1911 Encyclopædia Britannica/Conveyors

CONVEYORS. “Conveyor” (for derivation see Conveyance) is a term generally applied to mechanical devices designed for the purpose of moving material in a horizontal or slightly inclined direction; in this article, however, are included a variety of appliances for moving materials in horizontal, vertical and combined horizontal and vertical directions. The material so handled may be conveyed in a practically uninterrupted stream, as in the case of worms, bands and pushplate conveyors, or elevators carrying grain or coal, &c.; or it may be conveyed from one point to another, intermittently, that is to say in a succession of separate loads, as happens with single bucket elevators, furnace hoists, rope and chain haulage, and also in the case of ropeways and aerial cableways. Some of these devices are of great antiquity, others are of quite modern origin. The principles of their construction are simple and easy of understanding, but by variations in the details of their construction the engineer has adapted these few appliances to the most varied work. At one end of the scale they may be used for such light duties as conveying the goods purchased by a customer to the packers and bringing them back made up into a parcel or for taking his money to the cashier and returning the change. At the other they are adopted for handling large quantities of heavy material at a minimum expenditure of human labour. Coal, for instance, a more or less friable substance, the value of which is seriously diminished by fracture, may be mechanically handled with a minimum risk of breakage. The difficult problem of handling the contents of gas retorts and coke ovens, and of simultaneously quenching and conveying the glowing material, has been solved. Perhaps an even more astonishing piece of work is the manipulation of the iron from the blast furnace; for instance, liquid metal is drawn from a furnace into pouring pots which in their turn discharge it to and distribute it over a pig-iron casting machine, which is practically a conveyor for liquid metal, consisting of a strand of moving moulds from which the solidified pigs, after cooling in water, are automatically removed after reaching the loading terminal over the railway trucks. Certain types of conveyors may be made to combine efficiently, with their primary work of transport, complex sorting, sifting, drying and weighing operations.

|

| Fig. 1.—Early Flour Mill Conveyor.[1] |

|

| Fig. 2.—Paddle Worm Conveyor. |

Worm Conveyors.—The worm conveyor, also known as the Archimedean screw, is doubtless the most ancient form of conveyor. It consists of a continuous or broken blade screw set on a spindle. This spindle is made to revolve in a suitable trough, and as it revolves any material put in is propelled by the screw from one end of the trough to the other. Such conveyors have been used in flour-mills for centuries. The writer has seen in an East Anglian mill which was over 250 years old disused screw conveyors, probably as old as the mill, consisting of spindles of octagonal shape, made of not too hard wood, around which a broken blade screw was formed by the insertion at regular intervals of small blades of hard wood (fig. 1). Modern worm conveyors usually consist of a spindle formed of a length of wrought iron piping, to which is fitted either a broken or continuous worm. In the former case (fig. 2) the worm is composed of a series of blades or paddles arranged like a spiral round the spindle; each blade is fixed, by means of its shank, in a transverse hole in the spindle, and the shank is held in position by being tapped and fitted with a nut. In this way is formed, out of separate blades, a practically complete screw, technically known as a “paddle worm.” The lengths or sections of the worm run to about 8 ft., the various lengths being coupled by turned gudgeons, which also serve as journals for the bearings. In the so-called continuous worm conveyors the screw is formed of a continuous sheet-iron spiral (fig. 3). Sometimes a narrow groove is cut in spiral form on the spindle, and in this groove the sheet-iron spiral is secured.

|

| Fig. 3.—Continuous Worm Conveyor. |

|

| Fig. 4.—Spiral or Anti-Friction Conveyor. |

The spiral or anti-friction conveyor (fig. 4) was introduced about 1887. In this case a narrow spiral, which passes concentrically round the spindle, with a space between both, is fixed to it at set intervals by small blades, each of which is itself fixed by its shank and a nut to the spindle. The spiral may be made of almost any section, from a round bar about ½ in. in diameter to L or T section, but is preferably a flat bar. Worms are fitted into wooden or iron troughs leaving a clearance of 18 to 14 in. The spindle must be supported at suitable intervals by bearings, preferably of the bush type. A continuous worm, being more rigid than a paddle worm, needs fewer supports. The lid of the worm trough should be loose, not screwed on, because in case of an accumulation of feed through a choke in a delivery spout the paddles of a paddle worm would be broken, or a continuous worm stripped, unless the material could throw off the lid and relieve the worm. The ratios of the pitch of the worm to the diameter must be regulated by the nature of the material to be conveyed, and will vary from one-third to a pitch equal to, or even exceeding, the diameter. The greater the pitch the larger the capacity, but also the greater the driving power required, at the same speed. For handling materials of greater specific gravity, such as cement, &c., it is advisable to use a smaller pitch than for substances of lower specific gravity, such as grain. The capacity of a continuous worm exceeds that of either a paddle or spiral conveyor of the same diameter, pitch and speed. As regards the relative efficiency of paddle and spiral conveyors a series of careful tests made by the writer indicated that, run at a slow speed the paddle worm, but at a high speed the spiral worm, has the greater efficiency. There is of course a speed at which the efficiency of both types is about equal, and that is at 150 revolutions per minute for conveyors 4 to 6 in. in diameter.

The power necessary to drive worm conveyors under normal conditions is very considerable; a continuous worm of 18 to 20 in. diameter running at 60 revolutions per minute will convey 50 tons of grain per hour over a distance of a hundred feet at an expenditure of 18½ to 19 H.P. A material like cement would require rather more power because of the greater friction of the cement against the blades and the trough. Delivery from a worm conveyor can be effected at any desired point, all that is necessary being to cut an outlet, which should preferably be as wide as the diameter of the worm, because the worm delivers only on its leading side, and is practically empty on the other side, so that a smaller outlet might only give exit to a portion of the feed, unless it was on the leading side.

|

| Fig. 5.—Tubular Worm Conveyor. |

A special form of worm conveyor is the tubular (fig. 5), which consists of an iron tube with a continuous spiral fitted to its inner periphery, or of iron or wooden tubes of square sections fitted with fixed baffle plates inside. In working it revolves bodily on suitable rollers. This type is more costly than the ordinary worm conveyors, and also requires more power. Its efficiency is, moreover, easily impaired if run at too high a speed, because the centrifugal force asserts itself and counteracts the propulsion, which in this case is effected by gravity. Some experiments made in 1868 by George Fosbery Lyster, engineer of the Liverpool docks, gave convincing results (see Proc. Inst. Mech. Eng., August 1869). The tubular worm conveyor is suitable where a granular material has to be moved over a comparatively short distance, say from one building to another on the same level, and where no bridge is available for the installation of any other kind of conveyor. Conveyors of this type have, however, come into use for conveying hard and cutting substances over considerable lengths. Ordinary worm conveyors are practically debarred from use for such substances on account of the short life of the intermediate bearings, which are not necessary with externally supported tubular worms.

To sum up, worm conveyors are of the simplest construction and of small prime cost. The terminals again are much less expensive than those of most other kinds of conveyors. When the distance to be traversed by the material is short, the worm conveyor has this advantage, that it is cheaper than other kinds of conveyors. If it be desired not only to convey but also to mix two or more materials, such as cement and sand in a dry state, or poultry food, this appliance is thoroughly well adapted for the work. On the other hand, there is a grinding action exercised on any material conveyed, and when hard or cutting substances are handled the wear and tear on the conveyor blades, trough and bearings is very great, and the power absorbed by a worm conveyor is a sensible item.

