1911 Encyclopædia Britannica/Incubation and Incubators

INCUBATION and INCUBATORS. The subject of “incubation” (Lat. incubare, to brood; in-cumbere, to lie on), a term which, while strictly signifying the action of a hen in sitting on her eggs to hatch them, is also used in pathology for the development within the body of the germs of disease, is especially associated with the artificial means, or “incubators,” devised for hatching eggs, or for analogous purposes of an artificial foster-mother nature, or for use in bacteriological laboratories.

Life is dependent, alike for its awakening and its maintenance, upon the influence of certain physical and chemical factors, among which heat and moisture may be regarded as the chief. It is therefore obvious that any method of incubation must provide for a due degree of temperature and moisture. And this degree must be one within limits, for while all organisms are plastic and can attune themselves to a greater or less range of variation in their physical environment, there is a given degree at which the processes of life in each species proceed most favourably. It is this particular degree, which differs for different species, which must be attained, if artificial incubation is to be successfully conducted. In other words, the degree of temperature and moisture within the incubation drawer must remain uniform throughout the period of incubation if the best results are to be reached. It is not easy to attain these conditions, for there are many disturbing factors. We may therefore next consider the more important of them.

The chief causes which operate to make the temperature within the incubator drawer variable are the changes of the temperature of the outer air, fluctuations in the pressure of the gas when that is used as the source of heat, or the gradual diminution of the oxidizing power of the flame and wick when an oil lamp is substituted for gas. Also, the necessary opening of the incubator drawer, either for airing or for sprinkling the eggs with water when that is necessary, tends to reduce the temperature. But there is another equally important though less obvious source of disturbance, and this resides within the organism undergoing incubation. In the case of the chick, at about the ninth or tenth days of incubation important changes are occurring. Between this period and the fourteenth day the chick becomes relatively large and bulky, and the temporary respiratory organ, the allantois, together with its veins, increases greatly in size and extent. As a consequence, the respiratory processes are enabled to proceed with greater activity, and the chemical processes of oxidation thus enhanced necessarily largely increase the amount of heat which the chick itself produces. Thus an incubator, to be successful, must be capable of automatically adjusting itself to this heightened temperature.

The drawer of an incubator is a confined space and is usually packed as closely as possible with the contained eggs. The eggs are living structures and consequently need air. This necessitates some method of direct ventilation, and this in its turn necessarily increases the evaporation of water vapour from the surface of the egg. Unless, therefore, this evaporation is checked, the eggs will be too dry at the period—from the tenth day onwards—when moisture is more than ever an important factor. There is, according to some poultry authorities, reason to believe that the sitting hen secretes some oily substance which, becoming diffused over the surface of the egg, prevents or retards evaporation from within; presumably, this oil is permeable to oxygen. In nature, with the sitting hen, and in the “Mamal” artificial incubating establishments of the Egyptians, direct air currents do not exist, owing to the large size of the chambers, and consequently incubation can be successfully achieved without any special provision for the supply of moisture.

Artificial incubation has been known to the Egyptians and the Chinese from almost time immemorial. In Egypt, at Berme on the Delta, the trade of artificial hatching is traditionally transmitted from father to son, and is consequently confined to particular families. The secrets of the process are guarded with a religious zeal, and the individuals who practise it are held under plighted word not to divulge them. It is highly probable that the process of artificial incubation as practised by the Egyptians is not so simple as it is believed to be. But as far as the structures and processes involved have been ascertained by travellers, it appears that the “Mamal” is a brick building, consisting of four large ovens, each of such a size that several men could be contained within it. These ovens are in pairs, in each pair one oven being above the other, on each side of a long passage, into which they open by a circular aperture, just large enough for a man to obtain access to each. The eggs are placed in the middle of the floor of the oven, and in the gutters round the sides the fire is lighted. The material for this latter, according to one account, consists of camels’ dung and chopped hay, and according to another of horses’ dung. The attainment of the right degree of heat is apparently reached wholly by the skill of the persons employed. When this has been attained, they plug the entrance hole with coarse tow. On the tenth to twelfth days they cease to light the fires.

Each “Mamal” may contain from 40,000 to 80,000 eggs. There are 386 “Mamals” in the country, which are only worked for six months of the year, and produce in that time eight broods. Many more than two-thirds of the eggs put in are successfully hatched. It is estimated that 90,000,000 eggs are annually hatched by the Bermeans.

A method of incubating that appears to have been altogether overlooked in England—or at least never to have been practised—is that carried on by the Couveurs or professional hatchers in France. They make use of hen-turkeys for the purpose, and each bird can be made to sit continuously for from three to six months. The modus operandi is as follows: a dark room which is kept at a constant temperature throughout the year contains a number of boxes, just large enough to accommodate a turkey. The bottom of the box is filled with some vegetable material, bracken, hay, heather, straw or cocoa-fibres. Each box is covered in with lattice-work wire, so arranged that the freedom of the sitting bird is limited and its escape prevented. Dummy eggs, made by emptying addled ones and filling with plaster of Paris, are then placed in the nest and a bird put in. At first it endeavours to escape, but after an interval of a few days it becomes quiet, and the dummy eggs being then removed, fresh ones are inserted. As soon as the chickens are hatched, they are withdrawn and fresh eggs substituted. The hen turkeys are also used successfully as foster-mothers. Each bird can adequately cover about two dozen eggs.

Incubation as an industry in Europe and America is of recent development. The growing scarcity of game birds of all kinds, coincident with the increase of population, and the introduction of the breech-loading gun, together with the marked revival of interest in fancy poultry about the year 1870, led, however, to the production of a great variety of appliances designed to render artificial incubation successful.

Previously to this, several interesting attempts had been made. As long ago as 1824, Walthew constructed an incubator designed to be used by farmers’ wives with the aid of no more than ordinary household conditions. It consisted of a double-walled metal box, with several pipes opening into the walled space round the sides, bottom and top of the incubator. These pipes were connected with an ordinary kitchen boiler. Walthew, however, constructed a fire grate, with a special boiler adapted to the requirements of the incubator. Into the walled space of the incubator, steam from the kitchen boiler passed; the excess steam escaped from an aperture in the roof, and the condensed steam through one in the floor. Ventilating holes and also plugs, into which thermometers were placed, pierced the door of the incubator.

In 1827, J. H. Barlow successfully reared hens and other birds by means of steam at Drayton Green, Ealing. He constructed very large rooms and rearing houses, expending many thousands of pounds upon the work. He reared some 64,000 game birds annually. The celebrated physician Harvey, and the famous anatomist Hunter were much interested in his results.

To John Champion, Berwick-on-Tweed, in 1870, belongs, however, the credit of instituting a system which, when extended, may become the system of the future, and will rival the ancient “Mamals” in the success of the incubation and in the largeness of the numbers of eggs incubated. He used a large room through which passed two heated flues, the eggs being placed upon a table in the centre. The flues opened out into an adjoining space. The temperature of the room was adjusted by personal supervision of the fire. This system, more elaborated and refined, is now in use in some parts of America.

Bird Incubators.

Owing to the great variety in the details of construction, it is difficult to arrange a classification of incubators which shall include them all. They may, however, be classified in one of two ways. We may either consider the method by which they are heated or the method by which their temperature is regulated.

In the former case we may divide them into “hot-air” incubators and into “hot-water” or “tank” incubators. In the latter ease we may classify them according as their thermostat or temperature-regulator is actuated by a liquid expanding with rising temperature, or by solids, usually metals.

In America incubators of the hot-air type with solid and metallic thermostats are most used, while in Europe the “tank” type, with a thermostat of expansible liquid, prevails.

For the purpose of more adequately considering the various forms which have been in use, or are still used, we shall here divide them into the “hot-air” and “hot-water” (or “tank”) classes.

In the hot-air types the incubator chamber is heated by columns of hot air, while in the tank system this chamber is heated by a tank of warmed water.

