Popular Science Monthly/Volume 56/January 1900/What Makes the Trolley Car Go I

| WHAT MAKES THE TROLLEY CAR GO. |

By WILLIAM BAXTER, Jr., C. E.

I.

OF all the wonderful operations accomplished by the aid of electricity at the present time, none so completely mystifies the beholder as the action of the trolley car. The electric light, although incomprehensible to the average layman, does not excite his curiosity to the same extent. The glowing filament of an incandescent lamp or the dazzling carbon points of an arc light stimulate the inquisitive proclivities to some extent, but as the popular notion with respect to the nature of electricity is that it is some kind of fluid that can flow through wires and other things like water through a pipe, the conclusion arrived at is that the current, in its passage through the filament or the carbon points, generates a sufficient amount of heat to raise the temperature of the material to the luminous point. The fact that energy is required to raise the temperature of the mass to the incandescent point is not taken into consideration by those not versed in technical matters, owing to the fact that, as nothing moves, it is not supposed that power can be expended. When a trolley car is seen coming down the street at a high rate of speed the effect upon the mind is very different. Here we see a vast amount of weight propelled at a high velocity, and yet the only source through which the power to accomplish this result is supplied is a small wire. The mystifying cause does not stop here, for if we look further into the matter we see that the energy has to pass from the trolley wire to the car through the very small contact between it and the trolley wheel. After contemplating these facts, it appears remarkable that the energy that can creep through this diminutive passage can by any means be made to develop the force necessary to propel a car with a heavy load up a steep grade. An electrical engineer, if asked to explain the action, would say that the force of magnetic attraction was made use of to accomplish the result, but this explanation would fail to throw any light upon the subject. In what follows, it is proposed to explain the matter in a simple manner, and then it will be seen that what appears to be an incomprehensible mystery, when not understood, is, in fact, no mystery at all.

Electricity and magnetism are two forces that are intimately associated with each other, and, although radically different, it is

difficult, if not impossible, to obtain one without the other, although it is a simple matter to make one inactive under certain conditions. It is very generally understood that a magnet possesses the power of attraction, and that it will draw toward it pieces of iron, steel, and other magnets. The laws governing the attractive properties of magnets, however, are not so well understood, and many are not aware of the fact that under certain conditions one magnet will repel another, but such is nevertheless the case.

In Fig. 1 the lower outline, M, represents a magnet fixed in position, and the upper bar represents another magnet arranged to swing freely around the pivot a. A magnet, as is generally known, will arrange itself in a north-to-south position if suspended from its center, like a scale beam, and allowed to swing freely, and the same end will always point toward the north. On this account the ends of a magnet are called its poles, and the one that will point toward the north is designated the north pole, while the  Figs. 1, 2, 3.—Diagrams illustrating the Attraction and Repulsion of Magnets. other one is the south pole. The terms north and south poles were applied to magnets centuries ago, but at the present time the ends are more commonly designated as positive and negative. In Fig. 1 it will be noticed that the stationary magnet has its positive end upward, and this attracts the negative end of the swinging magnet. If the order of the poles is reversed, so that the positive of the swinging magnet will come opposite the positive of the stationary one, then there will be a repulsive action instead of an attraction, as is shown in Fig. 2. If the two negative ends were placed opposite, the effect would be the same. From this we see that to obtain an attraction we must place the magnets so that opposite poles come together, and that by reversing the order we obtain a repulsive action.

Figs. 1, 2, 3.—Diagrams illustrating the Attraction and Repulsion of Magnets. other one is the south pole. The terms north and south poles were applied to magnets centuries ago, but at the present time the ends are more commonly designated as positive and negative. In Fig. 1 it will be noticed that the stationary magnet has its positive end upward, and this attracts the negative end of the swinging magnet. If the order of the poles is reversed, so that the positive of the swinging magnet will come opposite the positive of the stationary one, then there will be a repulsive action instead of an attraction, as is shown in Fig. 2. If the two negative ends were placed opposite, the effect would be the same. From this we see that to obtain an attraction we must place the magnets so that opposite poles come together, and that by reversing the order we obtain a repulsive action.

