Thus this “very murdering battle” as Marlborough called it—the last and greatest pitched battle of the war—was almost barren of results. The Allies lost not less than twenty thousand men, or nearly a quarter of the whole force, the thirty battalions of the Dutch infantry losing half their numbers. On the French side there were some twelve thousand casualties. If further evidence were necessary to prove that the French fought their hardest, it could be found in the fact that whereas in almost every other battle, from 1660 to 1792, there were deserters and prisoners by the thousand, at Malplaquet only 500 of the French fell into the hands of the victors unwounded.

MALSTATT-BURBACH, a town of Germany, in the Prussian Rhine province on the right bank of the Saar (Sarre), which separates it from Saarbrücken. Pop. (1900), 31,195. It lies in the midst of an important coal-mining and industrial district,

and is itself little more than a long and narrow row of manufactories

and workmen’s houses. The largest factories are

engaged in the production of iron, steel and cement. There is

a large wharf on the river for the export of coal.

Malstatt received municipal rights in 1321. These, however, were afterwards resigned to the newer town of Saarbrücken, and in 1818 Malstatt and Burbach were two small villages with a joint population of only about 800. About the middle of the century the population began to increase rapidly, in consequence of the development of the mining industry of the district and the extension of the railway system, and in 1874 the two villages were united to form a town.

MALT (O. Eng., mealt; O. Sax., malt; O. Teut., maltos; Mod.

Ger., Malz; Scand., malt; probably derived from the Sanskrit

mrdu, soft, thus having reference to the fact that malt is raw

grain rendered soft or tender), the name given to grain in which

germination has been caused to proceed to a certain stage and

has then been arrested by the removal of water and the application

of heat. During this limited germination enzymes are

developed (see Fermentation), and the constituents of the grain

modified so that the finished malt, when ground and submitted

to the mashing process (see Brewing), differs from the original

raw grain in that the greater portion dissolves. This solubility

is, however, a direct one to a slight extent only; it is due for

the most part to the action of the malt enzymes, diastase, &c.

on the constituents of the grain, the main portion of which are

of themselves insoluble. Thus starch, the main constituent of

all graminaceous seeds, probably exists in the same condition

in raw grain and in malt. When however the malt is mashed,

the starch is attacked by the enzyme diastase, and converted

by the process of hydrolysis into a mixture of soluble compounds,

e.g. the crystalline sugar, maltose, and a number of gummy

substances known as maltodextrins. But to a certain extent

starch and other carbohydrate substances are rendered directly

soluble and diffusible during the malting process, some of

the products serving the respiratory needs of the growing germ,

others being assimilated by the plantlet and reconverted into

reserve carbohydrates in the tissues of the germ and rootlets,

whilst the remaining portions are retained as such in the finished

malt. Similarly certain of the nitrogenous constituents of

the grain, the proteïns, are broken down and rendered soluble

by proteolytic enzymes, the products being assimilated to a

certain extent by the germ and rootlets, by the cells of which

they are again built up into complex proteïns, whilst others

remain in their simplified form. It is now known that proteolytic

enzymes exist in finished malt, and that, when the

mashing process is conducted under certain conditions, these

are able to degrade and render soluble some of the higher proteïns

present in the malt. When germination is allowed to proceed

as it does when the grain is planted in the soil, the whole of

the contents are rendered soluble by degrees and in turn assimilated

by the growing plantlet. By the limited germination

which constitutes the malting process, however, the balance

of soluble compounds left in the finished malt is from 15 to

25% of the total weight of the corn.

Although other seeds of the natural order Gramineae are occasionally malted, the greater portion of malt is made from the various species of Hordeum, known by the name of barley (q.v.), bigg, or bere. Indeed ordinary beer derives its characteristic flavour to the greatest extent from barley malt. A small proportion of malted oats or malted wheat is sometimes used in conjunction with barley malt for certain kinds of beer, whilst rye, maize, and even rice are occasionally malted. Barley is, however, the grain best adapted for making malt intended for brewing beer, and accordingly some space will be devoted to a description of those varieties of this grain which are used by the brewer.

Barley belongs to the genus Hordeum, of which there are numerous species and varieties. Linnaeus and the earlier botanists recognized six species of cultivated barleys, but modern botanists usually consider all cultivated barleys as belonging to one species to which the name H. sativum has been given. Körnicke regards H. spontaneum, a very long thin-grained two-rowed barley (see below) which grows in the East, as being the parent form; but E. S. Beaven inclines to the view that wild species of more than one form were originally used as food and subsequently cultivated. The last-named author has drawn up a scheme of classification for the varieties and races of cultivated barleys.

| |||

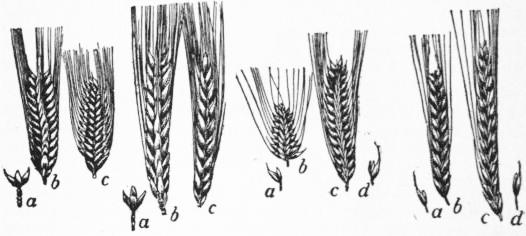

| Fig. 1. | Fig. 2. | Fig. 3. | Fig. 4. |

| Six-rowed barleys. | Fig. 1.—H. hexastichum. | |

| a. Three spikelets in situ on the rachis, showing short internodes. | ||

| b. Spike. Median spikelets uppermost, and with lower awns removed. | ||

| c. Spike. Lateral spikelets uppermost, and with lower awns removed. | ||

| Fig. 2.—H. vulgare. | ||

| a. Three spikelets in situ on the rachis, showing long internodes. | ||

| b. Spike. Median spikelets uppermost. | ||

| c. Spike. Lateral spikelets uppermost. | ||

| Two-rowed barleys. | Fig. 3.—H. zeocriton. | |

| a, d. Spikelets. Rachis edgewise, showing short internodes. | ||

| b. Var. zeocrithum (fan barley). Spike converging. | ||

| c. Var. erectum (Goldthorpe). Spike parallel. | ||

| Fig. 4.—H. distichum. | ||

| a, d. Spikelets. Rachis edgewise, showing long internodes. | ||

| b. Var. nutans (Chevallier). | ||

| c. Ouchak barley. |

In an ear of barley the primary axis or rachis is divided into internodes of which there may be any number up to forty. Each internode bears three single-flowered spikelets arranged alternately on either side of the rachis. In the six-rowed varieties the whole of these spikelets attain maturity, whilst in the two-rowed varieties only one on each side of the rachis, viz. the median, develops. British beer is brewed principally from the malt made from home-grown two-rowed barleys. Of late years, however, it has been found advantageous to employ a proportion of malt made from the thinner and more husky foreign barleys, mostly six-rowed varieties. The corns of two-rowed barleys are as a rule plumper than those of six-rowed barleys.

The most favourite barley for malting purposes grown in the United Kingdom is the narrow-eared two-rowed H. distichum, commonly known as Chevallier, from the name of the original cultivator, the Rev. John Chevallier. Of late years the quantity of