught loaded 16 ft. 5 in. The maximum dredging depth is 40 ft., and the minimum dredging depth is only limited by the vessel’s draught, she being able to cut her own way. The bucket ladder works through the well in the stern and weighs with buckets 120 tons. The buckets have each a capacity of 30 cub. ft. and raised on trial 1600 tons per hour. The dredger is propelled by two sets of independent triple expansion surface-condensing engines of 1800 i.h.p. combined, working with steam at 160 ℔ pressure, supplied by two mild steel multitubular boilers. Each set of engines is capable of driving the buckets independently at speeds of 16 and 20 buckets per minute. The bucket ladder is fitted with buffer springs at its upper end to lessen the shock when working in a seaway. The dredger can deliver the dredged material either into its own hopper or into barges lying on either side. The vessel obtained a speed of 934 knots per hour on trial. The coal consumption during 6 hours’ steaming trial was 1·66 ℔ per i.h.p. hour. Fig. 9 (Plate I.) shows a still larger hopper dredger by the same constructors.

Dredgers fitted with Long Shoot or Shore Delivering Apparatus.—The first instance of dredgers being fitted with long shoots was in the Suez Canal. The soil in the lakes was very variable, the surface being generally loose mud which lay in some places in the sand, but frequently more or less on hard clay. Resort was had to shoots 230 ft. long, supported on pontoons connected with the hull of the dredger. The sand flowed away with a moderate supply of water to the shoots when they were fixed at an inclination of about 1 in 20, but when the sand was mixed with shells these formed a coating which prevented the stream of water from washing out the shoot, and even with an inclination of 1 in 10 material could not be delivered. A pair of endless chains working down the long shoot overcame the difficulty, and also enabled hard clay in lumps to be dealt with. One dredger turned out about 2000 cub. yds. of thick clay in 15 hours, and when the clay was not hard it could deliver 150,000 cub. yds. in a month for several consecutive months.

Shore delivery has been successfully effected by raising the material by buckets in the ordinary way and delivering it into a vertical cylinder connected with floating jointed pipes through which the dredgings pass to the shore. This, of course, can only be done where the place of deposit is near the spot where the material is dredged. Two plans have been satisfactorily employed for this operation. At the Amsterdam Canal the stuff was discharged from the buckets into a vertical cylinder, and after being mingled with water by a revolving Woodford pump was sent off under a head of pressure of 4 or 5 ft. to the place of deposit in a semi-fluid state through pipes made of timber, hooped with iron. These wooden pipes were made in lengths of about 15 ft., connected with leather joints, and floated on the surface of the water. A somewhat similar process was also employed on the Suez Canal.

A dredger (Plate I. fig. 5), constructed by Messrs Hunter & English for reclamation works on Lake Copais in Greece was fitted with delivery belts running on rollers in steel lattice frames on each side of the vessel supported by masts and ropes. It could deliver 100 cub. metres per hour at 85 ft. from the centre of the dredger, at a cost of 1·82d. per cub. metre for working expenses, with coal at 45s. per ton, including 0·66d. per cub. metre for renewal of belts, upon which the wear and tear was heavy.

Another instance of the successful application of shore delivery apparatus is that of a dredger for Lake Titicaca, Peru, constructed by Messrs Hunter & English, which was fitted with long shoots on both sides, conveying the dredged material about 100 ft. from the centre of the dredger upon either side. The shoots were supported by shear-legs and ropes, and were supplied with water from a centrifugal pump in the engine room. This dredger could excavate and deliver 120 cub. yds. per hour at a cost of 1·725d. per cub. yd. with coal costing 40s. per ton. If coal had been available at the ordinary rate in England of 20s. per ton, the cost of the dredging and delivery would have been 0·82d. per cub. yd. for wages, coal, oil, &c., but not including the salary of the superintendent.

An interesting example of a shore delivering dredger is a light draught dredger constructed by Messrs Hunter & English for the Lakes of Albufera at the mouth of the river Ebro in Spain (Plate I. fig. 6). The conditions laid down for this dredger were that it should float in 18 in. of water and deliver the dredged material at 90 ft. from the centre of its own hull. In order to meet these requirements the vessel was made of steel plates 18 in. thick, and longitudinal girders from end to end of the vessel, the upward strain of flotation being conveyed to them from the skin plating by transverse bulkheads at short intervals. The dredger was 94 ft. long, 25 ft. wide, and 3 ft. deep, and the height of the top tumbler above the water was 25 ft. When completed the dredger drew 17 in. of water. The dredgings were delivered by the buckets upon an endless belt, driven from the main compound surface-condensing engine, which ran over pulleys supported upon a steel lattice girder, the outer end of which rested upon an independent pontoon. This belt delivered the dredgings at 90 ft. from the centre of the dredger round an arc of 180°. The dredger delivered 125 cub. yds. per hour of compact clay at a cost of 1·16d. per cub. yd. or 0·86d. per ton for wages, coal and stores. Another method of delivering dredgings is that of pneumatic delivery, introduced by Mr F. E. Duckham, of the Millwall Dock Co., by which the dredgings are delivered into cylindrical tanks in the dredger, closed by air-tight doors, and are expelled by compressed air either into the sea or through long pipes to the land. The Millwall Dock dredger is 113 ft. long, with a beam of 17 ft. and a depth of 12 ft. The draught loaded is 8 ft. It contains two cylindrical tanks, having a combined capacity of 240 cub. yds., and is fitted with compound engines of about 200 i.h.p., with a 20 in. air-compressing cylinder. The discharge pipe is 15 in. diameter by 150 yds. long. The nozzles of the air-injection pipes must not be too small, otherwise the compressed air, instead of driving out the material, simply pierces holes through it and escapes through the discharging pipe, carrying with it all the liquid and thin material in the tanks. The cost of working the Millwall Dock dredger is given by Mr Duckham at 1·75d. per cub. yd. of mud lifted, conveyed and deposited on land 450 ft. from the water-side, for working expenses only. This dredger is believed to be the first machine constructed with a traversing ladder, as suggested by Captain Gibson when dock-master of the Millwall Docks.