Band Conveyors.—The inventor of band conveyors for the handling of grain and minerals was G. F. Lyster, who, as already mentioned, in 1868 carried out exhaustive experiments at the Liverpool docks, where he established the band conveyor as a grain-handler. For granaries the band conveyor is an ideal appliance. Its capacity is great, and it can be run at relatively high speeds with a moderate expenditure of power. The band conveyor of to-day is an endless belt of canvas or more often india-rubber with insertion, and when fitted with the usual receiving and delivery appliances can be used to handle grain from or into granaries and also to feed bins or sections of a warehouse. The endless bands run over terminal pulleys, and are also supported on their way by a series of guide rollers, which are in greater number on the loaded than on the empty strand. The band is usually run quite flat, except that at the point or points where the grain is fed on it is slightly hollowed for a few feet, by means of two curving rolls which are set obliquely so as to make it trough-shaped. The supporting or guide rollers are 4 in. to 6 in. in diameter, and are sometimes made of wood, but more often consist of steel tubes to which spindles with conical end gudgeons are secured. The gudgeons generally run in suitable bush-bearings, which should be well lubricated. Band conveyors should be driven on the delivery and not the receiving terminal, as the tight side of the band is the flattest. The guide rollers, for ordinary grain conveyors, are fitted to the upper or working side of the band at intervals of about 6 ft., and at distances of 12 ft. on the lower or return strand. In cases where both strands of the band are used for carrying grain, the lower strand must be supported by as many rollers as the upper. Under such conditions, terminal pulleys must be of larger diameter than usual, the object being to throw the two strands farther apart, so as to give sufficient space between the two strands to spout the feed in and out again at the other end. The two strands can be run any distance apart by the use of two additional pulleys for the terminals. This arrangement would be in place where it was desired, as it might be, to run one strand of the band along the top floor of the granary to distribute, while the other strand travelled along the ground-floor or basement to withdraw, the grain.

|

| Fig. 6.—Throw-off Carriage for Band Conveyor. |

Band conveyors are kept tight, when the band is not very long, by a tightening gear, similar to that used on elevators, and consisting of two screws which push or better pull the two pedestals of one terminal pulley farther away from the other terminal. If the band is of such length that an adjustment of 4 to 5 ft. on the tightening gear is not sufficient, it is advisable to use in place of screws a tightening pulley, over which the belt passes, but which is itself held in tension by weights. The choice of the exact tightening gear will depend on various considerations, the length of the belt, the type of throw-off carriage used, and the quality of the belt all being factors to be considered. The throw-off carriage (fig. 6), which serves to withdraw material from the band at any desired point, is a simple but ingenious appliance consisting essentially of guide pulleys which by raising one part of the band and lowering the other have the effect of causing the grain to quit the surface of the band at the point where it is deflected upwards. The grain is thus cast clear of the band, and into the air, being caught as it falls in a hopper and spouted in any desired direction. Throw-off carriages differ in certain details, but the principle is the same. For feeding a band conveyor it is important to give the material a horizontal velocity, approaching that of the band. The grain should therefore be fed through a spout rather less in breadth than half of the width of the band, and set at an incline of 42½° to the horizontal. Band conveyors run at a speed of 400 to 600 ft. per minute, according to the nature of the material; oats, for instance, would be liable to be blown off the band at a speed in excess of 500, which would be suitable for wheat. Nuts, maize and the heavier seeds could be carried at 600. The power consumption by a grain-laden band compares favourably with any other form of conveyor. An 18-in. band 100 ft. in length running 500 ft. per minute would carry 50 tons per hour at an expenditure of only 4.5 H.P.

|

| Fig. 7. |

While the band conveyor is an ideal conveyor in warehouses and mills, it is also capable of rendering good service in handling such heavy materials as coal and minerals. Of course for such purposes the band and its fittings must be of much more substantial construction. The central portions of the band carrying the load, being subjected to great wear and tear, are often made of solid india-rubber extending to nearly half the thickness of the band in the middle, and tapering off towards the edges, while the surface facing the guide rollers is of insertion coated with india-rubber. Bands properly prepared and stretched will bear a strain of 3 tons to the square inch. Balata bands may be used in place of india-rubber, but though less expensive are not so lasting. Bands that have to carry coal or minerals are usually curved along the entire length of the upper or loaded strand into a trough shape by guide rollers (fig. 7). Bands of woven wire are sometimes used with coal-washing plants, but have the disadvantage of lack of durability. They are more liable to stretch and are high in price. They may be run as high as about 600 ft. per minute, but to ensure proper grip-driving terminals must either be faced with leather or made of wood. The speed of band conveyors loaded with coal or minerals greatly depends on the size of the fragments; the proper speed for large pieces would be 150–200 ft. per minute, while smaller material could be carried at a maximum velocity of 700–750 ft. Band conveyors will carry in an upward direction, up to 24 degrees, without any loss of capacity. They can be used not only to carry light and heavy bodies, such as grain and coal, in a continuous stream, but also to convey relatively large bodies such as sacks of flour, or cement, &c., intermittently. Thus a band 26 in. wide and 350 ft. long is used at a flour-mill in York to load sacks of flour into railway trucks; by this means 12 wagons can be loaded by two men in 1 hour. Band conveyors are not necessarily fixed in one place. A portable model has rendered good service in tunnel-cutting, mining and quarrying. This band is mounted in a light steel frame, itself fitted with small wheels, so as to be readily put in any required position, and is entirely self-contained, being provided with tightening gear, a small motor, &c. If required, several lengths can be joined together, or one band can deliver upon another at a lower level. The same advantages that attend the use of the band-conveyor for handling grain may be claimed for this appliance when carrying coal and heavy bodies, namely the demand for relatively small power, smooth and noiseless work, and gentle handling of material. On the other hand the feed cannot be withdrawn at intermediate points except by means of a throw-off carriage. The numerous bearings of the guide rollers require careful lubrication, and the rubber bands should be protected as much as possible from changes of temperature.

The metal band or belt conveyor, a modification of the rubber or canvas band conveyors, is an endless belt composed of iron plates connected to endless chains, usually of malleable cast iron, running under the plates. Such appliances, being obviously more cumbrous than band conveyors, are only used in handling material of a hard and cutting nature. They usually deliver only at the end, but if intermediate delivery be desired a scraper may be so fixed across the band at a given point, at an angle of 45°, as to scrape the whole or part of the feed into a shoot, or a scraper may be mounted obliquely on a suitable carriage which can be moved to any points at which delivery may be required. In some bands of this type supporting rollers are attached to the links and travel with them, or are fixed to the framing so that the band runs over them, an arrangement which has the advantage of economizing driving power and of promoting smooth running. Metal band conveyors are tightened in the same way as textile or rubber bands, and may run at a speed of 60 to 120 ft. per minute. The driving gear must always be placed at the delivery terminal, so that the loaded strand is in tension. Such appliances are often used as sorting tables or picking bands, for instance, for coal, cement, minerals, &c.

In another modification of the metal band conveyor, the travelling trough conveyor, the sides of each plate are turned up so as to form the conveying surface of the band into a continuous trough. With this arrangement intermediate delivery is impossible, as the sides of the trough will not allow the use of a scraper. As compared with push-plate conveyors (which consist of scrapers mounted on endless travelling chains that run usually in troughs), travelling trough conveyors are gentle handlers of material.