(a) Hot-Water Incubators.—In 1866 Colonel Stuart Wortley described in The Field an incubator constructed upon a novel principle, but which appears never to have been adopted by breeders. The descriptive article is illustrated with a sketch. Essentially the incubator consists of four pipes which extend across the egg chamber some little distance above the eggs. The pipes pass through holes in the side of the incubator, which are furnished with pads, so as to render their passage air-tight. Externally they are connected with a boiler. This is provided with a dome through which steam escapes, and also with a glass gauge to show the height of the water within the boiler. The water in the boiler is kept at the boiling point, and the temperature of the incubator is regulated by adjustment of the length of the hot-water pipes within the egg chamber. To raise the temperature, a greater length of the pipes is pushed into the chamber, and to reduce it, more of their length is pulled outwards. It is claimed for this instrument that since the temperature of boiling water at any particular locality remains practically constant, the disadvantages due to fluctuations in the activity of a lamp flame or the size of a gas flame are obviated. But it has the serious disadvantage that there is no automatic adjustment to compensate for fluctuations of atmospheric temperature. And experiments by C. Hearson have shown that even if the temperature of the tank or source of heat be constant, that of the incubator drawer will nevertheless vary with fluctuations of external temperature. Probably if the mechanical difficulties of providing a self-regulator were overcome, it would prove an efficient and reliable incubator. The difficulties do not seem to be insuperable, and it appears possible that a thermostatic bar could be so arranged as to automatically increase or decrease the length of hot-water pipes within the incubator, and therefore the incubator temperature.

Another early form of incubator is Brindley’s, which was first in use about 1845, and in his hands it appeared occasionally to act successfully, but it never became generally used. The egg chamber was lined with felt, and was placed beneath a heated air chamber, the floor and roof of which were composed of glass. The air chamber was heated by a number of hot-water pipes which were connected with a copper boiler. This latter was heated by means of a lamp so constructed as to burn steadily. The temperature of the air chamber was regulated within certain limits by means of a balanced valve, which could be so adjusted that it would open at any desired temperature.

In Colonel Stuart Wortley’s incubator the hot-water tubes passed directly into the egg chamber, and in Brindley’s into a chamber above it. But in other forms of incubators in which the principle of an external boiler connected with water tubes is adopted, the latter pass not into the egg chamber nor into an air chamber, but open into and from a tank of water. The floor of this tank forms the roof of the egg chamber, so that the eggs are heated from above. This device of warming the eggs from above was adopted in imitation of the processes that presumably occur with the sitting hen; for it is generally assumed that the surface of the eggs in contact with the hen is warmer than that in contact with the damp soil or with the material of the nest.

One of the earliest of this form of incubator is that invented by F. Schröder, manager of the now extinct British National Poultry Company. In this incubator the form is circular, and there are four egg drawers, so that each one occupied the quadrant of a circle, and the inner corner of each drawer meets in the middle of the incubator. From the centre of the incubator a vertical chimney passes upwards and opens out from the inner corners of the four egg drawers. This chimney acts as a ventilator to the incubating chambers. These latter are open above, but their floors are made of perforated zinc, and when in use they are partially filled with chaff or similar material. Under them is a tank containing cold water and common to all four drawers; the slight vapour rising from the surface of the water diffuses through the egg drawers and thus insures a sufficient degree of humidity to the air within. Above the egg drawers is a circular tank containing warm water. The floor of this tank constitutes the roof of the egg drawers, while the roof forms the floor of a circular chamber above it, the side wall of which is composed of perforated zinc. This upper chamber is used to dry the chicks when they are just hatched and to rear them until they are strong enough for removal. It is partially filled with sand, which serves the double purpose of retaining the heat in the warm-water tank beneath and of forming a bed for the chicks. The water in the warm-water tank is heated by means of a boiler which is external to the incubator, and in communication with the tank by means of an inlet and an outlet pipe. There is no valve to regulate the temperature, and the latter is measured by means of a thermometer, the bulb of which is situated not in the incubator drawers, but in the warm-water tank. This is a wrong position for the thermometer, since it is now known that the temperature of the water tank may be different by several degrees to that of the egg drawer; for with a fall of external temperature that of the latter necessarily tends to fall more rapidly than the former. But, none the less, in skilful hands this incubator gave good results.

|

| Fig. 1.—Christy’s Improved Incubator. |

T. Christy’s incubator, which we shall describe next, has passed through several forms. We shall consider the most recent one (1894). The incubator (fig. 1) is double walled, and the space between the two walls is packed with a non-conducting material. In the upper part of the incubator there is a water tank (T) divided by a horizontal partition into two chambers, communicating with each other at the left-hand side. Below the tank is the incubation drawer (E), which contains the eggs and also a temperature regulator or thermostat (R). The tank is traversed by a ventilating shaft (V), and inserted into this is a smaller sliding tube passing up to it from a hole in the bottom of the incubator drawer. The floor of the incubator drawer is perforated, and beneath it is an enclosed air space which opens into the sliding air shaft just described. Fresh air is let into the incubator drawer from a few apertures (I) at its top. The ventilating shaft (V) is closed externally by a cap (C), which can be raised from or lowered down upon its orifice by the horizontal arm (H) working upon pivot joints at (P). This arm is operated by the thermostat (R), through the agency of a vertical rod. The water in the tank is heated by an external boiler (B) through two pipes, one of which (T) serves as an inlet, and the other (L) as an outlet channel from the tank. These two pipes do not open directly into the tank, but into an outer vessel (O) communicating with it. Communication between this vessel and the tank may be made or broken by means of a sliding valve (S), which is pierced by an aperture that corresponds in position with the upper of the two in the wall of the tank when the valve is up. When this valve is in its upper position, the tank (T) communicates with the outer vessel (O) by two apertures (A and A′), the top one being the inlet and the lower one the outlet. These coincide in position with the tubes from the boiler. This latter (B) is a conical vessel containing two spaces. The heated water is contained in the outer of these spaces, while the central space is an air shaft heated by a lamp flame. This particular form of the boiler results in the water at its top part being more heated than that in its lower. As a consequence of this, a continual circulation of water through the tank ensues. The more heated water, being specifically lighter, passes into the outer vessel, where it remains among the higher strata, and therefore enters the tank through the upper aperture. In passing along the upper division of the tank it becomes slightly cooled and sinks therefore into the lower compartment, passes along it, and out through the aperture A′. Hence it passes into the lower portion of the boiler, where it becomes warmed and specifically lighter; in consequence it becomes pushed upwards in the boiler by the cooler and heavier water coming in behind and below it.

Should the temperature in the incubator drawer rise, the bimetallic thermostat (R) opens out its coil and pulls down the vertical rod. This simultaneously effects two things: it raises the cap (C) over the ventilating shaft and allows of a more rapid flow of fresh air through the incubator drawer, and it also lowers the slide-valve (S) so that the tank becomes cut off from communication with the outer vessel (O) and therefore with the boiler. The temperature thereupon begins to fall and the thermostat, coiling closer, raises the vertical rod, closes the ventilating shaft, and once more places the tank in communication with the boiler.

The structure of the thermostat is given below.

The Chantry Incubator (Sheffield) is also an incubator with a hot-water tank, the circulation of which is maintained by an outside boiler. Its temperature is regulated by a metal regulator.

In Schröder’s and Christy’s incubators the hot-water pipes from the boiler simply entered the warm-water tank but did not traverse it. In the two incubators to be next described the hot-water pipes are made to pass through the water in the tank, and are so arranged as to minimize the possibility that the outside of the tank may become colder than the centre. Both of them are also fitted with an ingenious though slightly complex valve for maintaining an approximately constant temperature.