If the swinging magnet is replaced by a bar of iron, as is shown in Fig. 3, there will be an attraction, no matter what end of the magnet may be uppermost, thus showing that either end of a magnet will attract a bar of iron. The explanation of these different actions is that when two magnets are brought into proximity to each other each one exerts its force without any regard to the other, and if the two are set to act together they will attract one another, but if set to act in opposition they will repel. When one of the bars is not a magnet, but simply a piece of iron or steel, this bar, having no attractive or repulsive force of its own, can only obey the attractive action of the other, which is the only one that exerts a force.

In Fig. 4 M is a magnet bent into the form of a U, commonly called a horseshoe magnet. The short bar set between the upper ends is also a magnet, and is arranged so as to revolve around the shaft s. From what has just been explained in connection with Figs. 1 and 2 it will be understood that, with the poles as indicated by the letters, there will be an attractive force set up between the top end of the straight bar and the P end of the horseshoe, and thus rotation will be produced in the direction of the arrow. The rotation, however, will necessarily stop when the bar reaches the position shown in Fig. 5, for then the attraction between the poles will resist further movement. If the straight bar were not a magnet, but simply a piece of iron or steel, it is evident that when in the position of Fig. 4 the attraction would be just as much toward the right as toward the left, and if the  Figs 4, 5.—Diagrams illustrating the Method of obtaining Rotary Motion with Magnets.bar were placed accurately in the central position it would not swing in either direction. It would be in the condition called, in mechanics, unstable equilibrium. In practice this condition could not be very well realized, as it would be difficult to set and retain the bar in a position where the attraction from both sides would be the same, therefore the rotation would be in one direction or the other; but whichever way the bar might move, it would only swing through one quarter of a revolution, into the horizontal position of Fig. 5.

Figs 4, 5.—Diagrams illustrating the Method of obtaining Rotary Motion with Magnets.bar were placed accurately in the central position it would not swing in either direction. It would be in the condition called, in mechanics, unstable equilibrium. In practice this condition could not be very well realized, as it would be difficult to set and retain the bar in a position where the attraction from both sides would be the same, therefore the rotation would be in one direction or the other; but whichever way the bar might move, it would only swing through one quarter of a revolution, into the horizontal position of Fig. 5.

If we reflect upon these actions we can see that if we could destroy the magnetism of both parts before the straight bar reaches the position of Fig. 5 it would be possible to obtain rotation through a greater distance than one quarter of a turn, for then the headway acquired by the rotating part would cause it to continue its motion. If, after the completion of one half of a revolution, we could remagnetize both parts, we would then set up an attraction between the lower end of the straight bar and the loft side of the horseshoe, for then the polarity of the former would be the reverse of that shown in Fig. 4—that is, the lower end would be negative. By means of this second attraction we would cause the bar to rotate through the third quarter of the revolution, and if, just before completing this last quarter, we were to remove all the magnetism again, the headway would keep up the motion through the final quarter of the revolution, thus completing one full turn. From this it will be realized that if we could magnetize and demagnetize the two parts twice in each revolution a continuous rotation could be obtained.