A conveyor which is capable of dealing with many different kinds of material is known as the vibrating trough conveyor. It is so far like the band and travelling trough conveyor that the material it conveys from one point to another is conveyed without the use of any stirring or pushing agent, such as belong to worm, push-plate and cable trough conveyors. For materials requiring gentle treatment, this type of conveyor is eminently suitable. There are different kinds of vibrating trough conveyors. In one type the trough is caused to make a reciprocating motion by means of a crank and connecting rod, the trough itself being supported on rollers. In another type the trough is actuated by a cam, or by cranks with some kind of quick return motion. In the appliance known as the Zimmer or swinging conveyor the trough is supported in its reciprocating motion by means of laminated spring legs set obliquely to the trough. These legs are securely bolted at one end to the floor or any other solid support, and at the other end to the trough itself; hence no lubrication is required, as would be the case with supporting rollers. Moreover the combined action of the reciprocating motion of the crank and the rocking of the spring legs has the effect of causing the material to travel faster in the trough with a given stroke of the crank than would be the case with any other support. The material to be conveyed is not carried along with its support as in the case of a band or travelling trough conveyor, but is caused to move in a series of hops, to use popular language.

|

| Fig. 8.—Swinging or Zimmer Conveyor. |

The action will be sufficiently explained by the appended diagram (fig. 8), which, however, is exaggerated to give a clearer idea of the actual movements, which are on quite a small scale. The line AB represents the bottom of the trough, while CC are two of the spring legs; the full lines indicate the spring legs at the extreme backward position of the crank, while the dotted lines show the spring legs and bottom of the trough at the extreme forward position of the crank D. The material to be conveyed, represented by E, is thrown forward by the forward movement of the crank, and describes a short parabolic curve; it is thrown at about a right angle to the inclined legs CC, but before it has time to complete its parabolic course, the trough has been moved by the crank into its original position. As soon as the material has dropped down, the trough makes another forward movement, whereupon the material is thrown forward another stage, and this process, which is continually repeated, as indicated by the letters E1, E2, E3, has the effect of carrying or conveying the material in the direction desired. It is important to note that the actual movement both of trough and material is within narrow bounds; the horizontal movement of the trough is only about 1 in., while the vertical or upward movement is about 18 in. The material is conveyed by this vibrating trough with a minimum of friction, as it is evident that the material is carried forward without any contact with the trough, while the very nature of the motion precludes injurious friction between the particles themselves. When the trough is full the material will move as it were in a solid mass.

An important improvement in this type of vibrating trough conveyor is the balanced conveyor, in which the trough is made in two sections, one being placed at a slightly lower level than the other, so that one-half may deliver into the other half. The two sections are driven by triple or quadruple cranks set at an angle of about 180° to one another. In this case one-half of the conveyor will move forward while the other moves backward, thus balancing each other (fig. 9). At the same time the material keeps moving in the same direction because all the spring legs are of the same inclination. It is usual to drive balanced conveyors at or near the centre of their length, but they may also be driven from one end, in which case the balancing of the conveyor would be effected by a powerful volute spring which is compressed and released by a crank and connecting rod, in place of being connected to one-half of the conveyor. Two sections of a Zimmer conveyor can be made to run in opposite directions by merely reversing the inclination of the spring legs; in such a case the sections of a trough would be connected by a flexible coupling. Conveyors of this type have been used in lengths up to 500 ft., and in widths of over 6 ft. The feed can be received or discharged at any desired point in the length; for drawing off material at intermediate points it is only necessary to open a slide in the bottom of the trough. If a great increase be desired in the capacity of this conveyor the connecting rod may be attached, not to the trough at all, but to the spring legs at a point of about a third or half-way from the base, so that the free ends of the legs can swing the trough backward and forward; by this means the stroke is amplified and consequently the capacity is increased, while the driving power required is practically the same.

|

| Fig. 9. |

The power absorbed by the Zimmer conveyor is comparatively small; a length of 100 ft. conveying a load of 50 tons per hour takes 8.75 h.p. With a speed of 300–370 revolutions per minute of the conveyor, the material will traverse 40-70 ft. per minute. The gentle action of this appliance has caused it to be largely used in dealing with friable materials, such as coal. The simplicity of the mechanism leaves little to get out of order, and the entire absence of travelling gear, such as supporting rollers, is a valuable feature. The capacity of the conveyor may be sensibly increased by running it on a downward gradient, while the capacity will be correspondingly diminished by working in an upward direction. Among many purposes for which this type of conveyor has been found suitable is that of a drainer in connexion with coal-washing plants. A perforated plate at the head will allow the water to escape, while the coal is carried to the other end. A slight upward slant permits the water left with the coal to run back and escape. In colliery work this conveyor makes a suitable picking table. The motion of the trough, while not so fast as to baffle the pickers, has the advantage of uniformly spreading the lumps of coal. This apparatus also lends itself to the grading of coal. All that is necessary is to fit the trough with a sieve which divides it into an upper and lower deck. The coarser material passes along the top of the sieve, while the finer coal, sifted out by the perforations, travels along the bottom of the trough till discharged. In spite of the gentle propelling action of this conveyor, it has a thorough sifting action; a perforated plate from 10 to 12 ft. long is usually sufficient to separate any desired grade, and at a certain Belgian colliery a conveyor of this type fitted with grading sieves feeds seven trucks standing in a row, but each on a different siding, and each taking coal of a different size. This conveyor has been found useful both as a drying and cooling appliance. Several substances of a sticky nature, such as moist sugar, which are difficult to deal with mechanically, can be efficiently handled by the swinging conveyor.

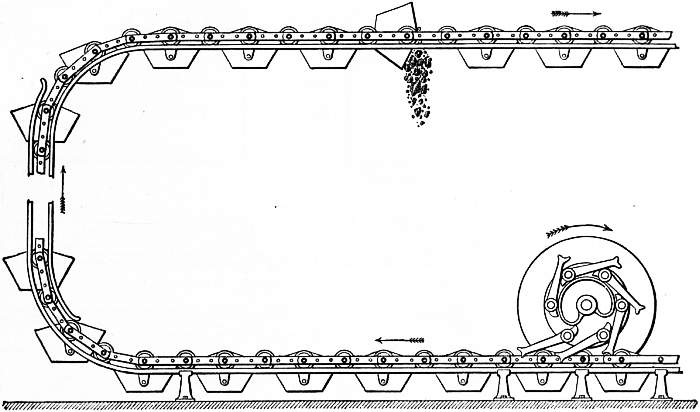

The gravity or tilting bucket conveyor can be used as a combined elevator and conveyor. It consists essentially of two endless chains or ropes held at fixed distances apart by suitable bars which are fitted with small rollers at each end. Every link, or second link, carries a bucket, and the whole forms an endless chain of buckets. But these buckets, unlike elevator buckets, which are bolted on to a band or chain, are free to move on the axis on which they are suspended above their centre of gravity. When the conveyor is at work the buckets will always be in an upright position, whether the motion be vertical or horizontal. Each bucket carries its load to the point at which delivery is required, where an adjustable tippling device is ready to catch and tilt the bucket, thus emptying it. This type of conveyor is chiefly used in connexion with coal stores and boiler houses, where it has undeniable advantages. For instance, in feeding overhead bunkers a well-designed gravity bucket conveyor may do the work of (1) a horizontal conveyor in bringing coal from the railway siding, (2) a vertical elevator in raising it to the bunkers, and (3) a horizontal conveyor in distributing it to the respective bunkers. In some cases the returning empty strand of buckets is used to clear the ashes from under the boilers.

Conveyors of this type run at a mean rate of 40 ft. per minute, and if it be desired to attain a given capacity the size of the buckets must be adapted to the increased load as an increase of speed for a higher capacity is impracticable. The power absorbed is not great, the heaviest demand on the motive force being made by the elevating operation. Such conveyors have the merit of handling the material gently, while feeding and discharging can take place at any point. There are many journals to be looked after, but in the most approved systems their lubrication is effected automatically. Whilst such a plant has the advantage of requiring only one driving gear, a breakdown at one point of the installation means the stoppage of the whole.

