Paper and Its Uses/Chapter 16

CHAPTER XVI

PAPER TESTING[1]

A full scheme for the analysis and testing of papers will include the following: Checking the weight of the ream and sheet; the thickness of the ream and sheet; examination of the physical and chemical constituents—fibre, sizing, loading, and colouring matter; testing the tensile strength and elasticity, the resistance to folding or crumpling, and microscopical examination of the fibres. It is not necessary to carry out all these tests on every paper, but it is well to be prepared, if required, to compare two samples, using appropriate tests.

Weight.—The weight of the ream is checked on the scales, and variation should not exceed 4 to 8 per cent, above or below the nominal weight. (See various kinds of papers under "Variations in Weight," on page 136.) A sheet of paper is weighed on a balance which gives a direct reading for a ream of 480, 500, or 516 sheets. The demy scale is a very useful little balance. A metal plate is supplied with the scale, a piece of paper is cut exactly to the size of the plate with a sharp knife. The piece is placed on the end of a hook, and the scale, marked for reams of 480, 500, and 516 sheets, gives the weight of a ream of demy of the substance of the pattern, and by reference to tables the equivalent weight in any other size can be found.

Size.—The size of the paper is checked, and the papermaker guarantees to be within one-half per cent. of the measurement ordered. The paper is tested at the same time for squareness.

Thickness of Sheet.—For testing the thickness of the sheet a micrometer is used. The screw micrometer is not so exact on a yielding material like paper as is the spring micrometer, which gives the reading on a dial in thousandths of an inch. Machines are obtainable in pocket or stand form, giving measurements as close as 12000 of an inch. The micrometer serves to check the thickness of supplies of paper or cards, and to indicate the bulk of a volume consisting of a certain number of pages or leaves, enabling covers for books to be prepared before the printing is completed.

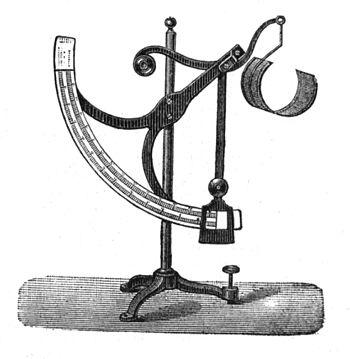

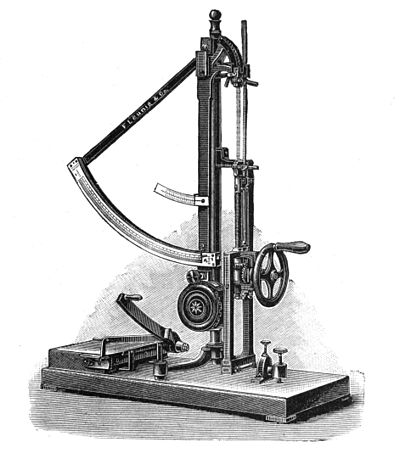

Tensile Strength and Elasticity.—These tests may be carried out on various machines. The method adopted is to cut strips of a standard width, clamp in the machine clips which are a definite distance apart, and to place the strip to be tested under tension by turning the handle of the machine, until breakage of the paper takes place. The machine registers the strain put upon the strip, and also the elongation which the strip sustained before fracture. The Marshall machine takes strips of various lengths and widths, and registers the tension on a hydraulic pressure gauge, the stretch being measured exactly and calculated on the length of the strip used. Leunig's testing machine

Fig. 15.—Marshall's Paper-Testing Machine.

A, Cylinder in which compression of liquid is produced by turning wheel B.

C, Registering dial.

D, Clips for securing slips.

E, Clips for registering stretch.

F, Cutting knife.

G, Cutting gauge.

registers breaking strain and stretch on two scales. The strip, ⅝ inch wide, is clamped between two clips 7 inches apart, and, by turning a handle, the strip under tension raises a weight at the end of a lever. The strain exerted by the weight is indicated on a scale marked in quarter-pound divisions. The stretch is registered at the same time by a pointer actuated by a separate rack. The stretch scale and pointer are kept in unison with the strength lever, and the elongation at the time of fracture is registered. This machine, although expensive, is acknowledged to be the best for high-class papers where the narrow strip

can be used. The Carrington machine for coarse papers takes a strip 2 inches wide and 7 inches between the clips, the strain is exerted by a weighted lever, and the reading is in pounds.