If the magnetizing and demagnetizing action were only applied to the rotating part we would fail to keep up a continuous rotation, for, as was shown in connection with Fig. 3, the action when the straight bar reached the position of Fig. 5 would be the same as if it were magnetized, owing to the fact that a magnet always exerts an attraction upon a mass of iron. Suppose, however, that we were to reverse the polarity of the rotating part just as it reaches the position of Fig. 5, then there would be two poles of the same polarity opposite each other, and, as shown in Fig. 2, the force acting between them would be repulsive, and would push the bar around in the direction of rotation. Not only would the right-side pole of the horseshoe force the end of the bar away from it, but the negative pole, on the left side, would attract this same end, and thus a force would be exerted by the two poles of M to keep up the rotation through the next half of a circle. On reaching this last position the rotation would stop if the polarity of the revolving bar were left unchanged, for then the poles facing each other would be of opposite polarity. If, however, we again reversed the polarity, a repulsion would be set up between the poles facing each other, and thus a force would be exerted to continue the rotation. Thus we see that if the polarity of the horseshoe magnet is not disturbed it is necessary to reverse that of the rotating part to obtain a continuous motion, but if we change the magnetic conditions of both parts, then it is only necessary to magnetize and demagnetize them alternately.

From the foregoing it is seen that there are two ways in which the force of magnetism could be utilized to keep up a continuous rotation, and the question now is, Can either of them be made available in practice? To this we answer that, by the aid of the relations existing between electricity and magnetism, both can be and are made available, as will be shown in the following paragraphs:

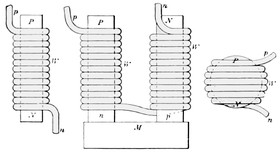

In Fig. 6 W represents a coil of wire provided with a cotton covering, so that there may be no actual contact between the adjoining convolutions. If the ends p n of this coil are connected with a source of electric energy, an electric current will flow through it, and if a bar, as indicated by N P, of iron or steel is placed within the coil it. will become magnetized. If the bar is made of steel and is hardened it will retain the magnetism, and become what is called a permanent magnet; such a magnet, in fact, as we have considered in all the previous figures. If the bar is made of iron it will not retain the magnetism, but will only be a magnet as long as the electric current  Figs. 6, 7, 8.—Diagrams illustrating the Principles of Electro-Magnets.lows through the coil W. A magnet of the latter type is called an electro-magnet. If the iron is of poor quality—that is, from an electrical standpoint—it will require an appreciable time to lose its magnetism, but if it is soft and high grade, electrically considered, it will lose its magnetism instantly, or nearly so. If we take two bars of soft iron and arrange them side by side, as in Fig. 7, and wind coils around them as indicated each one will become magnetized when the ends p n of the coils are connected with an electric circuit. If the lower ends of the two bars are joined by a piece, as shown at M, we will have a horseshoe electro-magnet. If we take a round disk of iron, as in Fig. 8, and wind a coil around it, it will also become a magnet when an electric current traverses the coil. Thus it will be seen that it makes little difference what the shape of the iron may be, providing it is surrounded by a coil of wire and an electric current is passed through the latter. This being the case, it is evident that either of the processes explained in connection with Figs. 4 and 5 can be made available for the production of a continuous rotation by the aid of electro-magnets. Suppose we make a drum, as shown in Fig. 9, and wind a wire coil around it in the direction indicated, then when a current passes through the wire the drum will be magnetized, with poles at top and bottom. If the electric current passes through the wire from end p to end n the drum will be magnetized positively at the top and negatively at the bottom, and if the direction of the current through the wire is reversed the polarity of the drum will be reversed. If we construct a horseshoe magnet of the shape shown in Fig. 10, and place within the circular opening between its ends the drum of Fig. 9, we will have a device that is capable of developing a continuous rotation, providing we have suitable means for reversing the direction of the electric current through the wire coil; and this machine constitutes an electric motor in its simplest form.