Blasting combined with Dredging.—In some cases it has been found that the bottom is too hard to be dredged until it has been to some extent loosened and broken up. Thus at Newry, John Rennie, after blasting the bottom in a depth of from 6 to 8 ft. at low water, removed the material by dredging at an expense of from 4s. to 5s. per cub. yd. The same process was adopted by Messrs Stevenson at the bar of the Erne at Ballyshannon, where, in a situation exposed to a heavy sea, large quantities of boulder stones were blasted, and afterwards raised by a dredger worked by hand at a cost of 10s. 6d. per cub. yd. Sir William Cubitt also largely employed blasting in connexion with dredging on the Severn (see Proc. Inst. C.E. vol. iv. p. 362). The cost of blasting and dredging the marl beds is given as being 4s. per cub. yd. A combination of blasting and dredging was employed in 1875 by John Fowler of Stockton at the river Tees. The chief novelty was in the barge upon which the machinery was fixed. It was 58 ft. by 28 ft. by 4 ft., and had eight legs which were let down when the barge was in position. The legs were then fixed to the barge, so that on the tide falling it became a fixed platform from which the drilling was done. Holes were bored and charged, and when the tide rose the legs were heaved up and the barge removed, after which the shots were discharged. There were 24 boring tubes on the barge, and that was the limit which could at any time be done in one tide. The area over which the blasting was done measured 500 yds. in length by 200 in breadth, a small part being uncovered at low water. The depth obtained in mid-channel was 14 ft. at low water, the average depth of rock blasted being about 4 ft. 6 in. The holes, which were bored with the diamond drill, varied in depth from 7 to 9 ft., the distance between them being 10 ft. Dynamite in tin canisters fired by patent fuse was used as the explosive, the charges being 2 ℔ and under. The rock is oolite shale of variable hardness, and the average time occupied in drilling holes 5 ft. deep was 12 minutes. The dredger raised the blasted rock. The cost for blasting, lifting and discharging at sea was about 4s. per cub. yd., including interest on dredging and other plant employed. The dredger sometimes worked a face of blasted material of from 7 to 8 ft. The quantity blasted was 110,000 cub. yds., and the contract for blasting so as to be lifted by the dredger was 3s. 1d. per cub. yd. A similar plan was adopted at Blyth Harbour (see Proc. Inst. C.E. vol. 81, p. 302). The cost of the explosives per cub. yd. was 1s. 4d., of boring 1s. 9d. per cub. yd., and of dredging 3s. per cub. yd., including repairs, but nothing for the use of plant. The whole cost worked out at 6s. 1d. per cub. yd. on the average.

Sand-pump Dredgers.—Perhaps the most important development which has taken place in dredging during recent years has been the employment of sand-pump dredgers, which are very useful for removing sandy bars where the particular object is to remove quickly a large quantity of sand or other soft material. They are, however, apt to make large holes, and are therefore not fitted for positions where it is necessary to finish off the dredging work to a uniform flat bottom, for which purpose bucket dredgers are better adapted. Pump dredgers are, however, admirable and economical machines for carrying out the work for which they are specially suited.

In the discussion upon Mr J. J. Webster’s paper upon “Dredging-Appliances” (Proc. Inst. C.E. vol. 89) at the Institution of Civil Engineers in 1886, Sir John Coode stated that he had first seen sand-pump dredgers at the mouth of the Maas in Holland. The centrifugal pump was placed against the bulkheads in the after part of the vessel, and the sand and water were delivered into a horizontal breeches-piece leading into two pipes running along the full length of the hopper. The difficulty of preventing the sand from running overboard was entirely obviated by its being propelled by the pump through these pipes, the bottoms of which were perforated by a series of holes. In addition, there were a few small flap-doors fixed at intervals, by means of which the men were able to regulate the discharge. On being tested, the craft pumped into its hopper 400 tons of sand in 22 minutes. The coamings round the well of the hoppers were constructed with a dip, and when the hopper was full the water ran over in a steady stream on either side. The proportion of sand delivered into the hopper was about 20% of the total capacity of the pump. The dredger was constructed by Messrs Smit of Kinderdijk, near Rotterdam. In the same discussion Mr A. A. Langley, then engineer to the Great Eastern railway, gave particulars of a sand pump upon the Bazin system, which had been used successfully at Lowestoft. The boat was 60 ft. long by 20 ft. wide, and the pump was 2 ft. in diameter, with a two-bladed disk. The discharge pipe was 12 in. in diameter. The pump raised 400 tons of sand, gravel and stones per hour as a maximum quantity, the average quantity being about 200 tons per hour. The depth dredged was from 7 ft. to 25 ft. The pump was driven by a double-cylinder engine, having cylinders of 9 in. diameter by 10 in. stroke, and making 120 revolutions per minute. An important improvement was made by fitting the working faces of the pump with india-rubber, which was very successful and largely reduced the wear and tear. The cost of the dredging at Lowestoft was given by Mr Langley at 2d. per ton, including delivery 2 m. out at sea. The quantity dredged was about 200,000 tons per annum.

One of the earliest pumps to be applied to dredging purposes was the Woodford, which consisted of a horizontal disk with two or more arms working in a case somewhat similar to the ordinary centrifugal pump. The disk was keyed to a vertical shaft which was driven from above by means of belts or other gear coupled to an ordinary portable engine. The pump within rested on the ground; the suction pipe was so arranged that water was drawn in with the sand or mud, the proportions being regulated to suit the quality of the material. The discharge pipe was rectangular and carried a vertical shaft, the whole apparatus being adjustable to suit different depths of water. This arrangement was very effective, and has been used on many works. Burt & Freeman’s sand pump, a modification of the Woodford pump, was used in the construction of the Amsterdam Ship Canal, for which it was designed. The excavations from the canal had to be deposited on the banks some distance away from the dredgers, and after being raised by the ordinary bucket dredger, instead of being discharged into the barges, they were led into a vertical chamber on the top side of the pump, suitable arrangements being made for regulating the delivery. The pump was 3½ ft. in diameter, and made about 230 revolutions per minute. The water was drawn up on the bottom side and mixed with the descending mud on the top side, and the two were discharged into a pipe 15 in. in diameter. The discharge pipe was a special feature, and consisted of a series of wooden pipes jointed together with leather hinges and floated on buoys from the dredger to the bank. In some cases this pipe was 300 yds. long, and discharged the material 8 ft. above the water level. Each dredger and pump was capable of discharging an average of 1500 cub. yds. per day of 12 hours. Schmidt’s sand pump is claimed to be an improvement on the Burt & Freeman pump. It consists of a revolving wheel 6 ft. in diameter, with cutters revolving under a hood which just allows the water to pass underneath. To the top side of the hood a 20 in. suction pipe from an ordinary centrifugal pump is attached. The pump is driven by two 16 in. by 20 in. cylinders, at 134 revolutions per minute, the boiler pressure being 95 ℔ per sq. in. This apparatus is capable of excavating sticky blue clayey mud, and will deliver the material at 500 to 650 yds. distance. The best results are obtained when the mixture of mud and water is as 1 to 6.5. The average quantity excavated per diem by the apparatus is 1300 cub. yds., the maximum quantity being 2500 cub. yds.