Bursting Strain.—For quick comparative tests there are a number of machines to choose from. The list comprises the Mullen, Southworth, Woolley, Ashcroft, Eddy, and Rehse machines. Testing on the Mullen machine is by hydraulic pressure which is communicated through the medium of glycerine to a rubber diaphragm. The paper is clamped over the diaphragm; the handle of the machine is turned, pressure being exerted until the paper bursts; the reading is given on the gauge in pounds per square inch. The Southworth gives a similar indication, but the fluid is oil, and a steel plunger punctures the paper. The Woolley machine is actuated by a spring and gives a comparative figure. The Ashcroft is a very compact machine, a very small plunger piercing the paper, the dial reading indicating the bursting strain in pounds per square inch. Two machines of this pattern are made, one for thin papers, and the other for papers of ordinary and thick substances. The Eddy machines are screw machines, also made for thick and thin papers, and the result is given in similar terms to other machines. The Rehse machine is a cylindrical machine; pressure is exerted by a spring, and the pressure in pounds is registered on one scale, and from figures given on another scale the stretch can be calculated.

These machines are exceedingly useful for rapid comparisons of papers, the tests being made at the same time. Slight variations in results can be obtained by turning the handles of the machines at varying speeds, but if a uniform rate is maintained, scarcely any other precaution is necessary in their use.

Opacity.—While it is possible to obtain apparatus for exact determination of the degree of opacity in paper, comparison can readily be made in a simple manner. A printed page is covered by pieces of the papers to be compared brought edge to edge over the printed matter, and the comparative degree of opacity observed by the ease, or otherwise, with which the lettering can be seen through the papers.

Surface or Finish.—The degree of polish which is given to the paper may be compared by feeling with the hand, and also by looking along the sheet. The comparisons can be brought to a numerical basis, but apparatus which would seldom be used is required for that purpose.

Resistance to Wear.—An ingenious machine is made for testing the resistance which paper offers to wear as exemplified by repeated folding. A narrow strip is clamped at each end, kept under constant tension by springs, and folded backwards and forwards until breakage occurs. Some idea of the comparison can be seen by taking the following results:—

Folding Machine Tests

| Description of Paper. | Equivalent Weight in Demy. |

Number of Folds before Breaking. | ||

| Strong Direction. |

Weak Direction. |

Mean of Two Directions. | ||

| Japanese vellum | 28 | 15,840 | 6,174 | 11,007 |

| Manilla | 80 | 5,783 | 5,448 | 5,616 |

| Loan—hand-made | 37 | 2,581 | 1,416 | 1,998 |

| Ledger—mould-made | 29 | 1,344 | 1,023 | 1,183 |

| "machine-made | 39 | 1,243 | 1,123 | 1,183 |

| Bank—hand-made | 12 | 1,036 | 846 | 941 |

| Typewriting—machine-made, all-rag | 9 | 763 | 413 | 588 |

| Blue-laid—machine-made, air-dried | 29 | 510 | 394 | 452 |

| Blue-laid—machine-made | 28 | 94 | 86 | 90 |

| Printing paper | 17 | 15 | 9 | 12 |

The tests by the folding machine, being conducted on a very narrow strip, are only moderately reliable. To compare papers a more primitive method may be employed. It has the virtue of simplicity, and yet it gives a fair index to the amount of wear which the paper will withstand. Take a piece of the paper to be tested, about 6 inches square, roll it into a ball, then spread it out flat; repeat the performance, and notice how many such treatments the paper stands before perforation takes place. Papers which are very resistant, such as all-rag papers and air-dried browns, will assume a cloth-like appearance as they become softer, and it will be a long time before perforation takes place.

Sizing.—To test papers for efficiency of sizing write rather heavily upon the surface with ordinary pen and ink. Red ink is usually more penetrative than black, so it is better to use a good black ink as a standard test. As some papers, such as account book papers, have to stand erasure, they should be tested for ink bearing after abrasion of the surface.

