files are made in three degrees of fineness. For levelling down or topping saw teeth preparatory to sharpening, a flat file is necessary. The angles of saw teeth are set off with a protractor or hinged rule. For setting the teeth after they have been sharpened—that is, to bend each alternate tooth to one side—saw sets (Fig. 86) are used, or instead, patent contrivances are brought into requisition, these being so arranged that all the teeth can readily be set to one line. A useful form of plier saw set is shown by Fig. 87, and the method of

Fig. 86.—Saw Set with Gauge.

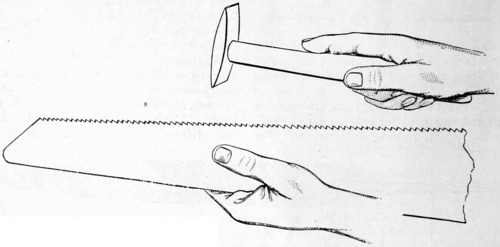

using it by Fig. 88. The amount of set can be regulated by the adjusting screw A. For hammer setting, however, a setting iron with bevelled edges is secured in the vice, the saw laid flat upon it, and the teeth struck one at a time with the pene of a small hammer (Fig. 89). This is the most satisfactory method of setting saw teeth when the operator has the necessary skill.

Tools of Percussion and Impulsion.

Hammers.—The carpenter and joiner has the choice between two or three shapes of hammer head. There is the Exeter or London pattern (Fig. 90), the Warrington

Fig.87—Plier Saw Set.

(Fig. 91), and the adze-eye claw pattern (Fig. 92), the last named being less used

Fig. 88.—Method of using Plier Saw Set.

than the others in the workshop, but being very convenient for many kinds of handiwork.

Fig. 89.—Hammer Setting Saw Teeth.

The hammer heads are of iron, with steel faces and penes. Two hammers, one weighing from 1 lb. to 1½ lbs., and the