Among typical conveyors on this system is the Hunt conveyor (fig. 10), which consists of a double link carrying a series of pivoted buckets which are free to revolve on their axes at all points, except at that point at which they discharge. This operation is effected by a cam action, the buckets on their release righting themselves and becoming ready for refilling. The driving gear propels the chain by means of pawls which engage with the cross studs of the chain and have a central thrusting action. Another well-known appliance of this type is the pan bucket conveyor. This consists of a continuous trough built in sections and supported on axles and guide wheels running on suitable rails. There is one axle to each section, and in each section of the trough a bucket is pivoted to the sides. There are several other conveyors of this type, amongst which the “Tipit” should be mentioned. For the Bousse gravity conveyor it is claimed that it will go round any curve backwards or forwards in both planes, and is therefore adaptable for installations when the typical gravity bucket would be useless. The buckets of this conveyor are coupled together by a link in the middle, which obviously allows more latitude in negotiating curves than the double chain of most of the other types.

Pneumatic Grain Elevators have been employed with good effect in loading and unloading grain from ships. This method of conveying grain falls under three systems: (1) the blast system; (2) the suction system; and (3) the combined blast and suction system.

In the first system a barge, known as a machinery barge, is fitted with a steam boiler, a set of air compressing engines, and a length of flexible piping long enough to reach from any part of the barge to the farthest corner of the ship to be loaded. A small pipe, known as the nozzle, is inserted at the inlet end of the piping, where the grain is taken in, and communicates with the air compressor at the other end. Compressed air can be admitted to the nozzle or shut off by a valve. The inlet end of the flexible pipe is pushed into the grain in the barge, while the other end is led over the hatches of the vessel to be loaded. As the compressor is set to work and the valve of the compressed air supply pipe opened, the air naturally rushes up the pipe and escapes at the other end which is lying over the ship’s hatchway. If the inlet nozzle be immersed in the grain to the depth of 12 to 18 in. the induced atmospheric air will follow the lead of the compressed air, and drawing the grain around into the inlet nozzle will carry it up the pipe and deliver it into the hold of the vessel loading.

|

| Fig. 10.—Travelling Bucket Elevator. |

In the suction system, which is identified with the name of F. E. Duckham, the process is somewhat different. An air-tight tank or receiver, 8 to 10 ft. in diameter and 10 to 20 ft. high, is fitted with a hopper bottom, and is erected, if floating, on a barge, at a sufficient height to allow grain falling from the hopper bottom, and passing through an air lock, to be delivered by gravity through a shoot into the vessel being loaded. A pipe connects the vacuum tank with the exhaust pumps. Several flexible pipes of sufficient length to reach any corner of the ship to be unloaded, may be connected with the vacuum tank. As the air pumps are set working a partial vacuum is formed within the tank, and as the nozzle end of the pipe is immersed into the grain to the depth of a few inches, the air and grain are drawn in at the mouth of the nozzle and carried along the pipe to the vacuum tank. The natural expansion of the air then lets the grain drop to the hopper bottom, whence it issues from an air-lock valve, while the air is drawn away by a pipe communicating with the pumps and is thence discharged into the open.

In the third system, or blast and suction combined, the grain is sucked into a vacuum tank, as just described, and drops from this through valves into a second receptacle, whence it is conveyed to any desired point by flexible pipes. This second tank is divided into two sections and provided with valves so that the two sections will alternately be under the influence of blast or suction. Alternatively the grain is discharged by an automatic valve from the vacuum tank into the second air-tight chamber which communicates with the compressed air chamber. From this section the grain is discharged by an outlet pipe by the agency of compressed air. A similar system was introduced by Messrs Haviland & Farmer, who have, however, since abandoned it on account of difficulties connected with the application of the blast, which was found to abrade the grain rather severely, especially at the bends in the pipes. An even greater objection was the delivery of dust with the grain, which made it impossible for trimmers to remain in the hold while the elevator was at work. Messrs Haviland and Farmer now work on the suction system, in which they claim to have introduced several improvements, notably in regard to the purification of the air between the vacuum chamber and the exhaustors, and in devising a new automatic air trap.

The first pneumatic suction elevator in Great Britain was erected at the Millwall docks (London) under the Duckham patents. At Sulina, on the Lower Danube, a pneumatic elevator erected on the Haviland-Farmer system, which has undergone one or two reconstructions, has been proved capable of elevating 160 tons of grain per hour with 375 i.h.p.

The only objection to pneumatic elevators appears to be that of expense. The cost of installation is relatively heavy, and the power required for working is large. But in dealing with vessels carrying heavy cargoes of grain the saving of labour and demurrage is sufficient to justify the large outlay of capital required in ports where there is sufficient grain traffic.

Hot Coke Conveyors.—Hot coke is admittedly one of the most difficult materials to handle by mechanical means, and though it might be too much to say that all difficulties have been surmounted by the engineer, it has, since the end of the 19th century, been more or less satisfactorily handled by machinery. Even in a dry state coke is a troublesome material to handle by machinery. It is of a gritty and rasping nature, and is at the same time very friable. Unless it is gently handled, breakage is bound to occur and to result in the making of a certain proportion of fine dust known as “breeze.” Apart from the depreciation in the value of the coke, this breeze is a sharp, cutting material, calculated to do considerable injury to the working parts of the conveyor, such as chains, and to the bearings, if it can get inside. Of course the conveying of the coke in an incandescent condition is another serious difficulty, as this glowing material must be quenched by water, a sufficiently delicate operation in itself. The chief use for hot coke conveyors has been found in connexion with gas works, but attempts have also been made to provide efficient machinery for the service of coke ovens of great capacity.

The justification of any kind of machinery must rest on its relative efficiency and economy. As compared with some other materials the mechanical handling of hot coke does not realize such a striking economy; a hot coke conveyor is expensive to build—on account of the great wear and tear it must be very solidly constructed—and it is costly in upkeep. Still in large gas works the use of machinery for treating glowing coke is economically advisable. Exact calculations are not very easy to make, because while the cost of hand labour in this department of a gas works is accurately known, the efficiency of different hot coke conveyors varies. G. E. Stephenson, of the Gathorn gas works, estimated that a saving of 4¾d. per ton had been realized on each ton of coke conveyed to the yard from the retort house, as against the same material wheeled in barrows. This saving represented the difference between the cost of twelve men, who formerly handled the hot coke with shovels and barrows, and the cost of one conveyor with the wages of one man to look after it. In an ordinary way one man would rake out the coke from the retort mouthpiece into a barrow placed underneath, while a second man quenched the glowing coke with buckets of water, or better still with a hose. Then the barrow would be wheeled out into the yard. Obviously this is a slow and relatively expensive method, apart from the deleterious fumes arising from the quenching of the coke. Some improvement was effected by the substitution for the old hand-barrows of cage-like tipping trucks; these are run on narrow gauge rails out of the retort house and the red-hot coke they contain is quenched by a copious spray, the truck being placed the while over a grating through which the surplus water is drained away, under an inverted funnel with an uptake to carry away the fumes and vapours. These trucks have been hauled, in lieu of human arms, by endless ropes or even small locomotives.

The earlier hot coke conveyors were of the pushplate type. The trough, some 27 in. wide, consisted of cast iron sections, while the pushplates, formed of malleable castings, were attached at a pitch of 24 in. to a central chain and were pulled along on a wrought iron bar, which could be renewed when necessary. These conveyors with a speed of 48 ft. per minute, had a capacity of some 20 tons per hour. A conveyor constructed on these lines was installed at the Gathorn works in 1903. The wear and tear was very great; moreover the chain, being central, suffered severely from the hot coke, to the action of which it was directly exposed.

The New Conveyor Company’s conveyor consists of a water-tight trough through which pass closely-fitting tray plates, attached to a single chain. These plates are joggled down at one end to receive the flat front part of the succeeding plate, with the aim of excluding the breeze from the under part of the carrying plate. The chain is made entirely of steel with side rollers attached to every third plate, the plates, ¼ in. thick, are dished in the shape of a tray, which is less liable to distortion (from heat) than a flat plate. The speed of travel is about 45 ft. per minute, while the capacity when handling coke from 20 ft. retorts is some 30 tons per hour.