To test for gelatine sizing cut up a small quantity of paper and boil for a few minutes in a beaker containing sufficient water to cover the paper. Pour off into a test tube, cool, add a few drops of a 2 per cent, solution of tannic acid. A flocculent precipitate indicates that the paper has been sized with gelatine. Heat the liquid, and the precipitate will coagulate and cling to the sides of the test tube. A comparative test is made by taking an equal quantity of each kind of paper, boiling in similar quantities of water for the same period, and adding the same amount of tannic acid solution, and comparing the results.

Resin sizing is determined in a different manner. A comparatively large quantity of paper is extracted in a small quantity of liquid. Take a strip of paper, about 8 inches by I inch, pleat it repeatedly until it can be placed in a test tube, and cover it with rectified spirit. Place the test tube in a beaker containing water, and heat slowly. The spirit will boil before the water reaches boiling point, and in a short time the resin will be dissolved. As soon as the solution is cool, pour it into a test tube half full of distilled water, and the resin will appear as a ring, whitish in colour, at the junction of the two liquids. If the test tube is shaken up the opalescent appearance of the liquid indicates the presence of resin.

Starch.—A very weak solution of iodine in potassium iodide is dropped on the paper with a glass rod, or a strip of the paper is dipped into the solution. If a very small quantity of starch is present in the paper a blue reaction will take place, and the larger the amount, the darker the coloration. Therefore in order to form an opinion as to the quantity of starch used, a very pale solution must be used, or the colour may be too dark to enable one to make comparisons. An aqueous extract of the paper may be treated with the iodine solution, and if a comparative test is to be made, it is necessary to work on each paper with identical quantities of water for boiling, and iodine solution for testing. A faint colour must not be taken as evidence of added starch, as in rag pulp it is very difficult to remove starch from the raw materials.

Colouring Matters.—The tests for colours should be for the purpose of discovering whether they are reasonably fast to light and when wetted. The first can be tested by exposing the paper to a steady light—not sunlight—for a period according to the time of year. A photographic printing frame with a black disc on plain glass is a convenient method of testing, and if, after forty-eight hours in summer, and a proportionately longer period at other times, the difference between the exposed and protected areas is marked, the paper must not be used where a permanent colour is required. Some tints will bleach completely with the treatment, and should be avoided as stock lines. To test water-fastness a piece of paper is left in warm water, or placed in cold water and heated slowly. If the colour is soluble it will very soon tint the water.

Coloured papers for pasting to book covers or boxes should be tested by pasting down to the boards intended for use. Some boards have a curious effect on certain tinted papers, owing to the presence of chemicals in the finished boards, and acidity or alkalinity may render change of covering paper necessary.

Absorbent Papers.—Blotting paper may be tested by the mounting, test. To carry this out, cut strips from each direction of the paper—length and width—6 inches long by 1 inch in width. Make a pencil mark half an inch from the end, and immerse the strip as far as the pencil mark in water or ink. The fluid immediately commences to mount the strip, and the speed at which this takes place is an indication of the relative initial absorbency of papers tested by this method. In practice, blotting paper must absorb immediately, as the pressure usually applied will, if the paper is not sufficiently absorbent, spread the ink. For this reason the rising of the fluid should be marked and checked in the first ten to sixty seconds, and when several tests in each direction have been made, the figures tabulated and the mean rate calculated. It is convenient to measure in millimetres rather than in fractions of an inch. Ink makes the better testing fluid, as the way in which the blotting paper carries up the colouring matter can be seen at once, and a paper which is superior in this respect will usually be the better paper. The zone test is an elaboration of the ink test. A small quantity (1 c.c. or .5 c.c.) is allowed to fall a drop at a time upon the blotting paper, and when the blot is dry, the area of the outer non-absorbent zone, its proportion to the inner absorbent zone, and its regularity will serve as an index to the behaviour of the paper in use. Other factors in the choice of blottings are the resistance to wear, absence of fluff, and the resistance to surface dirt. A very rough blotting paper may not be entirely satisfactory in those respects, but, on the other hand, a very smooth paper may be produced at the expense of absorbency.

Copying papers are tested in the copying press with a document written with copy able ink, and the efficiency of the paper judged either by comparison with a standard sample, or merely by the clearness of the resulting copy.

