128

��Popular Science Monthly

��This instrument is arranged to use motor drive, as motors are cheap and easily applied and if alternating current is available a constant speed is easily secured. The tone arm and reproducer are to be made of wood,

���Here is shown the horn or sound box beneath the turntable cover and the cabinet fastenings

which is more easily worked than metal and is generally more desirable. The most recent phonographs placed on the market have a wood tone arm.

Any type of motor, preferably shunt wound, may be used and should develop only a few hundredths of a horsepower. The motor usually used on an 8-in. fan is ideal and of the right size. The speed should preferably be not over 3,000 R. P. M.; but this is not essential as the speed can be controlled by resistance. A motor should be selected which has a uniform rate of speed. The method of mounting a motor of the "globe" type is shown in Fig. 1, in which the motor swings on pivots in a strap-brass frame secured to the top panel, and is held so that its friction wheel bears against the turntable by a* suitably arranged spring. For any other type of motor a suitable mounting must be developed but should always be sufficiently resil- ient to produce enough pressure for driving. In order to insure uniform speed of the turntable the disk is made very heavy, so as to act as a flywheel, driving pulley should be so proportioned as to give a speed normally of 80 revolutions per minute. The motor pulley should be cov-

��ered with a piece of soft rubber tube to cause proper friction. The turntable should be made of cast iron and carefully turned in a lathe. The center pin is forced into the disk and rotates freely in the bushing beneath, which is mounted in the crossbar shown secured to ^he underside of the top. The turntable is 12 in. in diameter and 1 in. thick.

The top view of the machine with the cover removed is shown in Fig. 2. Here the wooden tone arm is shown and the position of the motor. The two holes in the top are for new and used needles. The turntable is covered with a layer of felt stuck on with shellac.

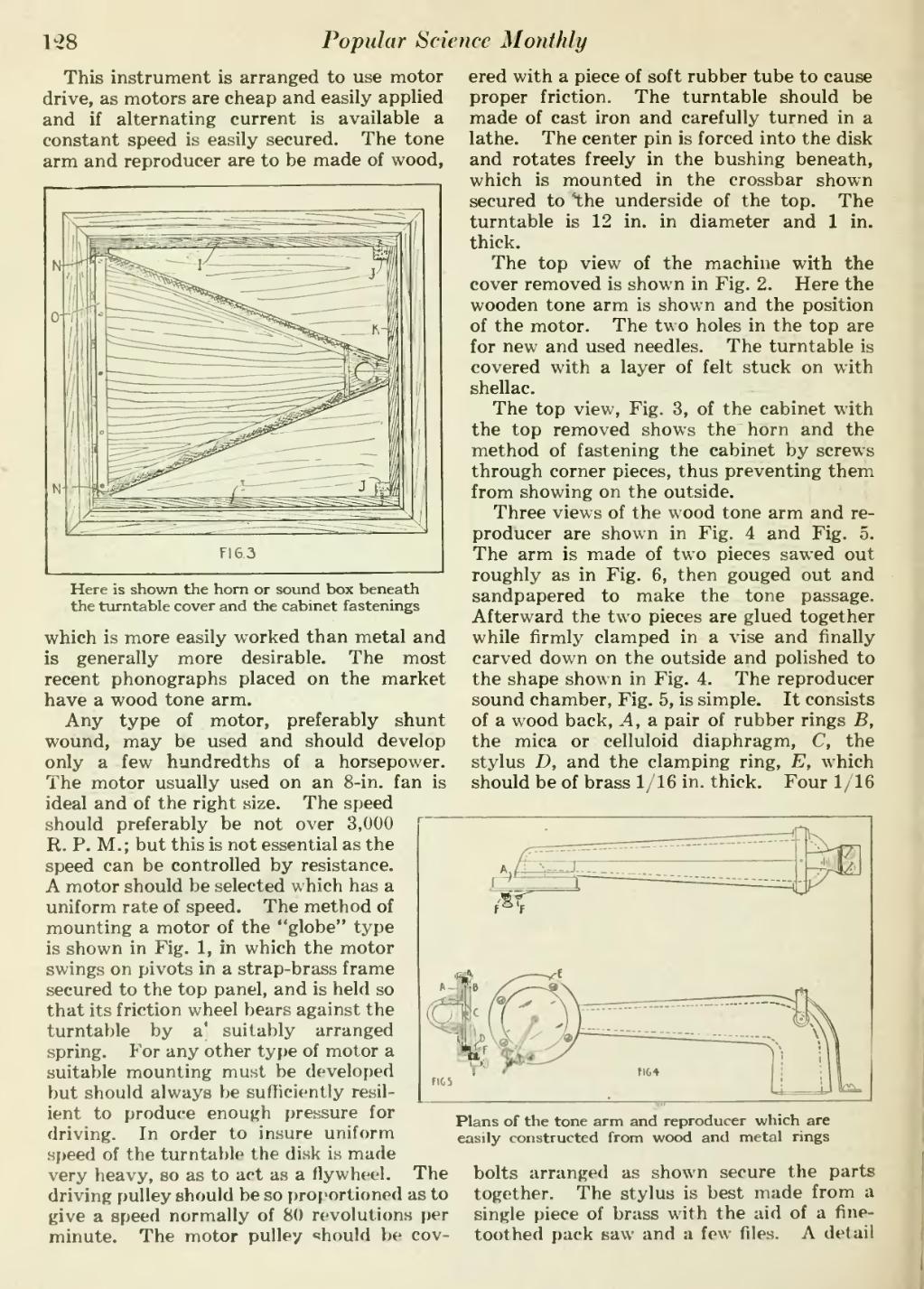

The top view. Fig. 3, of the cabinet with the top removed shows the horn and the method of fastening the cabinet by screws through corner pieces, thus preventing them from showing on the outside.

Three views of the wood tone arm and re- producer are shown in Fig. 4 and Fig. 5. The arm is made of two pieces sawed out roughly as in Fig. 6, then gouged out and sandpapered to make the tone passage. Afterward the two pieces are glued together while firmly clamped in a vise and finally carved down on the outside and polished to the shape shown in Fig. 4. The reproducer sound chamber, Fig. 5, is simple. It consists of a wood back. A, a pair of rubber rings B, the mica or celluloid diaphragm, C, the stylus D, and the clamping ring, E, which should be of brass 1/16 in. thick. Four 1/16

����The

��Plans of the tone arm and reproducer which are easily constructed from wood and metal rings

bolts arranged as shown secure the parts together. The stylus is best made from a single piece of brass with the aid of a fine- toothed pack saw and a few files. A detail

�� �