Kennard’s sand pump is entirely different from the pumps already described, and is a direct application of the ordinary lift pump. A wrought iron box has a suction pipe fitted at the bottom, rising about half way up the inside of the box; on the top of the box is fitted the actual pump and the flap valves. The apparatus is lowered by chains, and the pump lowered from above. As soon as the box is filled with sand it is raised, the catches holding up the bottom released, and the contents discharged into a punt.

Sand-pump dredgers, designed and arranged by Mr Darnton Hutton, were extensively used on the Amsterdam Ship Canal. A centrifugal pump with a fan 4 ft. in diameter was employed, the suction and delivery pipes, each 18 in. in diameter, being attached to an open wrought-iron framework. The machine was suspended between guides fixed to the end of the vessel, which was fitted with tackle for raising, lowering and adjusting the machine. The vessel was fitted with a steam engine and boiler for working and manipulating the pumps and the heavy side chains for the guidance of the dredger. The engine was 70 h.p., and the total cost of one dredger was £8000. The number of hands required for working this sand-pump dredger was one captain, one engineer, one stoker and four sailors. Each machine was capable of raising about 1300 tons of material per day, the engines working at 60 and the pump at 180 revolutions per minute. The sand was delivered into barges alongside the dredger. The cost of raising the material and depositing it in barges was about 1d. per ton when the sand pumps were working, but upon the year’s work the cost was 2.4d. per cub. yd. for working expenses and repairs, and 1.24d. per cub. yd. for interest and depreciation at 10% upon the cost of the plant, making a total cost for dredging of 3.64d. per cub. yd. The cost for transport was 3.588d. per cub. yd., making a total cost for dredging and transport of 7.234d. per cub. yd. Dredging and transport on the same works by an ordinary bucket dredger and barges cost 8.328d. per cub. yd.

Two of the largest and most successful instances of sand-pump dredgers are the “Brancker” and the “G. B. Crow,” belonging to the Mersey Docks and Harbour Board. Mr A. G. Lyster gave particulars of the work done by these dredgers in a paper read before the Engineering Congress in 1899. They are each 320 ft. long, 47 ft. wide and 20.5 ft. deep, the draught loaded being 16 ft. They are fitted with two centrifugal pumps, each 6 ft. in diameter, with 36 in. suction and delivery pipes, united into a 45 in. diameter pipe, hung by a ball and socket joint in a trunnion, so as to work safely in a seaway when the waves are 10 ft. high. The suction pipe is 76 ft. long and will dredge in 53 ft. of water. The eight hoppers hold 3000 tons, equivalent when solid to 2000 cub. yds.; they can be filled in three-quarters of an hour and discharged in five minutes. Mr Lyster stated that up to May 1899, the quantity removed from bar and main-channel shoals amounted to 41,240,360 tons, giving a width of channel of 1500 ft. through the bar, with a minimum depth of 27 ft. The cost of dredging on the bar by the “G. B. Crow” during 1898, when 4,309,350 tons of material were removed, was 0.61d. per ton for wages, supplies and repairs. These figures include all direct working costs and a proportion of the charge for actual superintendence, but no allowance for interest on capital cost or depreciation. On an average, 20% of the sand and mud that are raised escapes over the side of the vessel. Mr Lyster has, however, to a considerable extent overcome this difficulty by a special arrangement added to the hoppers (see Proc. Inst. C.E. vol. 188).

At the Engineering Conference, 1907, Mr Lyster read a note in which he stated that the total quantity of material removed from the bar of the Mersey, from the Crosby channel, and from other points of the main channel by the “G. B. Crow” and “Brancker” suction dredgers amounted to 108,675,570 tons up to the 1st of May 1907. “In the note of 1899 (he added) it was pointed out that the Mersey was a striking instance of the improvement of a river by dredging rather than by permanent works, and the economy of the system as well as the advantage which its elasticity and adaptability to varying circumstances permit, was pointed out.... The most recent experience, which has resulted in the adoption of the proposal to revet the Taylor’s bank, indicates that the dredging method has its limitations and cannot provide for every contingency which is likely to arise; at the same time, the utility and economy of the dredging system is in no way diminished.... Having regard to the ever-increasing size of vessels, a scheme for new docks and entrances on a very large scale received the authority of parliament during the session of 1905-1906 In this scheme it was considered necessary to make provision for vessels of 1000 ft. in length and 40 ft. in draught, and having regard to this prospective growth of vessels it has been determined still further to deepen and improve the outer channel of the Mersey. No fixed measure of improvement has been decided on, but after careful survey of existing conditions and a comparison with probable requirements, it has been determined to construct a dredger of 10,000 tons capacity, provided with pumping power equivalent to about three times that of any existing dredgers. By the use of this vessel it is anticipated that it will be possible to deal with very much larger quantities of sand at a cheaper rate, and to 10 ft. greater depth than the existing plant permits.”

The vessel in question was launched on the Mersey from the yard of Messrs Cammell, Laird & Co. in October 1908, and was named the “Leviathan.” Her length is 487 ft., beam 69 ft., and depth 30 ft. 7 in. Her dredging machinery consists of four centrifugal pumps driven by four sets of inverted triple expansion engines, and connected to four suction tubes 90 ft. long and 42 in. in internal diameter. Her propelling machinery, consisting of two sets of triple expansion engines, is capable of driving her at a speed of 10 knots.