Figs. 6, 7, 8.—Diagrams illustrating the Principles of Electro-Magnets.lows through the coil W. A magnet of the latter type is called an electro-magnet. If the iron is of poor quality—that is, from an electrical standpoint—it will require an appreciable time to lose its magnetism, but if it is soft and high grade, electrically considered, it will lose its magnetism instantly, or nearly so. If we take two bars of soft iron and arrange them side by side, as in Fig. 7, and wind coils around them as indicated each one will become magnetized when the ends p n of the coils are connected with an electric circuit. If the lower ends of the two bars are joined by a piece, as shown at M, we will have a horseshoe electro-magnet. If we take a round disk of iron, as in Fig. 8, and wind a coil around it, it will also become a magnet when an electric current traverses the coil. Thus it will be seen that it makes little difference what the shape of the iron may be, providing it is surrounded by a coil of wire and an electric current is passed through the latter. This being the case, it is evident that either of the processes explained in connection with Figs. 4 and 5 can be made available for the production of a continuous rotation by the aid of electro-magnets. Suppose we make a drum, as shown in Fig. 9, and wind a wire coil around it in the direction indicated, then when a current passes through the wire the drum will be magnetized, with poles at top and bottom. If the electric current passes through the wire from end p to end n the drum will be magnetized positively at the top and negatively at the bottom, and if the direction of the current through the wire is reversed the polarity of the drum will be reversed. If we construct a horseshoe magnet of the shape shown in Fig. 10, and place within the circular opening between its ends the drum of Fig. 9, we will have a device that is capable of developing a continuous rotation, providing we have suitable means for reversing the direction of the electric current through the wire coil; and this machine constitutes an electric motor in its simplest form.

In an electric motor the horseshoe magnet is called the field magnet, and the rotating part is called the armature, while the device by means of which the direction of the current through the armature coil is reversed is called the commutator. In this last figure it will be noticed that the coils wound upon the field magnet are represented as of wire much finer than that wound upon the armature. In actual practice machines are sometimes wound in this way, and sometimes the field wire is twice as large as that on the armature. When the field wire is very much finer than that of the armature the machine is what is known as shunt wound, which means that only a small portion of the current that passed through the armature passes through the field coils. Although with this type of winding the current that passes through the field coils is very weak, the magnetism developed thereby can be made greater than that of the armature if desired. This result is accomplished by increasing the number of turns of wire in the field coils. Thus if the current through the armature is one hundred times as strong as that through the field coils, the latter can be made to equal the effect of the former by increasing the number of turns in the proportion of one hundred to one, and if the increase is still greater the field coils will develop the strongest magnetism. The reason why a small current passing around a magnet a great many times Fig. 9. Fig. 10.

| Fig. 9. | Fig. 10 |

| Fig. 9. 10.—Diagrams illustrating the Principles of the Electric Motor. | |

will develop as strong a magnetization as a large current, can be readily understood when we say that the magnetism is in proportion to the total strength of the electric current that circulates around the magnet. Suppose we have two currents, one of which is one thousand times as strong as the other, then if the weak one is passed through a coil consisting of one thousand turns it will develop just as strong a magnetization as the large current passing through a coil of only one turn. This last explanation enables us to see how it is that the comparatively small current that can pass through the contact between the trolley wire and the trolley wheel can develop in the motor force sufficient to propel a heavy car up a steep grade. When that small current reaches the car motors it passes through a thousand or more turns of wire, and thus its effect is increased a corresponding number of times.

A motor having a single coil of wire upon the armature, as in Fig. 10, would not give very satisfactory results, owing to the fact that the rotative force developed by it would not be uniform. Such motors are made in very small sizes, but never when a machine of any capacity is required. For large machines it is necessary to wind the armature with a number of coils, so that the rotating force may be uniform, and also so that the current may be reversed by the commutator without producing sparks so large as to destroy the device. When an armature is wound with a number of coils the direction of the current is reversed, by the commutator, in each coil as it reaches the point where its usefulness ends, and where, if it continued to flow in the same direction, it would act to hold the armature back. The effect of this reversal of the current in one coil after another is to maintain the polarity of the armature practically at the same point, so that the strongest pull is exerted between it and the field magnet poles at all times. To explain clearly the way in which, the commutator reverses the current in one coil at a time it will be necessary to make use of a diagram illustrating what is called a ring armature. Such a diagram is shown in Fig. 11. The ring A is the armature core, and is made of iron; the wire coils are represented as consisting of one turn to each coil, and are marked w w w. The current enters the wire through the spring B, and passes out through C. As can be seen, the current from B can flow through the coils w w in both directions, thus dividing into two currents, each one of which will traverse one half of the wire wound upon the armature. The two half currents will meet at C. If the armature is rotated the springs B and C (which are called commutator brushes) will pass from one turn of the wire coil to another just back of it as the rotation progresses, and each time that contact is made with a new turn the direction of the current in the turn just ahead will be reversed. The current in the wire as a whole, however, will always be in the same direction—that is, in all the turns to the right of the two brushes; the current will flow toward the center of the shaft on the front side of the armature, and away from the shaft in all the turns on the left side. As the direction of the current on opposite sides of the brushes is always the same, the poles of the armature will remain under B and C, therefore the relation between the position of the poles of the armature and the field magnet will be the same substantially as that illustrated in Fig. 10, and, as a result, the force tending to produce rotation will at all times be the greatest possible for the strength of the current used and the size of the magnets.

