cobalt is utilized as a blue pigment called “smalt”; the nickel-speis

is worked up for metal.

Minor Reagents.—Besides the oxidizing and reducing agents present in the fire, and the “fluxes” added for the production of slags, various minor reagents may be noticed. Metallic iron as a desulphurizer has already been referred to.

Oxide of lead, PbO (litharge), is largely used as an oxidizing agent. At a red heat, when it melts, it readily attacks all metals, except silver and gold, the general result being the formation of a mixed oxide and of a mixed regulus, a distribution, in other words, of both the lead and the metal acted on between slag and regulus. More important is its action on metallic sulphides, which, in general, results in the formation of three things besides sulphur dioxide, viz. a mixed oxide slag including the excess of litharge, a regulus of lead (which may include bismuth and other more readily reducible metals), and, if the litharge is not sufficient for a complete oxidation, a “mat” comprising the more readily sulphurizable metals. Oxide of lead, being a most powerful solvent for metallic oxides generally, is also largely used for the separation of silver or gold from base metallic oxides.

Metallic lead is to metals generally what oxide of lead is to metallic oxides. It accordingly is available as a solvent for taking up small particles of metal diffused throughout a mass of slag, and uniting them into one regulus. This leads us to the process of “cupellation,” which serves for the extraction of gold (q.v.; see also Assaying) and silver from their alloys with base metals.

Fluxes.—All ores are contaminated with more or less gangue, which in general consists of infusible matter, and if left unheeded in the reduction of the metallic part' of the ore would retain more or less of the metal disseminated through it, or at best foul the furnace. To avoid this, the ore as it goes into the furnace is mixed with “fluxes” so selected as to convert the gangue into a fusible “slag,” which readily runs down through the fuel with the regulus and separates from the latter. The quality and proportion of flux should, if possible, be so chosen that the formation of the slag sets in only after the metal has been reduced and molten; or else part of the basic oxide of the metal to be extracted may be dissolved by the slag and its reduction thus be prevented or retarded. Slags are not a necessary evil; if an ore were free from gangue we should add gangue and flux from without to produce a. slag, because' one of its functions is to form a layer on the regulus which protects it against the further action of the blast or furnace gases. Fluxes may be arranged under the three heads of (1) fluor-spar, (2) basic fluxes and (3) acid fluxes.

Fluor-spar fuses up at a red heat with silica, sulphates of calcium and barium, and a few other infusible substances into homogeneous masses. It shows little tendency to dissolve basic oxides, such as lime, &c. One part of fluor-spar liquefies about half a part of silica, four parts of calcium sulphate and one and a half parts of barium sulphate. Upon these facts its extremely wide application in metallurgy is founded. Carbonate of soda (or potash) is the most powerful basic flux. It dissolves silica and all silicates into fusible glasses. On the other hand, borax may be taken as a type for the acid fluxes. At a red heat, when it forms a viscid fluid, it readily dissolves all basic oxides into fusible complex borates. Now the gangue of an ore in general consists either of some basic material such as carbonate of lime (or magnesia), ferric oxide, alumina, &c., or of silica (quartz) or some more or less acid silicate, or else of a mixture of the two classes of bodies. So any kind of gangue might be liquefied by means of borax or by means of alkaline carbonate; but neither of the two is used otherwise than for assaying; what the metal-smelter does is to add to a basic gangue the proportion of silica, and to an acid ore the proportion of lime, or, indirectly, of ferrous or perhaps manganous oxide, which it may need for the formation of a slag of the proper qualities. The slag must possess the pro r degree of saturation. In other words, taking SiO2+ nMeO (where MeO means an equivalent of base) as a formula for the potential slag, n must have the proper value. If n is too small, i.e. if the slag is too acid, it may dissolve part of the metal to be recovered; if n is too great, i.e. the slag too basic, it may refuse to dissolve, for instance, the ferrous oxide which is meant to go into it, and this oxide will then be reduced, and its metal (iron in our example) contaminate the regulus. In reference to the problem under discussion, it is worth noting that oxides of lead and) copper are more readily reduced to metals than oxide of iron Fe2O3 is to FeO, the latter more readily to FeO than FeO itself to metal, and FeO more readily to metal than manganous oxide is. Oxide of calcium (lime) is not reducible at all. The order of basicity in the oxides (their readiness to go into the slag) is precisely the reverse.