Another powerful and successful sand-pump dredger, “Kate” (Plate I. fig. 7), was built in 1897 by Messrs Wm. Simons & Co. Ltd. for the East London Harbour Board, South Africa. Its dimensions are: length 200 ft., breadth 39 ft., depth 14 ft. 6 in., hopper capacity 1000 tons. The pumping arrangements for filling the hopper with sand or discharging overboard consist of two centrifugal pumps, each driven from one of the propelling engines. The suction pipes are each 27 in. in diameter, and are so arranged that they may be used for pumping either forward or aft, as the state of the weather may require. Four steam cranes are provided for manipulating the suction pipes. Owing to the exceptional weather with which the vessel had to contend, special precautions were taken in designing the attachments of the suction pipes to the vessel. The attachment is above deck and consists of a series of joints, which give a perfectly free and universal movement to the upper ends of the pipes. The joints, on each side of the vessel, are attached to a carriage, which is traversed laterally by hydraulic gear. By this means the pipes are pushed out well clear of the vessel’s sides when pumping, and brought inboard when not in work. Hydraulic cushioning cylinders are provided to give any required resistance to the fore and aft movements of the pipes. When the vessel arrived at East London on the 18th of July 1897, there was a depth of 14 ft. on the bar at high tide. On the 10th of October, scarcely three months afterwards, there was a depth of 20 ft. on the bar at low water. Working 22 days in rough weather during the month of November 1898, the “Kate” raised and deposited 2½ m. at sea 60,000 tons of dredgings. Her best day’s work (12 hours) was on the 7th of November, when she dredged and deposited 6440 tons.

A large quantity of sand-pump dredging has been carried out at Boulogne and Calais by steam hopper pump dredgers, workable when the head waves are not more than 3 ft. high and the cross waves not more than 112 ft. high. The dredgings are taken 2 m. to sea, and the price for dredging and depositing from 800,000 to 900,000 cub. metres in 5 or 6 years was 7·25d. per cub. yd. The contractor offered to do the work at 4·625d. per cub. yd. on condition of being allowed to work either at Calais or Boulogne, as the weather might permit. Sand-pump dredging has also been extensively carried out at the mouth of the ports of Amsterdam, Rotterdam and on the north coast of France by sand dredgers constructed by Messrs L. Smit & Son and G. & K. Smit. The largest dredger, the “Amsterdam,” is 141 ft. by 27 ft. by 10 ft. 8 in., and has engines of 190 i.h.p. The hopper capacity is 10,600 cub. ft., and the vessel can carry 600 tons of dredgings. The pump fan is 6 ft. 3 in. in diameter by 10 in. wide, the plates being of wrought iron, and makes 130 revolutions a minute. The pump can raise 230 cub. ft. a minute from a depth of 33 ft., which, taking the proportion of 1 of sand to 7 of water, gives a delivery of 29 cub. ft. of sand per minute. The hopper containing 10,600 cub. ft. was under favourable circumstances filled in 40 minutes. The vessels are excellent sea boats.

Combined Bucket-Ladder and Sand-Pump Dredgers.—Bucket ladders and sand pumps have also been fitted to the same dredger. A successful example of this practice is furnished by the hopper dredger “Percy Sanderson” (Plate I. fig. 8), constructed under the direction of Sir C. A. Hartley, engineer of the Danube Commission for the deepening of the river Danube and the Sulina bar. This dredger is 220 ft. by 40 ft. by 17 ft. 2 in., and has a hopper capacity for 1250 tons of dredgings. The buckets have each a capacity of 25 cub. ft., and are able to raise 1000 tons of ordinary material per hour. The suction pump, which is driven by an independent set of triple expansion engines, is capable of raising 700 tons of sand per hour, and of dredging to a depth of 35 ft. below the water-line. The lower end of the suction pipe is controlled by special steam appliances by which the pipe can be brought entirely inboard. The “Percy Sanderson” raises and deposits on an average 5000 tons of material per day.

Grab Dredgers.—The grab dredger was stated by Sir Benjamin Baker (Proc. Inst. C.E. vol. 113, p. 38) to have been invented by Gouffé in 1703, and was worked by two ropes and a bar. Various kinds of apparatus have been designed in the shape of grabs or buckets for dredging purposes. These are usually worked by a steam crane, which lets the open grab down to the surface of the ground to be excavated and then closes it by a chain which forces the tines into the ground; the grab is then raised by the crane, which deposits the contents either into the hopper of the vessel upon which the crane is fixed or into another barge.

The Priestman grab has perhaps been more extensively used than any other apparatus of this sort. It is very useful for excavating mud, gravel and soft sand, but is less effective with hard sand or stiff clay—a general defect in this class of dredger. It is also capable of lifting large loose pieces of rock weighing from 1 to 2 tons. A dredger of this type, with grab holding 1 ton of mud, dredged during six days, in 19 ft. of water, an average of 5212 tons and a maximum of 6812 tons per hour, and during 12 days, in 16 ft. of water, an average of 48 tons and a maximum of 58 tons per hour, at a cost of 1·63d. per ton, excluding interest on the capital and depreciation. The largest dredger to which this apparatus has been applied is the grab bucket hopper dredger “Miles K. Burton” (Plate I. fig. 9), belonging to the Mersey Docks and Harbour Board. It is equipped with 5 grabs on Morgan’s patent system, which is a modification of Priestman’s, the grabs being worked by 5 hydraulic cranes. It raised and deposited, 12 to 15 m. at sea, 11 loads of about 1450 tons each with a double shift of hands, at a cost of about 1s. 5d. per cub. yd. of spoil, including the working expenses for wages of crew, fuel and stores. Mr R. A. Marillier of Hull has stated that “the efficiency of these grabs is not at all dependent upon the force of the blow in falling for the penetration and grip in the material, as they do their work very satisfactorily even when lowered quite gently on to the material to be cut out, the jaws being so framed as to draw down and penetrate the material as soon as the upward strain is put on the lifting chain. Even in hard material the jaws penetrate so thoroughly as to cause the bucket to be well filled. The grab is found to work successfully in excavating hard clay from its natural bed on dry land.” It is claimed on behalf of grabs that they lift a smaller proportion of water than any other class of dredger.