Armatures are wound with a number of turns of wire in each coil, unless the machine is very large, and present an appearance more like Fig. 12. In this figure the brushes are arranged to make contact with the outer surface of the ring C, which is the commutator. The segments s s are connected with the ends of the armature coils c c c, but are separated from each other by some kind of material that will not conduct electricity—that is, they are electrically insulated. As will be noticed from this, the armature

| ||

| Fig. 11. | Fig. 12. | |

| Figs. 11, 12.—Diagrams illustrating the Method of winding Armatures of Electric Motors and Generators. | ||

in Fig. 11 acts as a commutator as well as an armature, its outer surface performing the former office. In the winding the difference between Figs. 11 and 12 is simply in the number of turns in each coil, there being one turn in Fig. 11 and several in Fig. 12.

The armature shown in Fig. 1 is of the type called drum armature, but it can be wound so as to produce the same result as the ring, although it is not so easy to explain this style of winding. It will be sufficient for the present explanation to say that whatever the of armature may be used, the winding is always such that the direction of the current through the wire coils is reversed progressively, so that the magnetic polarity is maintained practically at the same point; therefore there is a continuous pull between this point of the armature core and the poles of the field magnet. The commutator is secured to the armature shaft, and the brushes through which the current enters and leaves are held stationary; keeping this fact in mind, it can be seen at once that in Fig. 12 the current will flow from the brush a through the two sides of the armature wire to brush b, hence all the coils on the right of the vertical line will be traversed by the current in the same direction—that is, either to or from the center of the shaft—and in the coils on the left the direction will be opposite, which is just the same order as was explained in connection with Fig. 11.

An electric motor can be turned into an electric generator by simply reversing the direction in which the armature rotates—that is, any electric machine is either a generator or a motor. This fact can be illustrated by means of Figs. 13 and 14, both of which show the armature and the poles of the field magnet. The first figure represents an electric motor, and, as can be seen, the pull between the N pole of the armature and the P pole of the field is in the direction of arrow b, hence the armature will rotate in the same direction, as indicated by arrow a. To obtain the polarity of the armature and field it is necessary to pass an electric current through both—that is to say, we must expend electrical energy to obtain power from the machine. As soon as the current ceases to flow, the polarity of the armature and field dies out, and the rotation of the former comes to an end. The magnetism, however, does not die out entirely; a small residue is always left, although it is never sufficient to produce rotation, and even if it were it could only cause the armature to revolve through one quarter of a turn. If, after the current has been shut off, the armature shaft is rotated in the reverse direction, as indicated by arrow a in Fig. 14, the motion will be against the pull of the magnetism; therefore, although the poles may be very weak, an amount of power sufficient to overcome their attraction must be applied to the pulley, otherwise rotation can not be accomplished. In consequence of the backward rotation a current is  Figs 13, 14.—Diagrams illustrating the Difference between an Electric Motor and a Generator. generated in the armature coils, and this current, as it traverses the field coils as well as those of the armature, of the increased polarity the resistance to rotation is increased, and more power has to be applied to the pulley. The increase in the strength of the poles results in increasing the current generated, and this in turn further increases the pole strength, so that one effect helps the other, the result being that the current, which starts with an infinitesimal strength, soon rises to the maximum capacity of the machine.