Halsted’s incubator was the earliest of this type. Since his original form was constructed he has designed an improved one, and it is this latter which will be described.

|

| Fig 2.—Halsted’s Incubator. |

The egg drawer (E, fig. 2) lies beneath the warm-water tank (T), and above this is a nursery (N). The egg drawer is ventilated by two tubular shafts (V), of which only one is represented in the illustration; the tubes are about 212 in. in diameter, and each one is fitted at its upper end, where it opens into the nursery, with a swing-valve (V′) which turns upon a horizontal axis (A), in its turn connected, by means of cranks (C) and shafts (S), with the heat regulating apparatus (R). A space of about 2 in. between the top of the incubating drawer and the warm-water tank is necessary for the insertion of this apparatus. The water in the tank (T) is heated by means of the boiler (B); the tank and boiler are connected by the two pipes (I) and (O), of which one is the inlet and the other the outlet channel. The boiler consists of an inner (I′) and an outer (O) division in communication with each other below. The latter is cylindrical in form, while the outer wall of the former is cylindrical and its inner wall conical. The conical wall of the inner boiler is the surface which is heated by the lamp (L). The arrangement of the inlet and outlet tubes is important. In the illustration, for the sake of clearness, they are represented as one above the other. In reality they lie in the same plane, and the fork (F) of the inlet pipe similarly lies in the horizontal plane and not vertically as represented. The inlet pipe not only differs from the outlet pipe in the possession of a forked end, but it is carried to the farther end (not shown in the diagram) of the water tank, while the outlet pipe opens from about the middle of the tank. The inlet pipe is connected with the inner portion of the boiler and the outlet one with the outer portion. The result of this adjustment of the parts is that the warmer water of the inner boiler, being specifically lighter than the cooler water of the outer boiler, rises up and passes through the inlet pipe (I) and is discharged into the tank through the two divergent orifices of the fork (F). Here the water strikes the side wall of the farther end of the tank and is reflected back along the back and front walls towards the nearer side. Hence it is again reflected, but in the opposite direction, and now forms a central current, which is directed towards the centrally situated orifice of the outlet tube (O). Through this it passes to the outer boiler, and sinking towards the bottom, reaches the base of the inner boiler. Here it becomes heated and lighter and consequently rises to the top, and once more passes through the inlet pipe to the water tank. The warm water thus travels round the outer walls of the tank and the cooled water is conducted away along the middle portion. A more equable distribution of temperature over the roof of the incubating chamber is thus ensured than would be the case if the heated water were discharged either into the centre or at any other single point only of the tank.

To a very large extent, the efficiency of this apparatus depends upon the approximately perfect performance of the lamp. A good, steadily burning one should be employed, and only the best oil used; for, should the wick become fouled the flame cannot freely burn. For this reason it is better to use gas, whenever obtainable.

The maintenance of an approximately uniform temperature is obtained by allowing the heated air of the egg-drawer to escape through the two ventilating shafts (V). The swing-valves of these are opened or closed by means of the regulator (R). This latter consists of a glass bowl prolonged into a tube, about 8 in. long and three-eighths of an inch in diameter. The glass tube swings upon an axis (A) which is situated as near as possible to the bowl of the regulator. The axis is connected with a crank (C′) which is disposed so as to act as a lever upon the vertical shaft (S), which in its turn is connected with the upper crank (C); this works the axis (A′) of the swing-valves, and so can open or close the apertures of the ventilating pipes. The bowl of the regulator is filled with mercury to such an extent that at the temperature of 100° F., and when the tube is slightly inclined upwards from the horizontal it just flows slightly into the tube from the bowl. On the lever-crank (C′) a weight is slung by a sliding adjustment, and is so placed that when the temperature of the egg-drawer is 103° it just balances the tube of the regulator when it is slightly inclined upwards. Should the temperature of the drawer now rise higher the mercury flows towards the distant end of the tube and, causing it to fall down, brings about a rotation of the regulator axis and as a consequence the opening of the ventilating valves. A transverse stay prevents the limb of the regulator from quite reaching the horizontal when it falls. As the temperature cools down the mercury contracts and retraces to the nearer end of the tube and to the bowl, and consequently results in the upward inclination of the limb; the valves are thus closed again.

The egg-drawer (E) is specially constructed so as to imitate as nearly as possible the natural conditions that exist under a sitting hen. The drawer is of wood and contains a zinc tray (Z) into which cold water is placed. Fitting into the zinc tray is another zinc compartment, the floor of which is made of a number of zinc strips (X) transversely arranged and placed in relation to each other like the limbs of an inverted Λ. The limbs are so disposed that those of one series do not touch the adjacent ones, and in fact a space is left between them. Thus a number of parallel troughs are formed, each of which opens below into the moist air chamber of the cold water tray beneath. In practice these troughs are covered with flannel which is allowed to dip into the water of the tray. Thus the eggs lie in a series of damp troughs and their lower surfaces are therefore damper and colder than their upper ones. This incubator, if carefully worked and the necessary practical details observed, has the reputation of being an efficient machine.

Somewhat similar to the Halsted incubator, but differing from it in the nature of the boiler and in the temperature regulator, is the Graves incubator, made in Boston, U.S.A. The incubator itself (fig. 3) consists of an incubating or egg-drawer (E) heated from above by a warm-water tank (T). Below the egg-drawer is a tank containing cold water, the vapour of which passes through the perforated floor of the former and keeps the air of the egg-chamber slightly humid. Above the warm-water tank is an air chamber (AC) to serve as a non-conducting medium and to prevent therefore undue loss of heat. Above this is a nursery or drying chamber (N), closed in, with a movable lid.

The warm-water tank is heated by means of a simple boiler (B) from which an inlet tube (I) carries heated water to the tank; the tube traverses the length of the tank and discharges at its farther end (not shown in the diagram). From the nearer end of the tank an outlet tube (O) passes out and opens into the boiler at a slightly higher level than the inlet one. The boiler is heated by an evenly burning lamp below, of special construction. The rectangular tube through which the wick passes is bevelled at its outer end, and upon this bevelled edge a metal flap (F) is allowed to rest more or less closely, according as the flame is to be smaller or larger respectively. The wick is, of course, bevelled to correspond to the form of its tube. The metal flap is raised or depressed by means of levers connected with the heat-regulator. When it is depressed upon the wick the flame is lessened; and it becomes proportionately bigger as the flap is raised more and more.

|

| Fig. 3.—Graves’s Incubator. |

The heat-regulator consists of a glass tube (T) which runs the whole width of the incubation chamber and lies in contact with the floor of the warm-water tank; it is filled with alcohol. Externally to the incubator this tube is connected with a U-shaped one containing mercury. The free limb of the U-tube contains a piston (P) which rests upon the surface of the mercury in that limb. From the piston a piston rod (PR) passes vertically upwards and is connected with a lever (L) which operates, through the agency of a second lever (L′) the movements of the ventilating valve (V) inserted over the orifice of the ventilating shaft (A) which opens from the roof of the incubator drawer. The lever (L) is further connected with a spiral spring (S) which works the metal flap of the lamp already described. The height of the piston in the U tube can be so adjusted, by varying the quantity of mercury in the tube, that when the temperature of the incubation drawer is 103° F., the ventilating valves are closed and the wick is burning to its full extent. Should the temperature rise, the alcohol in the glass tube (T) expands and causes the mercury in the free limb of the U tube to rise. This carries with it the piston, and this movement brings about the opening of the ventilating valves, and at the same time, through the agency of the lever (L) and the spiral spring (S) the metal flap is brought down upon the wick, cutting off more or less of the flame. Should the temperature then fall to 103° or lower, the contraction of the alcohol reverses these movements, the valve closes, and the wick once more burns to its full extent.

In practice, the boiler and the temperature regulator are duplicated, there being a set on both sides of the incubator. Any slight irregularity on the one side may be thus compensated for by the other side.

Graves’s incubator has the reputation of being a good machine.