Since the beginning of the 20th century considerable advance has been made in the use of Priestman grabs, not only for dredging and excavating (for which work they were originally designed), but also in discharging bulk cargo. The first quadruple dredger used by the Liverpool Docks Board had grabs of a capacity of 30 cub. ft., but subsequently second and third quadruple dredgers were put to work in the Liverpool Docks, with grabs having a capacity of 70 and 100 cub. ft. respectively. In discharging coal at Southampton, Havre, Erith, as well as at the coaling station at Purfleet on the Thames, grabs having a capacity of about 80 cub. ft. are in constant use. Perhaps the most difficult kind of bulk cargo to lift is “Narvick” iron ore, which sets into a semi-solid body in the holds of the vessels, and for this purpose one of the largest grabs, having about 150 cub. ft. capacity and weighing about 8 tons, has been adopted. This grab was designed as a result of experiments extending over a long period in lifting iron ore. It is fitted with long, forged, interlocked steel teeth for penetrating the compact material, which is very costly to remove by hand labour. The Priestman grab is made to work with either one or two chains or wire ropes. Grabs worked with two chains or ropes have many advantages, and are therefore adopted for large undertakings.

Wild’s single chain half-tine grab works entirely with a single chain, and has been found very useful in excavating the cylinders in Castries harbour. Upon experimenting with an ordinary grab a rather curious condition of things was observed with respect to sinking. On penetrating the soil to a certain depth the ground was found as it were nested, and nothing would induce the grab to sink lower. Sir W. Matthews suggested that a further set of external tines might possibly get over this difficulty. A new grab having been made with this modification, and also with a large increase of weight—all the parts being of steel—it descended to any required depth with ease, the outside tines loosening the ground effectually whilst the inside bucket or tines picked up the material.

Miscellaneous Appliances.—There are several machines or appliances which perhaps can hardly be called dredgers, although they are used for cleansing and deepening rivers and harbours.

Kingfoot’s dredger, used for cleansing the river Stour, consisted of a boat with a broad rake fitted to the bow, capable of adjustment to different depths. At the sides of the boat were hinged two wings of the same depth as the rake and in a line with it. When the rake was dropped to the bottom of the river and the wings extended to the side, they formed a sort of temporary dam, and the water began to rise gradually. As soon as a sufficient head was raised, varying from 6 to 12 in., the whole machine was driven forward by the pressure, and the rake carried the mud with it. Progress at the rate of about 3 m. an hour was made in this manner, and to prevent the accumulation of the dredgings, operations were begun at the mouth of the river and carried on backwards. The apparatus was very effective and the river was cleansed thoroughly, but the distance travelled by the dredger must have been great.

In 1876 J. J. Rietschoten designed a “propeller dredger” for removing the shoals of the river Maas. It consisted of an old gunboat fitted with a pair of trussed beams, one at each side, each of which carried a steel shaft and was capable of being lowered or raised by means of a crab. An ordinary propeller 3 ft. 6 in. in diameter was fixed to the lower end of the shaft, and driven by bevel gear from a cross shaft which derived its motion by belting from the fly-wheel of a 12 h.p. portable engine. The propellers were lowered until they nearly reached the shoals, and were then worked at 150 revolutions per minute. This operation scoured away the shoal effectively, for in about 40 minutes it had been lowered about 3 ft. for a space of 150 yds. long by 8 yds. wide.

A. Lavalley in 1877 designed an arrangement for the harbour of Dunkirk to overcome the difficulty of working an ordinary bucket-ladder dredger when there is even a small swell. A pump injects water into the sand down a pipe terminating in three nozzles to stir up the sand, and another centrifugal pump draws up the mixed sand and water and discharges it into a hopper, the pumps and all machinery being on board the hopper. To allow for the rising and falling of the vessel—either by the action of the tide or by the swell—the ends of the pipes are made flexible. The hopper has a capacity of 190 cub. yds., and is propelled and the pumps worked by an engine of 150 i.h.p. From 50 to 80 cub. yds. per hour can be raised by this dredger.

The “Aquamotrice,” designed by Popie, and used on the Garonne at Agen, appears to be a modification of the old bag and spoon arrangement. A flat-bottomed boat 5112 ft. long by 612 ft. wide was fitted at the bow with paddles, which were actuated by the tide. Connected with the paddles was a long chain, passing over a pulley on uprights and under a roller, and a beam was attached to the chain 14 ft. 8 in. long, passing through a hole in the deck. At the end of the beam was an iron scoop 2 ft. wide and 2 ft. 6 in. deep. When the tide was strong enough it drew the scoop along by means of the paddles and chains, and the scoop when filled was opened by a lever and discharged. About 65 cub. yds. of gravel could be raised by the apparatus in 12 hours. When the tide failed the apparatus was worked by men.

The Danube Steam Navigation Co. removed the shingle in the shallow parts of the river by means of a triangular rake with wrought-iron sides 18 ft. long, and fitted with 34 teeth of chilled cast iron 12 in. deep. This rake was hung from the bow of a steamer 180 ft. long by 21 ft. beam, and dragged across the shallows, increasing the depth of water in one instance from 5 ft. 6 in. to 9 ft., after passing over the bank 355 times.

A combination of a harrow and high pressure water jets, arranged by B. Tydeman, was found very efficacious in removing a large quantity of mud which accumulated in the Tilbury Dock basin, which has an area of about 17 acres, with a depth of 26 ft. at low-water spring tides. In the first instance chain harrows merely were used, but the addition of the water jets added materially to the success of the operation. The system accomplished in six tides more than was done in twelve tides without the water jets which worked at about 80 lb pressure per sq. in. at the bottom of the dock.

Ive’s excavator consists of a long weighted spear, with a sort of spade at the end of it. The spade is hinged at the top, and is capable of being turned at right angles to the spear by a chain attached to the end of the spear. The spade is driven into the ground, and after releasing the catch which holds it in position during its descent, it is drawn up at right angles to the spear by the chain, carrying the material with it. Milroy’s excavator is similar, but instead of having only one spade it generally has eight, united to the periphery of an octagonal iron frame fixed to a central vertical rod. When these eight spades are drawn up by means of chains, they form one flat table or tray at right angles to the central rod. In operation the spades hang vertically, and are dropped into the material to be excavated; the chains are then drawn up, and the table thus formed holds the material on the top, which is lifted and discharged by releasing the spade. This apparatus has been extensively used both in Great Britain and in India for excavating in bridge cylinders.