Figs 13, 14.—Diagrams illustrating the Difference between an Electric Motor and a Generator. generated in the armature coils, and this current, as it traverses the field coils as well as those of the armature, of the increased polarity the resistance to rotation is increased, and more power has to be applied to the pulley. The increase in the strength of the poles results in increasing the current generated, and this in turn further increases the pole strength, so that one effect helps the other, the result being that the current, which starts with an infinitesimal strength, soon rises to the maximum capacity of the machine.

The motor shown in Fig. 10 does not in any way resemble an electric railway motor, nevertheless the principle of action is precisely the same in both. The design of a machine of any kind has to conform to the practical requirements, and this is true of railway motors, just as it is true of printing presses, sawmills, or any other mechanism. A railway motor must be designed to run at

Fig. 15.—External View of Electric Railway Motor mounted upon Car-Wheel Axle.

a comparatively slow speed and to develop a strong rotative force, or torque, as it is technically called. It must also be so constructed that it will not be injured if covered with mud and water. It must be compact, strong, and light, and capable of withstanding a severe strain without giving out. To render the machine water-and mud proof it is formed with an outer iron shell, which entirely incases the internal parts. The first railway motors were not inclosed, and the result was that they frequently came to grief from the effects of a shower of mud. When the modern inclosed type of motor, which is called the iron-clad type, first made its appearance it was frequently spoken of as the clam-shell type, and the name is not altogether inappropriate, for while the outside may be covered with mud to such an extent as to entirely obliterate the design, the interior will remain perfectly clean and dry, and therefore its effectiveness will not be impaired.

To enable the motor to give a strong torque and run at a slow speed the number of poles in the field and armature is increased. The design of Fig. 10 has two poles in the field and two in the armature, and is what is known as the bipolar type. Machines having more than two poles in each part are called multipolar machines. The number of poles can be increased by pairs, but not by a single pole—that is, we can have four, six, eight, or any other even number of poles', but not five, seven, or any odd number. This is owing to the fact that there must always be as many positive as negative poles, no more and no less. Railway motors at the present time are made with four poles. The external appearance can be understood from Fig. 15, while Fig. 16 and Fig. 17 will serve to elucidate the internal construction. In Fig. 15 the motor casing is marked M, and, as will be seen, it forms a complete shell. The motion of the armature shaft is transmitted to the car-wheel axle F through a pinion, which engages with a spur gear secured to the latter. In Fig. 16 the pinion and gear are marked N and L respectively. As it is necessary that the armature shaft and the axle be kept in perfect alignment, the motor casing M is provided with suitable bearings for both, those for the armature shaft being marked P P in Fig. 16, and one of those for the axle being marked T in Fig. 15. It will be understood from the foregoing that the motor is mounted so as to swing around the car-wheel axle as a center, but, as it is not desirable to have all this dead weight resting upon the wheels without any elasticity, the motor is carried by the crossbars B B, Fig, 15, which rest upon springs s s at each end. The beam A and a similar one at the farther end of the B B bars extend out to the sides of the car truck and are suitably secured to the latter. The coils w w are the ends of the field coils and the armature connections, and to these

Fig. 16.—Railway Motor with Casing Open, showing Armature in Lower Half.

the wires conveying the current from the trolley are connected. The cover C on top of the motor at one end closes an opening through which access to the commutator brushes is obtained. The armature is shown at H in Fig. 16 and the commutator at K in the same figure. Directly under the armature may be seen one of the field magnet coils, it being marked R.