Among the most recent type of incubators made in England is that of Charles Hearson. This differs from any of those described in the simplicity and ingenuity of the heat regulator, and in that the tubes which traverse the water tank are hot-air flues, carrying the air heated by the flame and not warm water. Consequently a further simplification is introduced inasmuch as no boiler is required.

|

| Fig. 4.—Hearson’s Incubator. |

The essential features of this incubator are shown in fig. 4. The internal parts of the incubator are insulated by a double wall, the interspace being packed by a non-conducting material, which is not shown in the figure. The incubation or egg-drawer (E) is heated by the warm-water tank (T). Beneath the egg-drawer is a zinc tray (Z), so constructed that in the central part the floor is raised up into a short cylinder. Around the raised cylinder is a wide trough containing water and into this dips a canvas cloth which is stretched out over a perforated zinc support (F). By this means an extended moistened surface is produced which allows of a rapid evaporation. The floor of the incubator, which is raised by short feet from the table on which it stands, is perforated in the central portion by a number of holes, and which are so situated that they lie beneath the raised cylinder of the cold-water tray (Z). The incubation-drawer is thus supplied continuously by a slow current of moistened air because the air in the upper part of the drawer, i.e. in contact with the floor of the warm-water tank, is the warmest and lightest. It therefore tends to diffuse or pass through the narrow slits between the drawer and the walls of the incubator, and also through the aperture in the front wall of the egg-drawer, through which a thermometer is laced. To replace the air thus lost, fresh air passes in through the holes in the bottom of the incubator, and on its way must pass through the pores of the damp canvas which dips into the water in the zinc tray (Z).

The warm-water tank is heated by an inlet (I) and outlet (O) flue which are, however, continuous. The inlet flue opens out from a vertical chimney (C), the air in which is heated either by a gas flame or that of an oil lamp. The outlet or return flue passes back through the width of the tank and opens independently to the exterior. The vertical chimney (C) is capped by a lid (L) capable of being raised or lowered upon its orifice by the lever (L′). When the cap is resting upon the chimney all the heated air from within the latter passes through the flues and heats the water in the tank. If the cap is widely raised, practically all the heated air passes directly upwards through the chimney and none goes through the flues. If the cap be but slightly raised, part of the heated air goes through the flues and part directly escapes through the aperture of the chimney. The movement of the lever (L′) which raises the cap (L) is determined by the thermostatic capsule (S), situated within the egg-drawer.

The principle upon which this capsule is designed is that the boiling point of a liquid depends not only upon temperature but also upon pressure. A given liquid at ordinary atmospheric pressure will boil at a certain degree of temperature, which varies for different substances. But if the pressure be increased the boiling point of the liquid is raised to a higher degree of temperature. A liquid when it boils passes into a gaseous condition and in this state will occupy a very much larger volume—some two or three hundred times—than in the liquid condition. If, therefore, a hermetically sealed capsule with flexible sides be filled with some liquid which boils at a given temperature, the sides of the capsule will distend when the temperature of the air round the capsule has been raised to the boiling point of the liquid within it. The distension of this capsule can be used to raise the lever (L′). The thermostatic capsule is placed on a fixed cradle (F) and is filled with a mixture of ether and alcohol, the proportions being such that the boiling point of the mixed liquid is 100° F. Between the capsule and the lever (L′) is a vertical rod (V), articulating with the lever as close as possible to its fulcrum (M). The articulation with the lever is by means of a screw, so that the necessary nice adjustment between the height of the rod (V), the thickness of the capsule and the position of rest of the damper (L) upon the chimney, can be accurately made. The temperature at which it is desired that the liquid in the capsule shall boil can be determined by sliding the weight (W) nearer or farther to the fulcrum of the lever (L′). The farther it is moved outwards, the greater is the pressure upon the thermostatic capsule and consequently the higher will be the boiling point of its contained liquid. By means of the milled-head screw (A), the height of the lever at its outer end can be so adjusted that when the liquid of the capsule is not boiling the damper (L) closes the chimney, but that when it does boil the damper will be raised sufficiently high from it. If the weight is pushed as far as it will go towards the fulcrum end of the lever, the temperature of the egg-drawer will never rise more than 100° F. because at this temperature and under the pressure to which it is then subjected, the liquid in the capsule boils, and consequently brings about the raising of the damper. It matters not, therefore, how high the flame of the gas or lamp be turned, the temperature of the egg-drawer will not increase, because the extra heat of the enlarged flame is passing directly outwards through the chimney, and is not going through the flues in the tank. In order to raise the temperature within the incubation chamber to 102° or 103°, or any other desired degree, the weight (W) must be moved outwards along the lever (L′), about 1 in. for every degree of temperature increase desired. This thermostatic capsule works admirably, and the incubator will work for months at a time and requires no adjustment, however much, within the limits of our climate, the external temperature may vary. The capsule, like all other thermostats in which the expansible substance is a liquid, is, however, dependent upon external pressure for the point at which its contained liquid boils and therefore, for the degree of temperature prevailing within the incubator drawer. It is therefore responsive to variations in atmospheric pressure, and as the barometer may fall 1 or 2 in., this may possibly make a difference of two or three degrees in the fluctuation of temperature within the egg-drawer. It is not, of course, often that such large oscillations of the barometer occur, and as a matter of practical experience, under ordinary conditions, this incubator will work for months together without attention with only half a degree variation round the point at which it was set.

|

| Fig. 5.—The Bedford (Greenwood’s) Incubator. |

Greenwood’s incubator (fig. 5), named the Bedford, resembles Pearson’s in that hot-air flues (F and F′) and not hot-water pipes, traverse the water tank (T). And the method of regulation of the temperature is much the same, i.e. a thermostat (V) operating upon a lever which raises a cap (C) from off the aperture of the main flue (F) and thus allows all the heat of the flame to pass directly outwards, without passing through the series of flues (F) which horizontally traverse the water-tank. Fresh air enters through a wide circular aperture (A) which surrounds the main flue, and it thus becomes partially warmed before entering the egg-chamber. The eggs are placed upon a perforated floor (E) lying over water baths (B). The water tank (T) lies in the centre of the incubation chamber and is traversed through its central axis by the main hot-air flue (F). From this, four horizontal flues pass outwards through the water and open into small vertical flues, which in their turn communicate with the exterior.

The thermostat (V) consists of a glass tube of peculiar form. This is closed at the end of its short limb and open at its other extremity on the long limb. The bent portion of the tube is filled with mercury and between the mercury column and the closed end is a small quantity of ether. The thermostat is lodged in a box (G), which forms part of the lever (L). At one end this lever is pivoted to a fixed arm, and at the other to the vertical rod which operates the ventilating cap (C). If the temperature should rise, the ether in the thermostat expands and pushes the mercury column up along the inclined long limb. This disturbs the equilibrium of the lever (L), and it descends downwards, pulling with it the vertical rod, and thus raising the cap over the main flue. If the temperature falls the reverse series of changes occur. The temperature at which the cap will be raised can be adjusted within limits by the position of the weight (W) and by the adjustment of the degree of inclination of the thermostat.

The Proctor incubator, made at Otley, is apparently, in its main features, similar to the Greenwood.

|

| Fig. 6.—The Winchcombe Incubator. |

Somewhat similar, in certain features, to the Greenwood is the Winchcombe. Its improved form, in which metal replaces the wood casing, is named the Gladstone. In it there is a combination of the hot-air and the water-tank systems of warming the incubation chamber. The wall of the incubator is double, and the space between the outer and inner wall is packed with a non-conducting material. The incubation chamber is heated above by a water-tank (fig. 6 T) which is traversed by a main vertical flue (F) and four subsidiary horizontal ones which discharge externally. The main flue, however, in passing up to enter the water tank traverses the egg-chamber, and therefore serves to warm it, as in the hot-air type of incubator, by the heat of the flue itself. Around the lower half of the flue is a water vessel consisting of two concentric containers (C), holding water. In the space between these concentric containers, fresh air passes in through the aperture (A), and before it reaches the egg-chamber it passes through coarse canvas which dips into the water in the containers, and is therefore kept permanently moist. The containers are filled from a water tank (S) outside the incubator. Air passes out from the egg-chamber through the aperture (O). The temperature is regulated by a bimetallic thermostat (see below), which operates two levers, that by their arrangement can raise or depress the cap (D) over the main flue (F). The temperature at which this occurs will be determined, within limits, by the position of the adjustable weight (W).