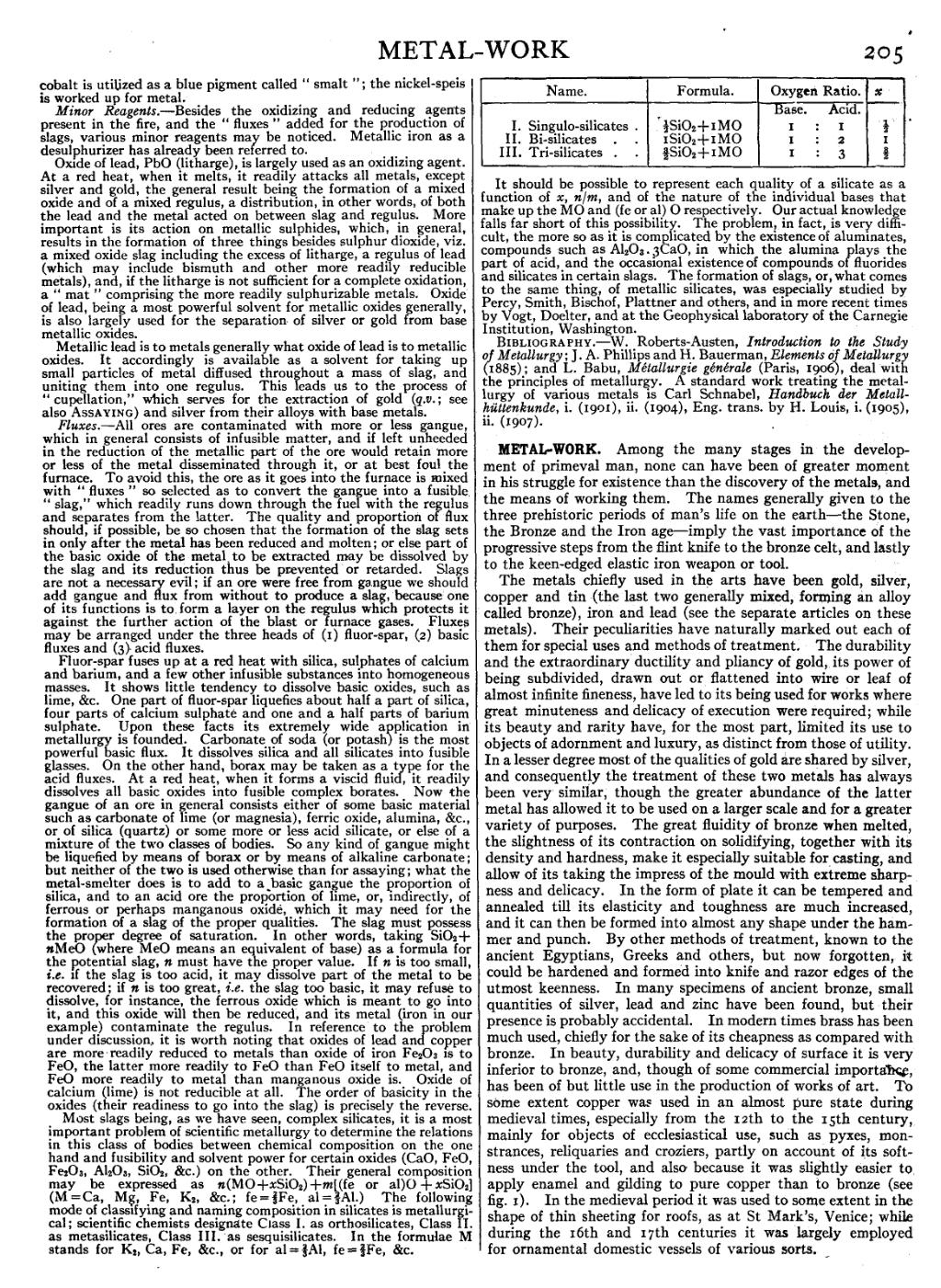

Most slags being, as we have seen, complex silicates, it is a most important problem of scientific metallurgy to determine the relations in this class of bodies between chemical composition on the one hand and fusibility and solvent power for certain oxides (CaO, FeO, Fe2O3, Al2O3, SiO2, &c.) on the other. Their general composition may be expressed as n(MO+xSiO2) +m[(fe or al)O +xSiO2] (M =Ca, Mg, Fe, Kg, &c.; fe=23Fe, al=23Al.) The following mode of classifying and naming composition in silicates is metallurgical; scientific chemists designate Class I. as orthosilicates, Class II. as metasilicates, Class III. as sesquisilicates. In the formulae M stands for K2, Ca, Fe, &c., or for al=23Al, fe=23Fe, &c.