The clam shell dredger consists of two hinged buckets, which when closed form one semi-cylindrical bucket. The buckets are held open by chains attached to the top of a cross-head, and the machine is dropped on to the top of the material to be dredged. The chains holding the bucket open are then released, while the spears are held firmly in position, the buckets being closed by another chain. Bull’s dredger, Gatmell’s excavator, and Fouracre’s dredger are modifications with improvements of the clam shell dredger, and have all been used successfully upon various works.

Bruce & Batho’s dredger, when closed, is of hemispherical form, the bucket being composed of three or four blades. It can be worked by either a single chain or by means of a spear, the latter being generally used for stiff material. The advantage of this form of dredger bucket is that the steel points of the blades are well adapted for penetrating hard material. Messrs Bruce & Batho also designed a dredger consisting of one of these buckets, but worked entirely by hydraulic power. This was made for working on the Tyne. The excavator or dredger is fixed to the end of a beam which is actuated by two hydraulic cylinders, one being used for raising the bucket and the other for lowering it; the hydraulic power is supplied by the pumps in the engine-room. The novelty in the design is the ingenious way in which the lever in ascending draws the shoot under the bucket to receive its contents, and draws away again as the bucket descends. The hydraulic cylinder at the end of the beam is carried on gimbals to allow for irregularities on the surface being dredged. The hydraulic pressure is 700 ℔ per sq. in., and the pumps are used in connexion with a steam accumulator.

An unloading apparatus was designed by Mr A. Manning for the East & West India Dock Co. for unloading the dredged materials out of barges and delivering it on the marsh at the back of the bank of the river Thames at Crossness, Kent. A stage constructed of wooden piles commanded a series of barge beds, and the unloading dredger running from end to end of the stage, lifted and delivered the materials on the marsh behind the river wall at the cost of 1 d. per cub. yd.

Dredging on the River Scheldt below Antwerp.—This dredging took place at Krankeloon and the Belgian Sluis under the direction of L. Van Gansberghe. At Melsele there is a pronounced bend in the river, causing a bar at the Pass of Port Philip, and just below the pass of Lillo there is a cross-over in the current, making a neutral point and forming a shoal. After dredging to 8 metres (26·24 ft.) below low tide, in clay containing stone and ferruginous matter, a sandstone formation was encountered, which was very compact and difficult to raise. A suction dredger being unsuited to the work, a bucket-ladder dredger was employed. The dredging was commenced at Krankeloon in September 1894 and continued to the end of 1897. A depth of 6 metres (19·68 ft.) was excavated at first, but was afterwards increased to 8 metres (26·24 ft.). The place of deposit was at first on lands acquired by the State, 2·17 m. above Krankeloon, and placed at the disposal of the contractor. The dredgings excavated by the bucket-ladder dredger were deposited in scows, which were towed to the front of the deposit ground and discharged by a suction pump fixed in a special boat, moored close to the bank of the river. The material brought by the suction dredger in its own hull was discharged by a plant fixed upon the dredger itself. In both instances the material was deposited at a distance of 1640 ft. from the river, the spoil bank varying in depth from 2 to 7 metres. The water thrown out behind the dyke with the excavated material returned to the river, after settlement, by a special discharge lock built under the dyke. After 1896 the material was delivered into an abandoned pass by means of barges with bottom hopper doors or by the suction dredger. One suction dredger and three bucket-ladder dredgers were employed upon the work, and a vessel called “Scheldt I.” used for discharging the material from the scows. Four tugboats and twenty scows were also employed.

The largest dredger, “Scheldt III.,” was 147·63 ft. long by 22·96 ft. wide by 10·98 ft. deep, and had buckets of 21·18 cub. ft. capacity. The output per hour was 10,594 cub. ft. This dredger had also a complete installation as a suction dredger, the suction pipe being 2 ft. diameter. The fan of the centrifugal pump was 5·25 ft. diameter, and was driven by the motor of the bucket ladder. The three bucket dredgers worked with head to the ebb tide. They could also work with head to the flood tide, but it took so long a time to turn them about that it was impracticable. The work was for from 13 to 14 hours a day on the ebb tide. The effective daily excavation averaged 4839 cub. yds. Each dredger was fitted with six anchors. The excavated cut was 164 ft. wide by 6·56 ft. deep. “Scheldt III.” was capable of lifting a mass 9·84 ft. thick. The suction dredger “Scheldt II.” was of the multiple type, and is stated to be unique in construction. It can discharge material from a scow alongside, fill its own hopper with excavations, discharge its own load upon the bank or into a scow by different pipes provided for the purpose, and discharge its own load through hopper doors. The machinery is driven by a triple expansion engine of 300 i.h.p. working the propeller by a clutch. Owing to the rise and fall in the tide of 23 ft. the suction pipe is fitted with spherical joints and a telescopic arrangement. The vessel is 157·5 ft. by 28·2 ft. by 12·8 ft. The diameter of the pump is 5·25 ft. The wings of the pump are curved, the surface being in the form of a cylinder parallel to the axis of rotation, the directrix of which is an arc of a circle of 2·62 ft. radius with the straight part beyond. The suction and discharge pipes are 2 ft. diameter. A centrifugal pump is provided for throwing water into the scows to liquefy the material during discharge. The dredger, which is fitted with electric lights for work at night, is held by two anchors, to prevent lurching backwards and forwards; it can work on the flood as well as on the ebb tide, and can excavate to a depth of 42·65 ft., the output depending upon the nature of the material. With good material it can fill its tanks in thirty minutes. To empty the tanks by suction and discharge upon the bank over the dyke takes about fifty minutes, depending upon the height and distance to which the material requires to be delivered. The daily work has averaged eighteen hours, ten trips being made when the distance from the dredging ground to the point of delivery is about 1 m. When the dredged material is discharged into the Scheldt, a quantity of 5886 cub. yds. has been raised and deposited in a day, the mean quantity being 4700 cub. yds. When the distance of transportation is increased to 212 m., six voyages were made in a day, and the day’s work amounted to 3530 cub. yds.

|

| Fig. 2.—Diagram showing Action of Lobnitz Gold Dredger. |

Gold Dredgers.—Dredgers for excavating from river beds soil containing gold are generally fitted with a screen and elevator. They have been extensively designed and built by Messrs Lobnitz & Co. (fig. 2) and also by Messrs Hunter & English.