Duplicating papers may be tested by drawing a fine pen charged with writing ink across the surface, and immediately rubbing the ink to see if it smears. Half-sized duplicating papers have the same method applied^but should be allowed five to ten seconds after writing. These methods are superseded by the use of the duplicating machine, if available.

Mineral Matter Loading.—A weighed quantity of paper—say 1 gm.—is torn into small fragments, placed in a porcelain crucible, previously weighed, and subjected to the intense heat of a Bunsen burner until the paper is consumed and the residue reduced to a white ash, or in any case until all carbonaceous matter is burnt off. See that any black deposit on the crucible is burnt away. Cool the crucible, weigh it with its contents, deduct the weight of the crucible, and the weight, multiplied by 100, will give the percentage of mineral matter present in the paper.

| Weight of crucible | 6.25 | gm. |

| Weight of paper | 1.00 | " |

| Weight of crucible and ash | 6.365 | " |

| Deduct weight of crucible | 6.25 | " |

| Weight of ash | .115 × 100 = 11.5 per cent. | |

The ash, if not required for subsequent examination, can be thrown away, the crucible wiped out and weighed again to check the net weight of ash. It is usual to calculate the whole of the ash as added mineral water, although all fibrous materials have ash of some weight, e.g., cotton 12 per cent, esparto 3½ to 5 per cent. A delicate balance with weights from 50 gm. to 1 mgm. is advised for exact results.

Fibre Composition. It is necessary to exclude mechanical wood from most papers, and its detection is rendered easy by the use of certain solutions. A solution is made up of 1 gm. of phloroglucine in 50 c.c. of rectified spirit with 25 c.c. of concentrated hydrochloric acid added. If a drop of this solution is placed on paper in which mechanical wood is present an intensely red coloration will follow. The amount of mechanical wood may be estimated by the depth of colour, but this is very difficult, as may be proved by comparing the results obtained on papers containing 40 and 70 per cent, of mechanical wood respectively. Some aniline colours are altered in colour by the acid of the solution, although the colour is not the same as that given by mechanical wood, and it appears and fades in a different manner. A solution of 2 per cent, of aniline sulphate (1 gm. in 50 c.c. of water) will give a yellow coloration in the presence of mechanical wood. As wood fibres, jute, and some other fibres which have not been thoroughly cleaned, give colour reactions as though mechanical wood were present, the microscope should be used for confirmation.

Papers containing straw or esparto fibre are coloured pink, pale or deep according to the quantity of these fibres present, when heated in a weak solution of aniline sulphate. Strips of paper treated at the same time will afford comparative tests. Bamboo paper gives a pink reaction in the heated aniline sulphate solution, but some grasses, such as delta grass, are not affected.

Microscopical Examination.—Colour reactions reveal the presence of mechanical wood, straw, and esparto in papers, but the reagents used do not reveal the presence of chemical wood or rag fibres, nor do they distinguish between cotton and linen fibres. In order to obtain more exact conclusions the microscope is employed. Although a powerful microscope is a valuable possession, a moderate instrument is preferable; a microscope equal to the "London," with a combination of eye-pieces and objectives to give magnifications of 59 to 270 diameters, will be found excellent for the examination of fibres. A supply of slips, 3 inches by 1 inch, and half an ounce of cover glasses 1 inch diameter will be required.

The fibres in most cases are securely fastened with the sizing materials, and to remove these the paper is boiled in a weak solution of caustic soda. After boiling, the paper is washed, and, with teasing needles, little pieces of paper picked out and placed on a glass slip. Or the paper is placed in a test tube with a little water, the thumb placed over the mouth of the tube, and by shaking violently the paper is soon reduced to pulp. A very small portion of pulp is placed on the slide, and superfluous moisture carefully removed with filter paper. A stain makes the markings on the fibres more easily seen, and if a suitable stain is employed, some differentiation in colouring the various fibres takes place.