A conveyor made by Messrs Graham, Morton & Co., consists of a travelling tray, the sections of which are joined together by steel spindles provided with a roller at each end, the latter running on suitable rails. These sections consist of steel castings with a number of lateral slots; thus the tray has the appearance of a travelling grating. To receive the quenching water that escapes through the grating a trough is placed beneath, and a scraper is used to free the trough of the dust escaping through the grating.

|

| Fig. 11.—Bronder Hot Coke Conveyor. |

An interesting conveyor is that of G. A. Bronder, of New York (fig. 11), which has some affinity with the gravity bucket conveyor. It runs in a water-tight trough which is filled up to a certain height, the water being slowly circulated by mechanism which resembles a water wheel. The chain of buckets runs in the trough, the sides forming the rails for the supporting rollers. The conveyor is covered in along its whole length, and forms a sort of flue which is connected at each bench with a number of shoots through which the coke drops into the conveyor buckets. A pipe of large diameter is connected with an exhaust fan, which draws away the fumes created by the quenching process, and sends them into a chimney discharging into the open. The chain and buckets, being carried on rollers which run on the outer edge of the trough, cannot come in contact either with the hot coke or with gritty particles. The chain of buckets is connected by horseshoe-shaped brackets extending upwards beyond the sides of the buckets and connected with the links of the driving chains. When the conveyor is at work the covers of the mouth-pieces are opened and the coke is fed into the buckets; simultaneously the water valves are opened and the glowing coke is quenched. Any breeze which may have fallen between the buckets is collected by a scraper and delivered into a tank at one end, while the propeller wheel draws the water from this tank and drives it back to the other end of the trough. The top strand is the working strand and delivers its load at the terminal. One important difference between an ordinary gravity bucket conveyor and this apparatus is that the buckets are here rigidly connected to the supporting wheels.

The West hot coke conveyor consists of a strongly-built trough in which a single wide chain partly carries and partly drags the coke. In the trough is a false bottom, the plates of which are loosely fixed and kept in position by angle irons on which the chain drags. By two arm-like extensions the links of the chain are widened right across the trough. The pitch of the chain is 12 in., so that all the large pieces of coke are more carried than dragged. The speed of travel is about 40 ft. per minute.

|

| Fig. 12.—Wild Coke Conveyor. |

The Wild conveyor (fig. 12) consists of a cast iron or steel trough 24 to 30 in. wide by 9 in. deep, supported by cast iron brackets to which the rails that support the strands of the chain are secured. Both chains run outside the trough, and are secured on either side to the pushplates, so that only the scraper comes in contact with the hot coke. Every second link of the 12 in. pitch chain carries a push or scraper-plate, as shown in illustration.

The De Brouwer hot coke conveyor, which is much used in gas works both in Great Britain and on the continent of Europe, was invented by a Belgian engineer. Its construction has undergone many modifications which experience has shown to be desirable. It consists of a trough of cast or wrought iron, or mild steel, 20 to 36 in. wide and 3 to 6 in. deep. Double endless chains run in the corners of the trough, the two chains being connected together by round cross bars set 30 in. apart, so as to form a sort of ladder. The hot coke is carried or dragged along by these bars. One end of the trough is closed and the other is bent upwards with a view to retaining the quenching water. As the hot coke is dragged along it is subjected to the action of jets of water. The conveyor bars, which act as scrapers, sweep the water and the coke along the trough till the point is reached where the latter curves upwards. Then the water flows back like a small cascade on the half-quenched coke, which is thus thoroughly extinguished. Considerable inclines can be negotiated with this conveyor; in some installations on the continent of Europe angles of 30° to the horizontal have been surmounted. In a modification of the De Brouwer conveyor, installed at the Cassel gas works, the bars which form the rungs of the conveyor were replaced by cast iron rakes. In another modified form, the work of F. A. Marshall, to be found in the Copenhagen gas works, sluices are provided for withdrawing an excess of water at any point in the trough.

|

| Fig. 13.—Sempster Coke Conveyor. |

In Great Britain a hot coke conveyor has been designed on similar lines by Messrs R. Dempster & Sons, Ltd. (fig. 13). The chains are parallel from end to end, and are composed of identical and interchangeable malleable cast links. Instead of the chains carrying the rollers, as is often the case, the chains are themselves carried and guided by flanged rollers supported from the framework. This arrangement has the advantage of decreasing the weight of the chain, as neither the rollers nor the lubricators have to be conveyed, being stationary. The scrapers are of cast steel and have a rake-like shape with a view to minimize the breakage of coke.

The essential features in a hot coke conveyor are strength and simplicity, a minimum of wearing parts, interchangeability of wearing surfaces and of worn and broken parts, protection of wearing and working parts from contact with the hot coke, and facilities for keeping the temperature of the conveyor as even as possible, so as to avoid distortion of parts through sudden changes. To attain these latter conditions, it appears essential to construct conveyors of the pushplate type. In these the hot coke is kept continually moving, and thus the good effect is secured of heating the conveyor from end to end uniformly and gradually. This applies particularly to gas works conveyors.

For the service of coke ovens the plate or tray conveyor might be suitable because more gentle. It must be remembered that coke oven conveyors must be of large capacity, and moreover in this case there is more scope for cooling the coke in front of the oven before it is removed to the conveyor, the work being all effected in the open.

Elevators.—This term is here confined to its proper meaning (in English engineering treatises) of a device for raising material in a vertical or slanting direction by means of buckets attached to endless belts or chains. Lifts for passengers are also sometimes termed elevators (q.v.), and in America the term is also currently applied to the granary or warehouse in which grain is stored (see Granaries).

In the bucket elevator, an endless belt or chain runs over terminal pulleys which are fixed at different levels, the distance from centre to centre of these pulleys beings known as the length of the elevator. The design and construction of the elevator will be varied to suit its purpose. Grain elevators are invariably cased in wooden or iron trunks, and the head and foot are also of wood or iron, iron trunks being particularly used in so-called fire-proof buildings. The trunk of the grain elevator (fig. 14) is almost always vertical whilst the band to which the buckets are attached may consist of leather, cotton, hemp, webbing or other suitable substances. When an elevator is intended for lifting heavy materials, such as coal, coke or cement, it is usually set at a slant (figs. 15 and 16), and the endless belt is replaced by one or two strands of endless chain which support the buckets and run over the terminal sprocket wheels. The buckets are attached to the links of the chains, and to prevent these heavy buckets and chains from sagging in their inclined position, rollers or more often short skidder bars are fixed to each bucket, sliding on well-oiled angle bars on each side of the elevator frame.

|

| Fig. 14.—Grain Elevator. |

Both grain and mineral elevators are usually fitted with tightening gears to keep the belt or chain taut; these are generally placed at the lower or well end so as not to interfere with the position of the upper terminal, which is almost invariably the driven one. The tightening of the band at the bottom terminal in the elevator well necessarily alters the space between the terminal pulley and the bottom of the well. This is of little consequence in grain elevators, but for elevators intended to handle coal or any material of varying size the ordinary tightening gear is unsuitable. In such a case the best plan is to attach the elevator-well to the terminal in such a way as to go up or down with the sprocket wheel when the chain is loosened or tightened, while the foot bracket which supports the well and terminal spindle remains a fixture. In order to tighten elevator chains without interfering with either of the terminals, adjustable jockey pulleys at some suitable point may be used, and the desired effect can thus be attained by pressing against the chains and thereby taking up the slack without any interference with either the feed or delivery end.