Tomlinson’s incubator, designed in 1880, is novel in principle. It possesses a very large water tank, holding 15 gallons for every hundred eggs. Through this tank there pass two hot-air horizontal flues, lying in the same plane. The novelty of the construction lies in the great volume of water used and in the disposition of the flues towards the top of the tank. It is said that very little circulation of water takes place beneath the flues, because warmed water rises instead of falling. The great body of water below the flues will therefore only take up heat relatively slowly, and will, on account of its bulk and its physical properties, but slowly lose it. Should the flame fall in power, or even go out for ten or twelve hours, it is claimed that no serious loss of efficiency of the apparatus will result.

Regulation of the temperature is by means of an air tube, the air in which expanding bulges out an india-rubber diaphragm and this moves a lever. The lever operates a valve which allows more or less of the heated air to escape from the egg-drawer.

|

| Fig. 7.—Hillier’s Incubator. |

(b) Hot-air Incubators.—W. H. Hillier’s Incubator (fig. 7) is circular in form and is constructed of a double-walled metal case. The space between the two walls is packed with a non-conducting material. The incubation or egg-chamber (C) is warmed by a circular heating box (H), and the air in this is heated by a lamp. The roof of this box forms part of the floor of the incubation chamber and from it a main flue (F) and four smaller ones (F′) pass upwards through the roof of the incubator and discharge to the exterior. Fresh air passes in to the incubator through two tubular channels (A and A′) on either side of the heating box and escapes through a hole in the roof, which serves at the same time as a passage for one of the rods (D) in connexion with the temperature regulating apparatus.

This apparatus (T) consists of a glass tube of 12 in. bore, and which is bent into the form of a circle of 5 in. diameter. The tube is fastened to a wooden disk, which rotates upon a pivot and in so doing operates a vertical rod (D), which in its turn works the cap (V) which covers the orifice of the main flue. The tube is partly filled with mercury and is closed at one end. At this end there is contained some spirit. As the temperature rises, this expands and pushes the mercury column farther along the tube. The equilibrium of the position of rest is thus disturbed, and the wooden disk consequently rotates, carrying with it the vertical arm, the downward movement of which raises the cap (V) of the flue. The temperature at which it is desired that this valve shall uncover the flue, can be adjusted within the necessary limits by sliding the weight (W) along the horizontal arm and by the amount of mercury present in the bent tube. The air of the incubation chamber is rendered sufficiently moist by the evaporation of water in the vessel (G).

In the Cornell incubator (New York) more personal attention is required than in other forms, since the ventilation of the egg-chamber is not wholly automatic but is regulated according to the results of observation. The great difficulty in ventilation is the proper combination of fresh air and moisture. The Cornell Incubator Company has endeavoured to obviate this difficulty by carrying out a series of observations on the rate at which evaporation occurs in incubating eggs under natural conditions. The rate of evaporation is measured by the size of the air-space within the egg-shell at successive days. This they have ascertained, and with their incubators they furnish a book of instructions in which diagrams showing the size of the air space on the 1st, 5th, 10th, 14th and 18th days are given. Examination of the eggs should therefore be made every two or three days, and the result compared with the diagrams. The incubator is provided with an adjustable ventilator and this should be so arranged that evaporation is neither too great nor too little. The ventilator should never be wholly closed, and if when closed to its minimum evaporation is still too great, then water should be placed in the moisture pans. In all cases lukewarm water should be placed in these on the 18th day and the ventilating slide opened wide.

It will thus be seen that in this machine there is an attempt to do away with the addition of water to the incubator drawer during the greater part of the period of incubation, and to rely upon the aqueous vapour naturally present in the atmosphere. This attempt is based upon the fact that water vapour is lighter than air, and will therefore rise to the top in any enclosed volume of air. If the direction of the ventilating current is downwards in the incubation chamber, and if it is slow enough, it is thought that the water vapour will be sifted out and tend to accumulate to a sufficient extent in the chamber. In the Cornell incubator consequently the ventilating current passes first upward through an external heater in order to warm it, whence it is then deflected downwards into the egg-chamber and diffuses through its perforated bottom. Then it passes along a space beneath the chamber into a space in the left-hand wall of the incubator and out to the exterior through an adjustable and graduated ventilating slide.

These incubators are hot-air machines, and the hot-air chamber is situated above the egg-drawer and is traversed by several flues opening out from a main one. The temperature regulating apparatus appears to be similar to that of Hearson’s machine and operates by a thermostat, which through the agency of levers opens or closes a valve over the main flue.

The Westmeria incubators (Leighton Buzzard) are of two patterns. One type is built on the hot-air principle and the other on the hot-water system. In both forms the heated air from the heating surfaces is deflected down on the eggs and escapes through the perforated bottom of the egg-drawer. The inlet air is first warmed by contact with the main flue. The thermostat is similar to that in the Hillier machine (fig. 7) and consists of a coil mounted on an axis, round which it can rotate. The coil is filled with mercury and is closed at one end. Between this end and the mercury column is a short column of air. By expansion of the air under a rising temperature, the mercury column is displaced and brings about a rotation of the disk to which the coiled tube containing it is attached. This rotation raises the cap over the main flue.

All the incubators so far described have been constructed with the idea of obtaining as nearly as possible a uniform temperature. But in E. S. Renwick’s incubator (America) no attempt is made to obtain uniformity in temperature. On the other hand, it is designed to give a periodical oscillation from one extreme to the other of a limited range, about 3°, of temperature. This is accomplished by means of a thermostatic bar made of plates of brass and vulcanite fastened together. This is connected with a clockwork and detent arrangement, which simultaneously opens a valve and actuates the lamp flame. The temperature falls to the lower limit of its range before the thermostatic bar is sufficiently bent to set the clockwork arrangement operating in the reverse direction, by which the valve is closed and the lamp flame increased. The temperature then rises to the higher limit, when the bending of the thermostatic bar again releases the detent and the clockwork opens the valve and reduces the flame.

The incubator is said to succeed well. It also possesses a mechanical arrangement by which all the eggs can be periodically turned on rollers at once.

Size.—The incubators which have been described are of relatively small size, and the numbers of eggs which they can incubate are strictly limited. For commercial purposes, however, operations of a much larger magnitude are desirable and necessary. And there can be no doubt that for these purposes the incubators of the future will be of great size and will contain from 15,000 to 30,000 eggs or more at a time. Already, at Aratoma Farm, Stamford, New York State, there is established a large incubation room, containing several thousands of eggs, and in which the heat regulation is controlled in part by the personal efforts of attendants. It constitutes almost a complete return, with added accessories, to the methods of the Egyptians, and to those of John Champion.

These differ from bird Incubators in that the heating surface of the incubation chamber generally surrounds all sides of it and there is, as a rule, no special arrangement for bringing about a more or less humid condition of the contained air. In some forms there is an arrangement to ensure a continuous supply of fresh and moist air, but in the majority the incubation chamber obtains its supply of fresh air vicariously. In some forms the chamber of the incubator is heated by a warm water tank of a simple kind, which extends round all its sides. But in other forms a series of tubes or flues passes through the water in this tank and thus simulates in principle the tube boiler. This latter form utilizes the heat of the flame to a greater degree than the former kind. In yet other forms the incubation chamber is heated by warm air chambers which surround it or flues which traverse it. Most bacteriological incubators are square or rectangular in form, but some bacteriologists prefer cylindrical forms, presumably on account of the ratio of volume to surface in connexion with the water tank.

