in fig. 18, a three-cylinder, single-acting, vertical engine, and an all-gear drive to the rear wheels.

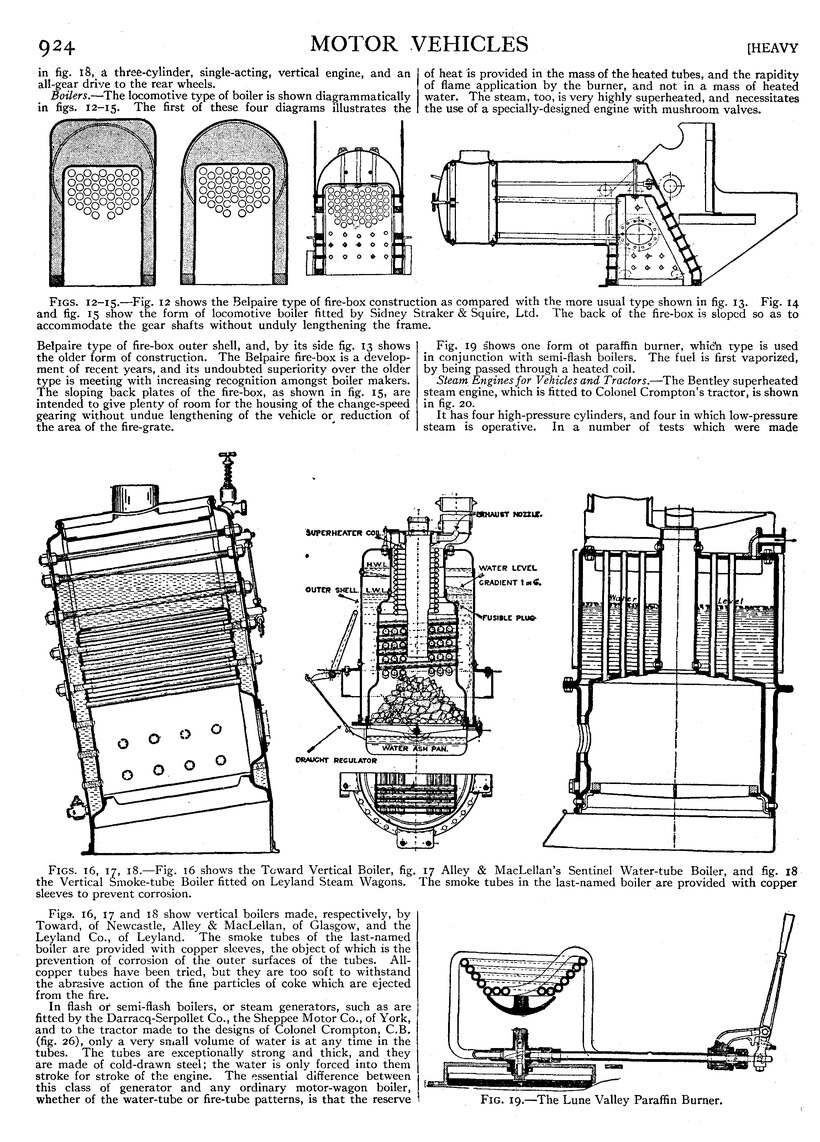

| Figs. 12–15.—Fig. 12 shows the Belpaire type of fire-box construction as compared with the more usual type shown in fig. 13. Fig. 14 and fig. 15 show the form of locomotive boiler fitted by Sidney Straker & Squire, Ltd. The back of the fire-box is sloped so as to accommodate the gear shafts without unduly lengthening the frame. |

Boilers.—The locomotive type of boiler is shown diagrammatically in figs. 12–15. The first of these four diagrams illustrates the Belpaire type of fire-box outer shell, and, by its side fig. 13 shows the older form of construction. The Belpaire fire-box is a development of recent years, and its undoubted superiority over the older type is meeting with increasing recognition amongst boiler makers. The sloping back plates of the fire-box, as shown in fig. 15, are intended to give plenty of room for the housing of the change-speed gearing without undue lengthening of the vehicle or reduction of the area of the fire-grate.

| Figs. 16, 17, 18.—Fig. 16 shows the Toward Vertical Boiler, fig. 17 Alley & MacLellan’s Sentinel Water-tube Boiler, and fig. 18 the Vertical Smoke-tube Boiler fitted on Leyland Steam Wagons. The smoke tubes in the last-named boiler are provided with copper sleeves to prevent corrosion. |

Figs. 16, 17 and 18 show vertical boilers made, respectively, by Toward, of Newcastle, Alley & MacLellan, of Glasgow, and the Leyland Co., of Leyland. The smoke tubes of the last-named boiler are provided with copper sleeves, the object of which is the prevention of corrosion of the outer surfaces of the tubes. All-copper tubes have been tried, but they are too soft to withstand the abrasive action of the fine particles of coke which are ejected from the fire.

In flash or semi-flash boilers, or steam generators, such as are fitted by the Darracq-Serpollet Co., the Sheppee Motor Co., of York, and to the tractor made to the designs of Colonel Crompton, C.B. (fig. 26), only a very small volume of water is at any time in the tubes. The tubes are exceptionally strong and thick, and, they are made of cold-drawn steel; the water is only forced into them stroke for stroke of the engine. The essential difference between this class of generator and any ordinary motor-wagon boiler, whether of the water-tube or fire-tube patterns, is that the reserve of heat is provided in the mass of the heated tubes, and the rapidity of flame application by the burner, and not in a mass of heated water. The steam, too, is very highly superheated, and necessitates the use of a specially-designed engine with mushroom valves.

Fig. 19 shows one form of paraffin burner, which type is used in conjunction with semi-flash boilers. The fuel is first vaporized, by being passed through a heated coil.

Fig. 19.—The Lune Valley Paraffin Burner.

Steam Engines for Vehicles and Tractors.—The Bentley superheated steam engine, which is fitted to Colonel Crompton’s tractor, is shown in fig. 20.

It has four high-pressure cylinders, and four in which low-pressure

steam is operative. In a number of tests which were made