Elevator buckets must be proportioned to the size and nature of the material they are intended to carry, and care must be taken to maintain a uniform feed. This may readily be effected by adjustable outlets and spouts for grain and the like, and by certain feeding devices for handling minerals of uneven size. For instance, an oscillating feed shoot making from 30 to 60 oscillations per minute can be installed in such a case, and adjusted to deposit at each backward and forward stroke the exact amount of material adapted to the capacity of the elevator. The speed of the shoot will naturally vary with the size of material to be fed. For small coal 60 oscillations would be about the correct speed; for large coal the speed might be reduced to 30 or less. Speaking generally, care should always be taken to prevent an undue rush of feed, that is, more than the elevator can take up, and if tenacious materials are handled, feeding devices should be employed provided with stirrers or agitators that will effectually keep the material moving and prevent any larger lumps from arching over the feed spout, and thus producing chokes. Elevators should always be fed from that side on which the buckets ascend, that the stream of material may meet the elevator buckets on their upward journey. This will prevent the material from filling up the elevator well and spare the buckets from dredging through an accumulation of feed. Elevators erected at an incline are best fed at a point several feet above the well into the chain of ascending buckets, as under such conditions little will miss the buckets and drop into the well.

The reason why grain elevators are set vertically, whereas elevators intended to carry heavy bodies such as coal and ore are generally inclined at an angle, is that the former can be run at a much greater velocity than the latter. Grain, for instance, would be uninjured by a velocity at the delivery end which would fracture coal and seriously reduce its value, to say nothing of the dust production and the damage which would be done to the receiving spouts and shoots. Elevators carrying a light material can be run at a circumferential velocity of 250 to 350 ft. per minute, and if vertically set, will throw the grain, &c., clear of the elevator into the shoot for its reception. On the other hand, elevators handling heavy material must be set at an angle in order to give a clear delivery at a much lower speed of 50 to 60 ft. per minute; in other words, the elevator is so inclined that the shoot for the reception of the material can be put underneath the delivering buckets which slowly disgorge their load. To obtain good results, without taking up too much space, an elevator carrying heavy material should be set at 40° to 60° to the horizontal. The same results can be obtained if the main portion of the elevator is vertical and only the upper portion inclined, or so curved as to bring the delivery over the shoot. The speed at which vertical elevators should be run will depend on the diameter of the terminal pulley, that is, the pulley over which the buckets and bands pass. The centrifugal force of pulleys revolving at the same speed is in direct proportion to their diameters, and this is twice as much in a 2 ft. as in a 1 ft. pulley. It may be taken that the centrifugal force of a pulley will increase in proportion to the square of its velocity; hence the centrifugal force of a pulley 2 ft. in diameter running at 50 revolutions per minute will be four times the centrifugal force of a pulley of the same diameter making only 25 revolutions per minute. It must not be forgotten that to effect a clean discharge of the buckets of a vertical elevator, the centrifugal force must be sufficient to overcome the gravity of the material, because the material thrown off the delivery pulley in a horizontal direction will be more rapidly deflected into a parabolic curve the higher its specific gravity. It follows that for a specifically heavy material a greater centrifugal force will be required; that is to say, the elevator will have to be higher speeded than in dealing with a lighter material.

|

| Fig. 15.—Mineral Elevator, upper terminal. |

Elevator buckets must be varied according to the nature of the material; for instance, shallow buckets will be found best for a soft and clinging material such as flour, moist sugar, sand, small coal, &c., while for a hard or semi-hard body such as wheat, coal, &c., deeper buckets are preferable. On account of their lower speed, elevators for specifically heavy material require much larger buckets and chains than grain elevators of the same bulk capacity. The most economical form of elevator is fitted with a continuous chain of buckets. Such elevators may be constructed to carry either grain or minerals. The advantages are greater capacity than an ordinary elevator of the same dimensions and a more uniform delivery; moreover, smoother running is secured, since the buckets being close together need not plunge intermittently through the contents of the elevator-well.

Intermittent Conveyors.—The elevators we have been considering, whether used for carrying and distributing coal or grain, have this in common, that they raise material from a lower to a higher level, so to speak, in a continuous stream, the continuity being broken only by the short spaces between the buckets. In the continuous bucket type indeed the stream of material is practically, if not absolutely, continuous. In all these cases the elevator is fed with the material in a continuous stream, and by some mechanical means; whether by band, worm or shoot, is immaterial. Elevators of a somewhat different and more substantial construction may be and are often used for handling filled sacks, barrels, carcases of animals and other bulky objects, which cannot be delivered in a uniform stream, but may have to be conveyed by the elevator intermittently. The ordinary buckets used for grain or coal are replaced by other appliances for gripping and holding the object to be raised from a lower to a higher level, but in principle these appliances are essentially elevators.

Another kind of elevator, known as a lift or hoist, is used in mines and quarries and in serving blast furnaces. This is an elevator with one or two buckets. Essentially a heavy load lifter, it is intended for material of too large a bulk to be handled economically by ordinary elevators, and is employed for lifting in either a vertical or, more often, an inclined direction.

For elevating materials, such as large coal, iron ore, limestone, &c., which are too large to be fed into ordinary elevators, and must therefore be handled intermittently, the single bucket elevator or hoist may be used with advantage. But as the essential use of mechanical appliances for handling material is to save human labour as far as possible, that hoist will prove the most economical the operation of which is as automatic as possible. The Americans seem to have been pioneers in the construction of furnace hoists, which form the principal elevators of this class, but some excellent examples of the modern furnace hoist are now to be found in Great Britain and elsewhere in Europe. Generally speaking, a furnace hoist consists of an inclined iron bridge girder set at an angle to the upright shaft of the furnace. On this incline are laid rails for the ascent and descent of the bucket, which in this case is known as a skip and is provided with suitable wheels, while the hoisting gear manipulating the skips by a steel rope is erected on or near the ground level. The rails when they approach the upper terminus are usually bent in a more or less horizontal position so as automatically to tilt and thereby unload the skip. To attain the same end, the rails supporting the back wheels of the skips may be bent at the terminus, or the back wheels may have additional wheels of a larger diameter on the other side of their flanges, so that during the ascent and descent the skip runs on its four normal wheels, while at the upper terminus the outer and larger back wheels engage with short lengths of extra rails and thus tilt and effect the automatic clearance of the skip. The dead weight of the skip may be balanced by a counter weight, or double tracks may be laid, so that the empty skip descends on one track whilst the loaded skip is being raised on the other. In this case the distributing hopper at the top of the furnace has an elongated shape so as to take the charges alternately from buckets on either track. Again, the two tracks may be laid one above the other, so that one skip runs on the upper rails and the other on the lower. The two buckets will pass each other at about the centre of the framing, where there will be plenty of room for clearance.

|

| Fig. 16.—Mineral Elevator, lower terminal. |

The capacity of the skip will of course depend to some extent on the capacity of the furnace, but an average charge may be put down at 2 tons of ore and lime, or 1 ton of coke. To raise such a charge to a furnace 80 ft. high would require, assuming no counter weight were used, a motor of about 100 h.p. On account of the great speed at which the hoist works, the time taken in raising the charged skip, discharging it, and returning it empty would be only 30 to 40 seconds. The hoist cable runs over guide pulleys placed at the top of the furnace, and the cable is often manipulated by an electrically driven winch in a cabin below. The descent of the empty skip in more modern installations is utilized to effect an even distribution of the feed from the hopper to the furnace by causing the hopper to revolve. To this end the latter is provided with an ingenious mechanism which only comes into operation as the car descends. After every charge shot into the hopper the latter is revolved a few degrees, and this has the effect of giving the delivery of the next load in another direction, so that the charges of the skip are in turn distributed over the whole area of the surface. This is deemed a most essential point in furnace-charging, and it is not one of the least recommendations of this mechanical system of furnace-charging that it can give an even feed without any hand labour whatever. A double hoist has been designed which has the advantage that if one elevator breaks down the work of the furnace is not interrupted. In this system two furnaces are connected at the top by a gantry or bridge, against which, between the furnaces, two inclined elevators are set, so that each can serve either furnace. The skips are on wheels and detachable from the elevator, and are loaded from the ore pockets at the lower terminal and drawn up on a cradle; as this reaches the top where the rails on the gantry correspond with the gauge of the skip or car, the latter is carried by its own weight down a slight incline to either furnace, discharging its contents as it passes over the conical mouth. Another advantage claimed for this system is that the rails of the cradle, when in its lowest position, correspond with the rails which lie parallel to the furnaces and run right under the store bins from which the skip is loaded. The economy to be realized from a furnace hoist will be in direct proportion to the use made of mechanical means of feed conveyance. For instance, the store bins in connexion with such elevators might be economically fed by suitable conveyors, or the material might be brought in self-unloading hoppered trucks into conveniently placed bins, ready to be drawn into the skips.

