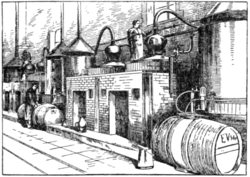

ripening, methodically supported by wire. The wines produced by the Charente vineyards are of a light(white) character and possess no marked "bouquet," but they nevertheless produce a spirit of a peculiarly fine and delicate character. It is remarkable that the fuller and more aromatic wines of the Gironde and of Burgundy, for instance, are not so suitable for the manufacture of brandy as the relatively poor growths of the Charente. The apparatus employed for the distillation of the fine Cognac brandies is generally of a very simple pot-still type. Fig. 5 depicts the still-room of a Charente distillery

Fig. 5.—Old Cognac Pot-still.

Fig. 6.—Modern Cognac Pot-still. (Martell & Co.)

of former times, and fig. 6 shows one of Messrs Martel's distilleries in Cognac, equipped on modern lines. It will be seen that, in principle, there is very little difference between the two sets of plant, the reason being that experience has shown that for wines producing the finest brandies, the simplest form of still is also the best. For the distillation of wines not of the highest quality (from the brandy distillers' point of view) more complicated apparatus is employed, as the spirit from these wines must be more highly rectified than is the case with the finest brandies. Broadly speaking, it may be said that the type of still is suited to the production in the most economical manner of the best spirit to be obtained from the wine of a particular district. In Cognac, brandy is generally, but not universally, made by the "brouillis et repasse" system, this being a double distillation in a simple pot-still. The stills are (compared with whisky pot-stills) very small, holding roughly one hundred gallons, and the distillation is conducted very slowly and carefully, lasting about eight hours. Sometimes the whole of the spirit is collected in one receiver (corresponding to the low wines of Scotch whisky), but frequently the "brouillis," as the results of the first distillation are termed, are divided into several fractions. The "brouillis" which contain about 25 to 35% of alcohol are redistilled, this second distillation being called the "bonne chauffe" or "repasse." The first runnings—which vary in quality according to the quality of the wine, the manner of heating, &c.—are termed "produit de tete" or "tetes," and are separately collected and mixed with the "brouillis" of the following operation. The spirit which next comes over (starting at a strength of about 80% and running down to about 55%) is the "cœur," and as a whole, marks roughly 66 to 70% of absolute alcohol by volume. The residue in the still is then run down to water, and the spirit so obtained, which shows 20 to 25%, is called "seconde," and is either mixed with a fresh charge of wine cr rectified separately, the stronger portion being mixed with the "brouillis," the weaker with a charge of wine (see Brandy).

There are two main kinds of rum, namely, Jamaica rum and rum of the type prepared principally in Demerara and Trinidad (see Rum). There are two varieties of Jamaica rum (a) the common clear rum, and (b) flavoured, or "German" rum. (a) "Common clear" rum is prepared Rum. from a mixture of sugar-cane molasses, "skimmings" (the scum from the boiling cane juice) and "dunder," this last name being given to the spent lees from previous distillations. Previous to use the "skimmings" are subjected to acid fermentation either alone or in conjunction with "trash" (crushed cane). The wort, which on the average contains about 10 to 15% of sugar, ferments very slowly, owing to the fact that very little yeast—the latter being derived from the cane rind—is present. Roughly five to ten days are occupied by this operation. At first the fermentation is mainly alcoholic, but it rapidly assumes an acid character, owing to the presence of a great number of acidifying bacteria derived from the "dunder" and "skimmings." The, distillation of the fermented wort is carried out in pot stills heated by fire or steam, either of a simple type or provided with rectifiers. In the former case two distillations are necessary, the first resulting in the production of a weak alcoholic liquid termed "low wines," the second, which consists in a rectification of the low wines, producing "high wines" or strong rum. The other type of still is provided with two rectifiers, which are interposed between the still and the condensing worm. These are charged with low and high wines respectively. The first runnings of the still (25 to 40 o.p.) constitute the rum proper, the next fraction the high wines, and the final distillate the low wines. (b) Flavoured or "German" rum is prepared from the same materials as the "common clear" variety, with the addition of "acid" and "flavour." "Acid" is obtained by acidifying fermented cane juice by means of cane "trash" and refuse from the wash backs. "Flavour" is prepared in much the same way as "acid," except that "dunder" sediment is also added. The fermentation, which is to a very great extent bacterial, results in the formation of large quantities of acid, including much butyric acid and compound esters. The distillation of "flavoured" rum is carried out in much the same manner as that of the "common clear." The manufacture of "Demerara rum" is differentiated from that of the Jamaica varieties mainly by the fact that the fermentation in the former case is practically purely saccharomycetic (i.e. yeast), whereas the latter is largely schizomycetic (i.e. bacterial). For the distillation of the Demerara rums, which are much lighter in flavour than the Jamaica varieties, stills of the "patent" (see below) or rectifying type are frequently employed (see Rum and Arrack).

For the manufacture of industrial spirit from saccharine materials see below, under Industrial Alcohol.

B. Spirits Derived from Starchy Materials.—The manufacture of spirit from saccharine materials is, as we have seen, a relatively simple operation, the sugar being transformed into alcohol by fermentation, and the latter then distilled off. To convert starchy matter into alcohol is a much more complicated matter. To the operations necessary for the transformation of sugar into spirit, must, in the case of starchy materials, be added that of converting the starch into sugar. This is accomplished either by the action of a diastatic ferment, such