734

��Popular Science Monthly

��The Automatic Furnace- Watchman. It Prevents Damage to the Boiler

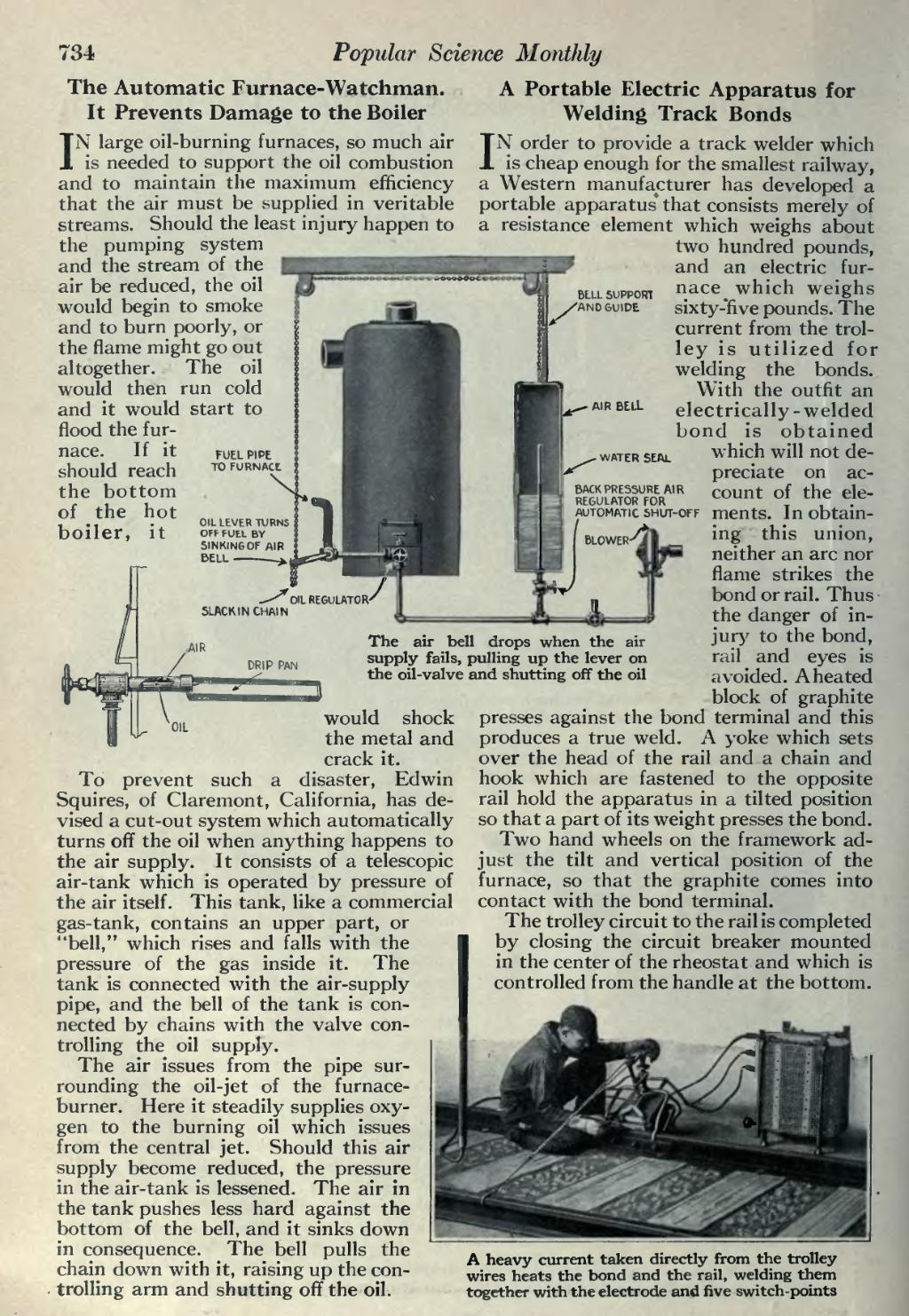

IN large oil-burning furnaces, so much air is needed to support the oil combustion and to maintain the maximum efficiency that the air must be suppHed in veritable streams. Should the least injury happen to the pumping system and the stream of the air be reduced, the oil would begin to smoke and to burn poorly, or the flame might go out altogether. The oi would then run cold and it would start to flood the fur- nace. If it should reach the bottom of the hot

, . , . OIL LEVtR TURNS

boiler, it OFFFUELBY

5INKING0F AIR

BELL

��BLLL SUPPORT AND GUIDE

��FUEL PIPE TO FURNACt

����BACK PRESSURE AIR REGULATOR FOR AUTOMATIC SHUT-OFF

��OIL REGULATOR

��would shock the metal and crack it. To prevent such a disaster, Edwin Squires, of Claremont, California, has de- vised a cut-out system which automatically turns off the oil when anything happens to the air supply. It consists of a telescopic air-tank which is operated by pressure of the air itself. This tank, like a commercial gas-tank, contains an upper part, or "bell," which rises and falls with the pressure of the gas inside it. The tank is connected with the air-supply pipe, and the bell of the tank is con- nected by chains with the valve con- trolling the oil supply.

The air issues from the pipe sur- rounding the oil-jet of the furnace- burner. Here it steadily supplies oxy- gen to the burning oil which issues from the central jet. Should this air supply become reduced, the pressure in the air-tank is lessened. The air in the tank pushes less hard against the bottom of the bell, and it sinks down in consequence. The bell pulls the chain down with it, raising up the con- trolling arm and shutting off the oil.

��A Portable Electric Apparatus for Welding Track Bonds

IN order to provide a track welder which is cheap enough for the smallest railway, a Western manufacturer has developed a portable apparatus' that consists merely of a resistance element which weighs about two hundred pounds, and an electric fur- nace which weighs sixty-five pounds. The current from the trol- ley is utilized for welding the bonds. With the outfit an electrically -welded bond is obtained which will not de- preciate on ac- count of the ele- ments. In obtain- ing this union, neither an arc nor flame strikes the bond or rail. Thus ■ the danger of in- jury to the bond, rail and eyes is avoided. A heated block of graphite presses against the bond terminal and this produces a true weld, A yoke which sets over the head of the rail and a chain and hook which are fastened to the opposite rail hold the apparatus in a tilted position so that a part of its weight presses the bond. Two hand wheels on the framework ad- just the tilt and vertical position of the furnace, so that the graphite comes into contact with the bond terminal.

The trolley circuit to the rail is completed by closing the circuit breaker mounted in the center of the rheostat and which is controlled from the handle at the bottom.

��The air bell drops when the air supply fails, pulling up the lever on the oil-valve and shutting off the oil

���A heavy current taken directly from the trolley wires heats the bond and the rail, welding them together with the electrode and five switch-points

�� �