| Name. | Formula. | Oxygen Ratio. | x |

| Base. Acid. | |||

| I. Singulo-silicates | 12SiO2+1MO | 1 : 1 | 12 |

| II. Bi-silicates | 1SiO2+1MO | 1 : 2 | 1 |

| III. Tri-silicates | 32SiO2+1MO | 1 : 3 | 32 |

It should be possible to represent each quality of a silicate as a function of x, n/m, and of the nature of the individual bases that make up the MO and (fe or al) O respectively. Our actual knowledge falls far short of this possibility . The problem, in fact, is very difficult, the more so as it is complicated by the existence of aluminates, compounds such as Al2O3.3CaO, in which the alumina plays the part of acid, and the occasional existence of compounds of fluorides and silicates in certain slags. The formation of slags, or, what comes to the same thing, of metallic silicates, was especially studied by Percy, Smith, Bischof, Plattner and others, and in more recent times by Vogt, Doelter, and at the Geophysical laboratory of the Carnegie Institution, Washington.

Bibliography.—W. Roberts-Austen, Introduction to the Study of Metallurgy; J. A. Phillips and H. Bauerman, Elements of Metallurgy 1885); and L. Babu, Métallurgie générale (Paris, 1906, deal with the principles of metallurgy. A standard work treating the metallurgy of various metals is Carl Schnabel, Handbuch der Metallhüttenkunde, i. (1901), ii. (1904), Eng. trans. by H. Louis, i. (1905), ii. (1907).

METAL-WORK. Among the many stages in the development of primeval man, none can have been of greater moment in his struggle for existence than the discovery of the metals, and the means of working them. The names generally given to the three prehistoric periods of man’s life on the earth—the Stone, the Bronze and the Iron age—imply the vast importance of the progressive steps from the flint knife to the bronze celt, and lastly to the keen-edged elastic iron weapon or tool.

The metals chiefly used in the arts have been gold, silver, copper and tin (the last two generally mixed, forming an alloy called bronze), iron and lead (see the separate articles on these metals). Their peculiarities have naturally marked out each of them for special uses and methods of treatment. The durability and the extraordinary ductility and pliancy of gold, its power of being subdivided, drawn out or flattened into wire or leaf of almost infinite fineness, have led to its being used for works where great minuteness and delicacy of execution were required; while its beauty and rarity have, for the most part, limited its use to objects of adornment and luxury, as distinct from those of utility. In a lesser degree most of the qualities of gold are shared by silver, and consequently the treatment of these two metals has always been very similar, though the greater abundance of the latter metal has allowed it to be used on a larger scale and for a greater variety of purposes. The great fluidity of bronze when melted, the slightness of its contraction on solidifying, together with its density and hardness, make it especially suitable for casting, and allow of its taking the impress of the mould with extreme sharpness and delicacy. In the form of plate it can be tempered and annealed till its elasticity and toughness are much increased, and it can then be formed into almost any shape under the hammer and punch. By other methods of treatment, known to the ancient Egyptians, Greeks and others, but now forgotten, it could be hardened and formed into knife and razor edges of the utmost keenness. In many specimens of ancient bronze, small quantities of silver, lead and zinc have been found, but their presence is probably accidental. In modern times brass has been much used, chiefly for the sake of its cheapness as compared with bronze. In beauty, durability and delicacy of surface it is very inferior to bronze, and, though of some commercial importance, has been of but little use in the production of works of art. To some extent copper was used in an almost pure state during medieval times, especially from the 12th to the 15th century, mainly for objects of ecclesiastical use, such as pyxes, monstrances, reliquaries and croziers, partly on account of its softness under the tool, and also because it was slightly easier to, apply enamel and gilding to pure copper than to bronze (see fig. 1). In the medieval period it was used to some extent in the shape of thin sheeting for roofs, as at St Mark’s, Venice; while during the 16th and 17th centuries it was largely employed for ornamental domestic vessels of various sorts.