Ropeways.—A ropeway has been defined as that method of handling material which consists of drawing buckets on ropes, and by means of ropes, such buckets being filled with the material to be handled and being automatically or otherwise discharged. At what period of history ropeways were first used it is impossible to say, but the fact that pulley blocks, and even wire ropes, were known to the ancients, renders a pedigree of 2000 years at least possible. In more modern days, an old engraving shows a single ropeway in working order in 1644 in the city of Danzig. This, the work of Adam Wybe, a Dutch engineer, was a single ropeway in its simplest form, consisting of an endless rope passing over pulleys suspended on posts; to the rope were attached a number of small buckets, which evidently carried earth from a hill outside the city to the rampart inside the moat. The rope was probably of hemp. Modern ropeways worked with wire ropes date from about 1860, when a ropeway was erected in the Harz Mountains. Since then several systems have been evolved, but in the main ropeways may be divided into the single and double rope class.

The ropeway is essentially an intermittent conveyor, the material being carried in buckets or skips, and practice has proved it an economical means of handling heavy material. The prime cost of a ropeway is usually moderate, though of course it varies with the ground and other local conditions. Working expenses should be low, because under the supervision of one competent engineer unskilled labour is quite sufficient. A ropeway may be carried over ground over which rails could only be laid at enormous cost. To a certain extent ropeways are independent of weather conditions, because their working need not be interrupted even by heavy snowfalls. Their construction is very simple, and there is little gear to get out of order. Sound workmanship and good material will ensure a relatively long life. As an instance, a certain rope in a Spanish ropeway tested new to a breaking strain of 29½ tons was shown after carrying 160,000 tons (in two years’ incessant work) still to possess a breaking strain of 27½ tons. The power absorbed by a ropeway is relatively moderate, and under special conditions may be nil. The only demand it makes on the superficial area of the ground traversed is the small emplacements of the standards, which in modern ropeways are few and far between. Wayleaves, or the permission to erect standards and run the line over private land, may of course mean an item in the capital outlay. This circumstance may have checked ropeway construction in Great Britain, but it must also be borne in mind that a large portion of that country is comparatively level and well provided with railways. In building a ropeway it is essential to take as straight a line as possible, because curves generally necessitate angle stations, which mean extra capital and working cost. On the other hand, ground that would be difficult for the railway engineer, such as steep hills, deep valleys and turbulent streams, has no terror for the ropeway erector. There is a case of a ropeway of a total length of 5400 ft. with a total difference in altitude of 2000 ft.; it is claimed this ground could not be covered by a railway with less than 15 m. of line graded at 1 in 40.

Perhaps the simplest type of a single rope system is an endless running rope from which the carriers are suspended, and with which they move by frictional contact. Or the carriers may be fixed to this rope and move with it. The ropeway itself would consist of an endless rope running between two drums, one, known as the driving drum, being provided with power receiving and transmitting gear, while the drum at the opposite terminal would be fitted with tightening gear. The endless rope is carried on suitable pulleys which themselves are supported on standards or trestles spaced at intervals varying with the nature of the ground. The rope runs at an average speed of 4 m. per hour, a speed at which the bucket or skip can automatically unload itself. In the double ropeway the carrier runs on a fixed rope, which takes the place of the rails of a railway. The carrier is fitted with running heads furnished with grooved steel wheels. The load is borne by a hanger pivoted from the carrier, and is conveyed along the rail rope by an endless hauling rope at an average speed of 4 to 6 m. per hour. The hauling is operated by driving gear at one end, and controlled by tightening gear at the other end just as in the single rope system. Double ropeways have been carried in one section over 18 to 20 m., and will transport single loads of 6 cwt. to a ton or more.

Broadly speaking, the single ropeway is not so suitable for heavy loads and long distances as the double, but in this connexion the work of Ropeways Limited should be noted, which favours a single rope system. Their engineer, J. Pearce Roe, introduced multiple sheaves for supporting the rope at each standard. Thus the rope may pass over one, two or four sheaves, which are provided with balance beams that have the advantage of adjusting themselves to the angle caused by the rope passing over the sheaves, thus equalizing the pressure over a number of sheaves. A ropeway erected on this system in Japan spans 4000 yds. of very broken ground; yet only 17 trestles are used, and as each support is placed as high as possible, no one is of great height. An altitude of 1130 ft. is reached in a distance of 1200 yds. The ropeway has a daily carrying capacity of 60 tons in one direction and of 30 tons in the other. Another installation on this system, which serves an iron mine in Spain, spans 6500 yds. of very rough country, so steep that in many places the sure-footed mule cannot keep on the track. This ropeway can deal with 85 tons per hour. The greatest distance covered by this system, on one section, is 7100 yds., or about 4 m., and the carrying capacity is 45 tons per hour.

The motive power required for a ropeway will vary with the conditions. In cases of descending loads the power generated is sometimes so considerable as to render it available for driving other machinery, or it may have to be absorbed by some special brake device. In a ropeway in Japan of 1800 yds., which runs mostly at an incline of 1 in 1½, the force generated is absorbed by a hydraulic brake the revolving fan of which drives the water against fixed vanes which repel and heat it. In this way, 50 h.p. is absorbed and the speed brought under the control of a hand brake.

Aerial Cableways.—The aerial cableway is a development of the ropeway, and is a conveyor capable of hoisting and dumping at any desired point. The load is carried along a trackway consisting of a single span of suspended cable, which covers a comparatively short distance. The trackway may either run in a more or less horizontal direction, i.e. the terminals may be on the same level, or it may be inclined at such an angle that the load will descend by gravity. The trackway or rail rope rests upon saddles of iron or hard wood on the tops of terminal supports, usually known as towers. These towers may be constructed either of wood or iron, and if the exigencies of the work render it desirable, they may be mounted on trolleys and rails, in which case the cableway is rendered portable, and can be moved about, sometimes a great advantage in excavating work. The motive power may be either steam, gas, or electricity. The motor is situated in what is termed the head tower, which is sometimes a little higher than the other or tail tower. Sometimes, but not frequently, the latter is also fitted with a motor. The span between the two towers sometimes extends to 2000 ft., but this is exceptional. Very heavy loads are dealt with, sometimes as much as 8 tons in a single load. The load, which may be carried in a skip or a tray, is borne by an apparatus called the carrier, which is a modification of a running head, consisting of pulleys and blocks and running along the main cable or trackway. The carrier is also fitted with pulleys or guides for the dump line. The carrier is drawn along the main cable by an endless or hauling rope which passes from the carrier over the head tower and is wound several times round the drum of the winding engine to secure frictional hold, then back over the head tower, to the tail tower, returning to the rear end of the carrier. The hoisting rope passes from the engine to the fall block for raising the load. The dump line comes from the other side of the winding engine drum and passes to a smaller block attached to the rear end of the skip or tray. The whole weight of the skip is borne by the hoisting rope, while the dump line comes in slack, but at the same rate of speed. Whenever it is desired to dump the load, the dump line is shifted to a section of the drum having a slightly larger diameter, and being thus drawn in at a higher rate of speed the load is discharged. The engine is then reversed, and the carriage brought back for the next load.