The writer is indebted to the Proceedings of the Institution of Civil Engineers, and especially to the paper of Mr J. J. Webster (Proc. Inst. C.E. vol. 89), for much valuable information upon the subject treated. He is also indebted to many manufacturers who have furnished him with particulars and photographs of dredging plant. (W. H.*)

2. Marine Biology

The naturalist’s dredge is an instrument consisting essentially of a net or bag attached to a framework of iron which forms the mouth of the net. When in use as the apparatus is drawn over the sea-bottom mouth forwards, some part of the framework passes beneath objects which it meets and so causes them to enter the net. It is intended for the collection of animals and plants living on or near the sea-bottom, or sometimes of specimens of the sea-bottom itself, for scientific purposes.

Until the middle of the 18th century, naturalists who studied the marine fauna and flora relied for their materials on shore collection and the examination of the catches of fishing boats. Their knowledge of creatures living below the level of low spring tides was thus gained only from specimens cast up in storms, or caught by fishing gear designed for the capture

Fig. 13.—Otho Frederick Müller’s Dredge (1770). of certain edible species only. The first effort made to free marine biology from these limitations was the use of the dredge, which was built much on the plan of the oyster dredge.

The Oyster Dredge.—At first naturalists made use of the ordinary oyster dredge, which is constructed as follows. The frame is an iron triangle, the sides being the round iron “arms” of the dredge, the base a flat bar called the shere or lip, which is sloped a little, not perpendicular to the plane of the triangle; an iron bar parallel to the base joins the arms. The net is fastened to the parallel bars and the portion of the arms between them, and consists of two parts: that attached to the shere is of round iron rings linked together by smaller ones of wire lashings, that attached to the upper bar is of ordinary network. Where these two portions of the bag meet a wooden beam is fastened. In use the frame is towed forward by its apex: the shere passes below oysters, &c., which pass back on to the iron netting. The length of each side of the triangular frame is about 6 ft., the width of the shere 3 in. and the height of the mouth just under a foot. The rings vary in size, but are usually some 212 in. in diameter. The weight is about 60 ℔. This dredge was soon abandoned: its weight was prohibitive for small boats, from which the naturalist usually worked, its wide rings allowed precious specimens to fall through, and its shallow net favoured the washing out of light objects on hauling through the moving water of the surface. Moreover, it sometimes fell on its back and was then useless, although when the apex or towing point was weighted no great skill is needed to avoid this.

Otho Müller used a dredge (fig. 13) consisting of a net with a square iron mouth, each of whose sides was furnished with a thin edge turned slightly away from the dredge’s centre. As any one of these everted lips could act as a scraper it was a matter of indifference which struck the bottom when the dredge was lowered. The chief defect of the instrument was the ease with which light objects could be washed out on hauling, owing to the size of the mouth. However, with this instrument Müller obtained from the often stormy Scandinavian seas all the material for his celebrated Zoologia Danica, a description of the marine fauna of Denmark and Norway which was published with excellent coloured plates in 1778; and historical interest attaches to the dredge as the first made specially for scientific work.

Ball’s Dredge.—About 1838 a dredge devised by Dr Ball of Dublin was introduced. It has been used all over the world, and is so apt for its purpose that it has suffered very little modification during its 70 years of life. It is known as Ball’s dredge or more generally simply “the dredge.”

|

| Fig. 14.—Ball’s Naturalist’s Dredge. |

Ball’s dredge (fig. 14) consists of a rectangular net attached to a rectangular frame much longer than high, and furnished with rods stretching from the four corners to meet at a point where they are attached to the dredge rope. It differs from Müller’s dredge in the slit-like shape of the opening, which prevents much of the “washing out” suffered by the earlier pattern, and in the edges. The long edges only are fashioned as scrapers, being wider and heavier than Müller’s, especially in later dredges. The short edges are of round iron bar.

Like Müller’s form, Ball’s dredge will act whichever side touches the bottom first, as its frame will not remain on its short edge, and either of the long edges acts as a scraper. The scraping lips thicken gradually from free edge to net; they are set at 110° to the plane of the mouth, and in some later patterns curve outwards instead of merely sloping. All dredge frames are of wrought iron.

The thick inner edges of the scrapers are perforated by round holes at distances of about an inch, and through these strong iron rings about an inch in diameter are passed, and two or three similar rings run on the short rods which form the ends of the dredge-frame. A light iron rod, bent to the form of the dredge opening, usually runs through these rings, and to this rod and to the rings the mouth of the dredge-bag is securely attached by stout cord or strong copper wire. Various materials have been used for the bag, the chief of which are hide, canvas and netting. The hide was recommended by its strength, but it is now abandoned. Canvas bags fill quickly with mud or sand and then cease to operate: on the other hand wide mesh net fails to retain small specimens. Probably the most suitable material is hand-made netting of very strong twine, the meshes half an inch to the side, the inter-spaces contracting to a third of an inch across when the twine is thoroughly soaked, with an open canvas or “bread-bag” lining to the last 6 in. of the net. A return to canvas covering has latterly occurred in the small dredge called the mud-bag, trailed behind the trawl of the “Albatross” for obtaining a sample of the bottom, and in the conical dredge.

The dimensions of the first dredges were as follows: Frame about 12 in. by about 4 in.; scraping lips about 2 in. wide; all other iron parts of round iron bar 58 in. diameter; bag rather more than 1 ft. long. These small dredges were used from rowing boats. Larger dredges were subsequently made for use from yawls or cutters. The mouth of these was 18 by 5 in., the scraping lips about 2 in. wide and bag 2 ft. deep; such a dredge weighs about 20 ℔. The dredge of the “Challenger” had a frame 4 ft. 6 in. by 1 ft. 3 in. and the bag had a length of 4 ft. 6 in.; the “Porcupine” used a dredge of the same size weighing 225 ℔. Doubtless the size of Ball’s dredge would have grown still more had it not been proved by the “Challenger” expedition that for many purposes trawls could be used advantageously instead of dredges.