One of the best known and most generally used of the cylindrical and water-tank kind is that of Dr d’Arsonval. It consists of two copper cylinders (fig. 8 C and C′), each terminating in a cone below. Between the cylinders is a wide interspace, in order that a large volume of water may be contained. This interspace therefore constitutes the water-tank of the incubator. The upper orifice of the inner cylinder is closed by a movable double lid, which contains an interspace filled with water. The outer cylinder has an oblique form at its upper end and is permanently closed. The result attained by this slope of the lid of the outer cylinder is that the water tank, which is fed from the highest point, becomes completely filled. The aperture at the highest point of the outer cylinder is plugged with a caoutchouc plug and through a perforation in this a glass tube (T) is placed. In the side of the outer cylinder below this, there is a wide and rimmed aperture, to which a gas regulator of special construction is fixed.

|

| Fig. 8.—D’Arsonval Incubator. |

This regulator was designed by Théophile Schloesing, and consists of a brass box, supplied with a rim (L) which fits on to the corresponding rim (L′) on the aperture of the incubator. Stretching across the orifice thus connecting the brass box of the regulator with the water-tank of the incubator is a thin india-rubber diaphragm (D). At its outer end a perforated cap (R) screws on to the brass box. Through the perforation the inlet gas tube passes (I); the outlet gas tube (O) leaves the brass box below and passes direct to the gas burners. The inlet gas tube is fitted at its inner end with a sliding flanged collar (F), which is kept pressed against the rubber diaphragm by a spiral spring. Just behind the collar the inlet tube is perforated by a small hole, so that the gas supply is never wholly cut off, even though the rubber diaphragm completely occludes the inner aperture of the pipe.

The mode of working of the regulator is as follows: when the water tank of the incubator is filled with distilled or rain water at the temperature required, it presses upon the india-rubber diaphragm with a certain degree of pressure. By screwing the inlet pipe in or out, as required, it can be so adjusted that the diaphragm does not occlude its inner aperture, and consequently the full volume of gas can pass through to the burners below. The temperature of the water in the water-tank therefore begins to rise, and in consequence the volume of the water to increase. This results in the water rising up into the tube (T), and therefore the dynamical pressure which is exercised by the water upon every part of the two cylinders of the incubator and consequently also upon the india-rubber diaphragm of the regulator is increased. As this pressure increases, the diaphragm becomes bulged outwardly and reduces the volume of gas passing through the aperture of the inlet pipe. At a certain point, of course, the diaphragm completely occludes the aperture, and the gas supply is wholly cut off, except for the very small hole, forming a by-pass, in the pipe, behind the collar. This hole is just sufficiently big to allow the minimum amount of gas requisite to keep the flames burning to pass through. The temperature will, therefore, begin to fall, the volume of water to decrease with its resulting descent from the glass tube (T) and consequent decrease in the dynamical pressure of the water upon the diaphragm. The latter therefore retracts away from the aperture of the inlet tube, and more gas consequently passes through; the flames again increase in size and the temperature rises once more. And as soon as the volume of water, owing to the rising temperature, has increased to the extent correlated with the temperature at which the apparatus has been set to work, it will have risen once more in the tube (T), and the gas will be again cut off. The three burners are placed upon a support that can be moved vertically up or down along one of the legs of the incubator. The flames are protected from draughts by mica chimneys. Ventilation is provided by an adjustable valve (V′) in the cylindrical termination of the incubator at its lower end, and by tubular orifices, also fitted with valves (V) in the lid above.

The incubator is very reliable and may be worked within very narrow limits of variation, provided that the gas-supply be regulated by a gas-pressure regulator, that the height of the water in the tube (T) is maintained by daily additions of a few drops of distilled water, and that the incubator itself be protected from draughts.

Another form of d’Arsonval incubator has a glass door in the side of it and a slightly modified form of the heat regulator.

Other cylindrical forms of incubators are made by Lequeux of Paris. In one of these the heat regulator is a bimetallic thermostat, the movements of which are enlarged by a simple series of levers, so that a valve can be automatically adjusted to allow more or less heat from the flame to pass through the heating flue.

In another form there is a movable interior, and an arrangement for keeping the air in the incubation chamber saturated. It is governed by a bimetallic thermostat of the Roux type.

In Dr Hüppe’s improved form of his incubator, which is approximately square in form, the double-walled water tank is completely surrounded externally by an air chamber, which is heated by the passage through it of the products of combustion of the two flames. The heated gases escape through an adjustable aperture at the top. In the earlier form the water tank was traversed by a number of hot-air flues, and there was consequently no external hot-air chamber. There is an arrangement of tubes for ventilation, which allow fresh air to enter the lower part of the incubation chamber and to leave it at the top. The incoming air is warmed before it enters. The walls are made of lead-coated steel, and externally the incubator is covered with linoleum. In the more expensive forms the inner chamber is of copper. The temperature may be controlled by any of the simpler mercury thermostats described below.

Dr Babes’ incubator is somewhat similar, but the water tank is not surrounded by a hot-air chamber. Instead it is traversed by a number of vertical flues through which the heated gases from the flames pass. Ventilation is provided for and there is an apparatus for controlling the humidity of the air in the incubation chamber. As in Hüppe’s incubator, the bottom is conical in form. The walls of the incubator are of lead-coated steel, and externally they are covered with linoleum; there are two doors, an inner one of glass and an outer one of metal. The temperature may be controlled as in Hüppe’s incubator.

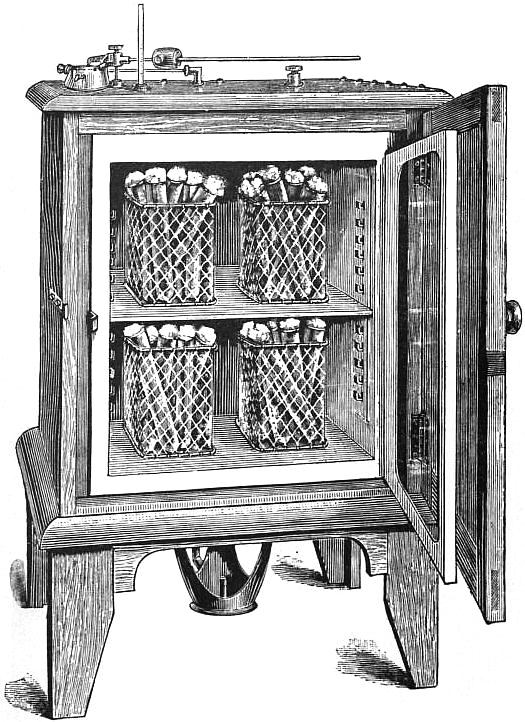

Hearson has designed several forms of bacteriological (biological) incubators, made by Chas. Hearson & Co., Ltd. Some are heated by a petroleum lamp and others by a gas flame. In the form heated by a lamp, for which, however, gas can be substituted, the incubation chamber is surrounded by a water tank (fig. 9, A) and the lowest part of this is traversed by an in-going (L) and an out-going flue. The mode of regulation of the temperature is by means of a thermostat which operates the movements of a cap (F) over the main flue (V), and it is identical in its chief features with the method employed in the chicken incubator. The thermostat (S) is situated in the upper part of the incubation chamber.

|

| Fig. 9.—Hearson’s Bacteriological Incubator. (Heated by a petroleum lamp.) |

In the other form (fig. 10) for which gas is used exclusively, there are no flues traversing the water tank. This latter is heated from its conical floor by a burner beneath the incubator. The heat regulation is controlled by a thermostat of the same nature as in the form of incubator just described, but instead of operating by lowering or raising a cap over a main flue, so as to direct the heated gases either through the water tank if the temperature is falling, or through the main flue directly to the exterior if it is rising, it actuates a gas-governor, so that the flame itself is increased or diminished in size according to the needs of the incubator. The gas-governor (fig. 11) is fixed to the roof of the incubator. The horizontal arm (D) is the same that raises the cap (fig. 9, F) over the flue in the other form of incubator, but in this case it simply acts as the bearer of the sliding weight. Beyond its fulcrum (fig. 11, G) it is continued into a detent-like spur (B) which pushes down upon a button attached to a rubber diaphragm, when the thermostat within the incubator is expanded by a rise in temperature. The button thus forced down, more or less completely closes the inlet gas aperture, and so reduces or cuts off the gas supply to the flame. There is a by-pass to prevent the flame from going out completely, and the size of this can be adjusted by the screw (S). Hearson’s incubators have the reputation of very accurate performance and practically need no attention for months, or even years.

|

| Fig. 10.—Hearson’s Bacteriological Incubator (heated by a gas flame). |

|

| Fig. 11.—Gas-governor. |

Schribaux’s incubator is a hot-air form. Its walls are of metal, but it is cased externally with wood, which serves as the insulating material. Against the inner metal wall of the incubator, and upon its internal surface, there are disposed a number of vertical tubes, which open through the roof above into a common discharging funnel. Below, at the bottom of the incubator they receive the heated gases of several burners, which as they pass through them radiate their heat evenly throughout the incubation chamber. In each side wall, at the bottom of the chamber, is an adjustable ventilating valve.

