by dampers, so that the generator yields more or less gas according to the requirements of the furnace. But the carbonic-acid gas thus produced would be of no value as fuel, for it is totally incombustible. Rising, however, through the mass of incandescent fuel above it, the gas is speedily reduced to the condition of carbonic oxide, that combustible gas whose blue flame plays over

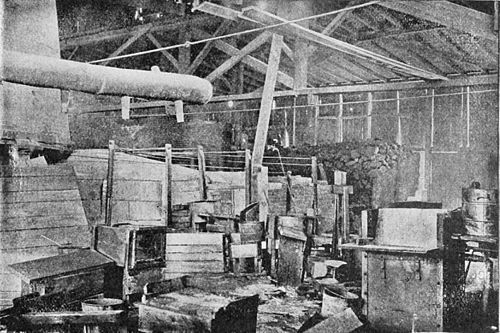

Fig. 2.—An Interior View, showing the Brick-work which contains the Gas Generators and Melting Tank.

the surface of an anthracite fire just after fresh fuel has been thrown on. This mixes with the volatile hydrocarbons the coal-gas given off when fresh coal is introduced into the generator and the mixture passes at once to the chamber above the melting tank. The air necessary for the burning of these generator gases is first heated by passing through a number of chambers in the lower part of the furnace. It is mixed with the gases to be burned just before they reach the fire-clay bridge separating the gas generator from the melting tank. The main combustion takes place right at this bridge, and produces an intense heat in the melting chamber, for both the gas to be burned and the air to burn it are highly heated before they are allowed to combine. The effect is the same as would be produced on a small scale if one fed his stove with the hot air from a register. This arrangement removes in a simple and inexpensive way one of the chief objections to the use of gas in glass-making. The fuel is so exceedingly convenient that its use in the industry was proposed, and indeed attempted, years ago, but a sufficiently intense heat could not be thus obtained.

The furnaces are in continuous operation for ten months in the