Operation of the Dredge from Small Vessels. For work round the coasts of Europe, at depths attainable from a row-boat or yawl, probably the best kind of line is bolt-rope of the best Russian hemp, not less than 112 in. in circumference, containing 18 to 20 yarns in 3 strands. Each yarn should be nearly a hundredweight, so that the breaking strain of such a rope ought to be about a ton. Of course it is never voluntarily exposed to such a strain, but in shallow water the dredge is often caught among rocks or coral, and the rope should be strong enough in such a case to bring up the boat, even if there were some little way on. It is always well, when dredging, to ascertain the approximate depth with the lead before casting the dredge; and the lead ought always to be accompanied by a registering thermometer, for the subsequent haul of the dredge will gain greatly in value as an observation in geographical distribution, if it be accompanied by an accurate note of the bottom temperature. For depths under 100 fathoms the amount of rope paid out should be at least double the depth; under 30 fathoms, where one usually works more rapidly, it should be more nearly three times; this gives a good deal of slack before the dredge if the boat be moving very slowly, and keeps the lip of the dredge well down. When there is anything of a current, from whatever cause, it is usually convenient to attach a weight, varying from 14 ℔ to half a hundredweight, to the rope 3 or 4 fathoms in front of the dredge. This prevents in some degree the lifting of the mouth of the dredge; if the weight be attached nearer the dredge it is apt to injure delicate objects passing in.

In dredging in sand or mud, the dredge-rope may simply be passed through the double eye formed by the ends of the two arms of the dredge-frame; but in rocky or unknown ground it is better to fasten the rope to the eye of one of the arms only, and to tie the two eyes together with three or four turns of rope-yarn. This stop breaks much more readily than the dredge-rope, so that if the dredge get caught it is the first thing to give way under the strain, and in doing so it often alters the position of the dredge so as to allow of its extrication.

The dredge is slipped gently over the side, either from the bow or from the stern—in a small boat more usually the latter—while there is a little way on, and the direction which the rope takes indicates roughly whether the dredge is going down properly. When it reaches the ground and begins to scrape, an experienced hand upon the rope can usually detect at once a tremor given to the dredge by the scraper passing over the irregularities of the bottom. The due amount of rope is then paid out, and the rope hitched to a bench or rowlock-pin. The boat should move very slowly, probably not faster than a mile an hour. In still water or with a very slight current the dredge of course anchors the boat, and oars or sails are necessary; but if the boat be moving at all it is all that is required. It is perhaps most pleasant to dredge with a close-reefed sail before a light wind, with weights, against a very slight tide or current; but these are conditions which cannot be commanded. The dredge may remain down from a quarter of an hour to twenty minutes, by which time, if things go well, it ought to be fairly filled. In dredging from a small boat the simplest plan is for two or three men to haul in, hand over hand, and coil in the bottom of the boat. For a large yawl or yacht, and for depths over 50 fathoms, a winch is a great assistance. The rope takes a couple of turns round the winch, which is worked by two men, while a third hand takes it from the winch and coils it down.

It is easier to operate a dredge from a steam vessel than a sailing boat, but if the steamer is of any size great care should be taken that the dredge does not move too rapidly.

Two ingenious cases of dredging under unusual conditions are worthy of mention, one case from shore, one from ice. In the Trondligem Fjord, Canon A. M. Norman in 1890 worked by hauling the dredge up the precipitous shores of the fjord. The dredge was shot from a boat close to the shore, to which after paying out some hundreds of fathoms of line it returned. The dredge was then hauled from the top of the cliffs up whose side it scraped. Hitches against projecting rocks were frequent and were overcome by suddenly paying out line for a time. The dredge was lifted into a boat when it reached the surface of the sea. The other case occurred during the Antarctic expedition of the “Discovery.” Hodgson dropped loops of line along cracks which occasionally formed in the ice. The ice always joined up again, but with the line below it; and a hole being cleared at each place at which the end of the line emerged, the dredge could be worked between them.

The dredge comes up variously freighted according to the locality, and the next step is to examine its contents and to store the objects of search for future use. In a regularly organized dredging expedition a frame or platform is often erected with a ledge round it to receive the contents of the dredge, but it does well enough to capsize it on an old piece of tarpaulin. There are two ways of emptying the dredge; we may either turn it up and pour out its contents by the mouth, or we may have a contrivance by which the bottom of the bag is made to unlace. The first plan is the simpler and the one more usually adopted; the second has the advantage of letting the mass slide out more smoothly and easily, but the lacing introduces rather a damaging complication, as it is apt to loosen or give way. Any objects visible on the surface of the heap are now carefully removed, and placed for identification in jars or tubs of sea-water, of which there should be a number secured in some form of bottle basket, standing ready. The heap should not be much disturbed, for the delicate objects contained in it have already been unavoidably subjected to a good deal of rough usage, and the less friction among the stones the better.

Examination of the Catch. Sifting.—The sorting of the catch is facilitated by sifting. The sieves used in early English expeditions were of various sizes and meshes, each sieve having a finer mesh than the sieve smaller than itself. In use the whole were put together in the form of a nest, the smallest one with the coarsest mesh being on top. A little of the dredge’s contents were then put in the top sieve, and the whole set moved gently up and down in a tub of sea water by handles attached to the bottom one. Objects of different sizes are thus left in different sieves. A simple but effective plan is to let the sieves of various sized mesh fit accurately on each other like lids, the coarsest on top, and to pour water upon material placed on the top one. In the United States Bureau of Fisheries ship “Albatross” these sieves are raised to form a table and the water is led on them from a hose: the very finest objects or sediments are retained by the waste water escaping from a catchment tub by muslin bags let into its sides. Any of these methods are preferable to sifting by the agitation of a sieve hung over the side, as in the last anything passing through the sieve is gone past recall.

Preservation of Specimens.—The preservation of specimens will of course depend on the purpose for which they are intended. For microscopic observation formaldehyde has some advantages. It can be stored in 40% solution and used in 2%, thus saving space, and it preserves many animals in their colours for a time: formalin preparations do not, however, last as well as do those in spirit. The suitable fluids for various histological inquiries are beyond the scope of the present article; but for general marine histology Bles’ fluid is useful, being simple to prepare and not necessitating the removal of the specimen to another fluid. It is composed of 70% alcohol 90 parts, glacial acetic acid 7 parts, 4% formaldehyde 7 parts.