As will be noticed in Fig. 16, the motor casing is made so as to open along the central line, and the lower half is secured to the top by means of hinges, g g, Fig. 15, and also by a number of bolts, which are not so clearly shown. The gear wheels are also located within a casing, which (Fig. 16) is made so as to be readily opened whenever it becomes necessary. All the vital parts of the machine are entirely covered, and are not easily injured by mud or water.

The construction of the armature and commutator is well illustrated in Fig. 17, which shows this part of the machine by itself. The armature is marked A, the shaft B, and the commutator C. In the diagrams, Figs. 9, 10, 11, and 12,  Fig. 17.—Armature of Eclectic Railway Motor. the wire coils are represented as wound upon the surface of the armature core, but, from Fig. 17, it will be noticed that they are located in grooves. A railway motor armature core, when seen without the wire coils, looks very much like a wide-faced cog wheel with extra long teeth, not very well shaped for gear teeth. In Fig. 17 the ends of the teeth are marked D, and the grooves within which the wire is wound are marked E. The coils are not wound so that their sides are on diametrically opposite sides of the armature core, but so that they may be one quarter of the circumference apart, and, as will be noticed, the wires are arranged so as to fit neatly into each other at the ends of the armature core. The bands marked F F F F are provided for the purpose of holding the wire coils within the grooves. The flanges H and I are simply shields to prevent oil, grease, or even water, if it should pass through the bearings, from being thrown upon the commutator or armature. The pinion through which the armature imparts motion to the car-wheel axle is not shown in Fig. 17, but it is mounted upon the taper end of the shaft.

Fig. 17.—Armature of Eclectic Railway Motor. the wire coils are represented as wound upon the surface of the armature core, but, from Fig. 17, it will be noticed that they are located in grooves. A railway motor armature core, when seen without the wire coils, looks very much like a wide-faced cog wheel with extra long teeth, not very well shaped for gear teeth. In Fig. 17 the ends of the teeth are marked D, and the grooves within which the wire is wound are marked E. The coils are not wound so that their sides are on diametrically opposite sides of the armature core, but so that they may be one quarter of the circumference apart, and, as will be noticed, the wires are arranged so as to fit neatly into each other at the ends of the armature core. The bands marked F F F F are provided for the purpose of holding the wire coils within the grooves. The flanges H and I are simply shields to prevent oil, grease, or even water, if it should pass through the bearings, from being thrown upon the commutator or armature. The pinion through which the armature imparts motion to the car-wheel axle is not shown in Fig. 17, but it is mounted upon the taper end of the shaft.

An electric railway motor is a machine that is characterized by extreme simplicity (there being only one moving part), compactness, and great strength. In addition, as none of the working parts is exposed it can not be injured, no matter how much mud may accumulate upon it. One of the reasons why the electric railway motor has met with such unparalleled success is that it is a machine that can withstand the roughest kind of usage without being damaged thereby. Another reason is that an electric motor can, if called upon, develop an amount of power two or three times greater than its full-rated capacity without injury, providing the strain is not maintained too long. A steam engine or any other type of motor that has ever been used for railway propulsion if loaded beyond its capacity will come to a standstill—that is, it will be stalled—but an electric motor can not be stalled with any strain that is likely to be placed upon it. If the load is increased the motor will run slower and the current will become greater, thus increasing the pull, but the armature will continue to rotate until the current becomes so great as to burn out the insulation. A railway motor calculated to work up to twenty-five-horse power will have to develop on an average about six-or seven-horse power, but if the car runs off the track on a steep grade, and has such a heavy load that the motor is called upon to develop one-hundred-horse power for a few seconds, the machine will be equal to the occasion. This result a steam, gas, or any other type of engine can not accomplish, and it is this fact as much as anything else that has given the electric motor the control of the street-railway field.

[To be continued.]

Note.—The illustrations of railway motor, generator, and switchboard (Figs. 15, 16, 17) were made from photographs kindly furnished by the manufacturers, the Westinghouse Electric and Manufacturing Company.