Inside the incubation chamber, and situated against its left-hand wall, is a U-shaped bimetallic thermostat of the Roux design, described below. This very accurately controls the temperature of the incubator.

(c) Cool Incubators.—In bacteriological laboratories there are two standards of temperature, one chiefly for the culture of non-pathogenic organisms and the other for the pathogenic forms. The first standard of temperature lies between 18° and 20° C., and the second between 35° and 38° C. But in hot countries, and even in temperate regions during the summer, the external temperature is much higher than the former of these two standards, with the result that many cultures, especially the gelatine ones, are spoiled. The difficulty is often partially overcome by running cold water through the incubator.

Hearson, however, has constructed a “cool biological incubator,” in which by an ingenious device the expansion or contraction of the thermostatic capsule deflects a horizontal pipe (C) (fig. 12), through which cold water from an ordinary tap is kept running, in one of two directions. If it is deflected so as to open into the tube (D), the cold water passes into the tank (F), where it is warmed by a gas flame, and thence it passes into the water-jacket of the incubator. If it is deflected so as to open into the pipe (E), it then runs through the ice tank (B), containing broken ice, before passing through the water-jacket of the incubator. If it poured into neither of these pipes it then simply passes out through the pipe (H) to the waste pipe (N). By this device the temperature of the incubator can be kept constant at any desired point, even though it may be some 30° to 40° C. below that of the external air.

Dr Roux has also designed an incubator which can be maintained at a constant temperature below that of the surrounding air. This also depends upon the principle of carrying water through an ice-safe, which then traverses a pipe within the incubator chamber before passing into the water-jacket of the machine. The heat-regulating apparatus is a bimetallic thermostat. The incubator is made by Lequeux of Paris.

The most recent forms of all kinds of incubators, made by Hearson of London, Lequeux of Paris and Lautenschläger of Berlin are both heated and regulated by electricity. The heating is accomplished by electric radiators.

|

| Fig. 12.—Hearson’s Cool Biological Incubator. |

In Hearson’s machines the regulation of the temperature is brought about by the breaking or making of the electric current, through the lifting or depression of a platinum contact, actuated by the expansion or contraction of the thermostatic capsule.

In Roux’s apparatus, made by Lequeux, the make and break is attained by the movement of one limb of a bimetallic thermostat, and in some forms a resistance coil and rheostat are placed in the circuit.

At the Pasteur Institute in Paris, and at other large laboratories in France, the bacteriological incubator is raised to the dimensions of a room. In the centre of this room is a large boiler heated by gas-burners, the fumes from which pass through a large flue to the outside. The flame of the burners is regulated by a bimetallic thermostat. The gas by-pass can be regulated by an attendant. The cultures are contained in vessels placed on shelves, which are ranged round the side of the room.

Human Incubators.

|

| Fig. 13.—Tarnier’s Incubator. |

The first incubator designed for rearing children who are too weak to survive under normal conditions, or who are prematurely born, is that of Dr Tarnier. It was constructed in 1880 and was first used at the Paris Maternity Hospital. Its form is that of a rectangular box measuring 65 × 30 × 50 centimetres (fig. 13). It is divided into an upper and lower chamber; the former contains the infant, while the latter serves as a heating chamber, and in reality is simply a modified water-tank. The partition (P) which divides the incubator into two chambers does not extend the whole length of it, so that the upper and lower chambers are at one end of the apparatus in communication with each other. It is through this passage that the heated air from the lower chamber passes into the upper one containing the infant. The narrow bottom chamber C serves to prevent loss of heat from the base of the water-bottles. The outside air is admitted into the lower chamber at the opposite end, through an aperture (A), and passing over a series of bottles (B) containing warm water, becomes heated. The air is rendered adequately moist by means of a wetted sponge (S) which is placed at the entrance of the lower chamber into the upper. The warmed and moistened air is determined in its direction by the position of the outlet aperture (O), which is situated above and just behind the head of the infant. It contains a helix valve (H) and the rotation of this is an indication that the air is circulating within the incubator.

The child is kept under observation by means of a sliding glass door (G) situated in the upper or roof wall of the incubator. Immediately beneath this, and attached to one of the side walls, is a thermometer (T) which records the temperature of the air in the infant-chamber. The temperature should be maintained at 31° to 32° C. The precise limit of temperature must of course be determined by the condition of the child; the smaller and weaker it is, the higher the temperature must be.

The warm water vessels contain three-quarters of a pint of water and four of them are sufficient to maintain the required temperature, provided that the external air does not fall below 16° C. The vessels are withdrawn and replaced through an entrance to the lower chamber, and which can be opened or closed by a sliding door (D).

The walls of the incubator, with the exception of the glass sliding door, are made of wood 25 millimetres thick.

The apparatus appears to have been successful, if by success is understood the indiscriminate saving of life apart from all other considerations, since the mortality of infants under 2000 grammes has been reduced by about 30%, and about 45% of children who are prematurely born are saved.

Dr Tarnier’s apparatus requires constant attention, and the water in the warm water vessels needs renewing sufficiently often. It is not provided with a temperature regulator and consequently fluctuations of internal temperature, due to external thermal variations, are liable to occur.

|

| Fig. 14.—Hearson’s “Thermostatic Nurse.” |

In Hearson’s Thermostatic Nurse these drawbacks are to a large extent obviated. This “Nurse” consists fundamentally of an application of the arrangements for heating and moistening the air and for regulating the temperature of Hearson’s chick incubator to Dr Tarnier’s human incubator. As in this latter form, there are two chambers (fig. 14), an upper (A) and a lower (B), connected with each other in the same way as in Tarnier’s apparatus. The upper chamber contains the infant, but the lower is not a heating but a moistening chamber. Through apertures (M) in the bottom of the lower chamber, the external air passes through, and as in the chick incubator it then passes through perforations in the inner cylinder of a water tray (O) and thence over the surface of the water in the tray, through a sheet of wet canvas, to the chamber itself. Hence it passes to the infant chamber and ultimately leaves this through a series of perforations round the top. The air in both chambers is heated by a warm-water tank. This tank forms the partition which divides the incubator into upper and lower chambers and is made of metal. Through the water contained in it, an incoming (R) and an outgoing (R) to the left flue, continuous with each other, pass. These two flues are related to each other as in the chick incubator (see above) and the inlet flue is heated in the same way and the outlet flue discharges similarly. The heat-regulating apparatus is identical with that in the chick incubator, and the thermostatic capsule (S) is placed in the upper chamber, near the head of the infant.

The child is placed in a basket which has perforated walls, and is open above. The basket rests upon two shallow supports (D) situated on the upper surface of the water-tank partition. The child is kept under observation through a glass door in the upper or roof-wall of the incubator.

In Great Britain this apparatus is in use at various hospitals and workhouses throughout the country, and provided there is no great fluctuation of barometric pressure, it maintains a uniform temperature.