A good standard solution is iodine in potassium iodide, with an accessory acid solution:—

| Iodine Solution. | Accessory Solution | ||

| Iodine | 1.15 gm. | Glycerine | 10 c.c. |

| Potassium iodide | 2.0 " | Water | 5 " |

| Water | 20 c.c. | Sulphuric | 15 " |

A drop of the iodine solution is placed on the fibre on the slide. After a minute or so it is blotted off, and a drop of the accessory solution is added. The fibres are separated with teasing needles (needles mounted in wooden handles) until well distributed on the slide. A cover glass is cleaned by rubbing with a piece of wash leather, and dropped on the slide. The excess of solution is carefully absorbed with the filter paper, and the slide is ready for examination. A description of each of the principal fibres is given, with the normal dimensions of the unbeaten fibres and the coloration given by the solutions specified. For general examination the lower powers of the microscope will be found most useful, the higher magnifications being employed for studying the markings and other characteristics of the fibres. The dimensions given of cotton, linen, and hemp fibres will not be met with in papers made from those materials, as in beating the lengths are shortened, and frequently the fibres are split longitudinally. Tissues, copyings, and Bible papers show the greatest reduction of the fibres.

Cotton.— Fibre 30 to 40 mm. x .02 mm. Stained violet-red to brown. The fibres are long flattened tubes with large channel and numerous twists, blunt ends, and some fibres have cross markings. For a blotting the fibres are cut into short lengths, and the PAPERMAKING FIBRES

Magnified 50 diameters

Fig. 17.—Rag Fibres Unbeaten. |

Fig. 18.—Rag Fibres Beaten. |

Fig. 19.—Hemp. | |

Fig. 20.—Manilla. |

Fig. 21.—Jute. |

characteristics can be easily observed. The fibres are reduced in diameter as well as in length by prolonged beating for strong papers, the ends are frayed, and it is not easy to identify the cotton in a finely-beaten rag mixture (Figs. 17 and 18).

Linen.—Fibre 30 to 40 mm. x .025 mm. Stained violet-red to brown. Linen is the fibre from the stem of the flax. The fibres have thicker walls than cotton, from which it is easily distinguished in its unbeaten state, being a smoother, rounder fibre, with marks like joints at intervals, small cross markings, and pointed ends. When beaten finely it is not possible to distinguish linen from cotton (Figs. 17 and 18).

Hemp.—Fibre 20 mm. x .02 mm. Stained, unbleached fibre, yellow to brown; bleached, brown-red to wine-red. In general appearance the fibre is similar to linen, with slightly thinner walls, more markings, and at the places where joint markings occur are also little hairs. The ends of the fibres are rounded or flattened. The fibre in paper is usually beaten so finely as not to be recognised (Fig. 19).

Manilla Hemp.—Fibre 7 mm. x .02 mm. Stained yellow to blue, according to amount of bleaching and cleaning of the raw material. The fibres are like hemp fibres, but the canal is much larger, and accompanying the fibres are many oblong transparent cells, sometimes occurring like blocks of bricks (Fig. 20).

Jute.—Fibre 2.5 mm. x .022 mm. Stained, unbleached, yellow; bleached, brown. Jute fibres resemble linen and hemp, but the central canal is irregular in width, widening in places and narrowing again. The ends of the fibres are pointed and somewhat flattened (Fig. 21).

Straw.—Fibre 1.5 mm. x .015 mm. Stained greyish to blue. Similar to esparto, but the fibres are more flexible, and become kinked when made into paper. Serrated cells and transparent oval cells are present (Fig. 22).

Esparto.—Fibre 1.5 mm. x .012 mm. Stained greyish-blue to colourless. The fibres are very fine and short with pointed ends. Characteristics of esparto are the comma-shaped hairs and the serrated cells (Fig. 23).

Bamboo.—Fibre 4 mm. x .015 mm. Stained yellow to pale brownish-green. Resembling esparto, with cylindrical fibres with pointed ends, and usually a large number of transparent oval cells are found in paper made from bamboo (Fig. 24).

Chemical Wood.—The fibres vary considerably in length and thickness. Stained blue to colourless. Consisting of flat ribbon-like fibres, broad flat cells pitted and perforated, others similar to sections of a plant stalk, they are on the whole unlike any other fibres. A few fibres resemble linen fibres, but comparison will reveal differences. The differentiation between pine, spruce, poplar, birch is unnecessary for ordinary paper testing (Fig. 25).

Mechanical Wood.—Stained yellow. This pulp is unmistakable, owing to the broken pieces of various sizes and shapes, fragments of fibres torn away from the original wood, held together by cells, and showing pits and pores. Most newspapers are made of a mixture of chemical and mechanical wood, and microscopic examination of these mixtures furnishes an easy way of becoming familiar with the appearance of the different wood pulps (Fig. 26).