This is in outline the mode of operating all cableways. This appliance has rendered great service as a labour saver in navvying, quarrying and mining work; in placer-mining, for instance, cableways have been found very useful when fitted with a self-filling drag bucket, which will take the place of a great number of hands. Cableways can be worked at a great speed, but a good mean speed would be 500 to 750 ft. for conveying and 200 to 300 ft. for hoisting. A cableway used in excavating work in Chicago was credited with a capacity of 400 to 600 cub. yds. per day at a total cost of 2d. per yard, including labour, coal, oil, waste, &c.

Coaling Ships at Sea.—In the coaling of ships at sea the cableway has rendered great service. The conditions under which this operation has to be carried out present many difficulties, especially in rough water. One of the chief obstacles is the maintenance of the necessary tension on the cable used in conveying the coal from the collier to the ship. The first test in coaling ships at sea, made by the British admiralty, took place in 1890 in the Atlantic at a point 500 m. south of the Azores in water 2000 fathoms deep. Ten ships of war were coaled, each vessel taking enough coal to enable it to steam back to Torbay, 1800 m. away. In this case the collier was lashed alongside the battleship it was feeding, thick fenders being interposed to prevent damage, but nevertheless as the colliers got light they pitched considerably, and one or two sustained dents in their sides. The ships did not roll, being kept bows-on to the swell, which became heavy before the coaling was completed. The coal was taken in by derricks at the main deck ports. It is clear that had the sea been really rough coaling in this fashion would have been impossible.

The most practicable method of coaling at sea yet devised is the marine cableway of Spencer Miller, which has been tried with some success in the American navy. It is intended for use between vessels 350 to 500 ft. apart. The ship being coaled takes the collier in tow, steaming at the rate of 4 to 8 knots; it has been found that a speed of five knots in moderately rough water will keep the cableway taut and maintain a sufficient distance between the crafts. The collier is fitted with an engine having double cylinders and double friction drums, which is placed just abaft the foremast. A steel rope ¾ in. in diameter is led from one drum over a pulley at the mast head and thence to a pulley at the head of shear-poles on the vessel being coaled, and brought back to the other drum. The engine moves in the same direction all the time and keeps on winding in both the strands of the conveying rope. Should the two vessels increase the distance between them during the operation of conveying the coal bags, of which two, weighing 420 ℔ each, may be fastened to the carrier, the extra rope called for is obtained by slipping the upper strand from the drum; this increases the speed of the upper cable. On the other hand should the distance between the vessels be reduced, this operation is reversed, the speed of the upper strand being reduced. To keep the carriage steady on its return empty, a rope, known as the sea-anchor line, is stretched above the two strands of the conveyor line, and under a pulley on the carriage. This cable is attached to the vessel, resting on a saddle on the shear head, whence it leads through the carriage over pulleys at the head of the foremast and mainmast of the collier, running on astern several hundred feet into the sea. A drag or sea-anchor, usually made of canvas and cone-shaped, is attached to the end of this rope. This anchor is used to support the empty carriage on its return to the collier. The diameter of the cone’s base is graduated to the speed of the vessels. Thus in a smooth-water test, with a ship steaming at 6 knots, one 7 ft. in diameter was used, while the same anchor answered its purpose very well with a ship doing 5 knots in rough water.

The results given by this system of coaling at sea are relatively satisfactory. Tests made in the United States navy showed that 20 to 25 tons of coal per hour could be delivered by a collier to a war-vessel during a moderate gale. As the ship was under steam all the time and consumed 3 to 4 tons of coal per hour, the balance of the coal bunkered amounted to between 16 and 20 tons per hour, or say 384 tons in 24 hours. It has been suggested that under service conditions the speed of the towing vessel might be increased to 8 or 10 knots an hour; this would of course increase the coal consumption unless the collier proceeded under her own steam. But in such a case the space between the two crafts might be diminished, which would have the effect of causing the cable to sag and of stopping the work, since the conveyor cable to act properly must be kept taut. In Great Britain the Temperley Transporter Company have taken up this method of coaling at sea, working in collaboration with Spencer Miller, and have introduced several improvements in detail. Their system has been tried by the British admiralty.

The coaling of a large vessel by this appliance has the advantage of economizing hand labour. One man is required to work the hoist on the collier, while 20 men will be in the hold filling the bags and delivering them to the deck, where 15 or so will transfer the bags to the lift. One or two men suffice for the overhead work; their station is in the trestle trees. On board the receiving ship a few men will be stationed at the shear head to empty the bags into a canvas shoot, and then return them, while there will be the usual force of bunker trimmers. A ton of coal per minute has been transferred from the collier to the vessel, but for this capacity the ships must not be too far apart, else the rope would not remain taut under such loads. During the Russo-Japanese War, many of the Russian battleships were coaled by means of aerial cableways. The coaling of vessels in this manner seems a success, but it would be desirable to increase the carrying capacity of the cableway or to duplicate the installations.

Telpherage.—A telpher ropeway or cableway may be defined as a ropeway or cableway worked and controlled electrically, only a rail rope being required besides the live rail or wire from which the electric current is taken. Telpherage was devised by Professor Fleeming Jenkin in 1881, and developed by him in conjunction with Professors W. E. Ayrton and J. Perry. The telpher itself consists of a light two-wheeled truck, carrying the driving motors, which, to avoid gearing or other complicated mechanism, are usually coupled directly to the axles of the telpher. Thus the telpher is a self-propelled electric carrier running on a mono-rail, which, according to the conditions, may be a steel rail or a steel cable. From the telpher are suspended carriers which can be adapted to any kind of material. In many cases the whole load may be suspended from the telpher, or the load, especially if of some length, may be supported at one end by a telpher, and at the other end by what is known as a trailer, or again, two telphers may be installed, one at each end of the load. The telpher carries a small trolley sheave or bow which serves to collect the current from a trolley wire stretched a little above the rail. Frequently the telpher is accompanied by an attendant who manipulates it, but by dividing the trolley wire into sections any system of telpherage may be constructed to work automatically, and by switching off the current from the section in which the telpher is required to stop it can be brought to a standstill at any required point. The speed of the telpher may be readily regulated by the introduction of a resistance between any section of the line and the supply of electricity. The speed may be high, as much as 1500 ft. per minute over the straight portions of the line, but slackened at curves and loading stations, or when approaching a terminus. The required power may be obtained from the mains of an ordinary electric supply with either direct or alternating current, but the former is preferable. The mean expenditure of power in a working day is said to average (including electrical hoisting) 1 H.P. per ton of average load.

The uses of telpherage are many and various. In factories and warehouses, where the buildings are scattered, it has been installed with excellent results. Being essentially an overhead system, there is a saving of floor space, the ground not being obstructed by trucks or trolleys. The same reasons which render ropeways an economical means of handling such material as coal, ore, stone, slate, &c., between the mine or quarry and the rail or barge, may be adduced in favour of telpherage. For the unloading of railway trucks in a crowded goods-yard it is undoubtedly applicable. Any kind of tipping or hoisting operations can be automatically effected by its aid, and any sort of grab may be used in dealing with such materials as sand, clay or gravel. Telpherage is clearly a labour-saving method of handling materials, but of course the exact conditions under which any system is to be used need careful study, while the economy to be effected by the installation of a telpher line must to a great extent depend upon the available supply of electrical energy. (G. F. Z.)

- ↑ The illustrations in this article are taken, by kind permission, from the Proceedings of the Institution of Civil Engineers.