Thermo-Regulators or Thermostats.

|

| Fig. 15.—Page’s Thermostat. |

Certain special forms of thermo-regulators, adapted to the requirements of the particular incubators to which they are attached, have already been described. It remains now to describe other forms which are of more general application. Only those kinds will be described which are applicable to incubators. The special forms used for investigations in physical-chemistry are not described. There are various types of thermo-regulators, all of which fall into one of two classes. Either they act through the expansion of a solid, or through that of a liquid. They are so adjusted, that, at a certain temperature, the expansion of the material chosen causes the gas supply to be nearly completely cut off. The gas flame is prevented from being wholly extinguished by means of a small by-pass.

We will first describe those which act through the expansion of a liquid. A very efficient and cheap form is that described by F. J. M. Page in the Journal of the Chemical Society for 1876. The regulator consists of a glass bulb (fig. 15 B), continuous above with a tubular limb (L). At the upper part of the limb is a lateral tubular arm (A) which bends downwards and constitutes the outlet pipe. At the upper extremity of the limb there is a short and much wider tube (T), the lower end of which slides upwards or downwards along it. The upper end of this wider tube is closed by a cork and through a perforation in this a very small glass tube (G) passes downwards into the limb of the regulator to a point a short distance below the exit of the outlet tube. The exact height of the lower aperture of the small tube can be varied by sliding the wider tube up or down along the limb. The by-pass (P) consists of a transverse connexion between the inlet and outlet gas pipes, and the amount of gas which travels through the short circuit thus formed is regulated by means of a stopcock. The by-pass, however, can be formed, as suggested by Schäfer (Practical Histology, 1877, p. 80), by making an extremely small hole in the small inlet tube, a little way above its lower extremity. But unless this hole be small enough, too much gas will be allowed to pass, and a sufficiently low temperature therefore unattainable. The regulator is filled with mercury until the top of the column reaches within 12 in. of the exit of the outlet tube, the bulb is placed in the incubator chamber, and gas is allowed to pass through it. By pushing down the inner inlet tube (G) until its aperture is immersed beneath the mercury, the gas supply is cut off, with the exception of that passing through the by-pass. The stopcock is now turned until only the smallest flame exists. The inlet pipe is then raised again above the mercury, and the flame consequently increases in size. The temperature of the incubator gradually rises, and when the desired degree is reached, the inlet tube is pushed down until the end is just beneath the surface of the mercury. The gas supply is thus cut off at the desired temperature. If the temperature of the incubator falls, the mercury contracts, the aperture of the inlet tube is uncovered, the gas supply is renewed and the flame increased. The temperature will then rise until the required point is reached, when the gas supply will again be cut off. A uniform temperature which oscillates within a range of half a degree is thus attained.

|

| Fig. 16.—Reichert’s Thermo-Regulator. |

Reichert’s Thermo-regulator (fig. 16) is another simple and also an earlier form. The stem (S) of the regulator is enlarged above and receives a hollow T-piece (P), the vertical limb of which fits accurately into the enlarged end of the stem, and one end of the cross-limb receives the inlet gas pipe; the other end is closed. The vertical limb of the T-piece is narrowed down at its lower extremity and opens by a small aperture. Above this terminal aperture is a lateral one of the smallest size. From the enlarged end of the stem there passes out a lateral arm (A) which is connected with the outlet pipe to the burner, and lower down another arm (L), which is closed at its outer extremity by a screw (R), is also attached. The stem and lower arm are filled with mercury and the bulb of the stem is placed in the incubator chamber, and gas allowed to pass. When the desired temperature is reached, the mercury in the stem is forced upwards until it closes the aperture of the T-piece, by screwing in the screw (R) of the lower lateral arm (L).

There are several modifications of Reichert’s original form. In one of these the screw arrangement in the lower arm is replaced by a piston rod working in a narrow bore of a vertically bent limb of the arm. In another form, the other end of the cross bar of the T-piece is open and leads through a stopcock to a third arm, which opens into the enlarged upper end of the stem opposite to the outlet arm (A); this modification acts as an adjustable by-pass and replaces the minute aperture in the side of the vertical limb of the T-piece.

In Babes’ modification the gas supply is cut off, not by the occlusion by the rising mercury of the aperture of the T-piece, but by a floating beaded wire-valve. The aperture of the vertical limb of the T-piece (P) is traversed by a fine wire which is enlarged at both ends into a bead-like knob. The wire fits loosely in the aperture and not only therefore works easily in it, but allows gas to freely pass. When the lower bead-like knob, however, is raised by the expansion of the mercury, the gas supply is cut off by the bead being carried up against the orifice.

|

| Fig. 17.—Cuccatti’s Thermo-Regulator. |

Cuccatti’s thermo-regulator (fig. 17) is an exceedingly simple and ingenious form. The stem (S) of the regulator is enlarged below into a bulb, while above it divides into a V. The two limbs of the V are of course traversed by a canal and they are connected above by a tubular cross bar (C). In the middle of this there is a stopcock situated between the two points where the bar joins the limbs of the V. One end of the cross-tube serves as an inlet and the other as an outlet for the gas. The stopcock serves as an adjustable by-pass. About an inch below the point where the two limbs of the V join the stem, the bore of the latter is enlarged, and it leads into a lateral arm (A), containing a screw (R), similar to the corresponding arm in Reichert’s regulator. When the mercury in the bulb and stem expands, it rises, and reaching the point when the two limbs of the V meet occludes the orifice to both and thus cuts off the gas supply, except that which is passing through the by-pass of the stopcock. The temperature at which this occlusion will take place can be determined by the screw in the lateral arm. The more this is screwed in, the lower will be the temperature at which the gas becomes cut off, and vice versa.

Bunsen’s, Kemp’s and Muenke’s regulators are in reality of the nature of air-thermometers, and act by the expansion and contraction of air, which raises or lowers respectively a column of mercury; this in its turn results in the occlusion or opening of the gas aperture. Such forms, however, are subject to the influence of barometric pressure and an alteration of 0.5 in. of the barometer column may result in the variation of the temperature to as much as 2°.

Lothar Meyer’s regulator is described in the Berichte of the German Chemical Society, 1883, p. 1089. It is essentially a liquid thermometer, the mercury column being raised by the expansion of a liquid of low boiling-point. The liquid replaces the air in Bunsen’s and other similar forms. The boiling-point of this liquid must be below the temperature required as constant.

|

| Fig. 18.—Dr Roux’s Thermostat (straight bar). |

The solid forms of thermostats are constructed upon the same principle as the compensation balance of a watch or the compensation pendulum of a clock. This depends upon the fact that the co-efficient of expansion is different for different metals. It therefore results that if two bars of different metals are fastened together along their lengths (fig. 18, Z and ST) with the same rise of temperature one of these will expand or lengthen more than the other. And since both are fastened together and must therefore accommodate themselves within the same linear area, it follows that the compound rod must bend into a curved form, in order that the bar of greater expansion may occupy the surface of greater length, i.e. the convex one. Conversely, when the temperature falls, the greater degree of contraction will be in the same bar, and the surface occupied by it will tend to become the concave one. If, then, one end of this compound rod be fixed and the other free, the latter end will describe a backward and forward movement through an arc of a circle, which will correspond with the oscillations of temperature. This movement can be utilized by means of simple mechanical arrangements, to open or close the stopcock of a gas supply pipe.

In the construction of this type of thermostat it is obvious that the greater the difference in the co-efficient of expansion of the two metals used, the larger will be the amplitude of the movement obtained. Steel and zinc are two metals which satisfy this condition. The co-efficient of steel is the lowest of all metals and is comparable in its degree with that of glass. Substances which are not metals, such as vulcanite and porcelain, are sometimes used to replace steel, as the substance of low co-efficient of expansion.

|

| Fig. 19.—Dr Roux’s Thermostat (U-shaped bar). |