To arrive at a correct result, as regards the proportion of fibres in a mixture, is not at all easy. By taking a series of fields on one slide, counting and tabulating the contents under the headings of the different fibres, and averaging the fields, a fair approximation can be obtained. For comparison of two or more papers this will usually suffice, but PAPERMAKING FIBRES

Magnified 50 diameters

Fig. 22.—Straw. |

Fig. 23.—Esparto. |

Fig. 24.—Bamboo. | |

Fig. 25.—Chemical Wood. |

Fig. 26.—Mechanical Wood. |

Printing Qualities.—The test for comparison with a standard paper is carried out by printing on the papers under examination at the same time, under the same conditions, and judging the brilliance, solidity of colour, absorption of ink, and noting how the colours dry. The test for the efficiency of sizing will have shown whether the paper is likely to be too porous or too hard, but the actual test for printing is advisable when taking a large quantity of a special making into stock.

The trouble of registering colour work has been dealt with at length elsewhere. If a paper has newly arrived from the mill, it is scarcely reasonable to condemn it on a trial for register before a little time has elapsed for maturing. It is well to examine the bulk to discover if all the supply is cut with the same machine direction.

Various Faults.—Paper which has not been properly retreed—that is, the extraction of faulty sheets has not been done closely—will be found unsuitable for the highest class of work. The faults in the sheets may comprise spots, specks, creases, superficial markings and torn paper. The spots and specks may be caused by various foreign substances—sand, dirt, knots of fibre, pieces of rubber, sealing-wax, little lumps of mineral matter or froth. The foreign matter varies with different papers, and will be more apparent in super-calendered papers than in those which are not highly rolled, as the rolling brings faults into greater prominence. Creases formed before or during calendering render sheets unfit for use. Superficial markings may occur at the drying cylinders or from marks on the other rolls, resulting in rust marks, streaks, and sometimes in bleaching coloured papers in lines. Torn paper shows hurried sorting, as it is not difficult to see such a fault when turning over the sheets. In various coated papers sheets with uneven coating or surface markings should not be included as "good" paper. A paper which is even in texture cannot be considered matched by a supply which is "wild" or cloudy in the look-through. Although wildness is sometimes accompanied by strength in paper, this is not always so, and it is desirable that printing papers should not be wild.

To analyse papers in order to discover chemical residues and to identify them requires some very delicate tests, and unless one has had an extensive chemical training, mistaken conclusions may result.

The various apparatus and chemicals necessary for paper testing as detailed in this chapter (other than machines, chemical balance and microscope) are detailed below.

| 1 glass measure, 50 c.c. capacity. |

| 2 beakers, 225 c.c. |

| 6 beakers, 60 c.c. |

| 1 dozen test tubes, 5 in. x ⅝ in. |

| 1 test-tube stand to take 6 tubes. |

| 6 porcelain crucibles without covers, No. 1. |

| 1 tripod stand, 7 in. x 5 in. |

| 1 piece gauze asbestos covered. |

| 1 pipeclay triangle. |

| 1 Bunsen burner 3 ft. rubber tubing or one spirit lamp, 70 c.c |

| 2 dozen glass slips, 3 in. x 1 in. |

| ½ oz. cover glasses, No. 3, ⅝ in. diameter. |

| 2 teasing needles. |

| 1 oz. tannic acid. |

| 1 oz. aniline sulphate. |

| 1 oz. caustic soda. |

| 5 oz. rectified spirit. |

| 25 c.c. iodine in potass. Iodide sol. |

| 25 c.c. sulphuric acid and glycerine sol. |

| 25 c.c. phloroglucine solution. |

- ↑ It is more convenient to use the metric system of weights and measures, as small quantities and dimensions are dealt with, and the decimal method is easier to use. Metric equivalents are:

1 millimetre (mm.) = .039 in. 1 in. = 25.4 mm. 1 gramme (grm.) = .035 oz. 1 oz. = 28.35 grm. 1 cubic centimetre (c.c.) = .035 fl. oz. 1 fl. oz. = 28.40 c.c.